Percussion drill with liquid spraying device

The technology of a liquid spray device and impact drill is applied in the field of impact drill, which can solve the problems of the impact drill without a liquid spray device, etc., and achieve the effect of improving the working environment, benefiting physical health, and ensuring normal work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

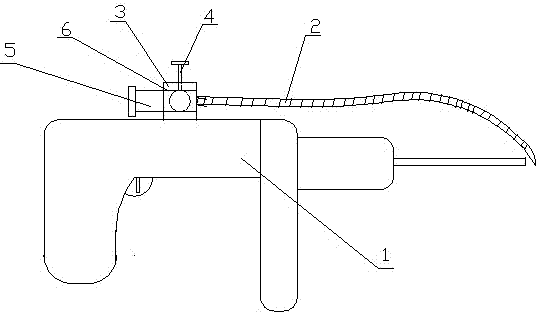

[0012] A percussion drill with a liquid spray device, such as figure 1 As shown, the hammer drill housing 1 is included, and the middle part of the upper end surface of the hammer drill housing 1 is provided with a mounting seat 3, and the right part of the mounting seat 3 is fixedly connected with a universal pipe nozzle 2. When the hammer drill with a liquid spraying device is working, The external infusion tube is directly inserted into the quick connector to connect with the liquid spray device, which is fast and convenient. The position of the universal tube can be adjusted according to the needs, and the liquid with pressure flows out from the nozzle and mixes with the dust in time, reducing the air pollution at the work site; The liquid plays the role of cooling and lubricating, keeps the temperature of the drill bit normal, improves the service life of the drill bit, does not need to be replaced frequently and fails; ensures normal work, improves the working environment...

Embodiment 2

[0014] The impact drill housing 1 has an internal thread in the middle of the upper end surface, and the center of the lower end surface of the mounting seat 3 has an external thread. The mounting seat 3 is threadedly connected with the middle of the upper end surface of the impact drill housing 1, and the connection is tight, detachable, easy to maintain and replace. .

[0015] The mounting seat 3 has a through hole 6 from left to right; the left part of the through hole 6 of the mounting seat 3 has an internal thread, the right end of the quick connector 5 has an external thread, and the right end of the quick connector 5 is threadedly connected with the left end of the mounting seat 3; the mounting seat 3 There is a regulating valve with a regulating handle in the middle 4, the regulating valve can adjust the flow and pressure of the input liquid in a timely manner according to the site conditions; the quick connector structure makes it easy to insert the external liquid pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com