Electric motor dynamic load control device

A control device and dynamic load technology, which is applied in the direction of motor generator testing, etc., can solve problems such as high energy consumption, inconvenient adjustment of load power, and inability to test the performance of motors, so as to optimize the control system and control process, and the energy saving effect is obvious , start the smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

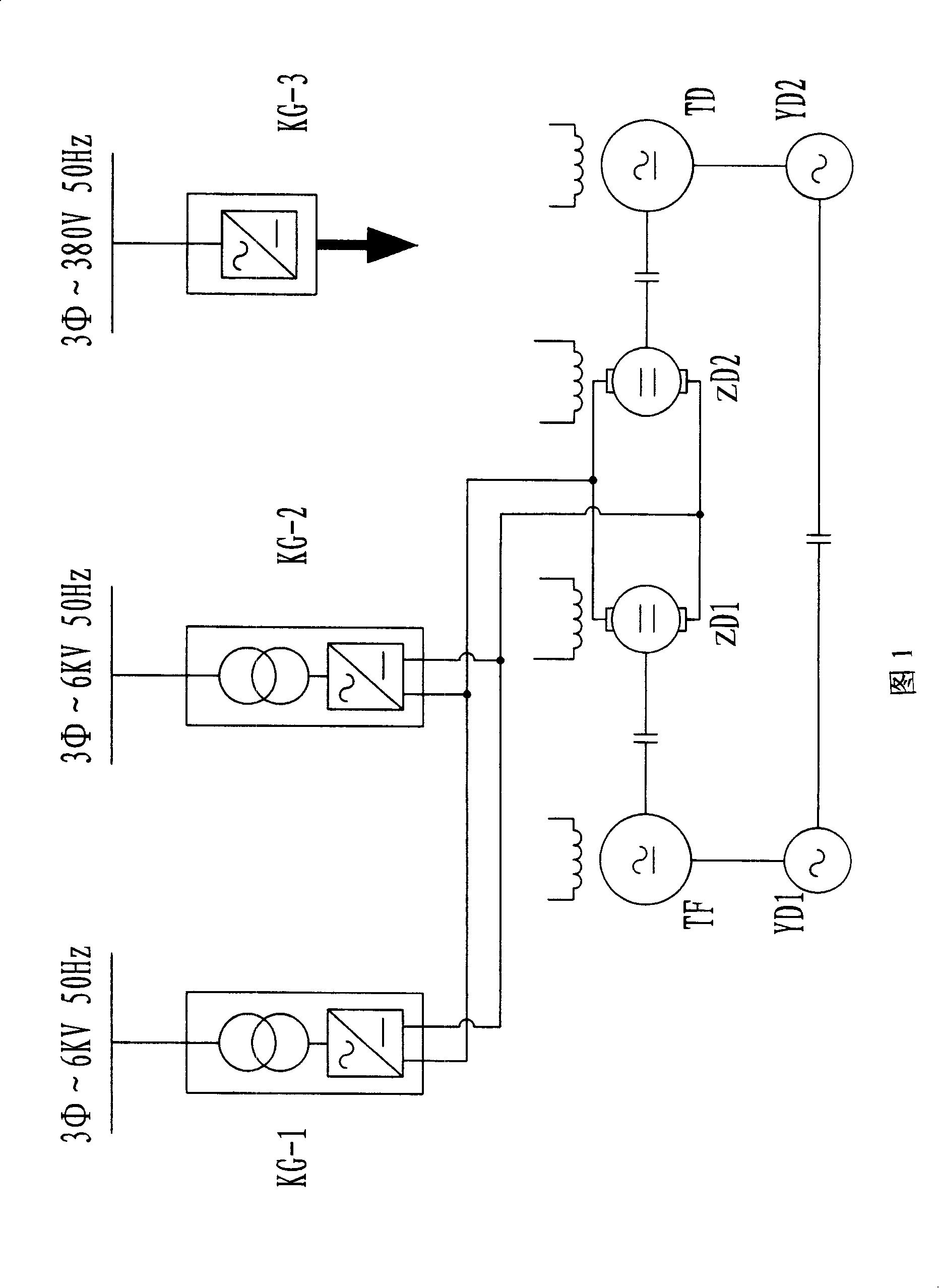

[0018] As shown in Figure 1, the DC speed control system adopts digital high-power DC motor speed control device, which is composed of DC motor control devices KG-1 and KG-2, and DC excitation control device KG-3. DC motor KG-1 and The power supply of KG-2 is provided by a 50HZ, 6 kV power grid, and the DC excitation control device KG-3 is provided by a 50HZ, 380V power grid. The digital high-power DC motor speed control device is an existing technology, and the DC motor control device KG- 1, KG-2 and DC motor excitation control device KG-3, the DC speed regulating device provides working power for the frequency conversion feedback power supply, and the frequency conversion feedback power supply is a DC motor ZD 1 Drive the synchronous generator TF to run, and the electric energy output by the synchronous generator TF is the measured asynchronous motor YD 1 Provide working power, the asynchronous motor YD under test 1 With a test motor YD 2 Coaxial connection, accompanying t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com