Use method of ice core during precision casting

A technology of precision casting and ice core, which is used in casting molding equipment, casting molds, cores, etc. It can solve the problem that the application of ice core molding is still blank, improve the on-site working environment, solve the problem of wax saponification, and shorten production. effect of cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

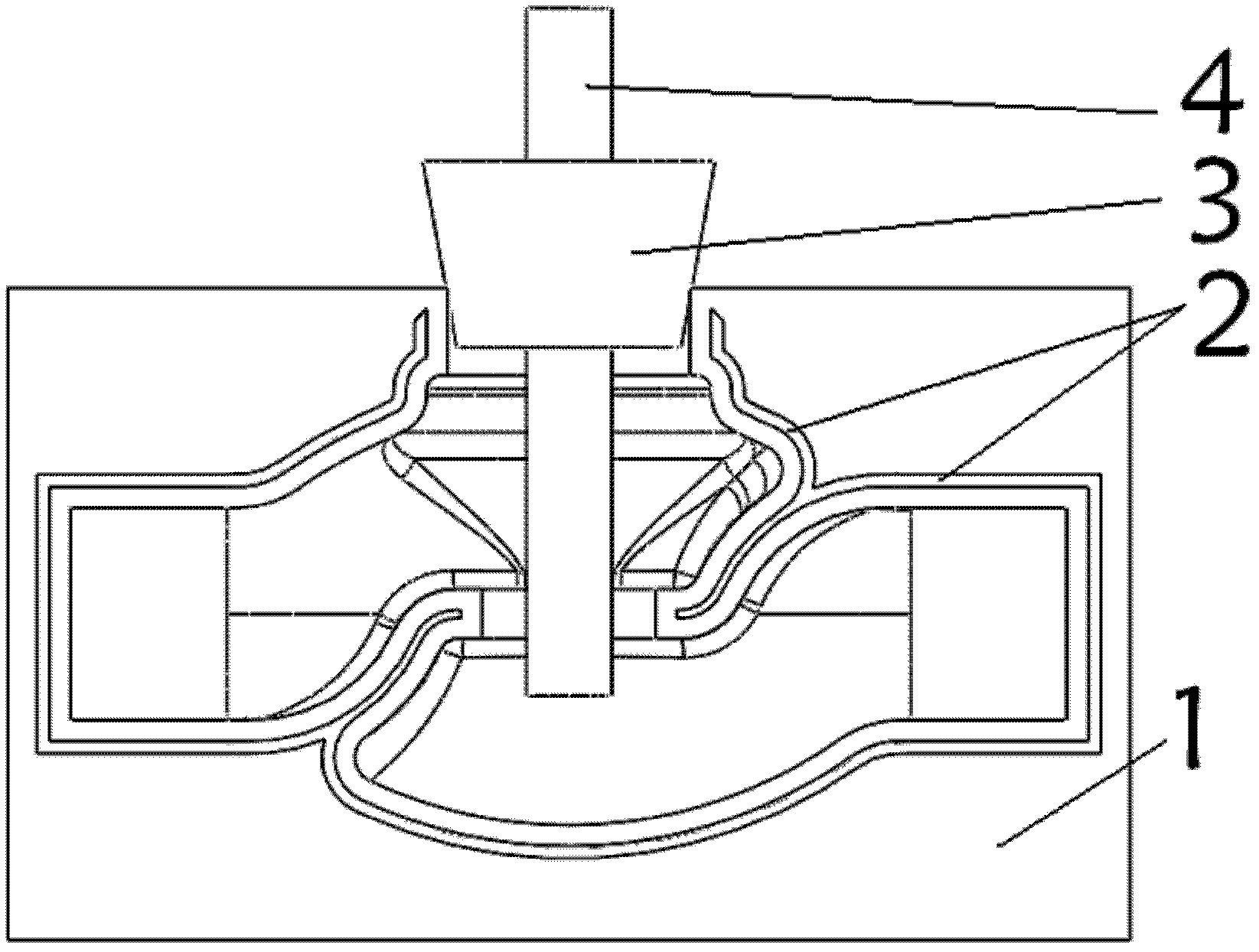

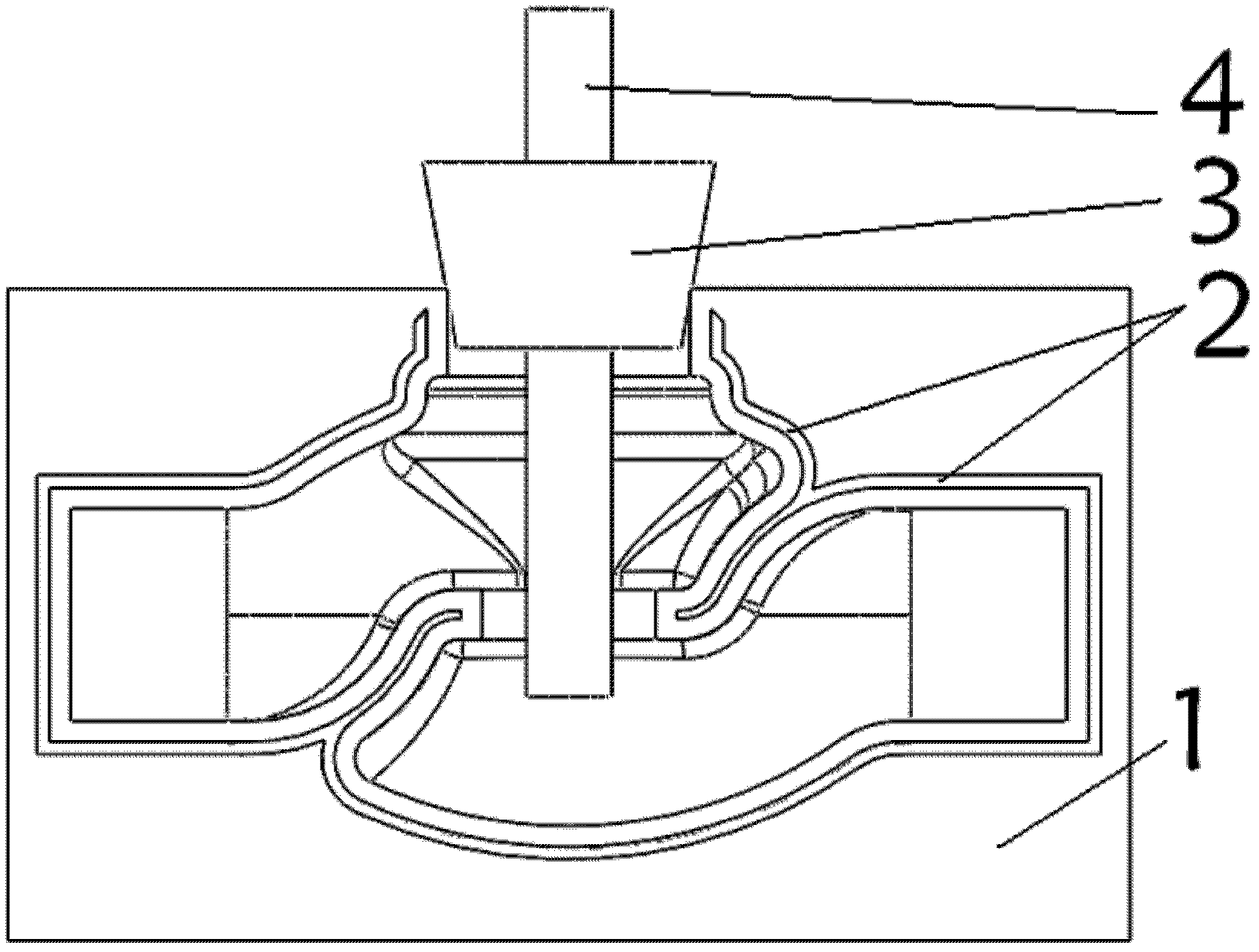

[0020] Referring to the accompanying drawings: the schematic diagram of the ice core mold structure: core mold 1; sealing strip 2; sealing plug 3; drainage conduit 4, a precision casting ice core molding process, followed by the following steps:

[0021] 1. A method of using ice cores in precision casting, characterized in that:

[0022] (1) Make ice cores of the required size and shape by using a special mold to condense water;

[0023] (2) Take the obtained ice core out of the mold and put it in a cryogenic environment for future use;

[0024] (3) When making the mold, put the ice core into the mold, inject wax, cool and melt the core, and obtain the wax mold;

[0025] (4) During the process of wax injection, fast filling can be realized by adjusting the temperature and pressure of wax injection;

[0026] (5) Various shell coating processes are used: after obtaining the mold shell and coating, the hollow cavity of fixed shape and size copied from the wax mold obtained by m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com