Segmented type deburring roller

A segmented, deburring roller technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large impact force, affecting the service life of the deburring machine, inconvenient replacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to clearly illustrate the technical features of this solution, the specific implementation of the present invention will be further described below according to the accompanying drawings.

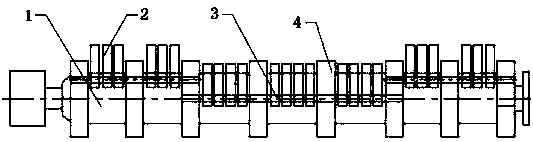

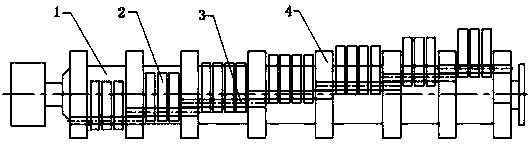

[0019] figure 1 A first embodiment of the invention is shown. Such as figure 1 As shown, a segmented deburring roller includes a roller body 1, a centrifugal throwing block 2, and a connecting shaft 3. A flange 4 is arranged on the roller body 1, and the flange 4 is a disc coaxial with the roller body 1. , the centrifugal rejection block 2 is a flat cuboid, the centrifugal rejection block 2 is provided with a through hole deviated from the center of the centrifugal rejection block 2, and the connecting shaft 3 passes through the through hole on the centrifugal rejection block 2 and is fixed on the flange 4; the centrifugal rejection block 2 The turning diameter when being thrown up is greater than the diameter of the flange 4; the axis of the connecting shaft 3 is parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com