Patents

Literature

32 results about "Unit injector" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

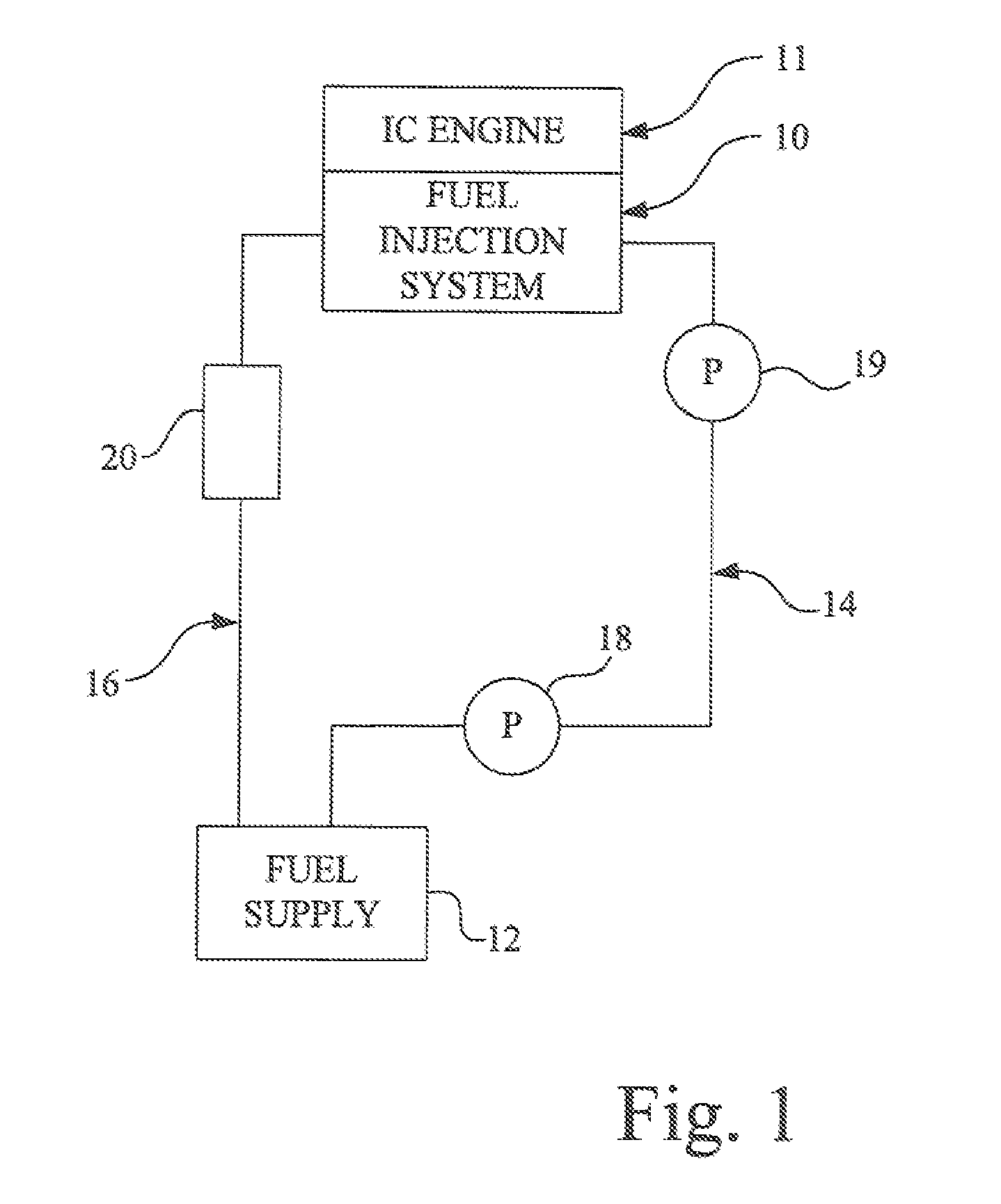

A Unit injector (UI) is a high pressure integrated direct fuel injection system for diesel engines, combining the injector nozzle and the injection pump in a single component. The plunger pump used is usually driven by a shared camshaft. In a unit injector, the device is usually lubricated and cooled by the fuel itself.

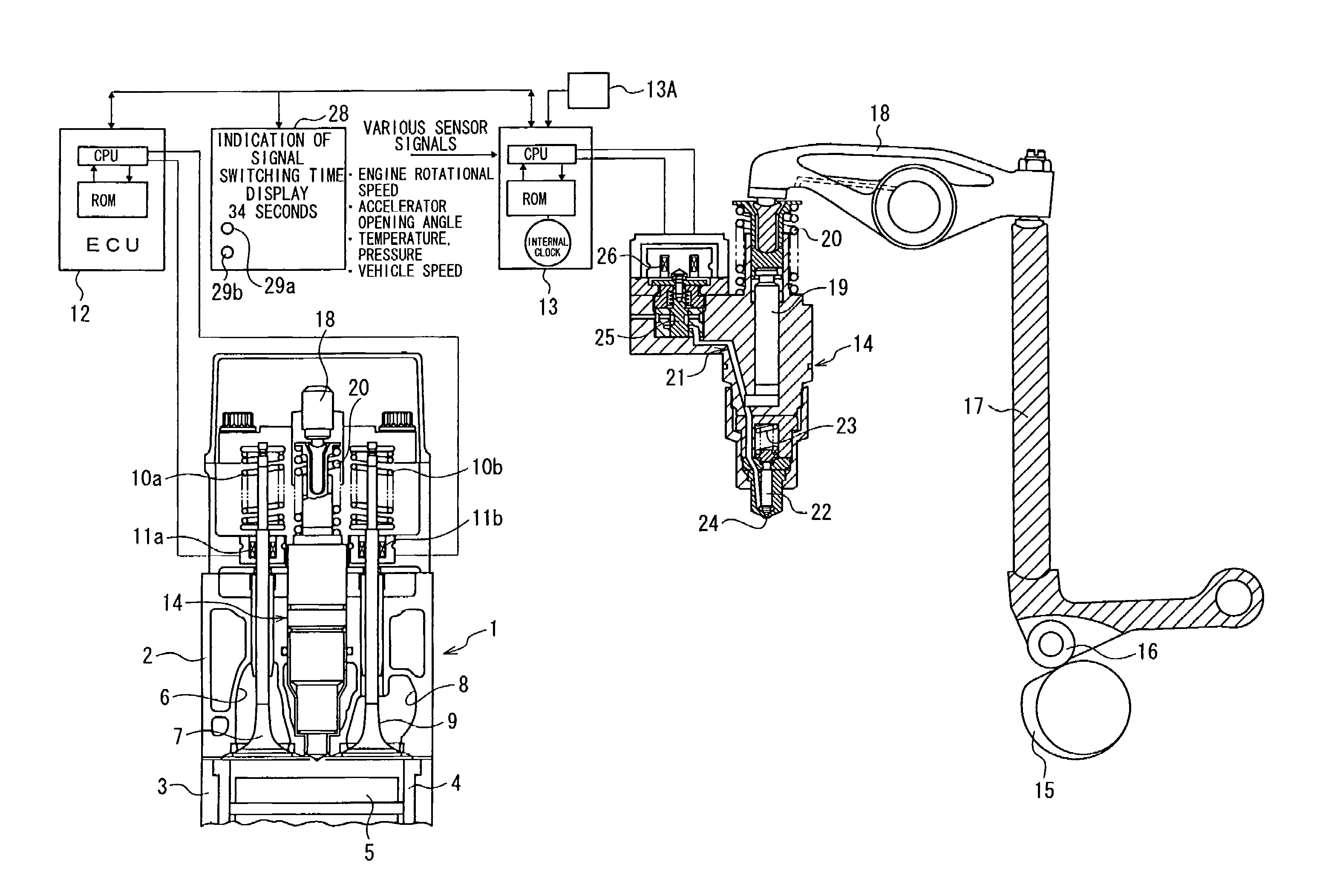

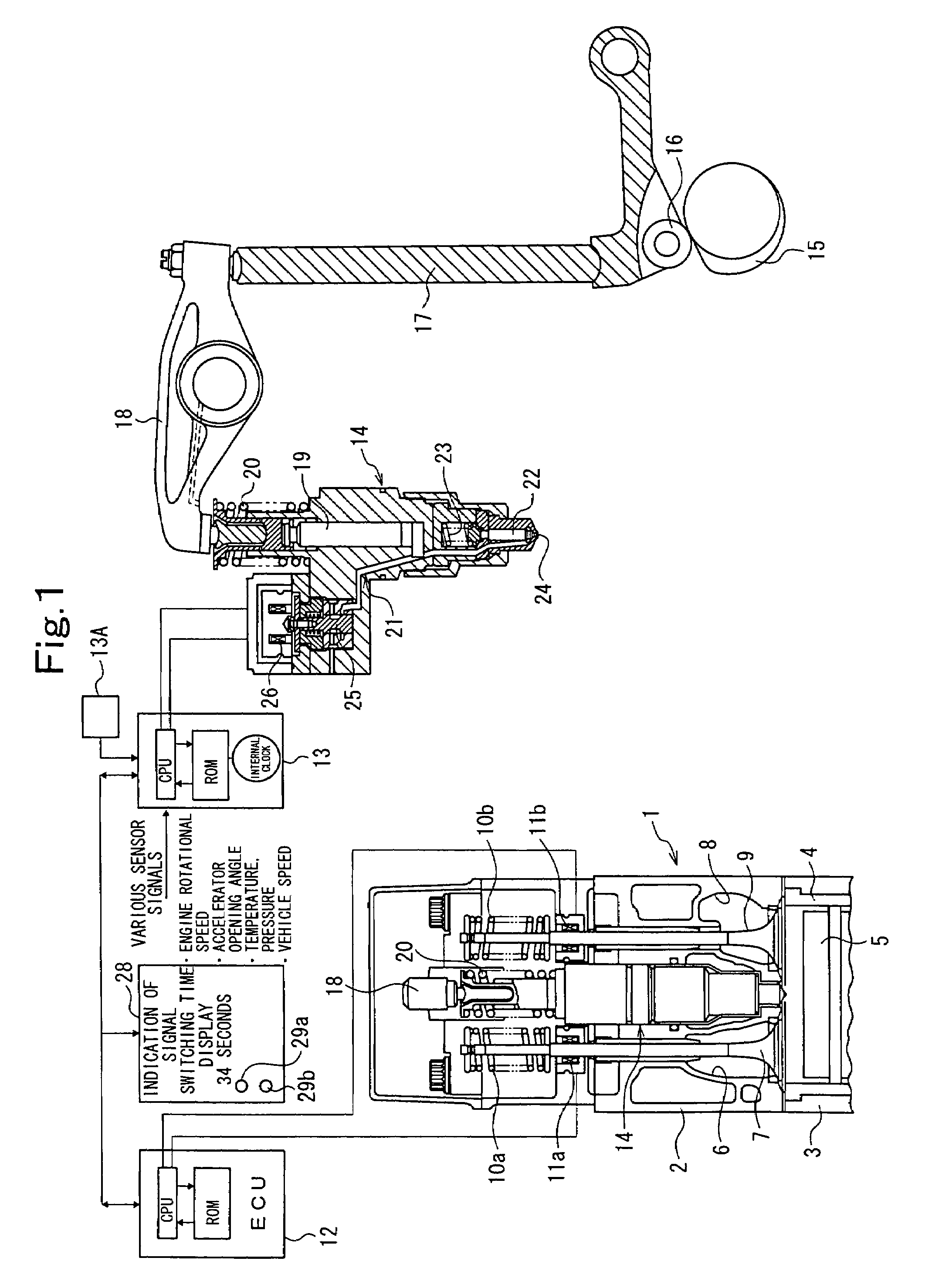

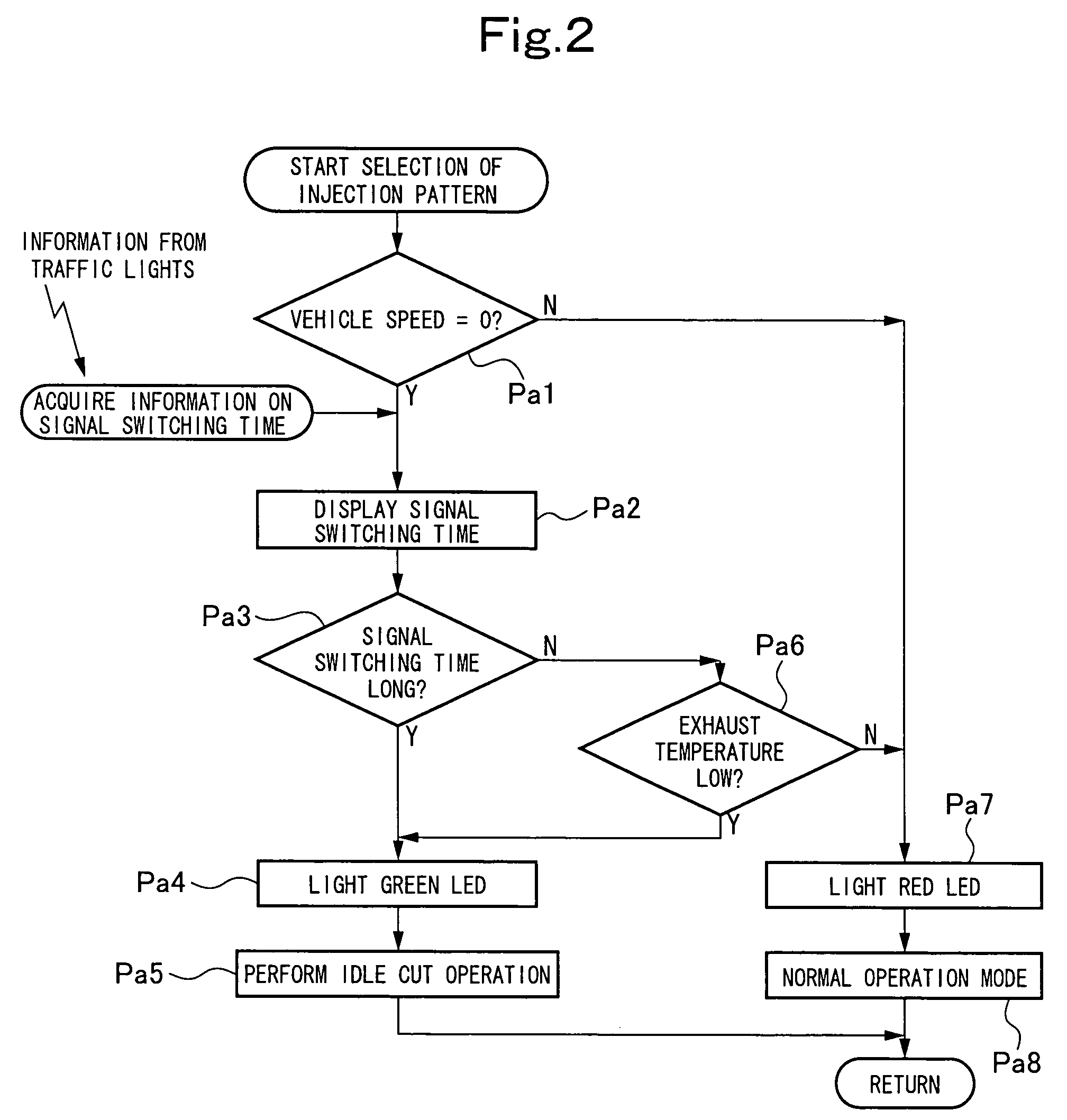

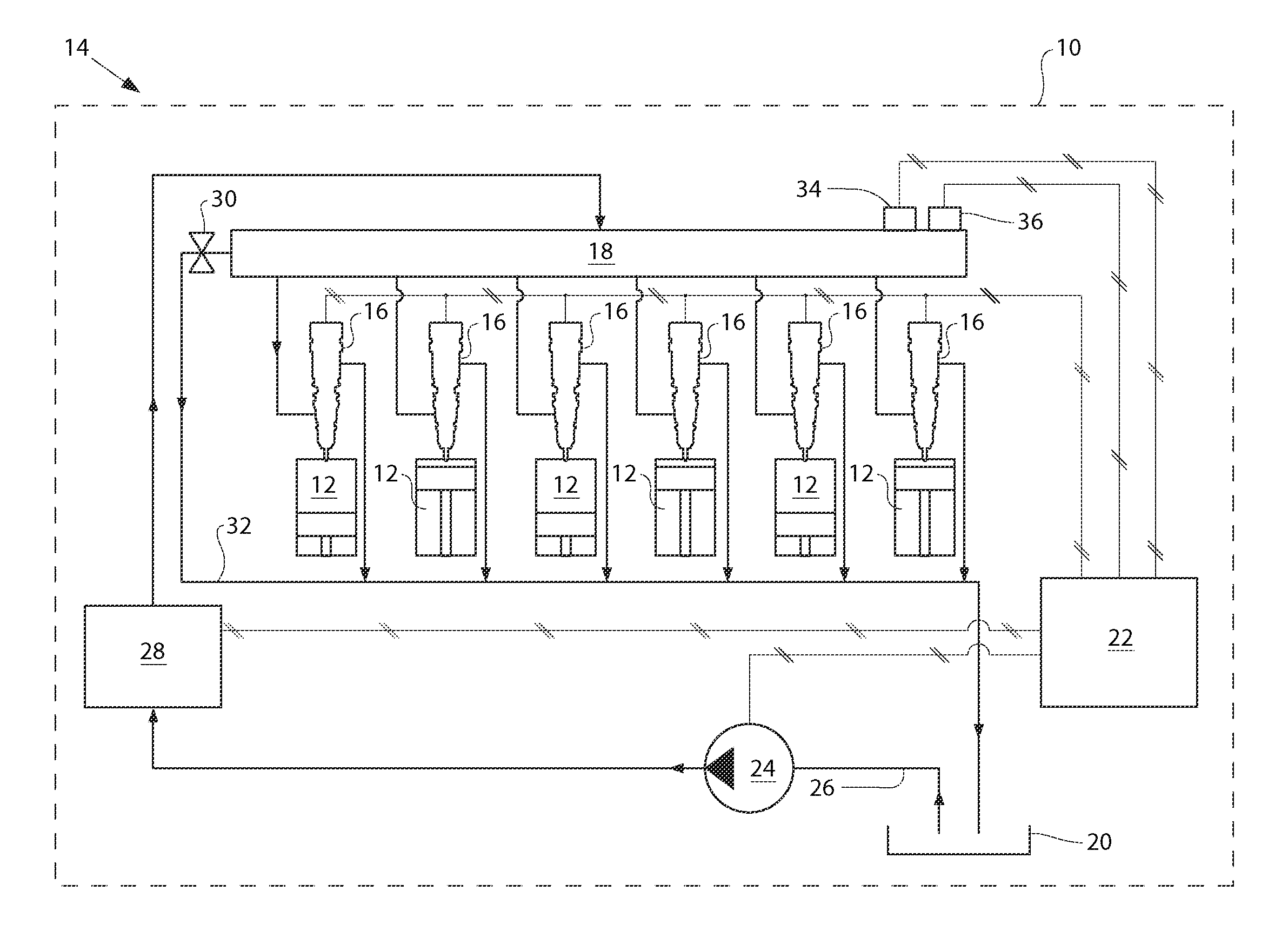

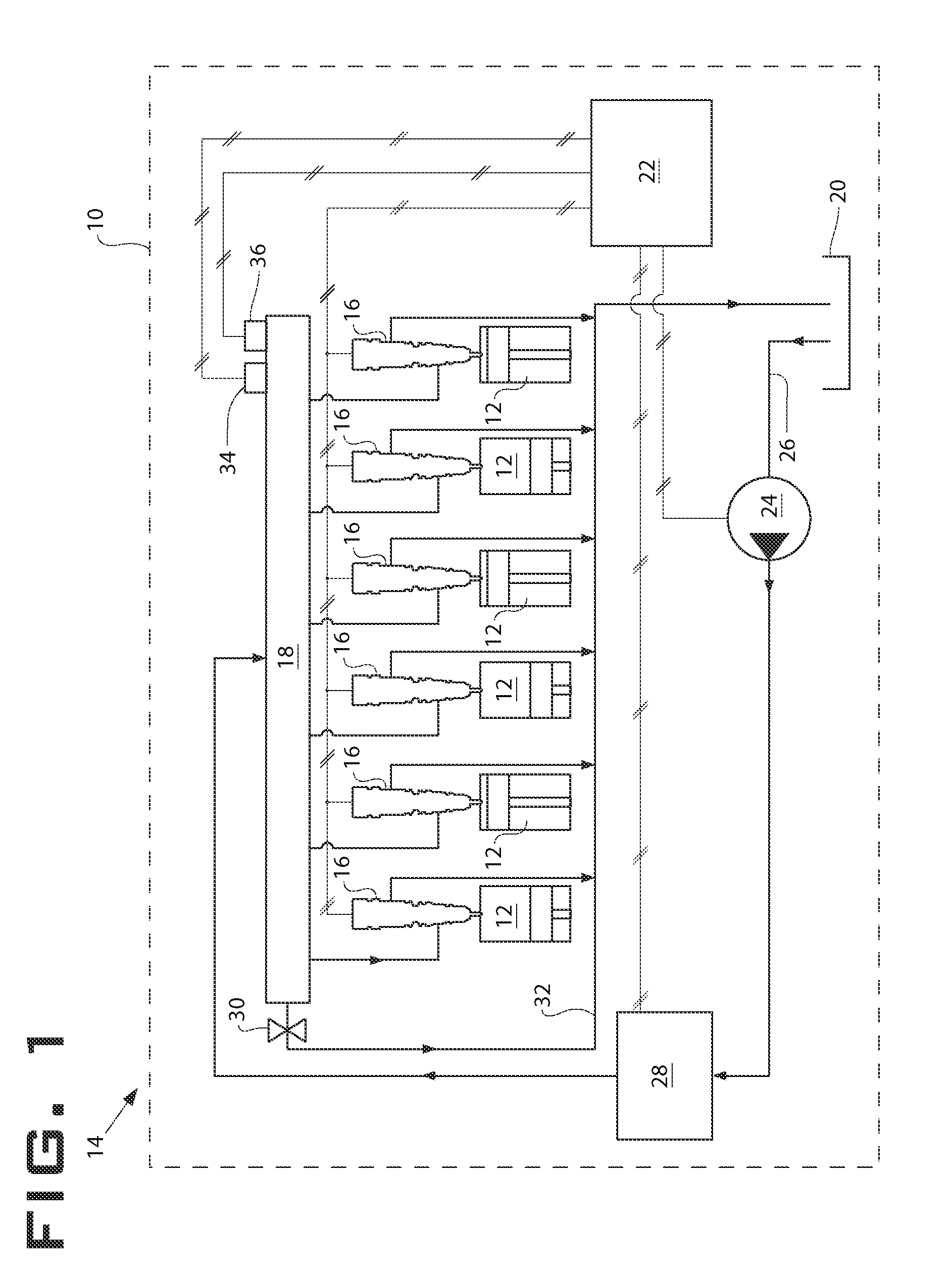

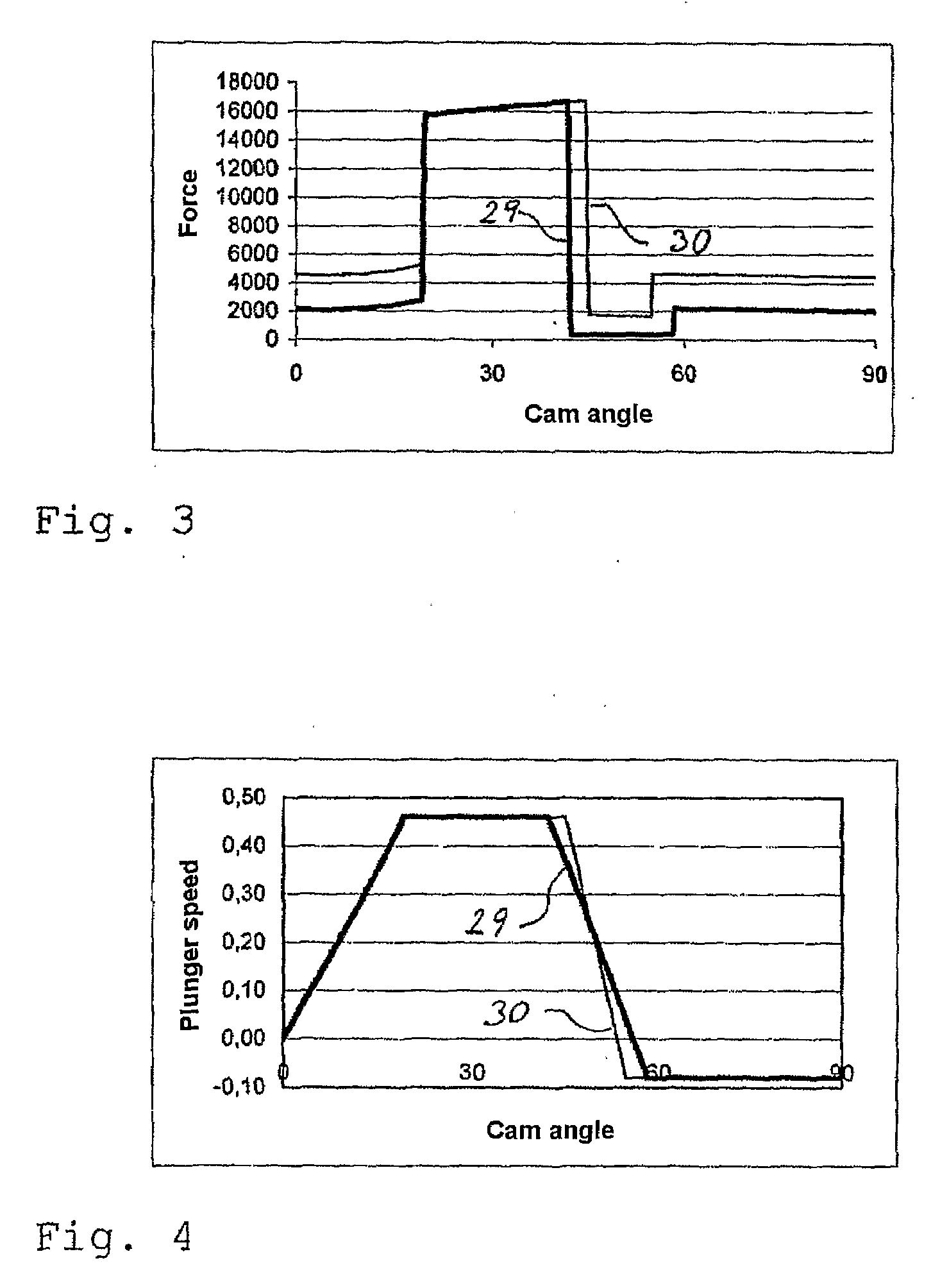

Control device for multi-cylinder internal combustion engine and signaling device capable of providing same with information

ActiveUS20050143898A1Improve economyImprove pollutionElectrical controlInternal combustion piston enginesExhaust valveUnit injector

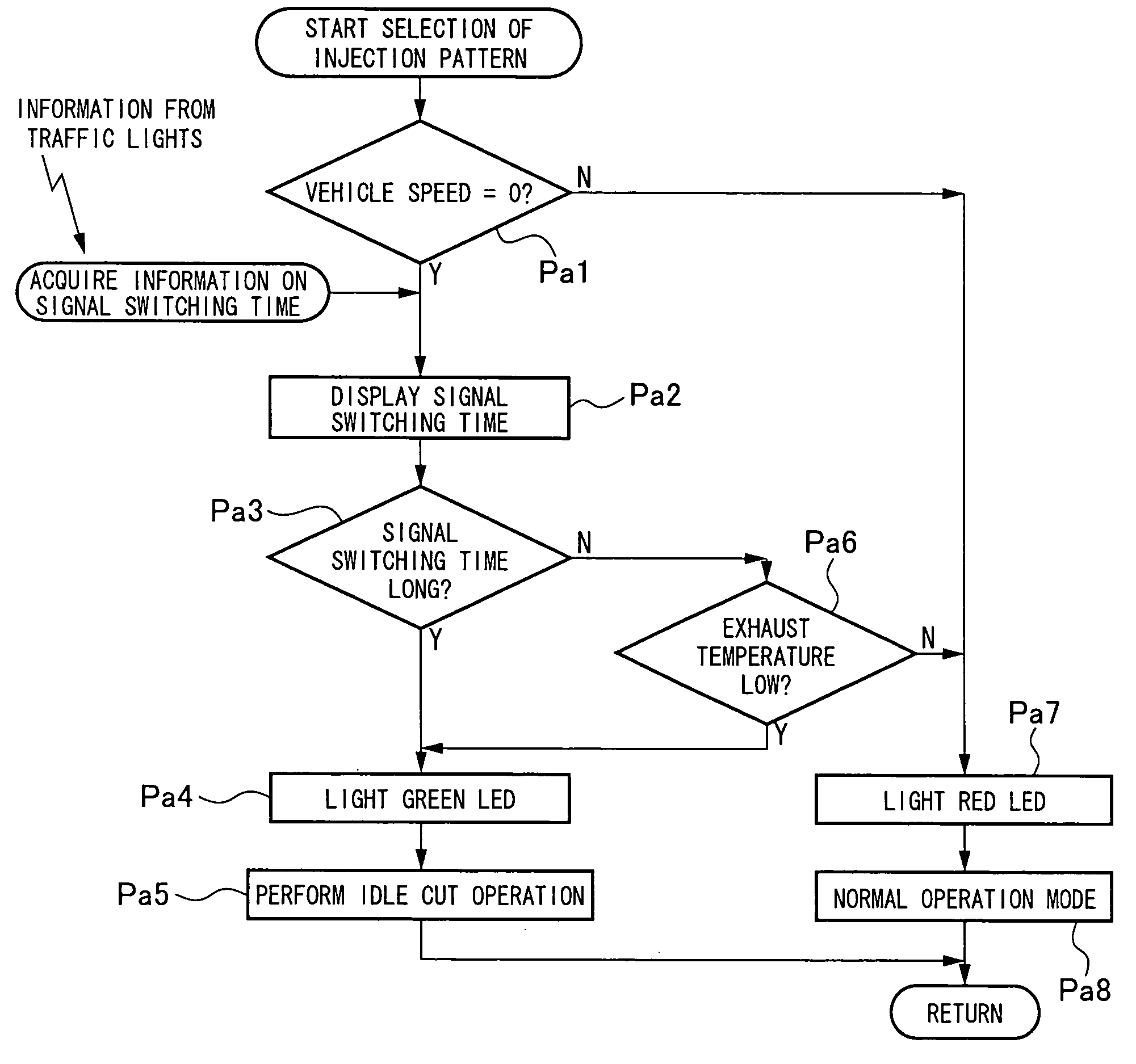

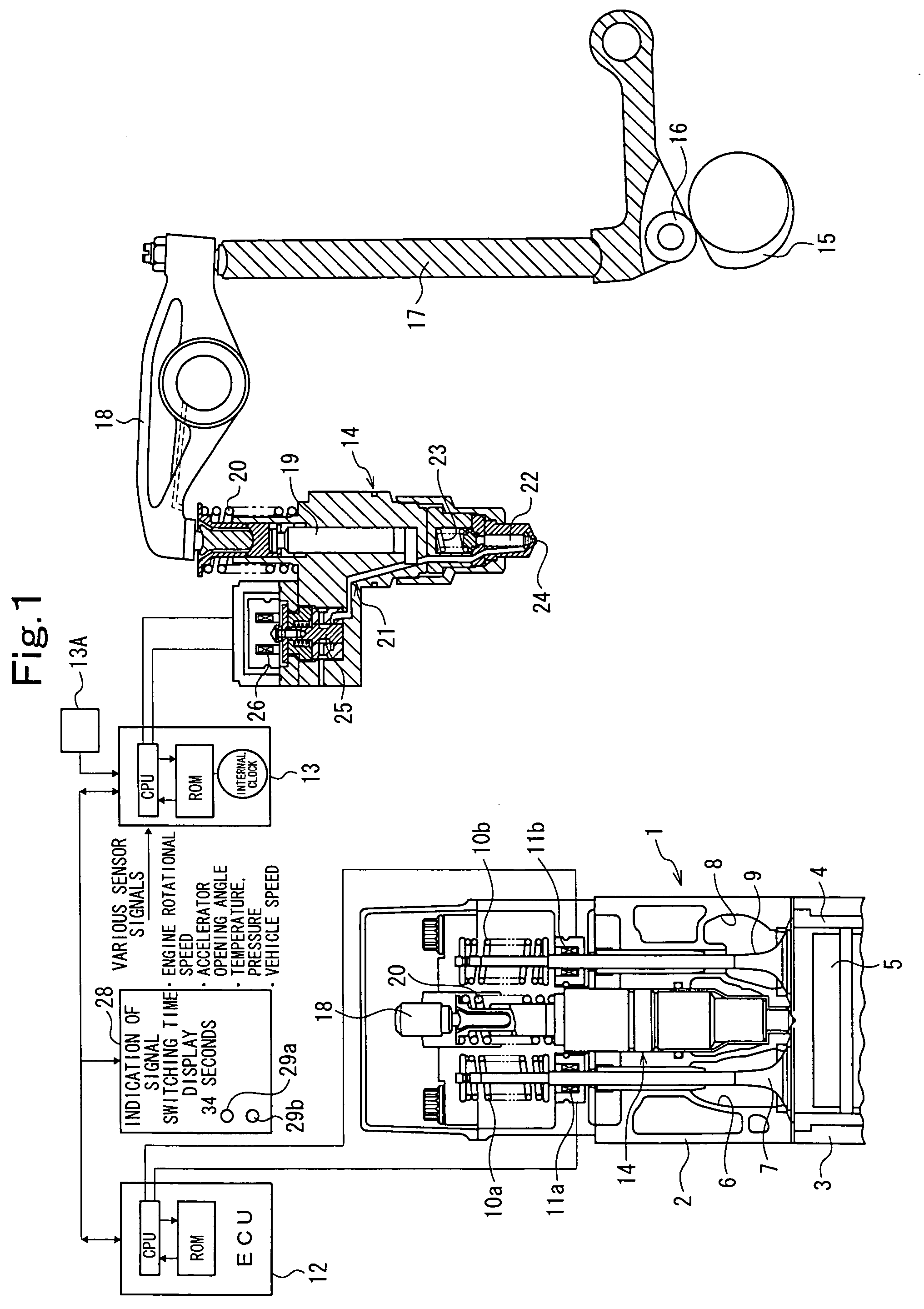

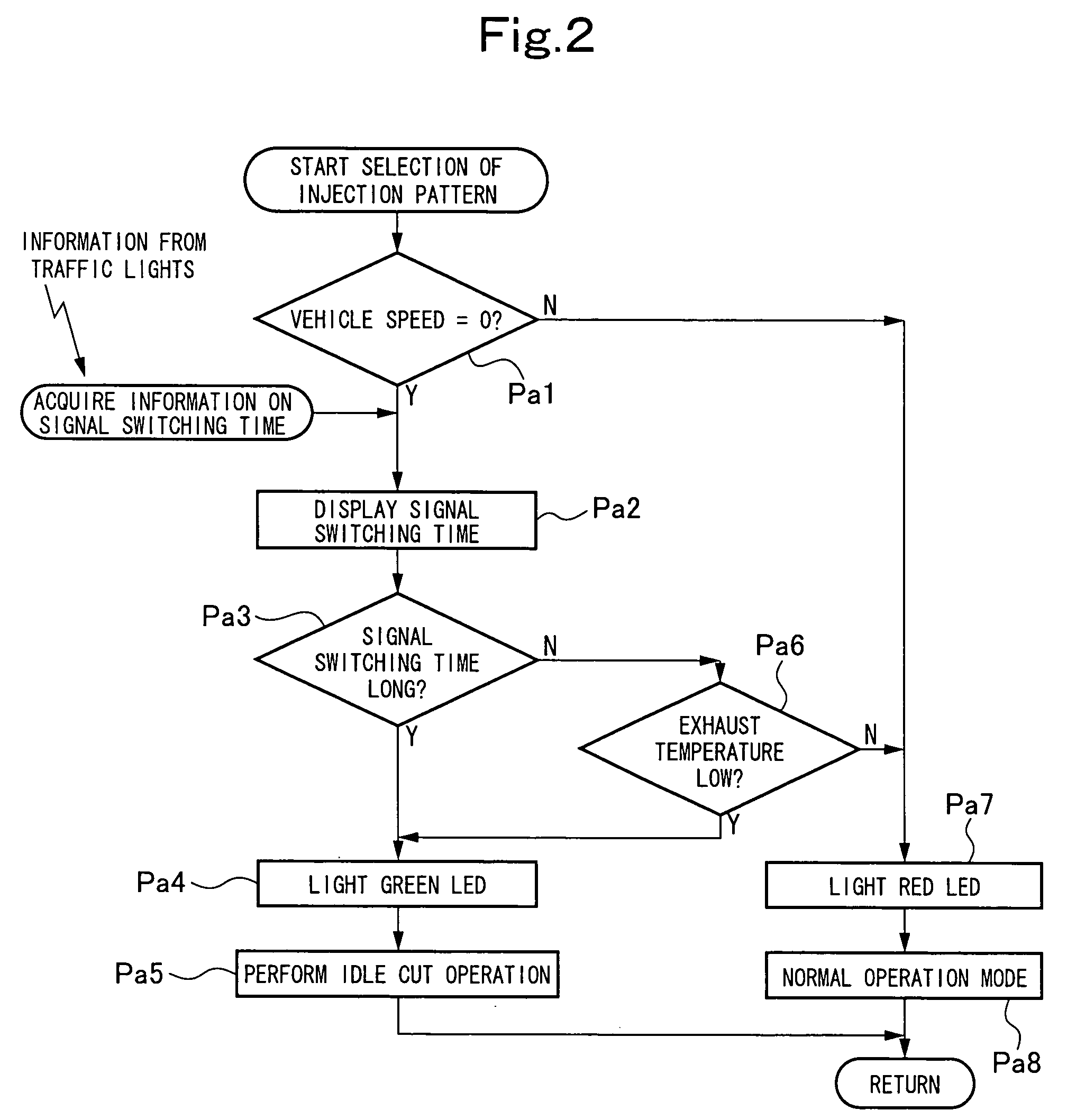

A control device for an engine, which includes a plurality of cylinders, an electronically controlled unit injector for injecting fuel into each cylinder, and an electronically controlled valve train for opening and closing an intake valve and an exhaust valve of each cylinder, comprises operating state detection means for detecting the operating state of the engine, and electronic control units for performing an idle cut operation, in which fuel injection into some of the cylinders is stopped, and the intake valve and the exhaust valve of the cylinder concerned are kept closed, if the signal switching time is long when the idling of the engine of a vehicle waiting at traffic lights is detected by the operating state detection means.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

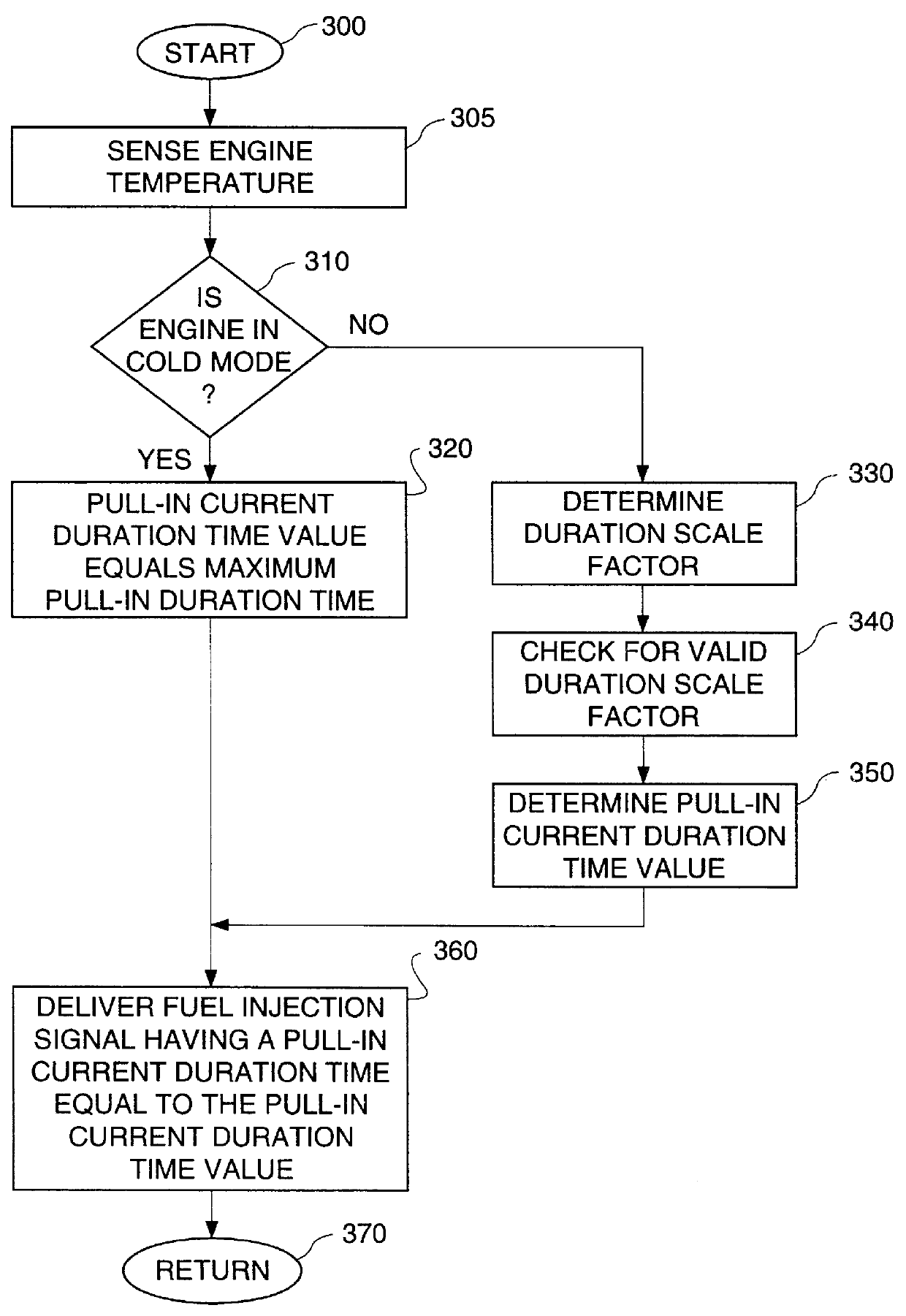

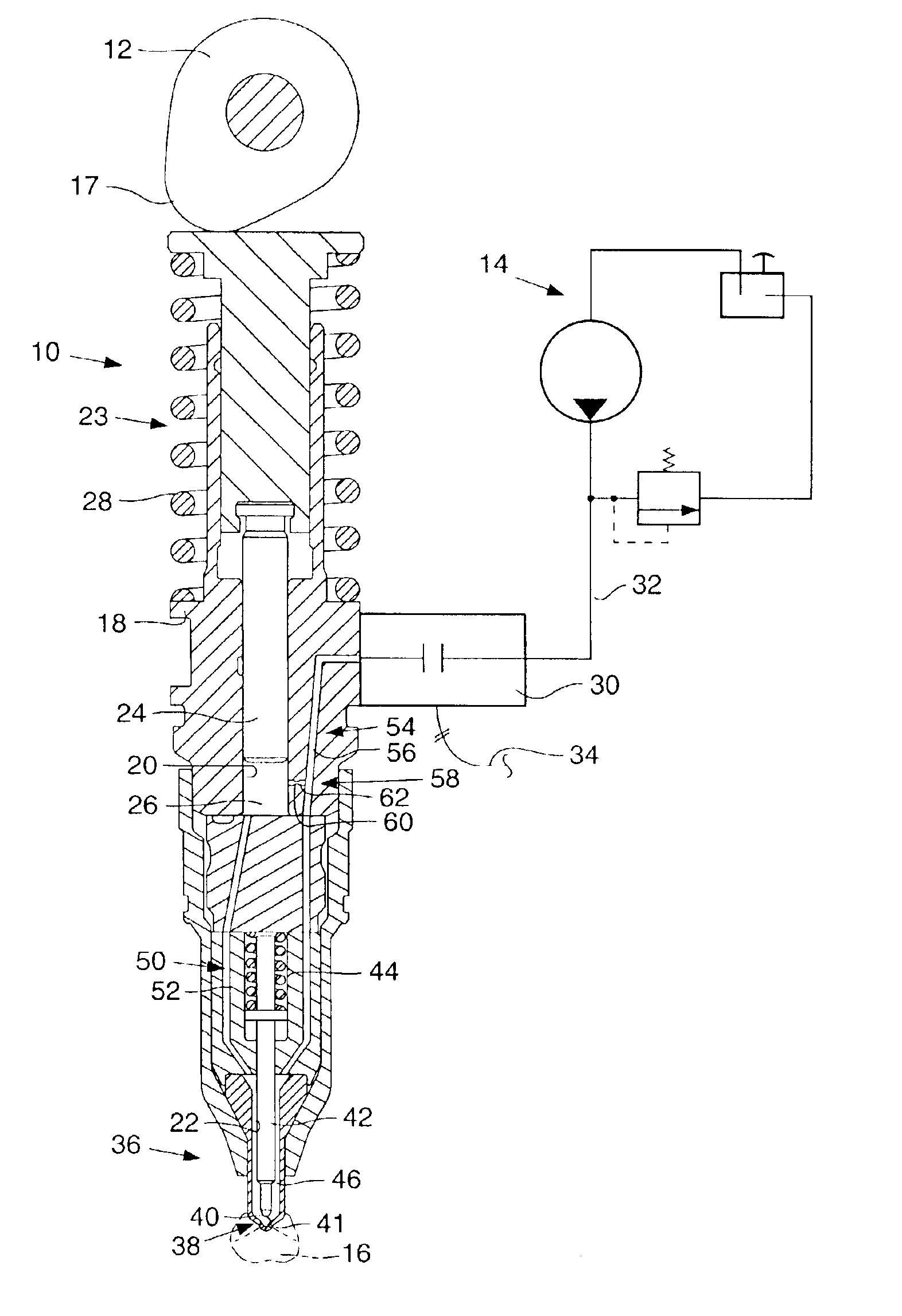

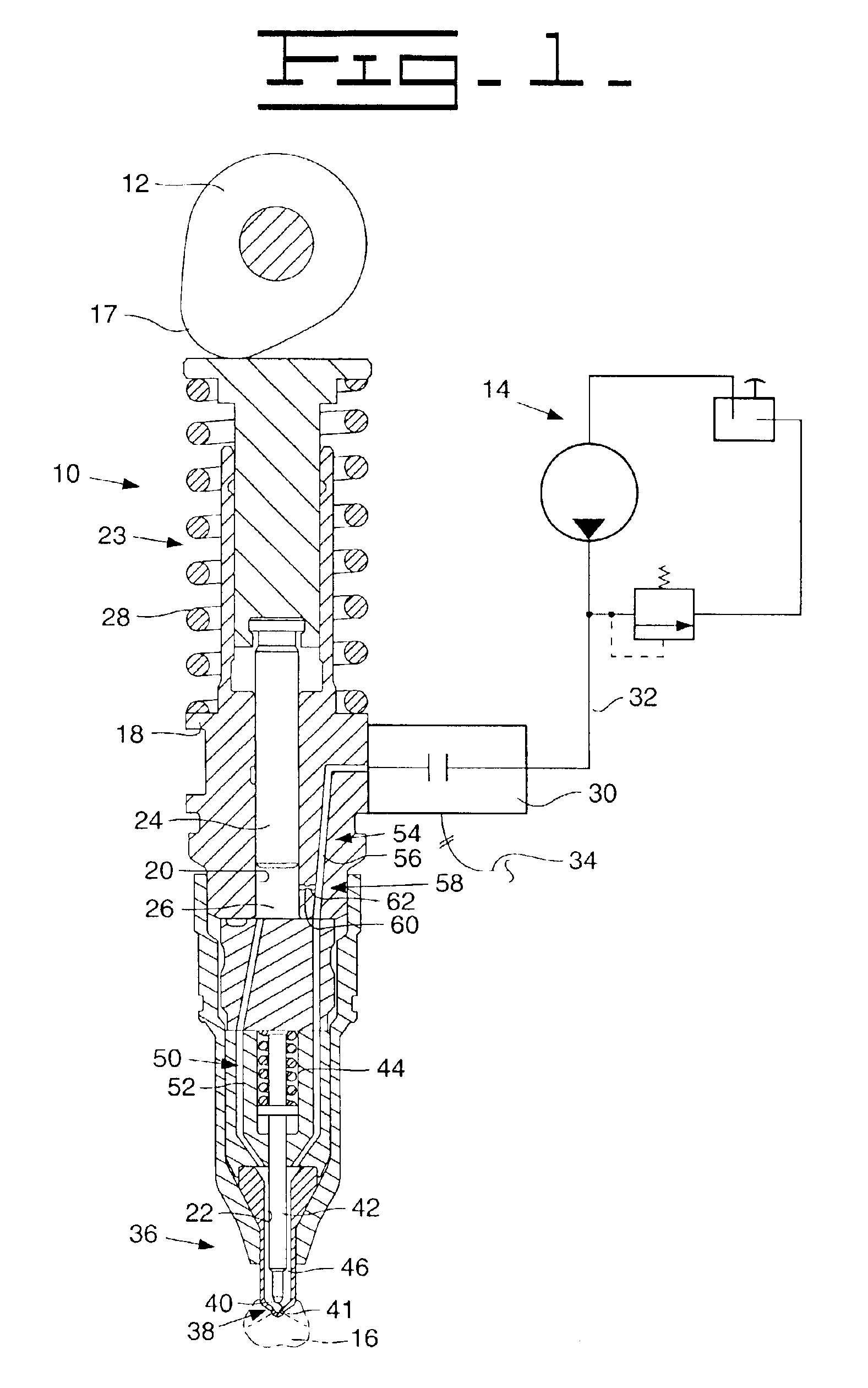

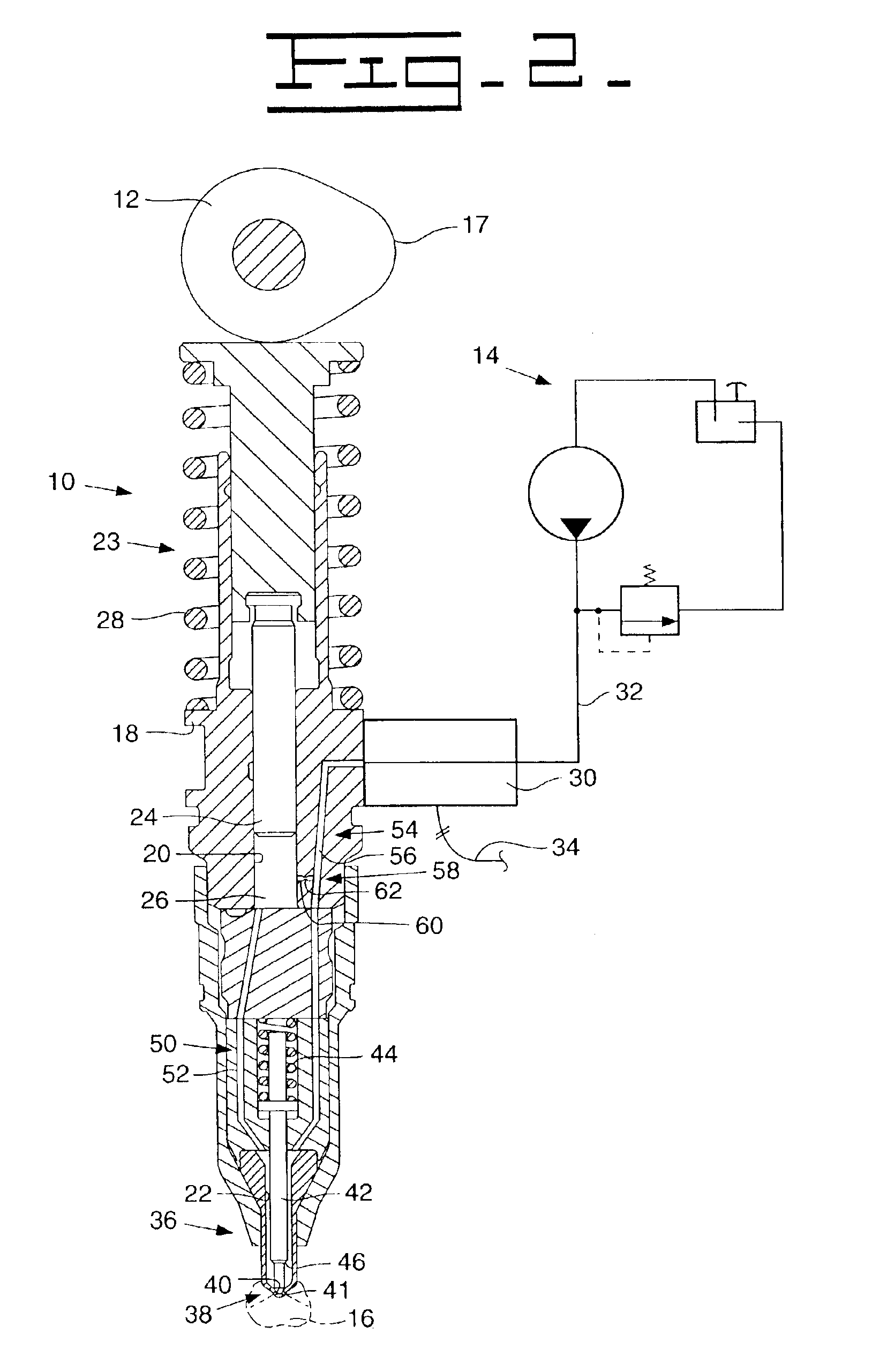

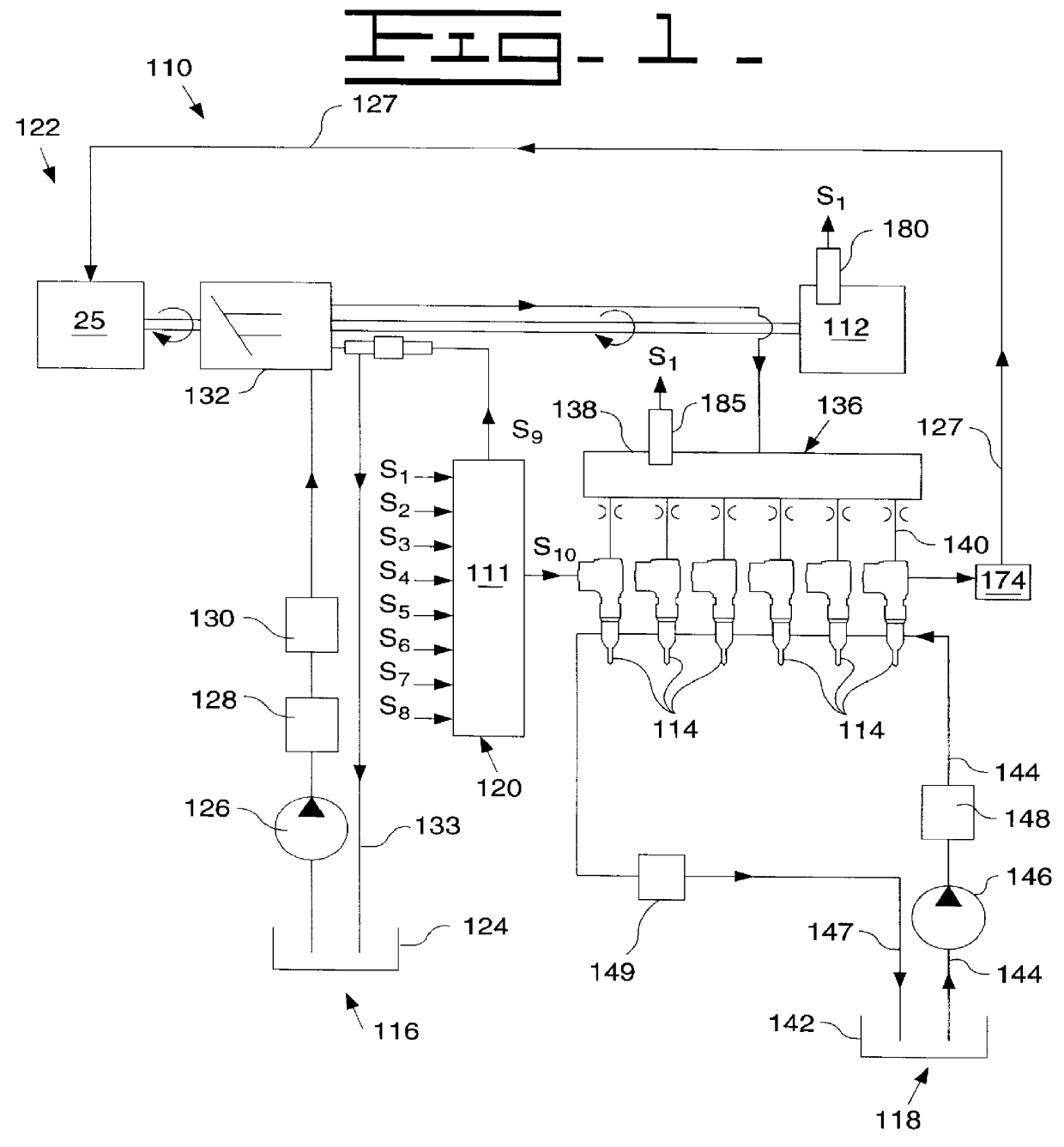

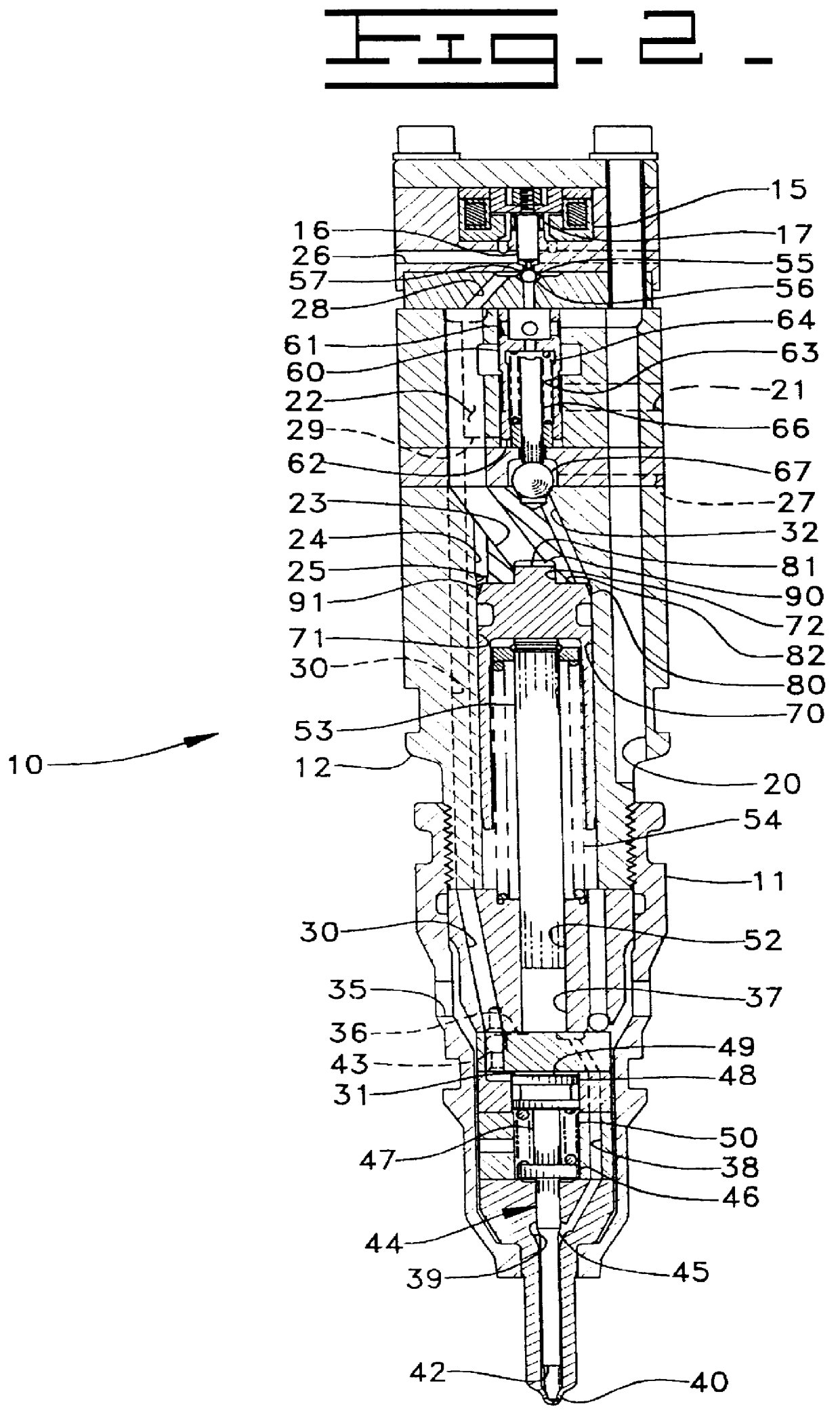

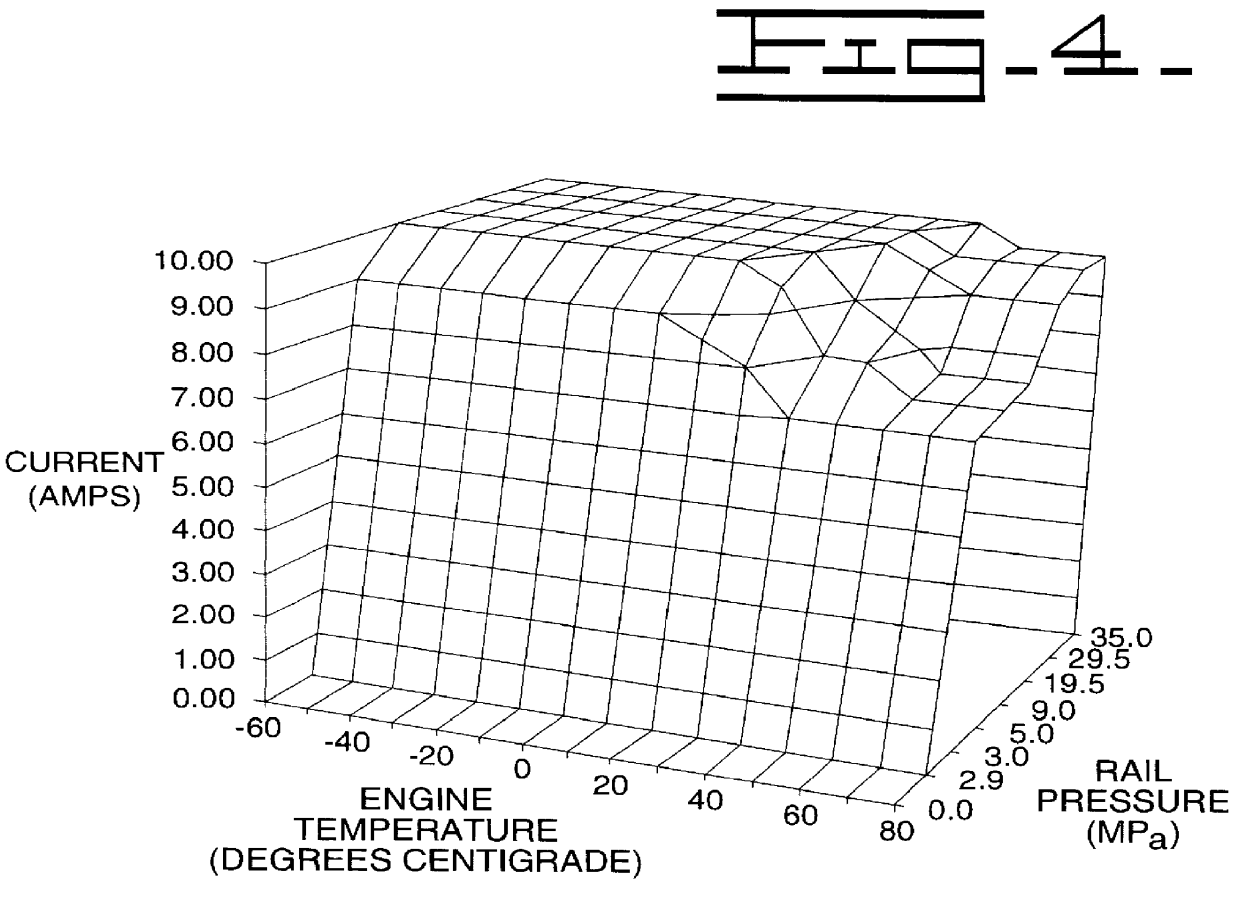

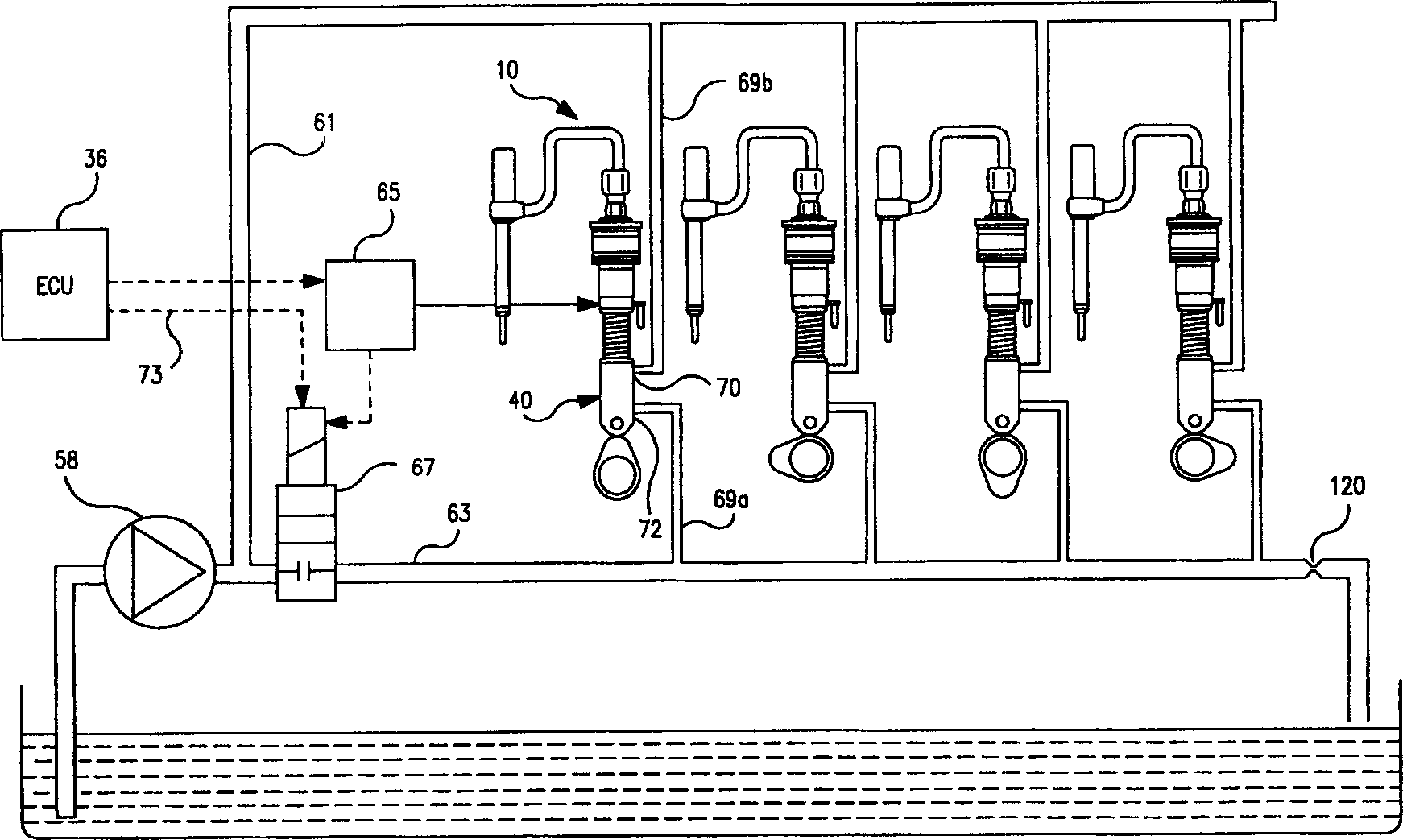

Electronic control for a hydraulically activated, electronically controlled injector fuel system and method for operating same

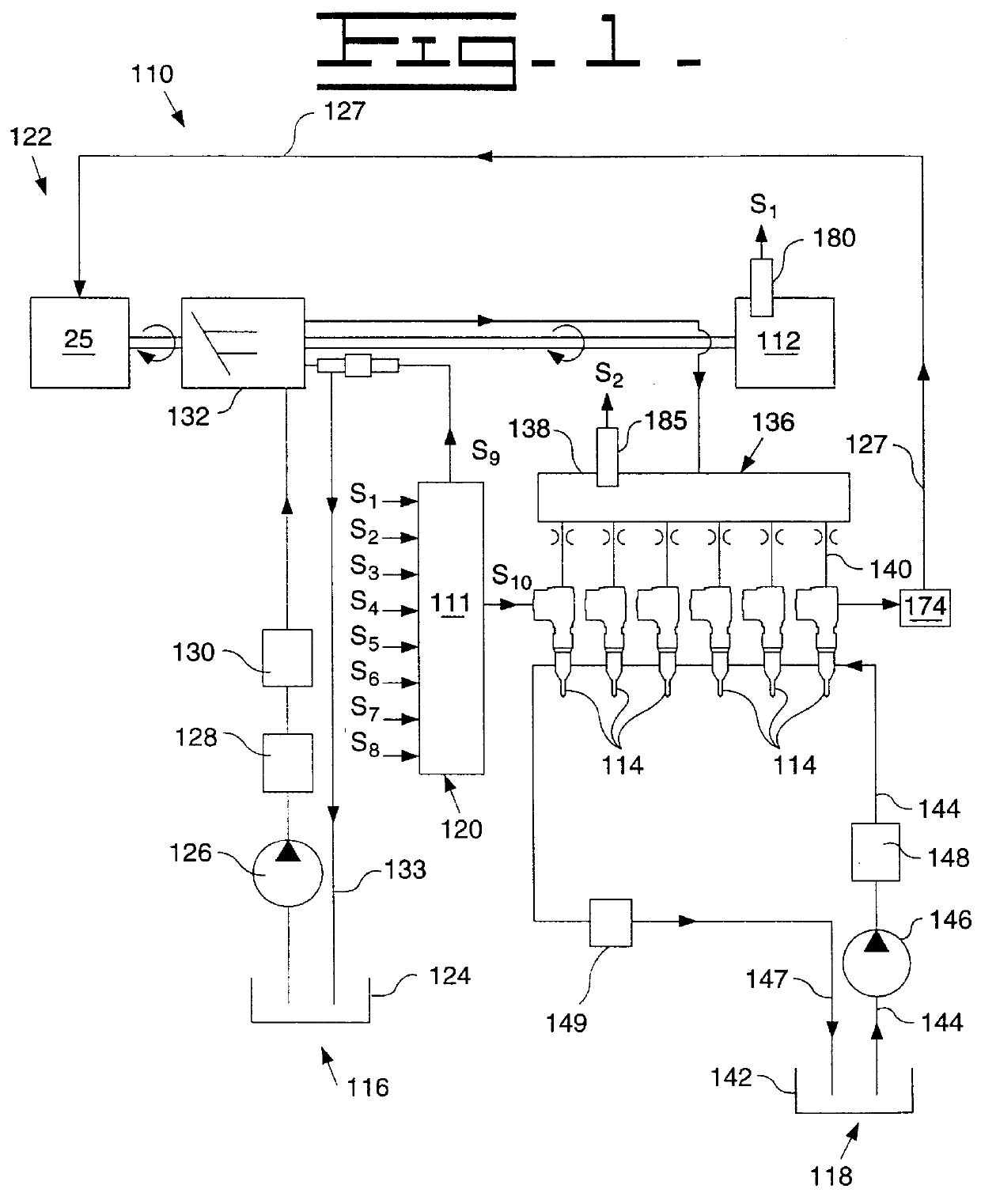

An apparatus and method for varying the duration of current levels of a fuel injection signal used in connection with an electronically controlled hydraulic actuator unit injector fuel system is disclosed. The apparatus and method varies the duration of the pull-in current of the fuel injection signal delivered to the unit injector based on sensed engine parameters, which preferably include a sensed temperature of the engine and engine speed.

Owner:CATERPILLAR INC

Control device for multi-cylinder internal combustion engine and signaling device capable of providing same with information

ActiveUS7203588B2Improve economyImprove pollutionElectrical controlInternal combustion piston enginesExhaust valveExternal combustion engine

A control device for an engine, which includes a plurality of cylinders, an electronically controlled unit injector for injecting fuel into each cylinder, and an electronically controlled valve train for opening and closing an intake valve and an exhaust valve of each cylinder, comprises an operating state detection unit for detecting the operating state of the engine, and electronic control units for performing an idle cut operation, in which fuel injection into some of the cylinders is stopped, and the intake valve and the exhaust valve of the cylinder concerned are kept closed, if the signal switching time is long when the idling of the engine of a vehicle waiting at traffic lights is detected by the operating state detection unit.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

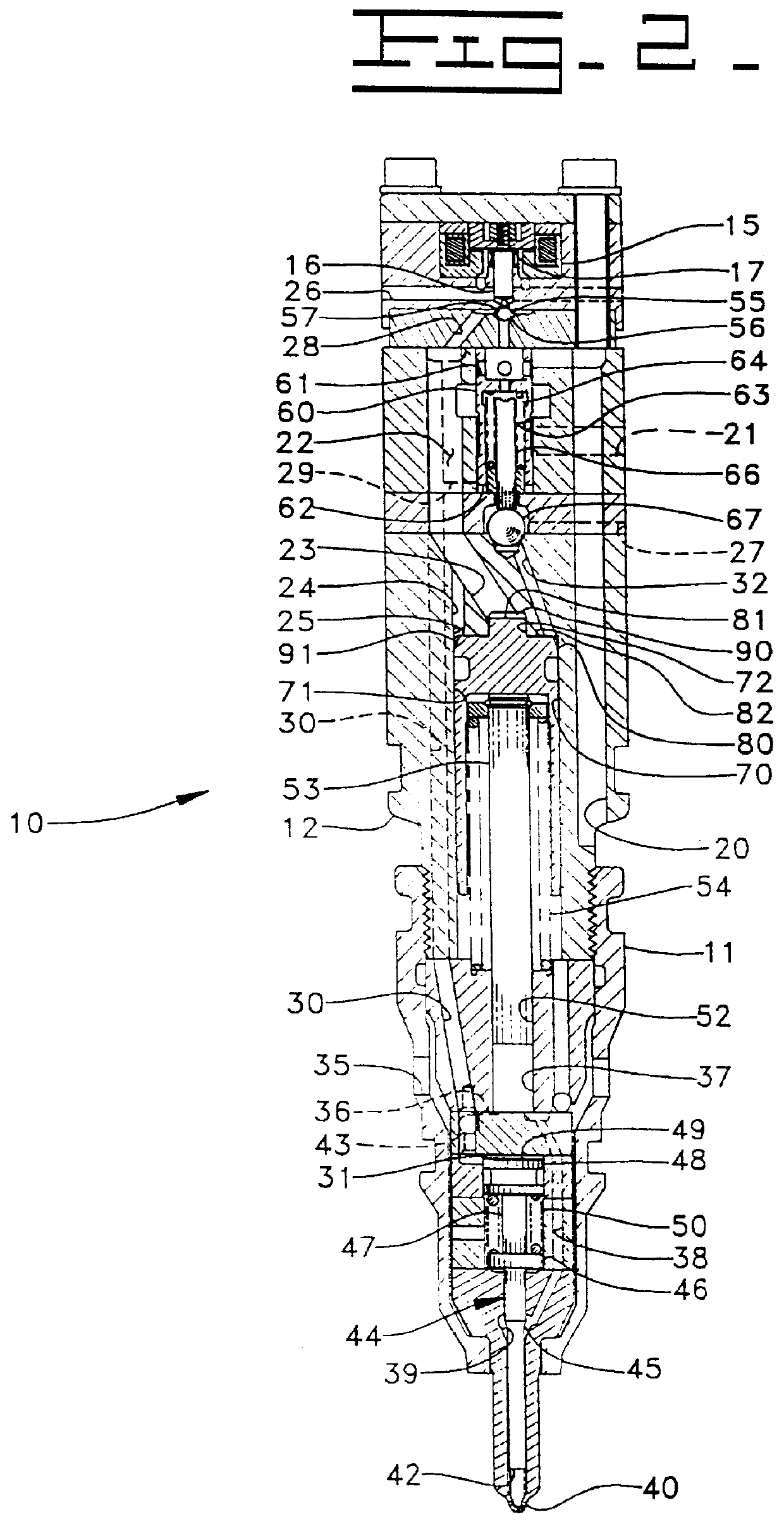

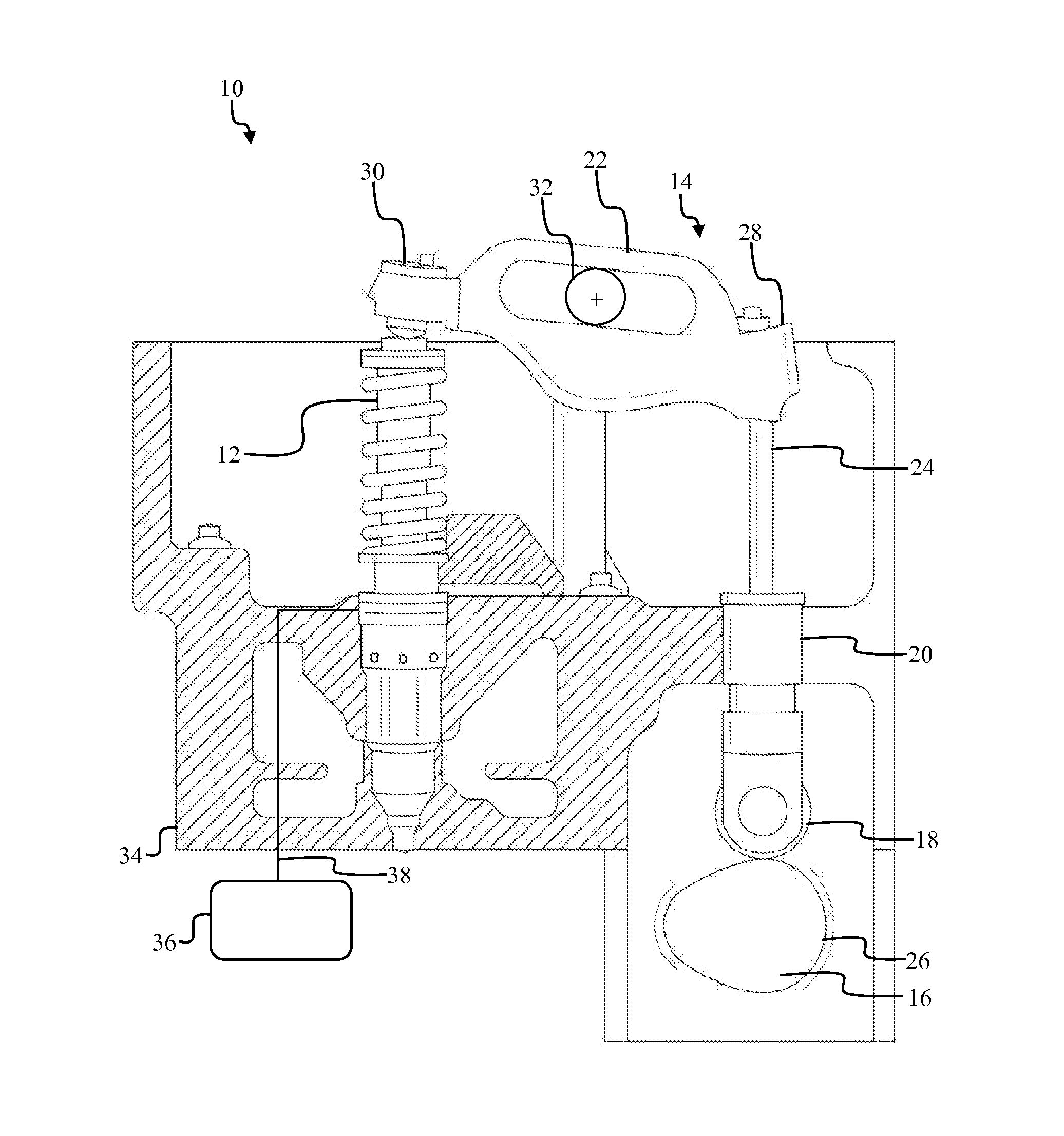

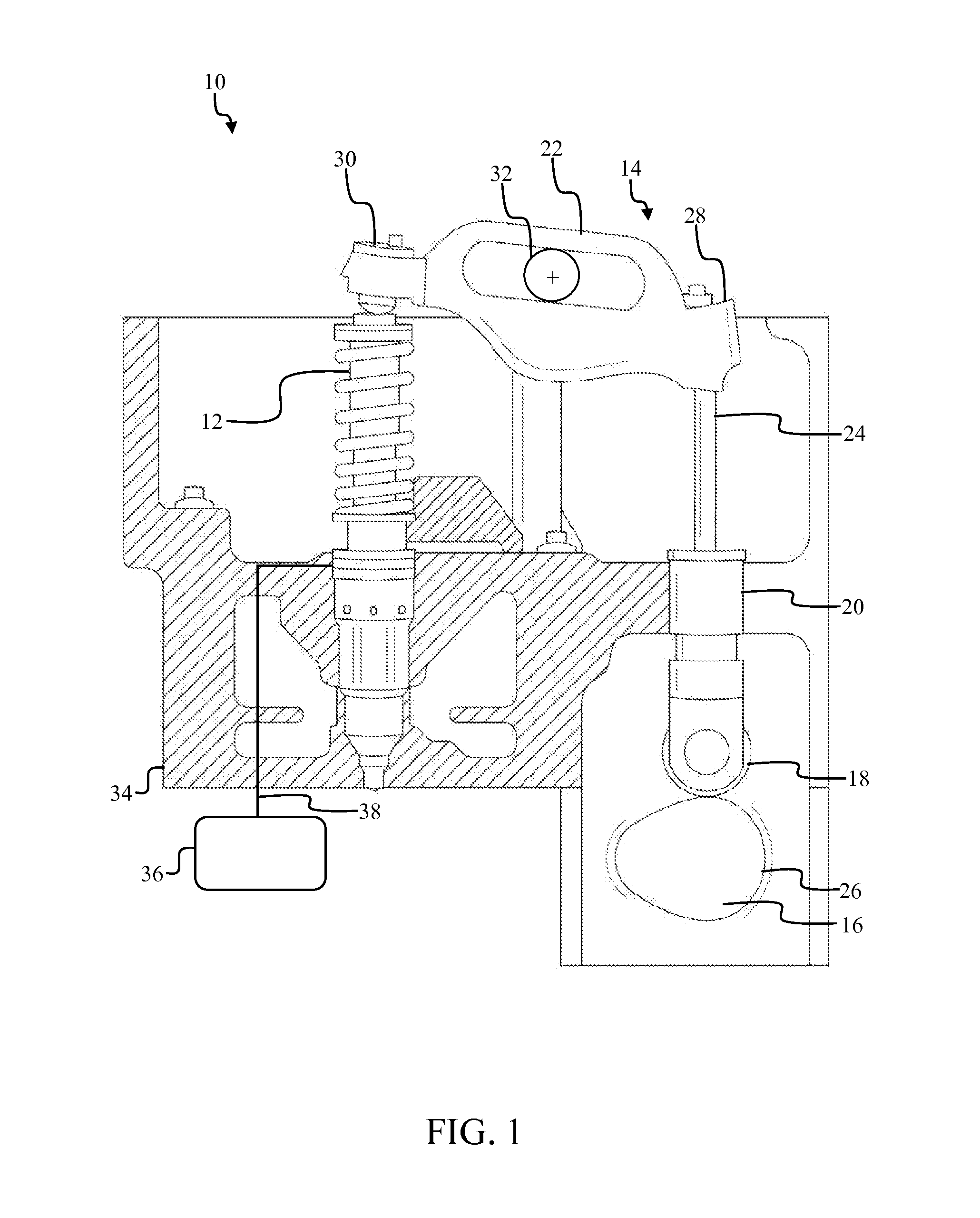

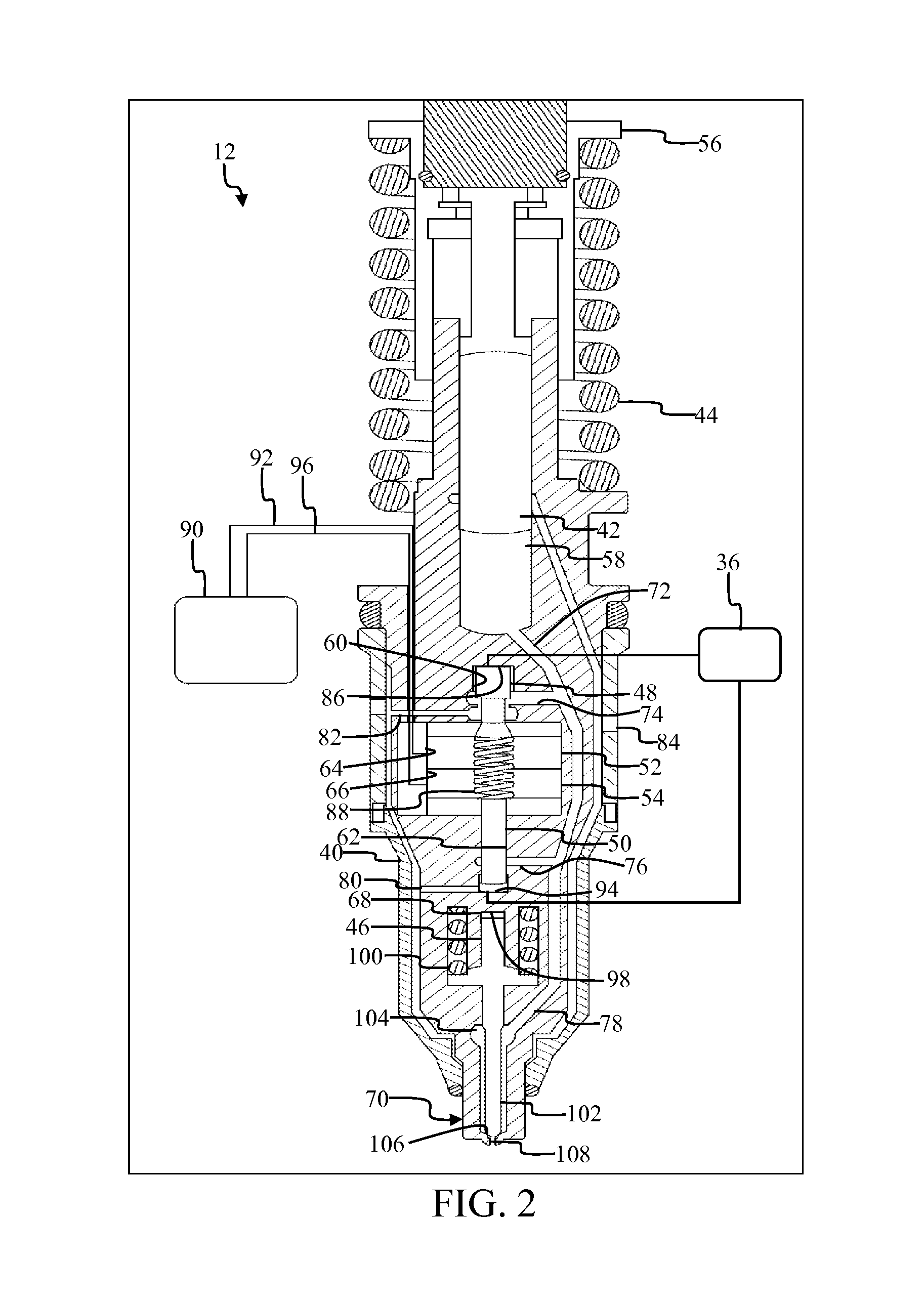

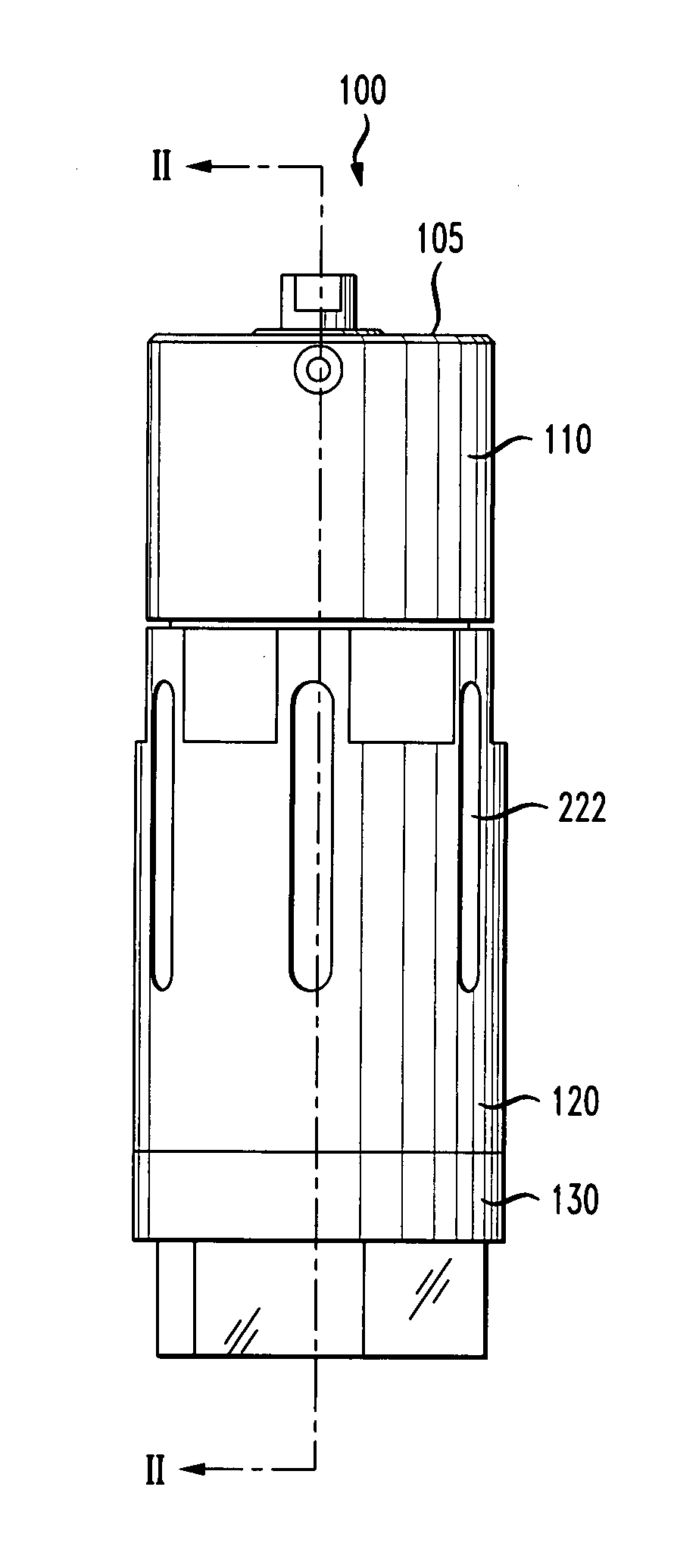

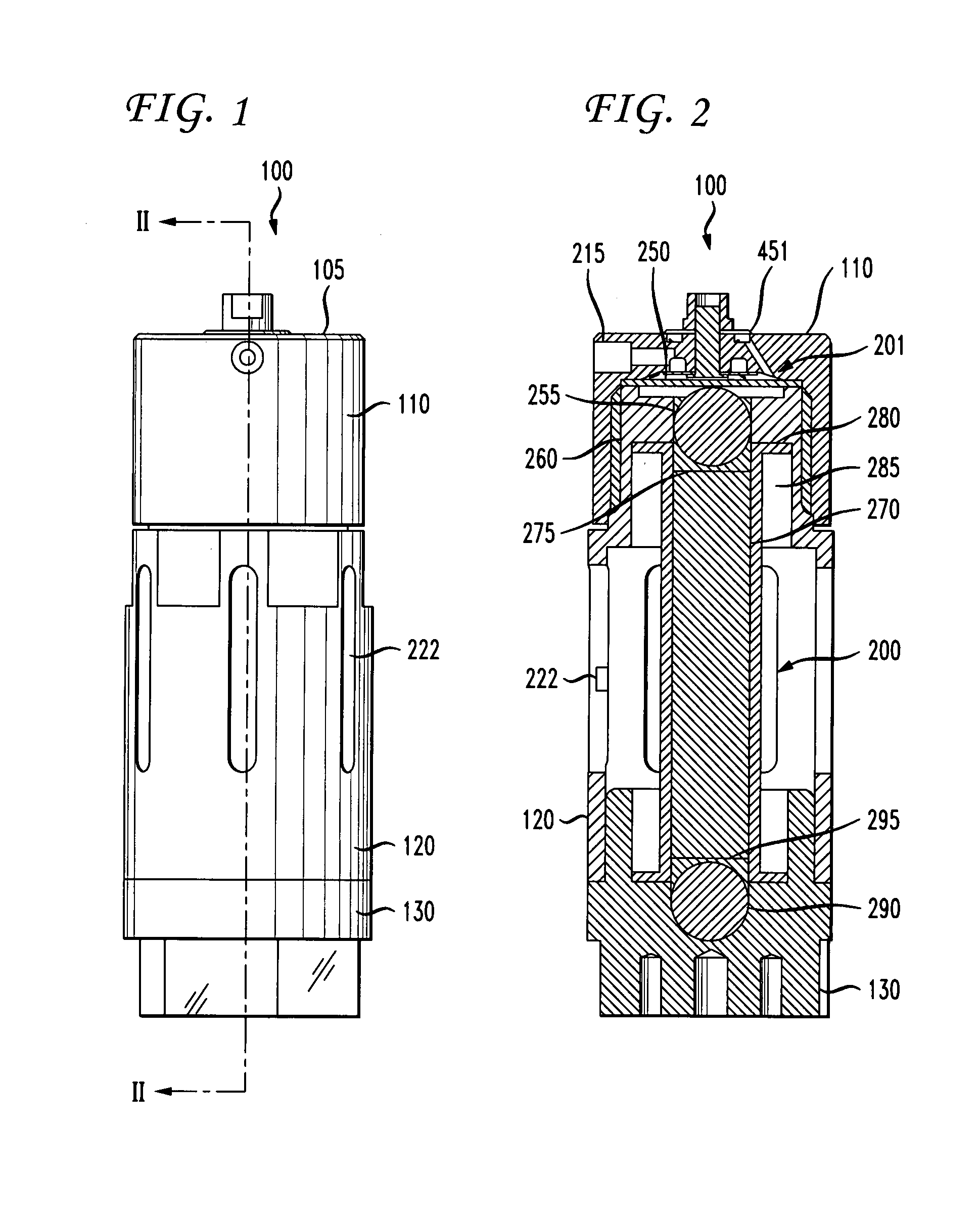

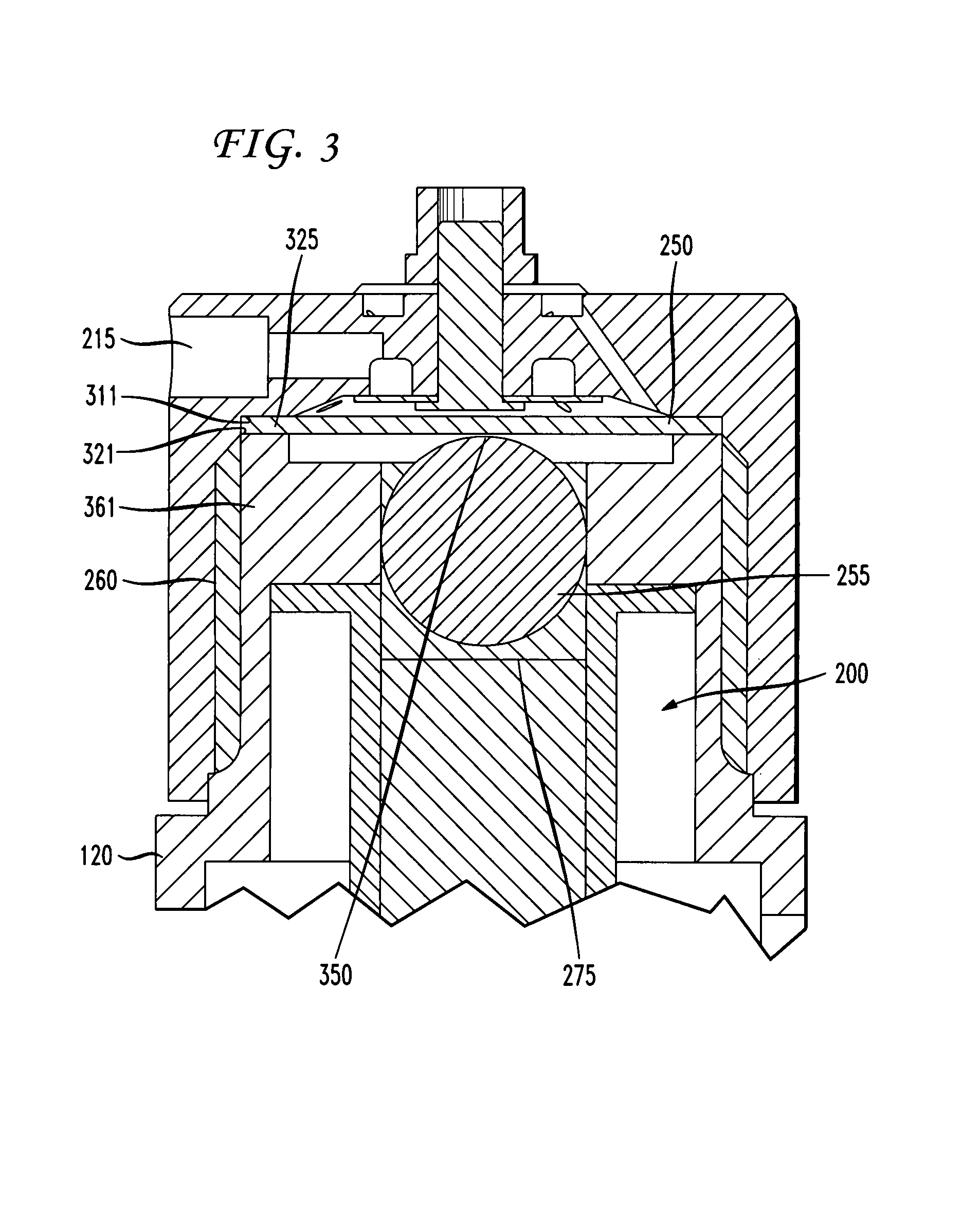

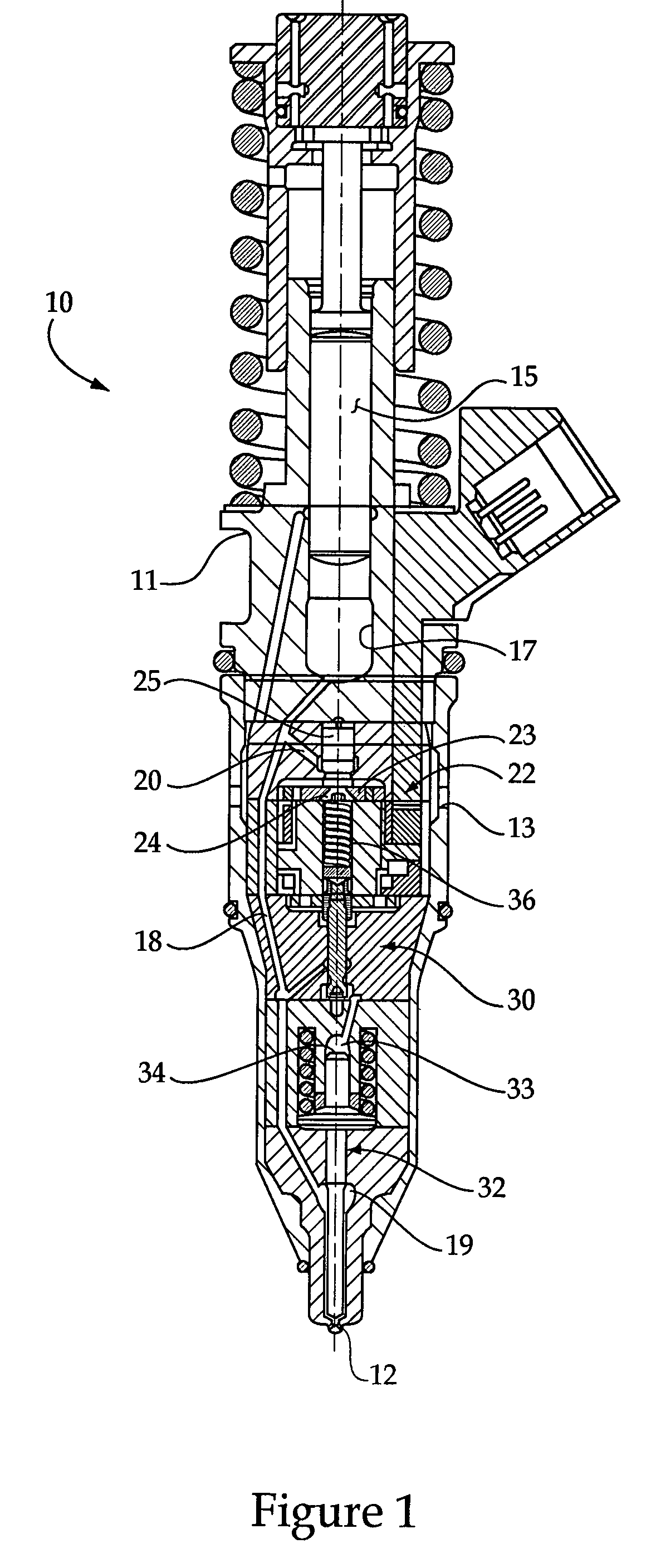

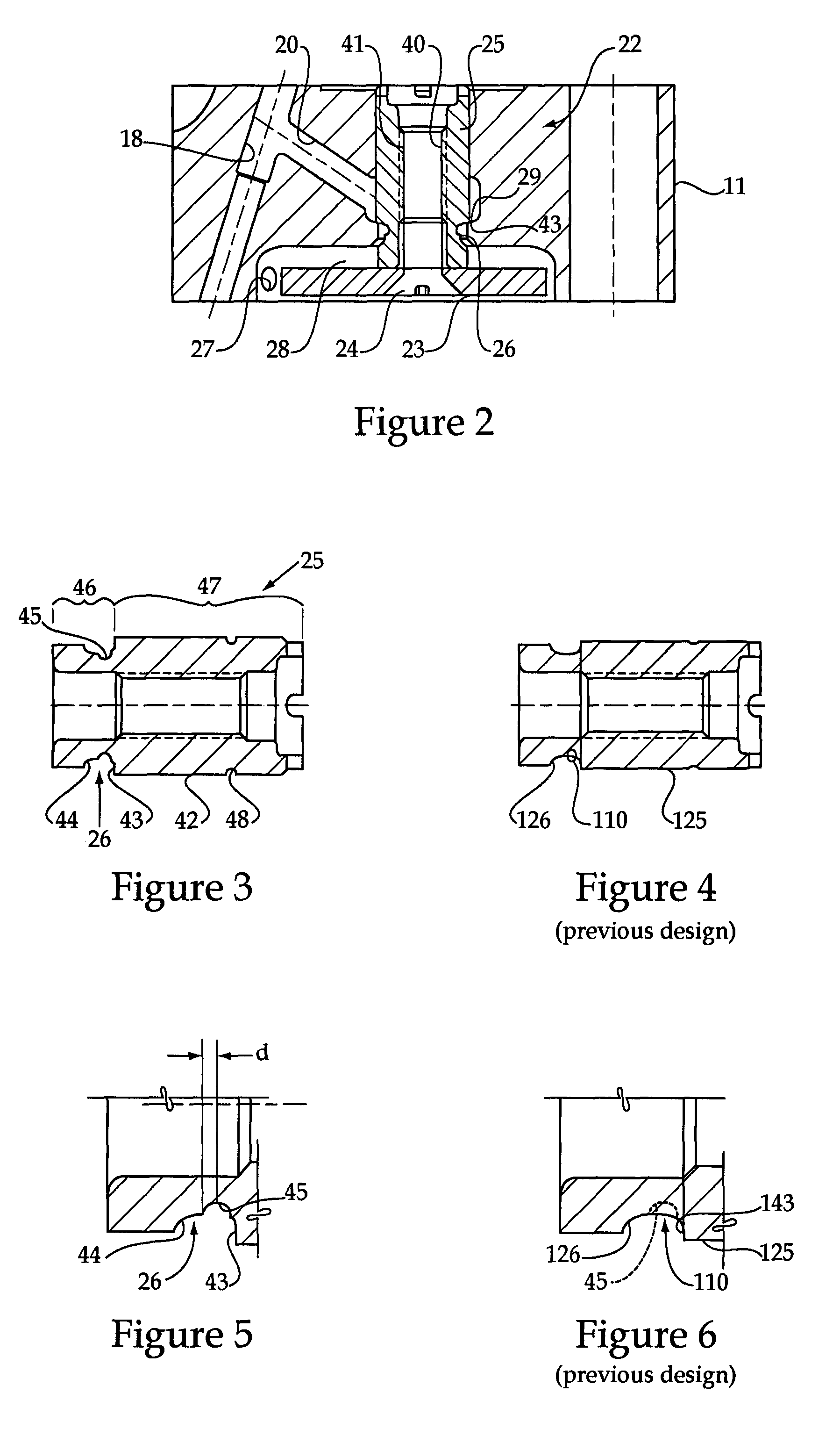

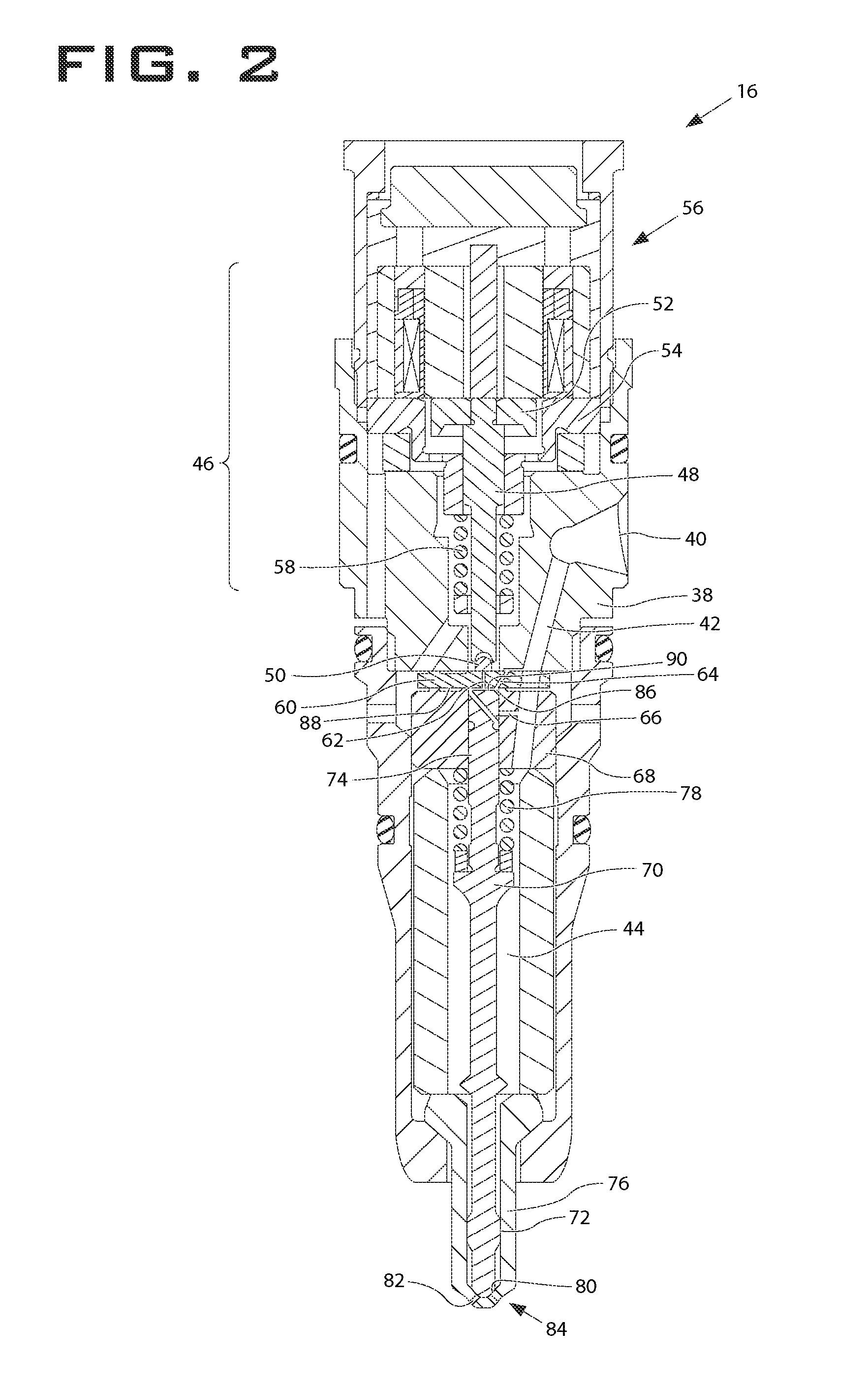

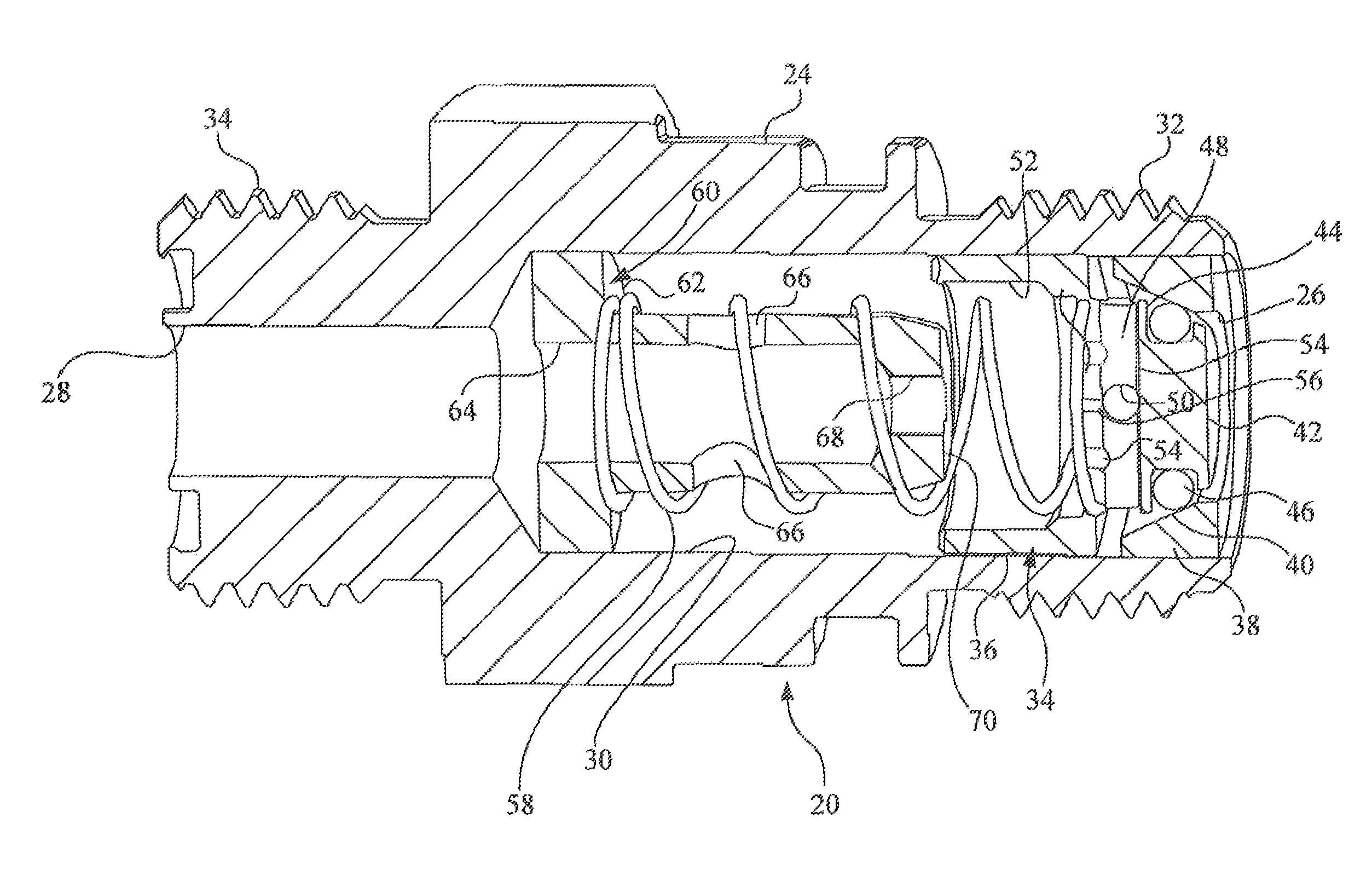

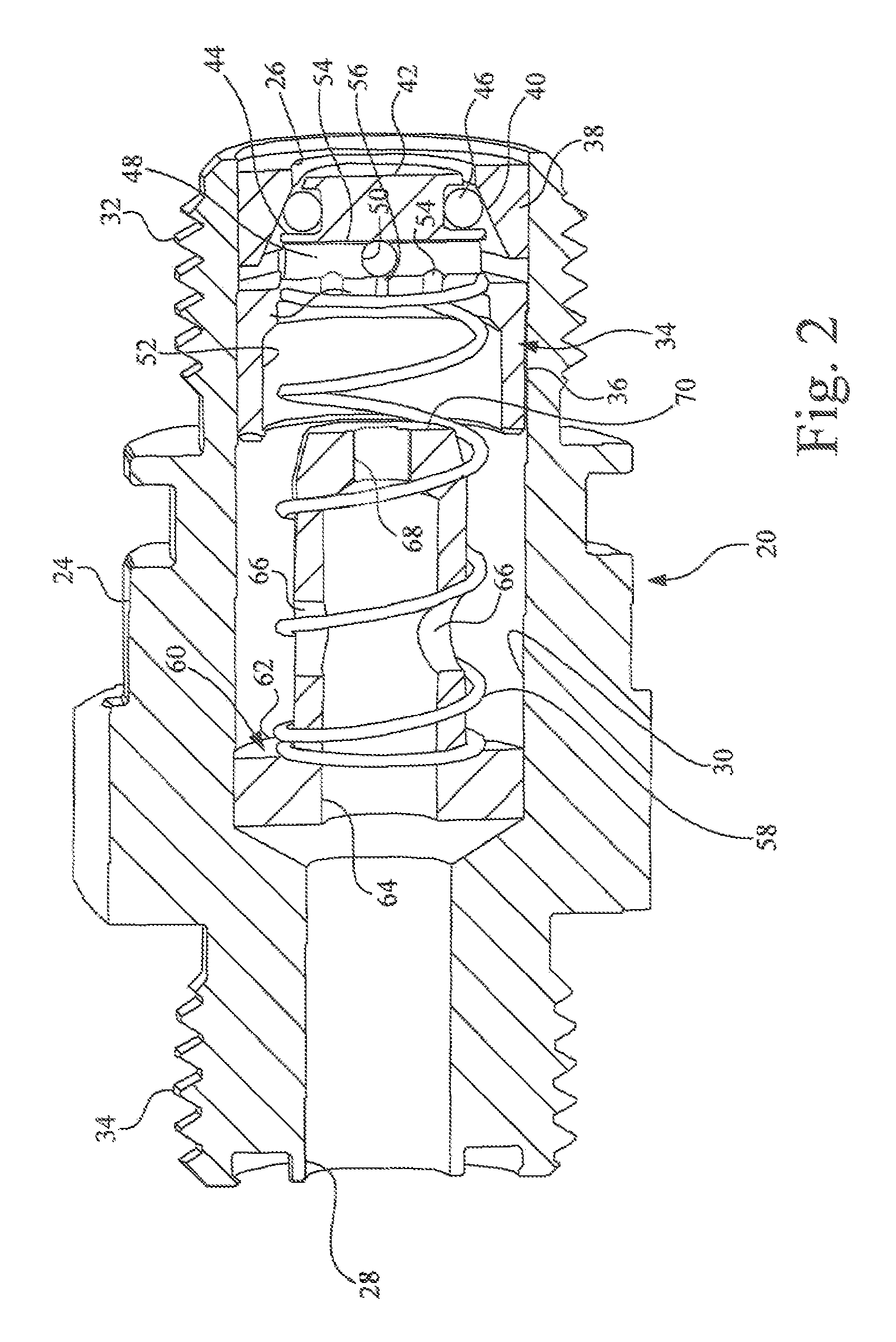

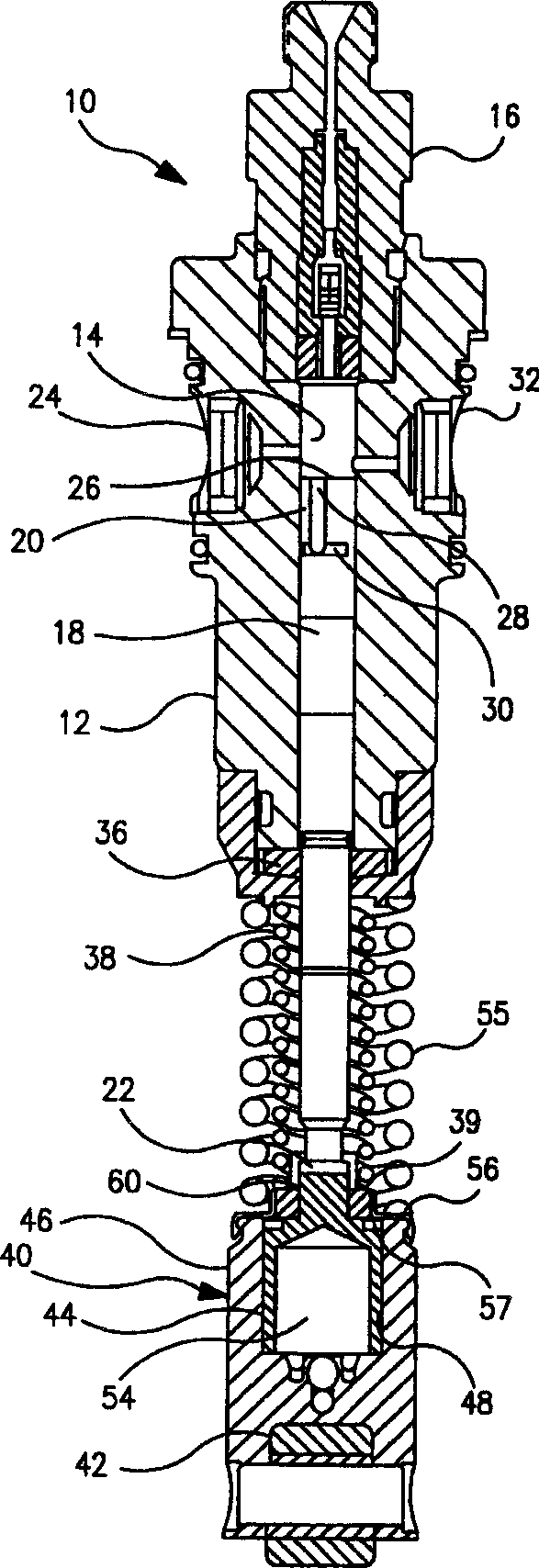

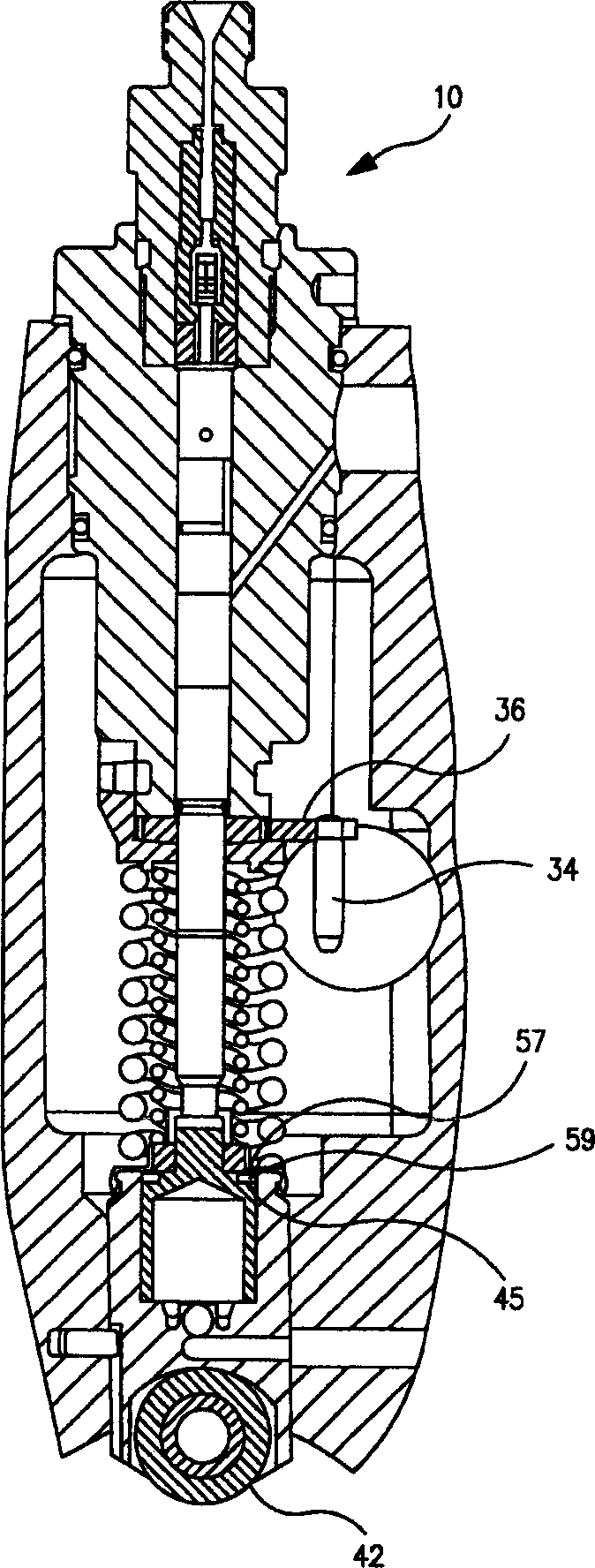

Unit injector with stabilized pilot injection

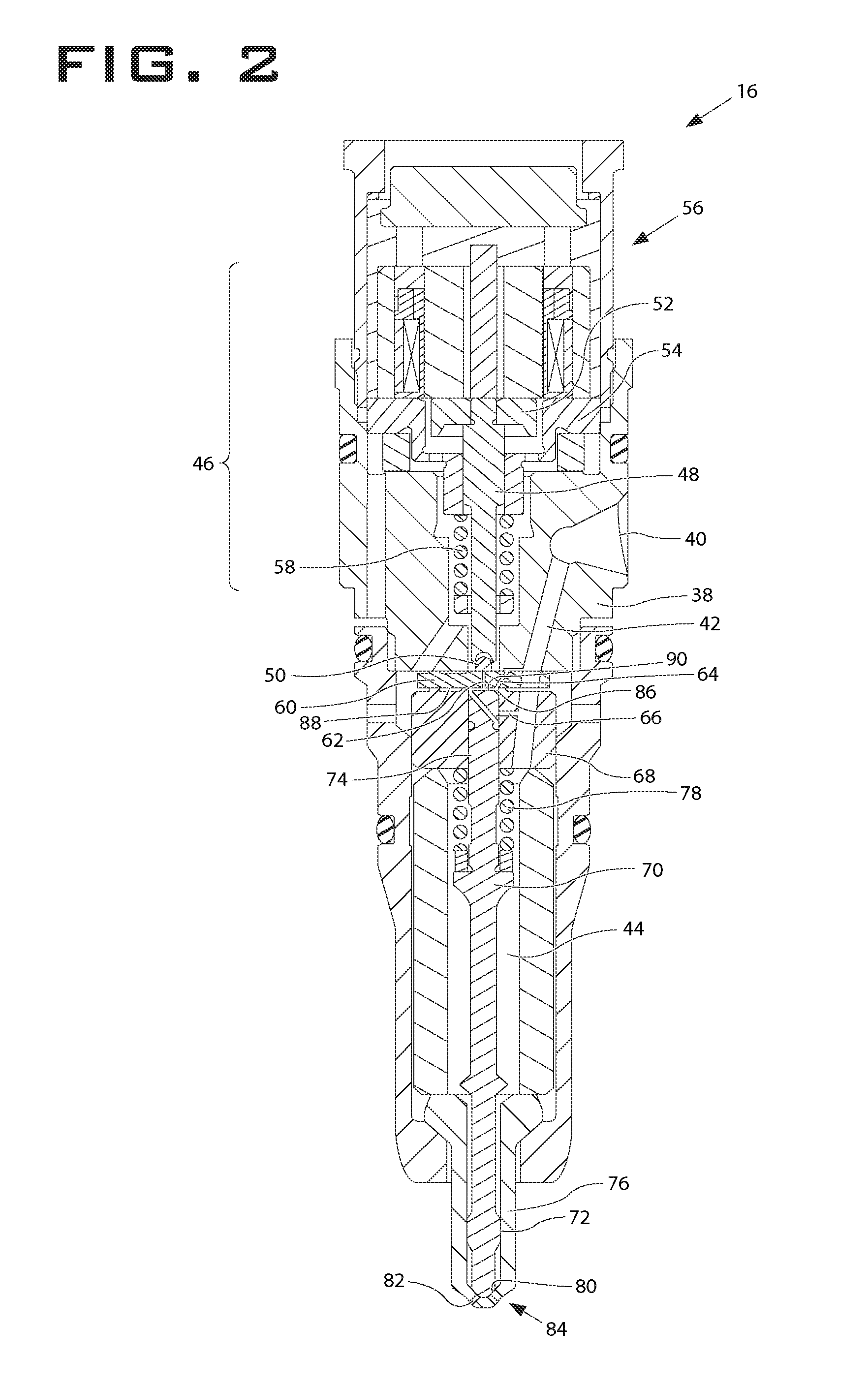

A unit injector assembly is provided that helps to ensure maximum injection flow while minimizing the harmful affects of pressure waves within the unit injector assembly. The unit injector assembly has a first fuel passageway extending from the plunger piston pumping chamber to the tip check stem injection chamber and valve seat. The unit injector assembly has a second fuel passageway extending from the tip check stem injection chamber to a fuel control valve assembly. A flow restricting fuel passageway connects one of the pumping chamber and the first fuel passageway with the second fuel passageway and acts to minimize cavitation at the valve seat and effectively eliminates pressure waves within the unit injector assembly.

Owner:CATERPILLAR INC

Electronic control for a hydraulically activated, electronically controlled injector fuel system and method for operating same

An apparatus and method for varying the current levels of a fuel injection signal used in connection with an electronically controlled hydraulic actuator unit injector fuel system is disclosed. The apparatus and method varies the current level of the fuel injection signal delivered to the unit injector based on sensed engine parameters, which preferably include a sensed pressure of hydraulic actuating fluid and a sensed temperature of the engine.

Owner:CATERPILLAR INC

Method of controlling injection pressure level in unit injectors

InactiveUS20150369160A1Easy to returnLimit pressure levelElectrical controlFuel-injection pumpsInjection pressureUnit injector

A method to control an injection pressure level of fuel within a unit injector is provided. The method includes provision of a second spill valve in the unit injector, which is connected in parallel to a first spill valve. The fuel is delivered to the unit injector with the first spill valve maintained in a passive state. This facilitates return of the first portion of the fuel to the low-pressure fuel manifold. The first spill valve is actuated to an active state to block the flow of fuel to the low-pressure fuel manifold, to maintain the unit injector at the injection pressure level. The second spill valve is actuated concurrently or prior to the actuation of the first spill valve. This facilitates return of a second portion of the fuel to the low-pressure fuel manifold. This is done to limit the injection pressure level within the unit injector.

Owner:CATERPILLAR INC

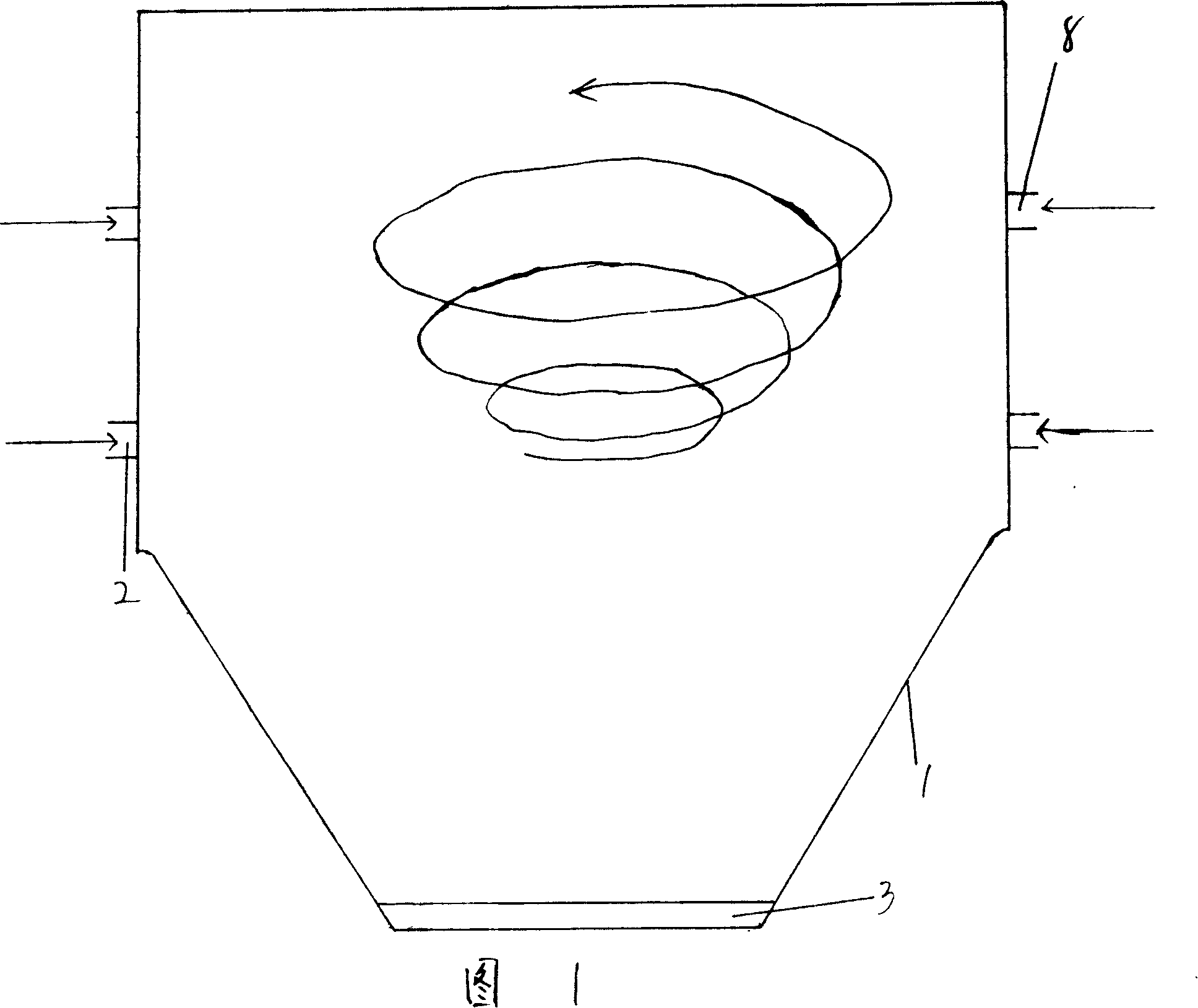

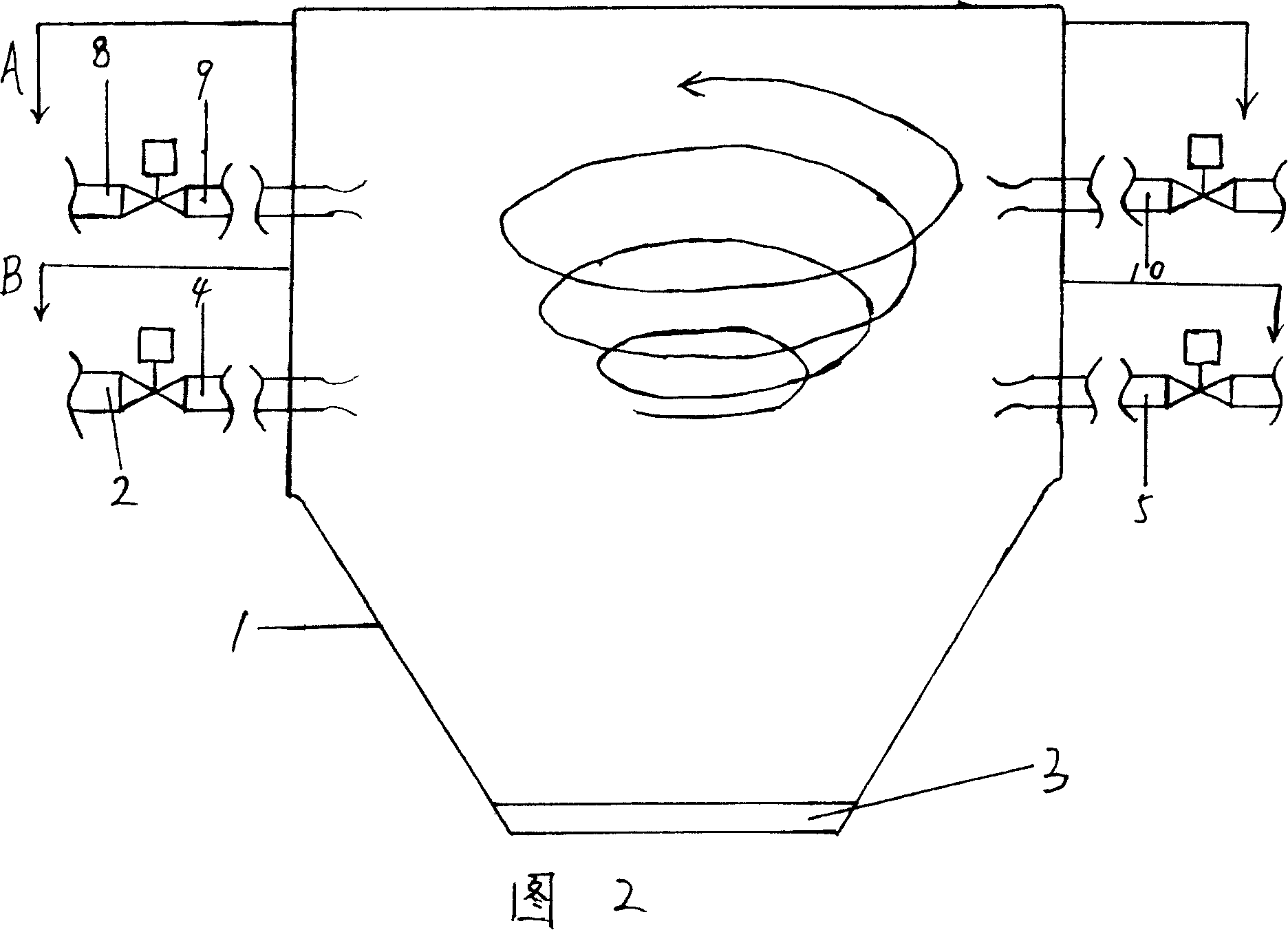

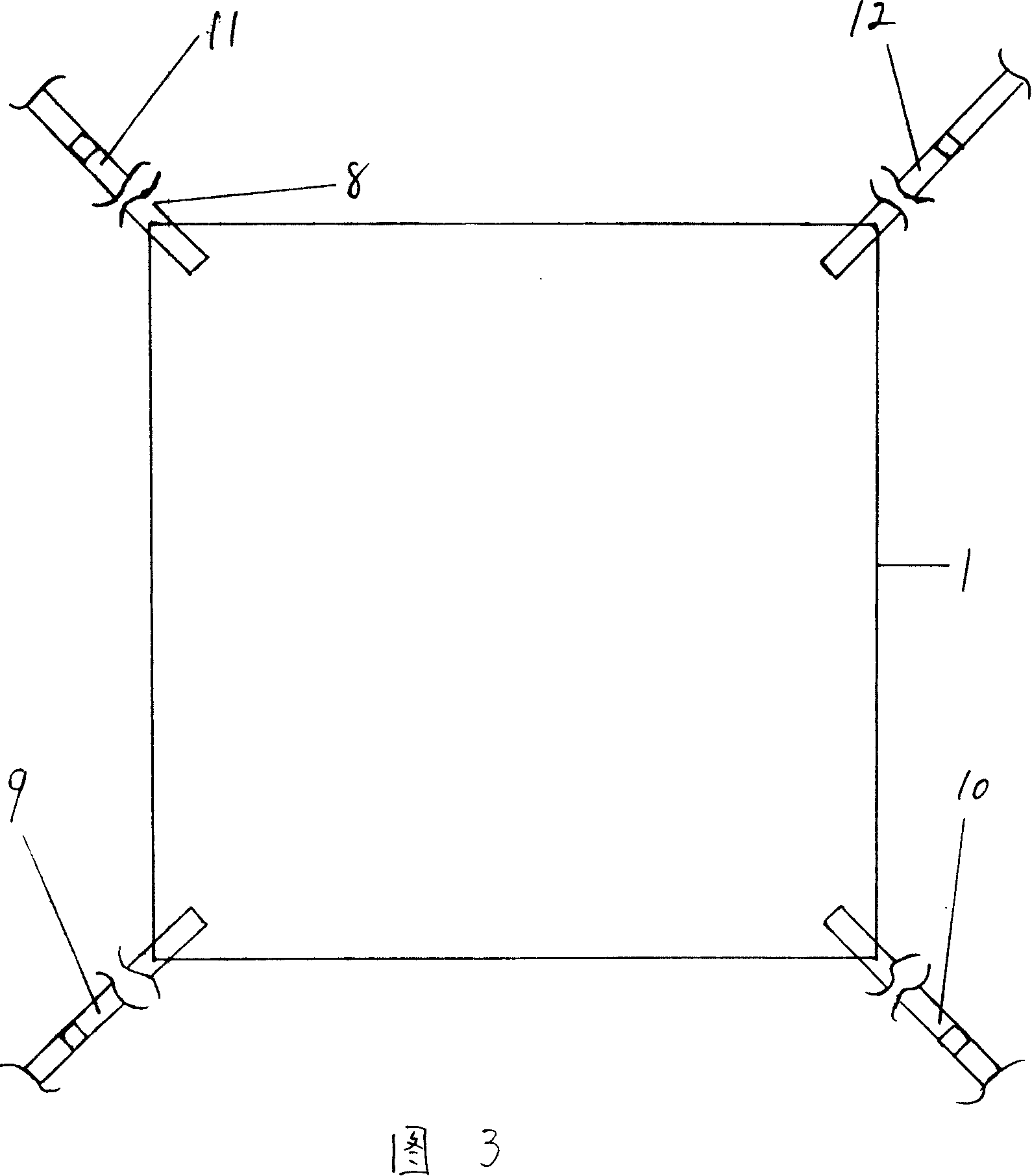

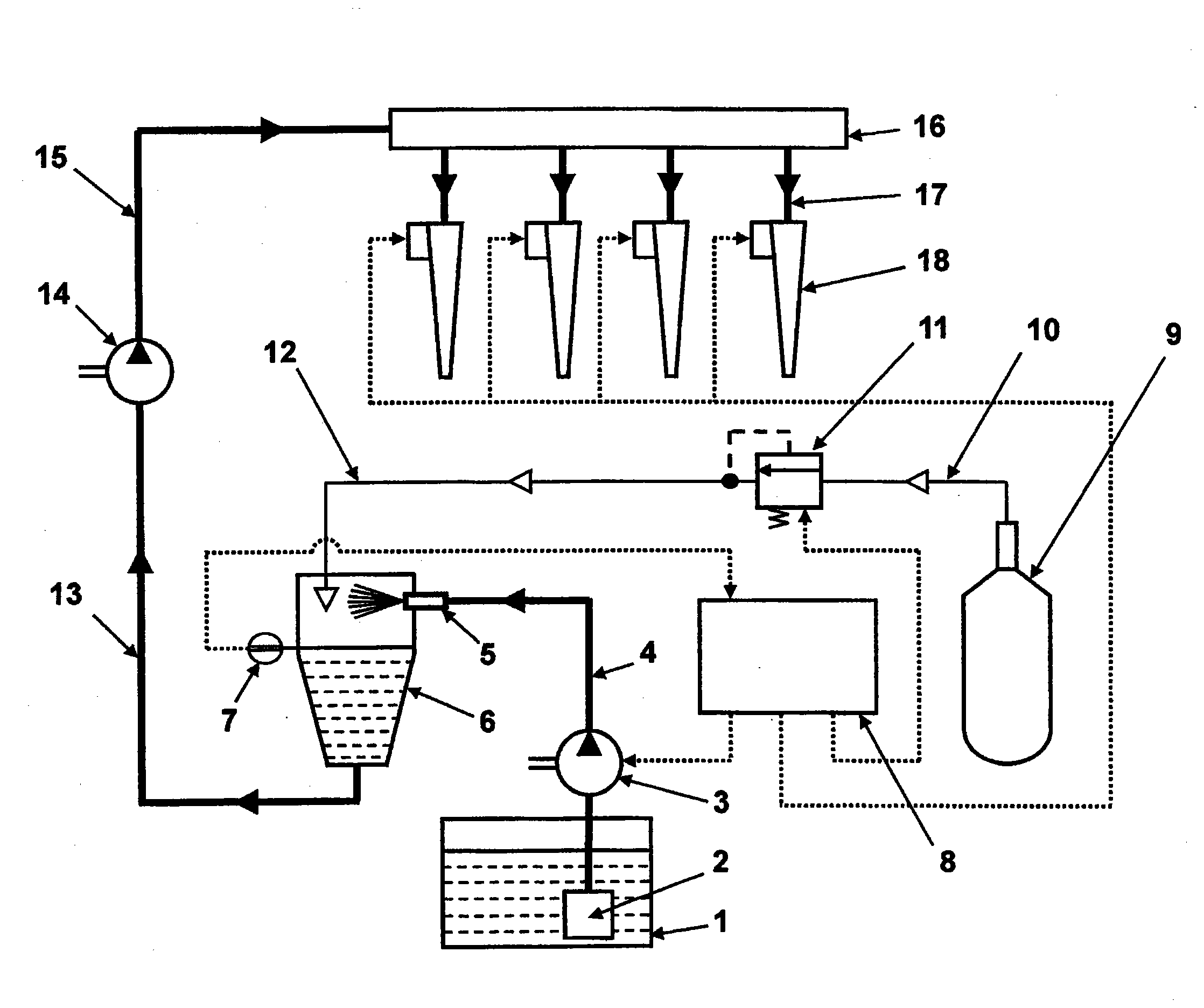

Circulated fluid bed boiler and tangential firing method

InactiveCN101086335AExtended stayImprove oxygenation uniformityFluidized bed combustionNon-combustible gases/liquids supplyCombustionFluidized bed

The invention involves a circulating fluidized bed boiler and its circle of contact burning method, the boiler consists essentially of boiler body and wind-forming plate, the wind-forming plate is installed below the boiler body, its structural characteristics are: two or more sets of injector device are installed below the dense phase area of boiler body, each set of injector device consists of four injectors which are both installed on the four corners of boiler body horizontal section separately, the injectors of bottom injector device are installed horizontally, and the injector device in other layers inclined toward down 5: . In the same horizontal surface, the central line of one unit injectors installed on four corners forms a circle of contact in the furnace tank, and the secondary wind or steam ejected out each injector device form a circle of contact air flow. The invention has the advantages of reasonable structural design, adequate fuel combustion, coal-saving, efficient, effective oxygen supplementary capacity improving through second wind energy, higher filling degree of furnace tank and full fuel combustion.

Owner:HANGZHOU HUADIAN ENERGY ENG +1

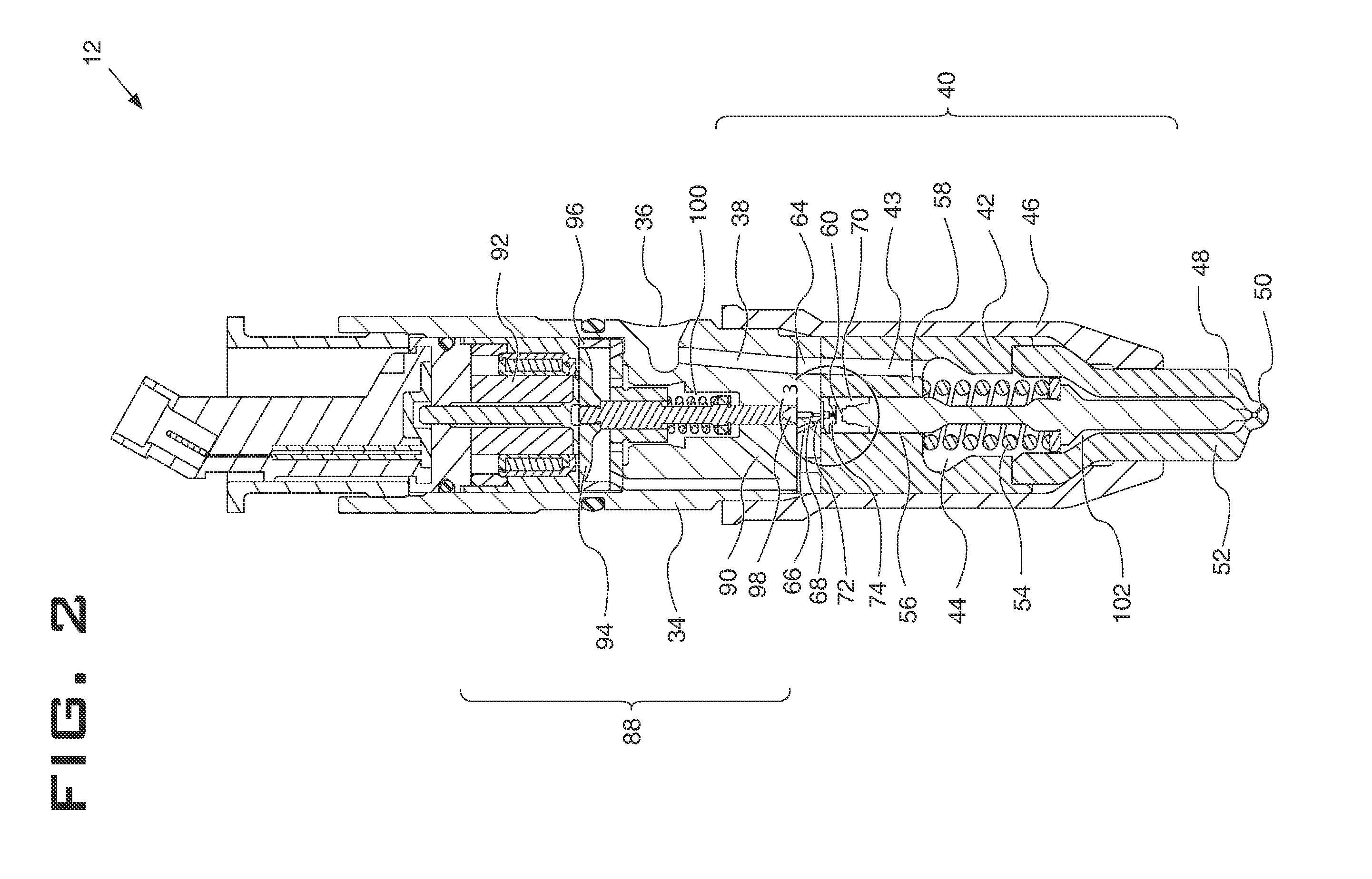

Fluid injector with back end rate shaping capability

ActiveUS20110253105A1Preventing fluid communicationControl speedFuel-injection pumpsSpray nozzlesCommon railRate shaping

A common rail single fluid injection system includes fuel injectors ramp shaped injection curves at both the front and back ends of an injection event. This is accomplished by including a check speed control device fixed in position within the check control chamber of a fuel injector. The check speed control device controls the speed of a check by restricting fuel flowing into and out of the check control chamber.

Owner:CATERPILLAR INC

High speed gasoline unit fuel injector

A gasoline unit injector includes a high speed, high force actuator such as a magnetrostrictive or piezoelectric actuator. The actuator operates a positive displacement diaphragm pump. The pumping volume is isolated from a supply rail by an inlet check valve, and is isolated from the engine manifold by an outlet check valve. Each of the check valves includes a disk having a central anchor and a peripheral valve seat. Diaphragm movement reduces pump volume and thereby displaces fuel at high pressure through outlet valve. Fuel spray is formed by geometry of outlet valve, the frequency of actuation, and mass and pressure of the displaced fuel. Relaxation of actuator, and therefore diaphragm, increases pump volume and thereby draws fuel into pump volume through the check valve.

Owner:VITESCO TECH USA LLC

Cavitation erosion reduction strategy for valve member and fuel injector utilizing same

A mechanically actuated electronically controlled unit injector includes an electronically controlled spill valve to precisely control timing of fuel pressurization within a fuel pressurization chamber. Cavitation bubbles may be generated in the region of the valve seat when the spill valve member is closed to raise fuel pressure in the fuel injector. This cavitation can cause erosion on the spill valve member and the surrounding injector body. In order to preempt cavitation damage, the valve member may be modified to include a compound annulus that includes a small annulus that corresponds to an identified cavitation damage pattern. Although the generation of cavitation bubbles may continue after such a strategy, cavitation erosion, and the associated liberation of metallic particles into the fuel system can be reduced, and maybe eliminated, by the preemptive cavitation reduction strategy.

Owner:CATERPILLAR INC

Fluid injector with auxiliary filling orifice

A common rail single fluid injection system including fuel injectors with the ability to produce multiple injection rate shapes. This is accomplished by including auxiliary filling orifices which selectively provide pressurized fluid to the check needle control chamber during injection events. In so doing, the speed and movement of the check needle is manipulated and differing injection rates may be achieved.

Owner:CATERPILLAR INC

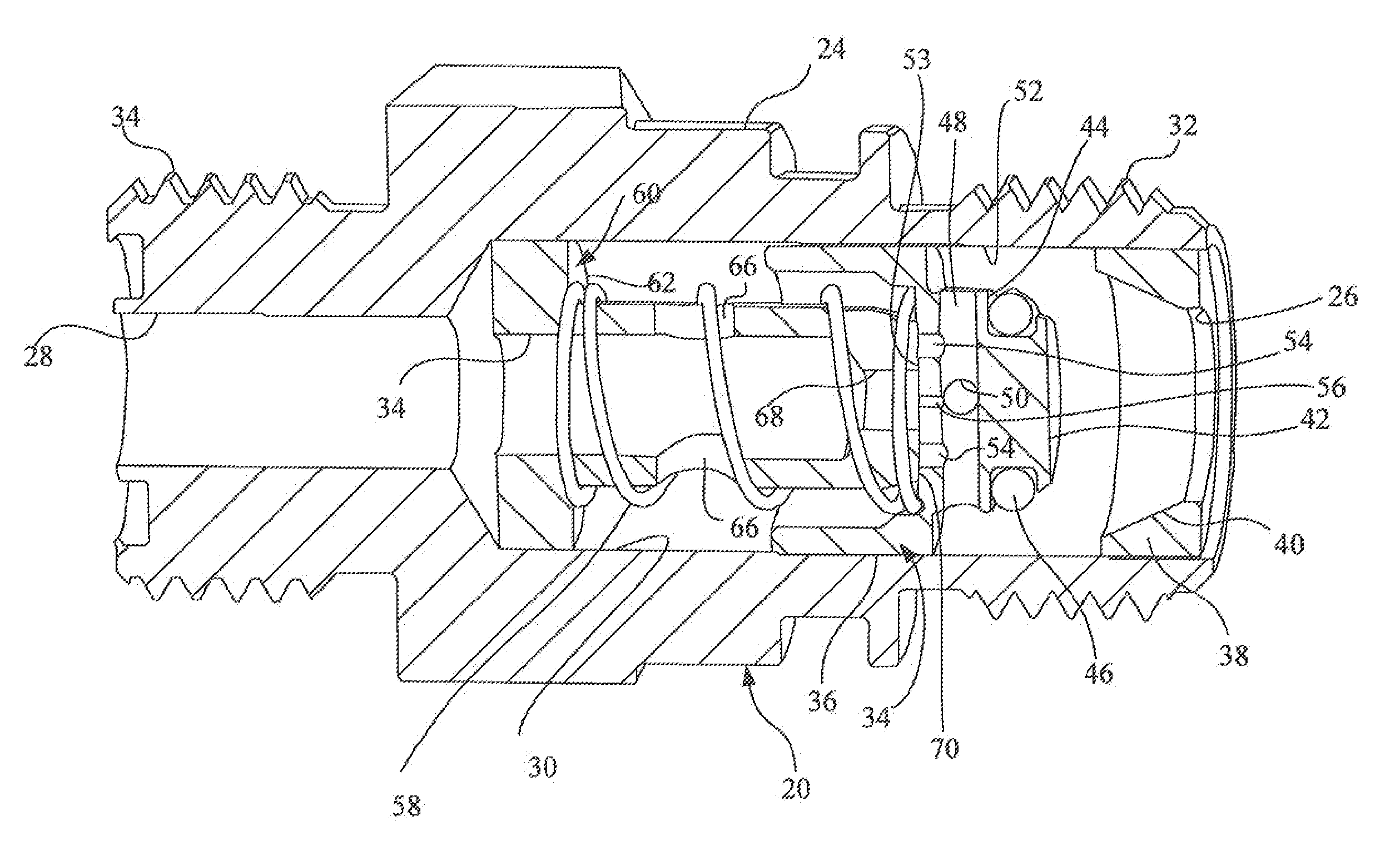

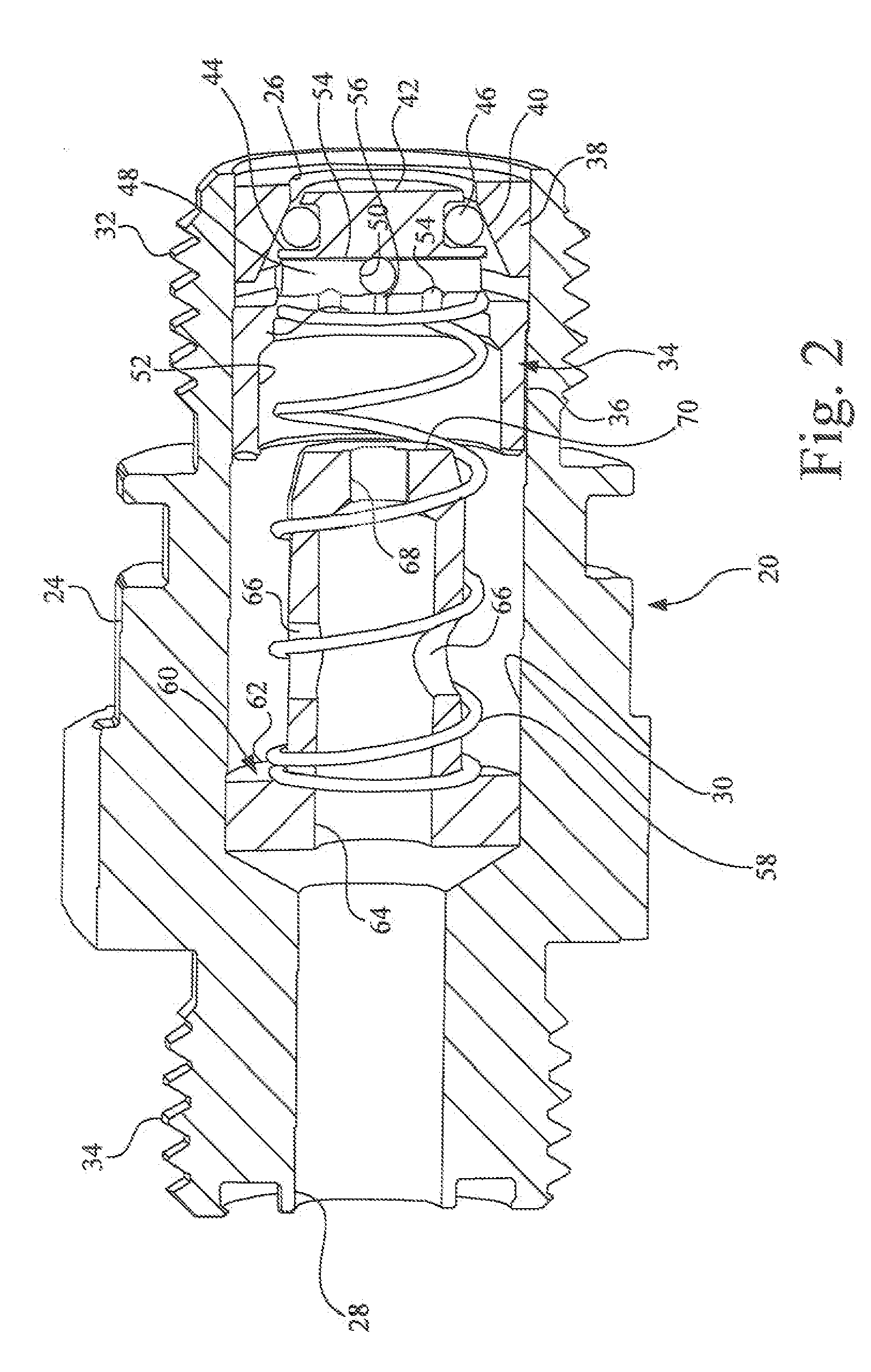

Internal combustion engine flow regulating valve

A flow regulating valve for a diesel engine in which a unitary valve element has three positions for controlling flow from a unit injector fuel injection system in response to valve inlet pressure. The valve has a first position wherein flow is blocked below about 10 psi, a second position between about 10 psi and 20 psi wherein flow is substantially unrestricted, and a third position above about 20 psi wherein flow is restricted to minimize return flow to a fuel supply and minimize fuel cooling requirements.

Owner:DEERE & CO

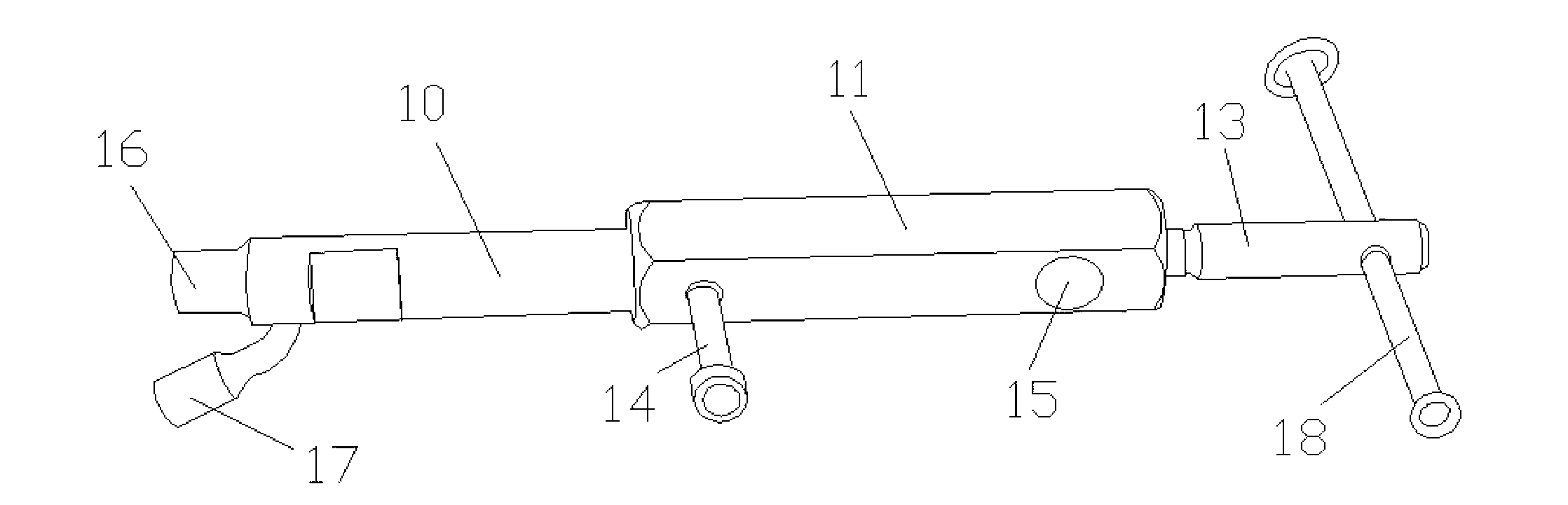

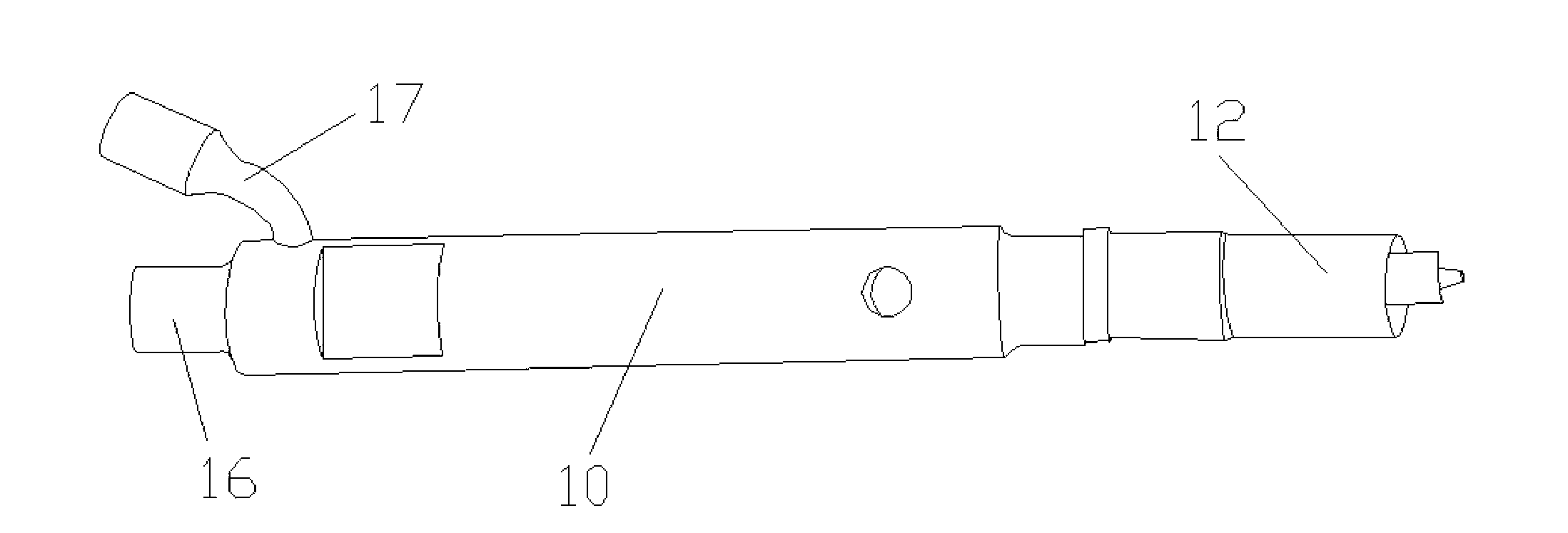

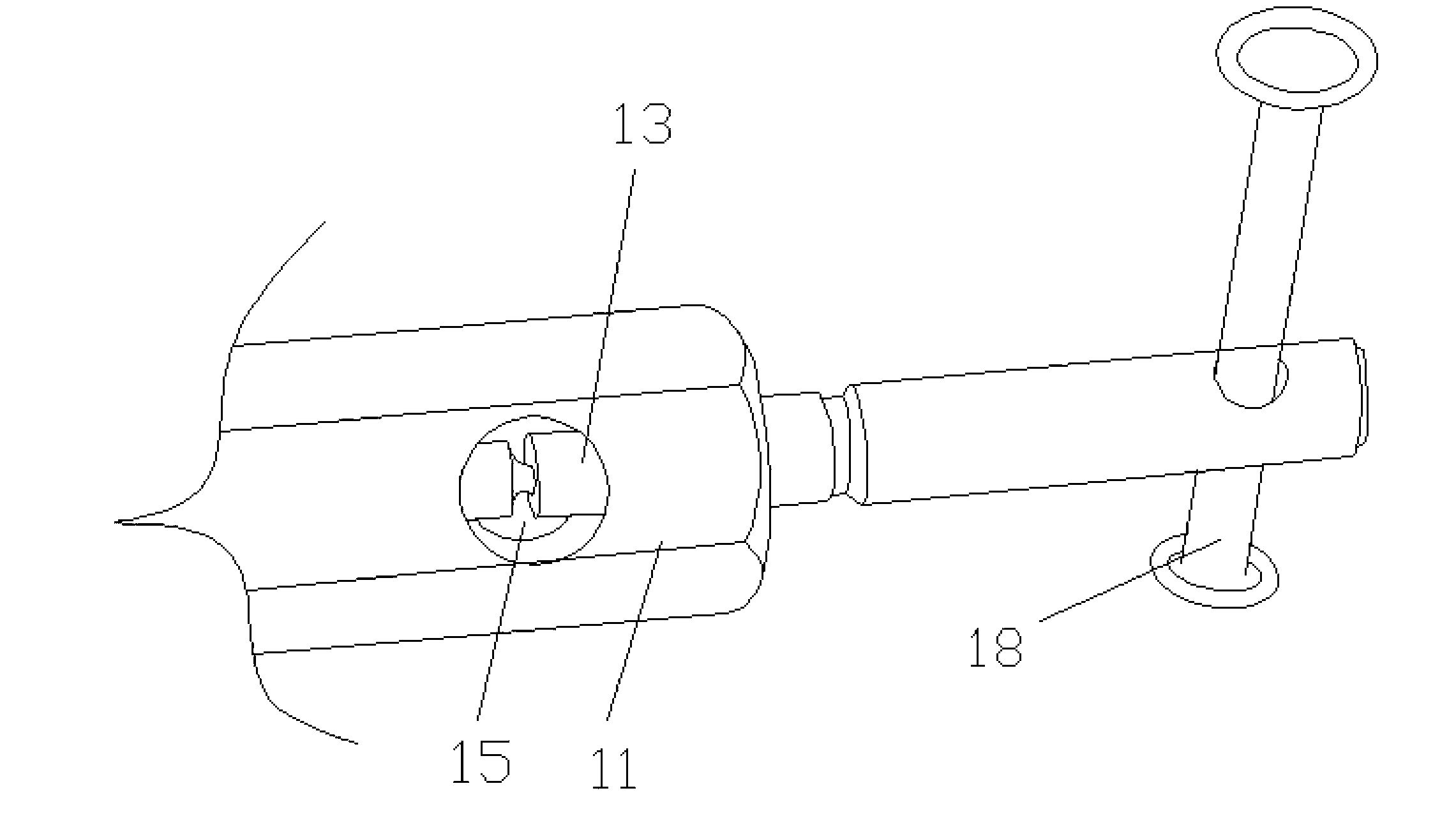

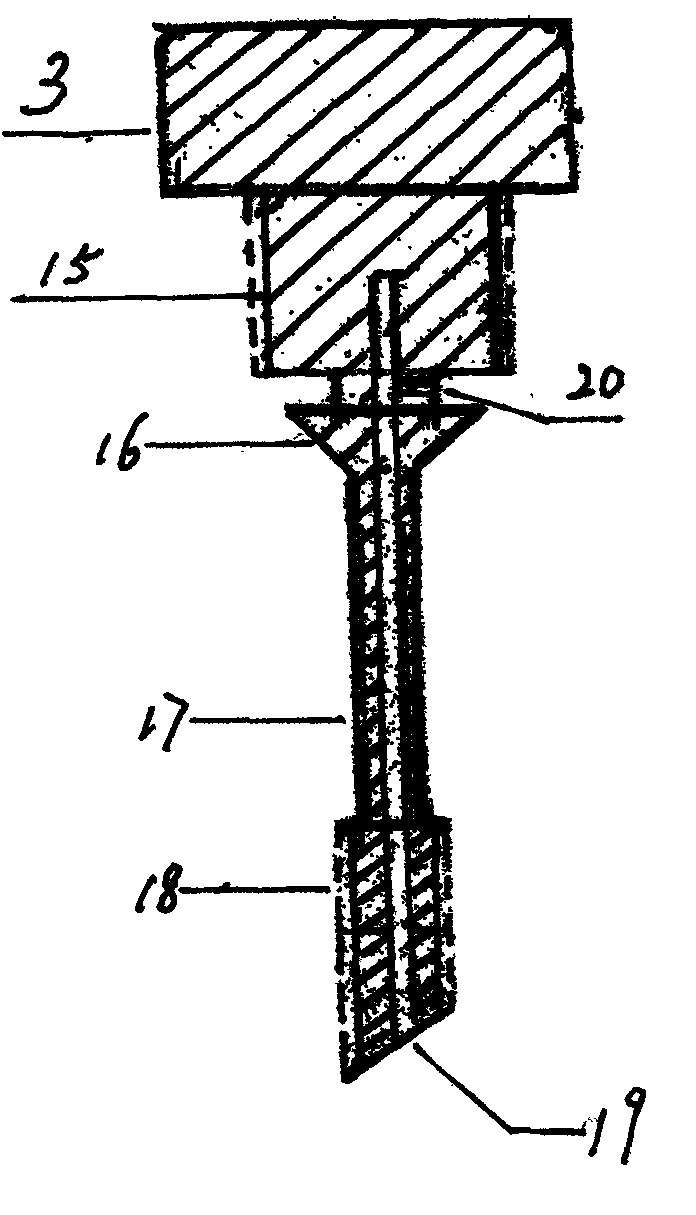

Withdrawal tool of oil injector needle valve

InactiveCN103016229ACause damageEasy to operateFuel injection apparatusMachines/enginesCouplingEngineering

The invention belongs to the technical field of withdrawal tools, and particularly relates to a withdrawal tool of an oil injector needle valve, which comprises an oil injector without a nozzle, and a shaft sleeve, wherein one end of the shaft sleeve is connected with the head part of the oil injector without the nozzle, the other end of the shaft sleeve is screwed with a fixed pin, a fixed sleeve inside which a nozzle can be arranged is screwed on the end part of an outlet of the oil injector without the nozzle in the shaft sleeve, and a threaded coupling and an oil return joint are arranged on the tail part of the oil injector without the nozzle. According to the invention, the needle valve can be completely withdrawn without any physical knocking in the whole withdrawal process, and the nozzle can not be damaged. Meanwhile, the withdrawal tool has the advantages of simpleness in operation, convenience for use, greatly increased working efficiency and low manufacture cost.

Owner:天台县唐宋汽车修配厂

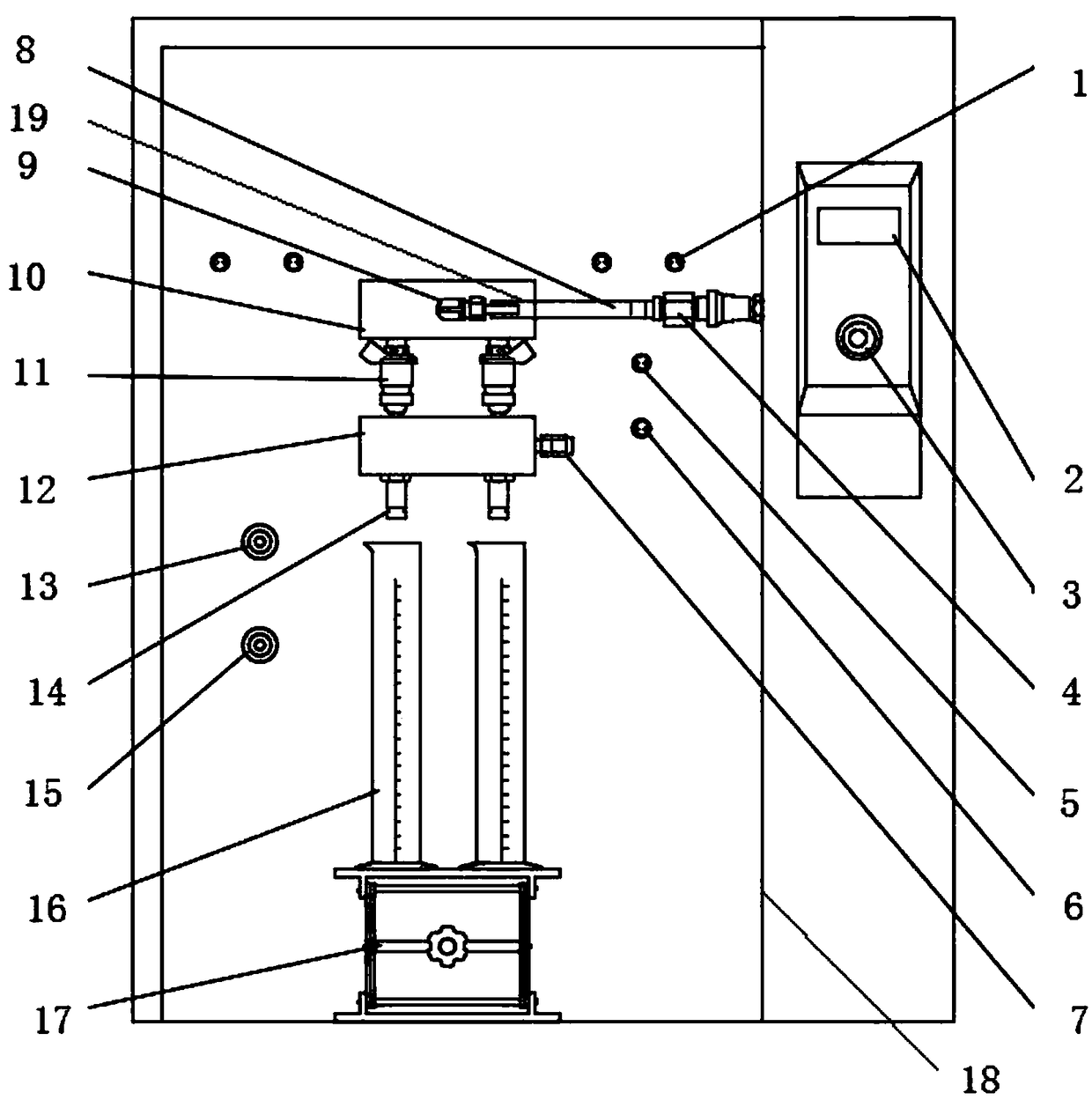

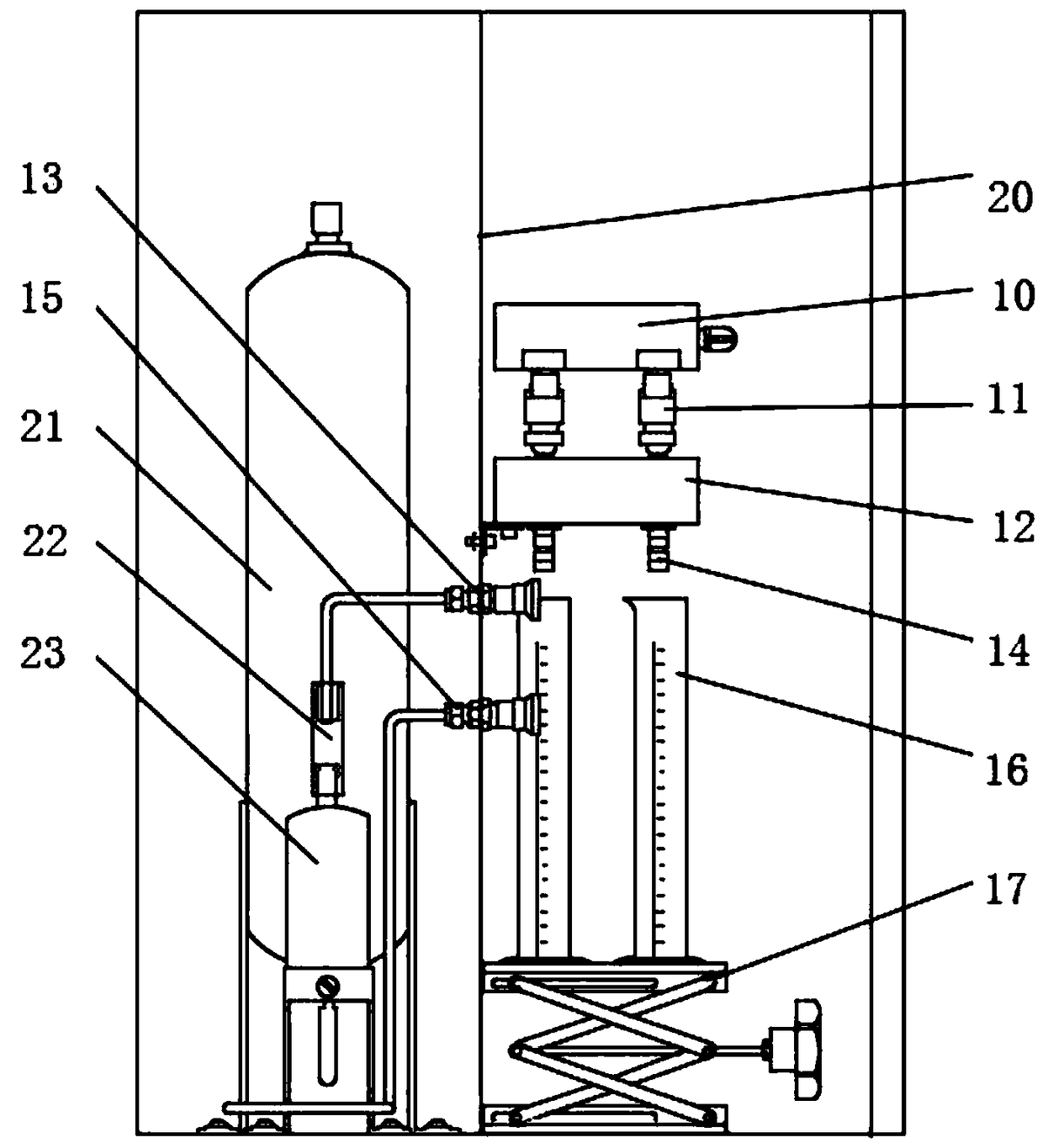

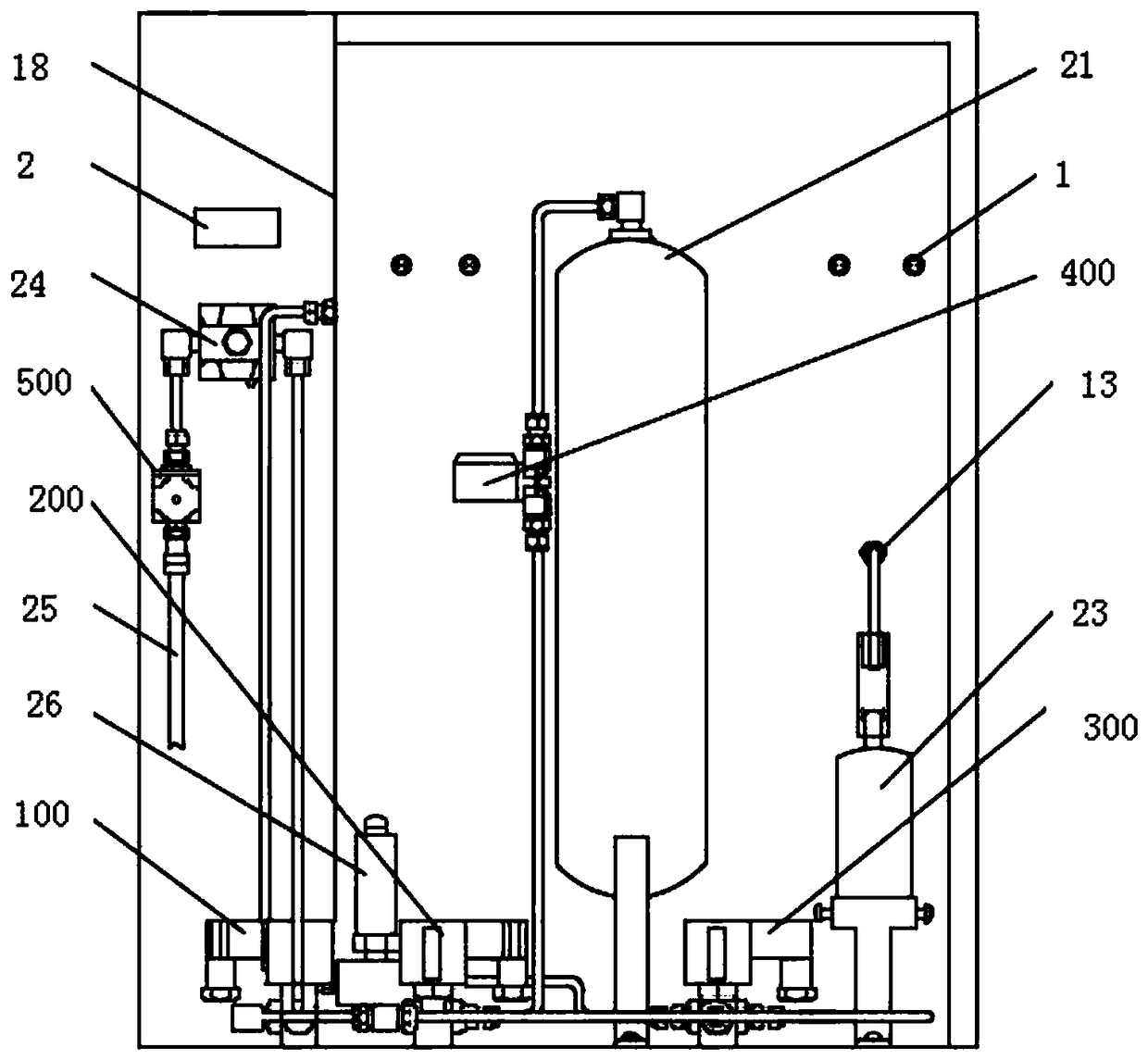

Main machine structure of simulation test machine for evaluating blockage ratio of electronically-controlled oil injector of gasoline engine

ActiveCN108708811AEasy to operateAccurate operationEngine testingFuel injection apparatusGasolineUnit injector

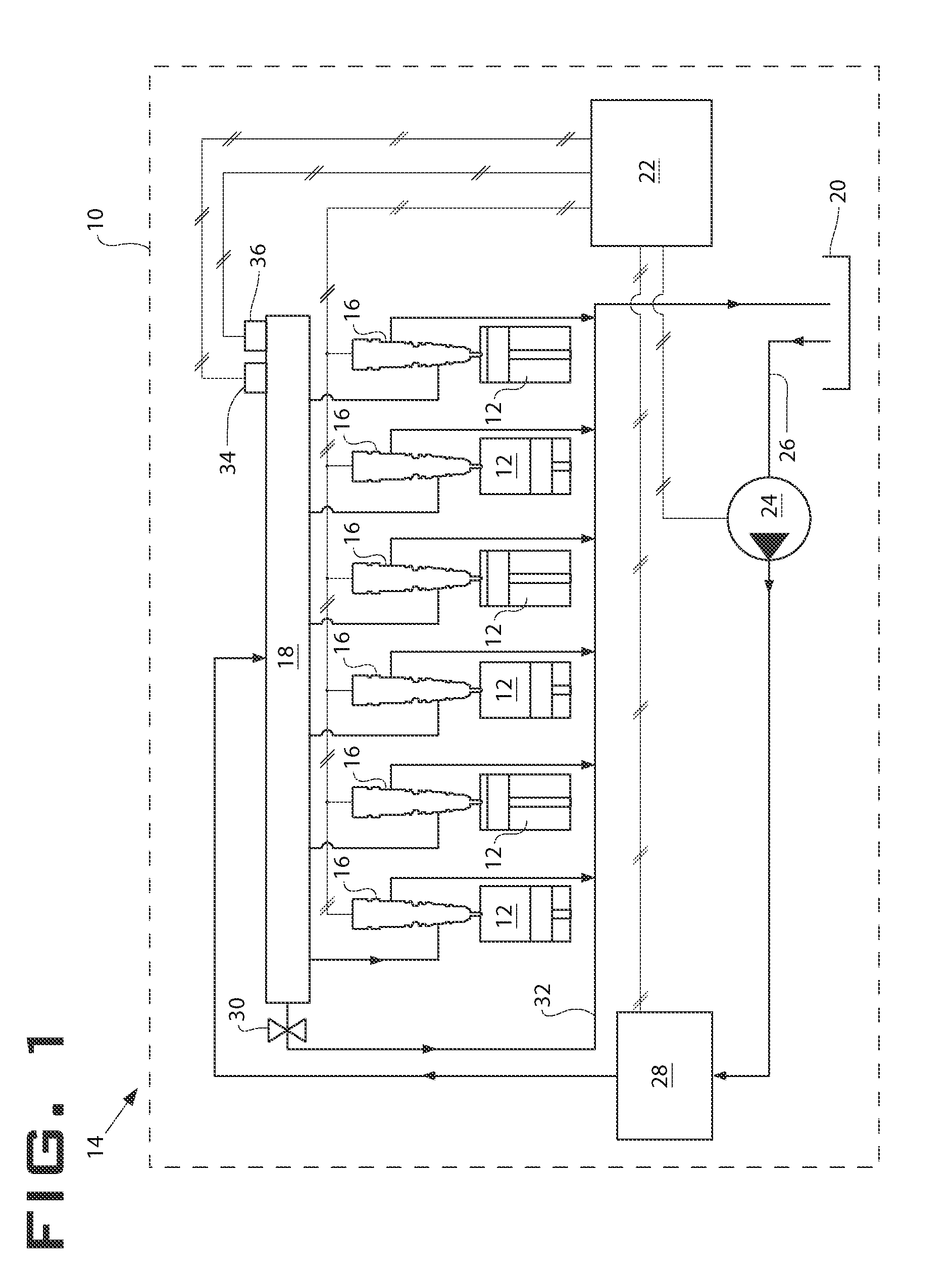

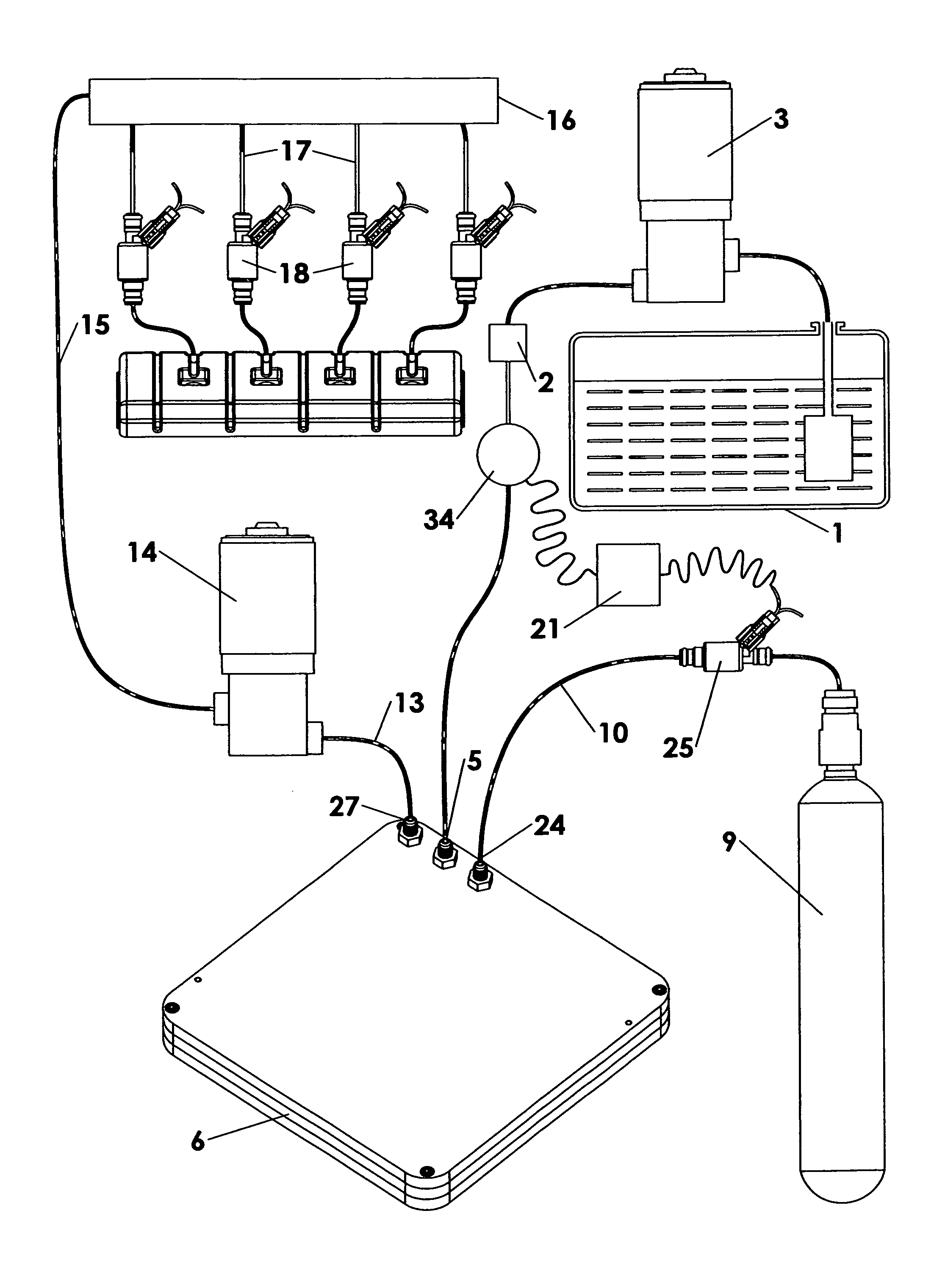

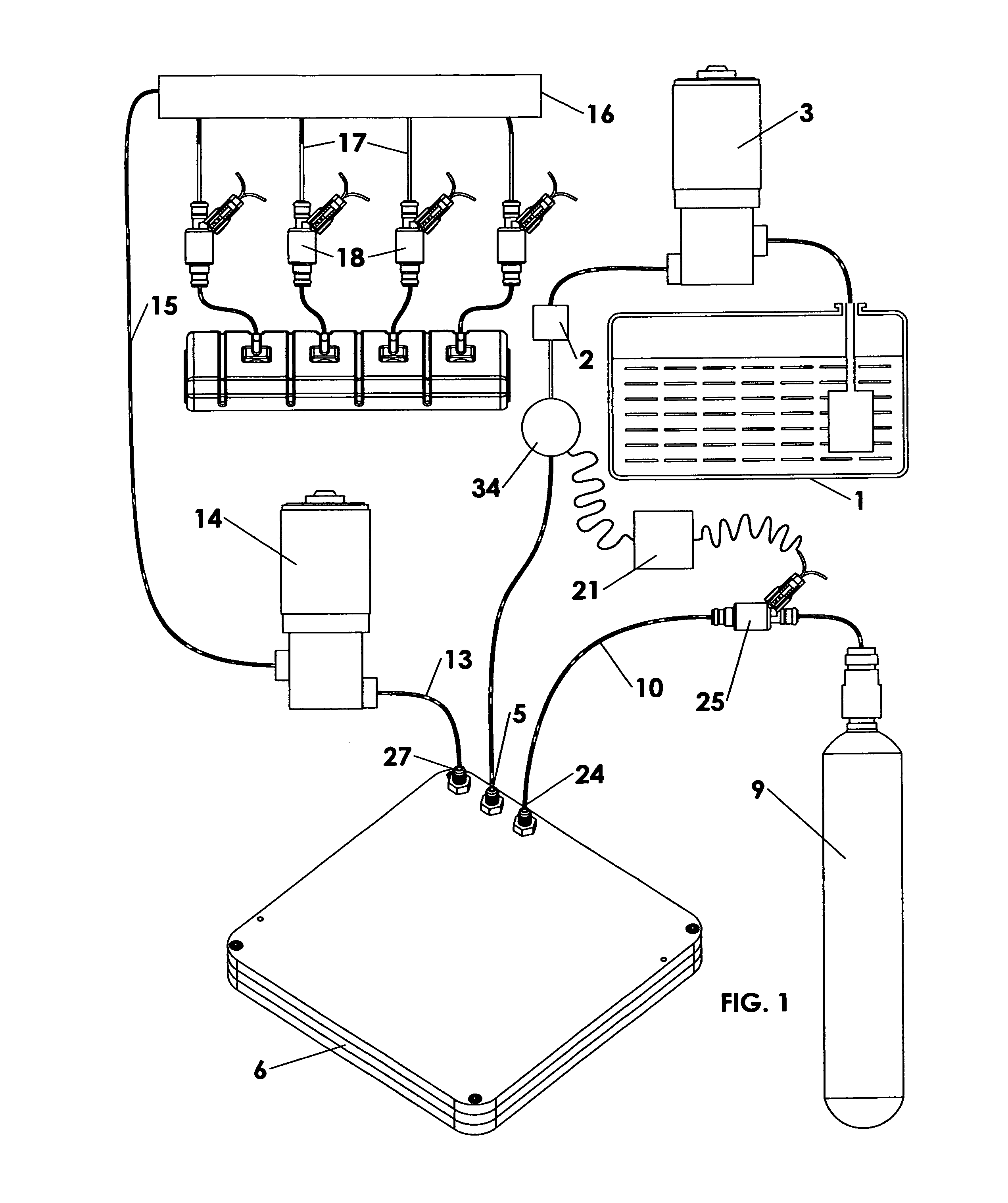

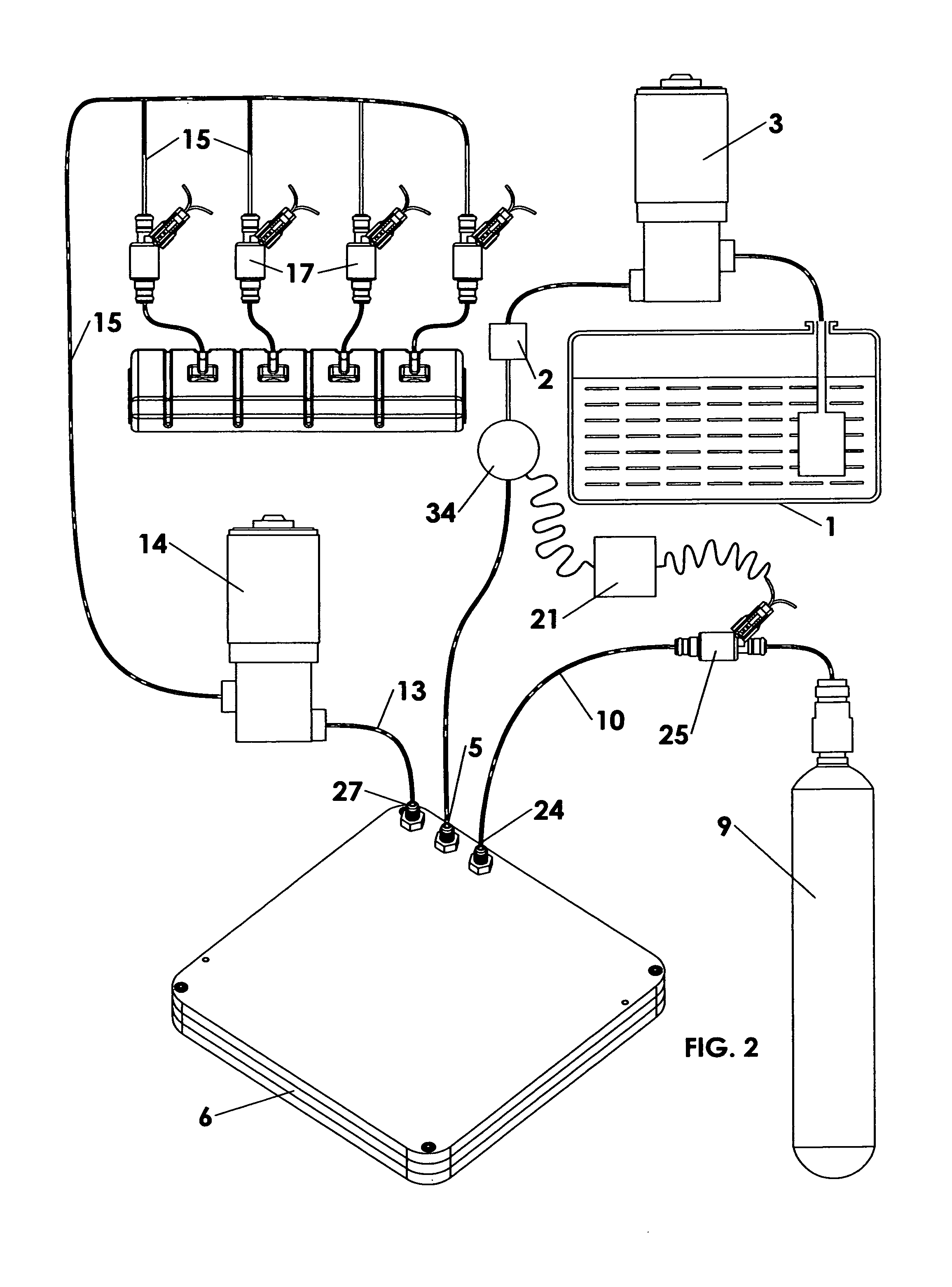

The invention discloses a main machine structure of a simulation test machine for evaluating the blocking ratio of the electronically-controlled oil injector of a gasoline engine. A simulation test device is used for detecting at least one electronically-controlled oil injector and comprises a nitrogen pressure regulating device, a fuel oil storage device, a fuel oil distributor, a heating deviceand a measuring device, wherein the fuel oil storage device is connected with the nitrogen pressure regulating device; the fuel oil distributor is communicated with the fuel oil storage device; the lower end surface of the fuel oil distributor is connected with the electronically-controlled oil injector; the heating device is used for heating a needle valve part of the electronically-controlled oil injector and measuring the temperature of the electronically-controlled oil injector; and the measuring device is arranged below the electronically-controlled oil injector and used for accommodatinga liquid injected from the electronically-controlled oil injector and measuring the amount of the liquid. Through the adoption of the simulation test device, the blockage tendency of the electronically-controlled oil injector can be judged by measuring the amount of the liquid flowing out from the electronically-controlled oil injector, thereby realizing long-time automatic detection on the electronically-controlled oil injector. The simulation test device can be filled with gasoline or a cleaning fluid, so that multiple functions are achieved.

Owner:BEIJING CHAOYANG GAOKE APPLIED TECH RES INST CO LTD

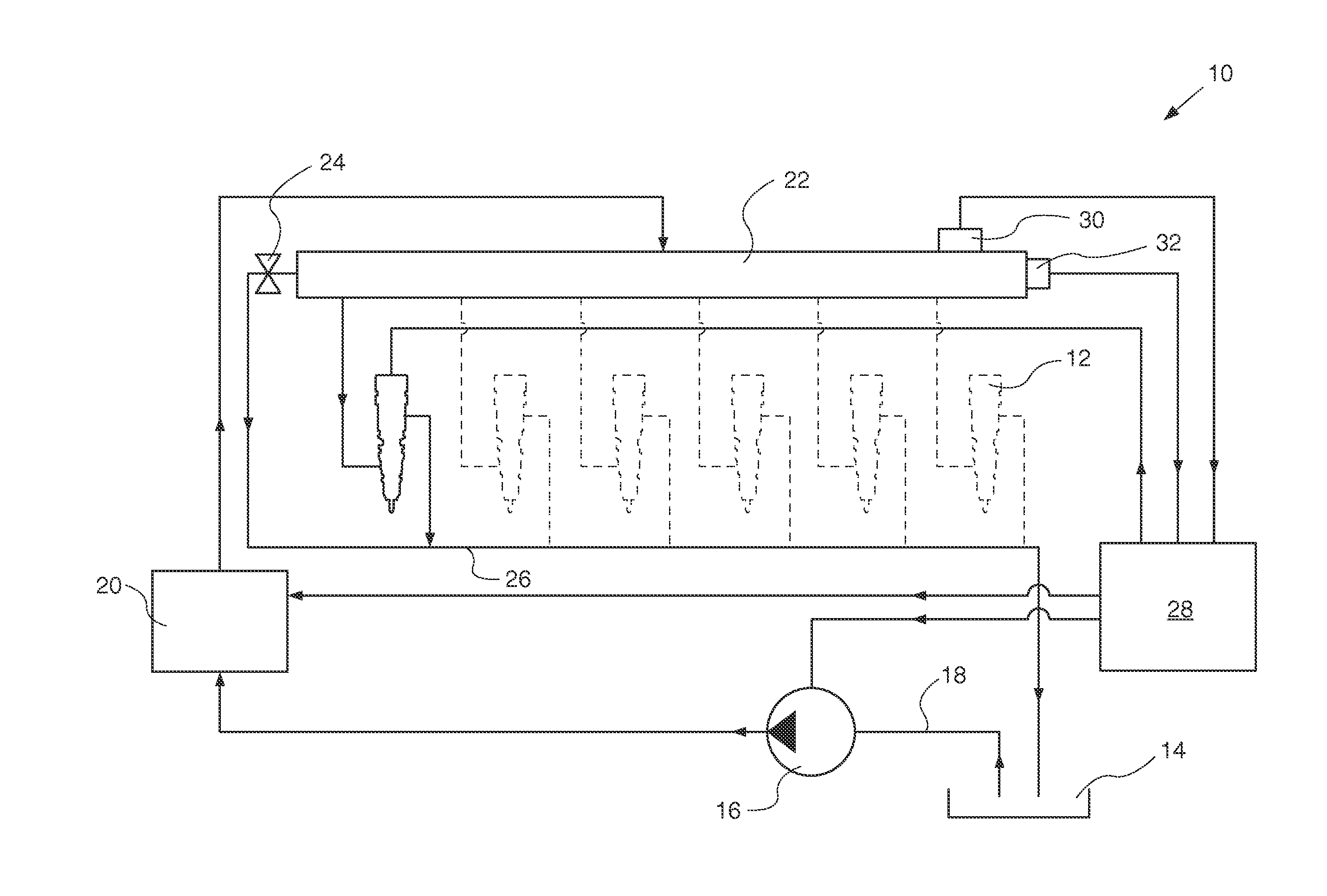

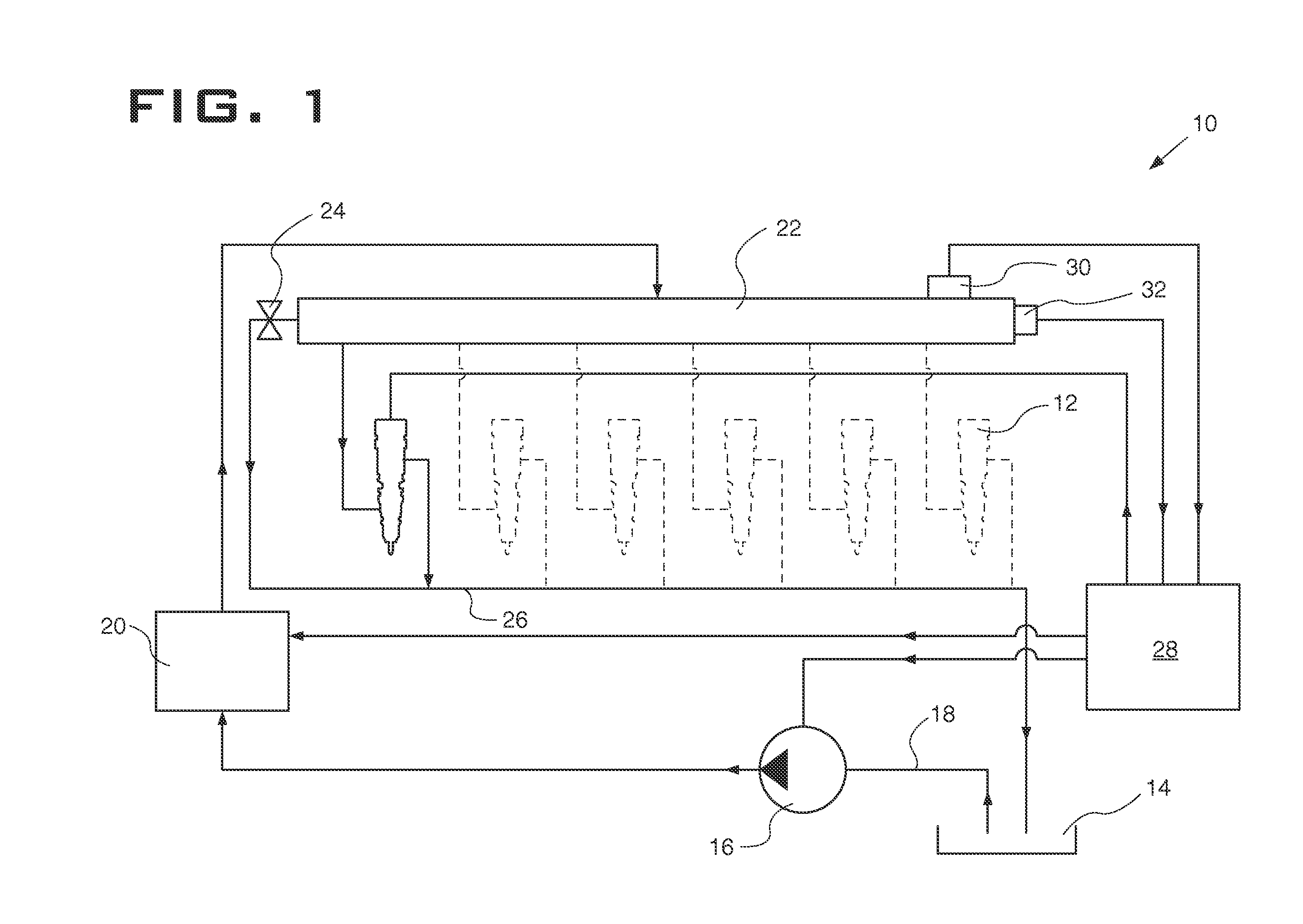

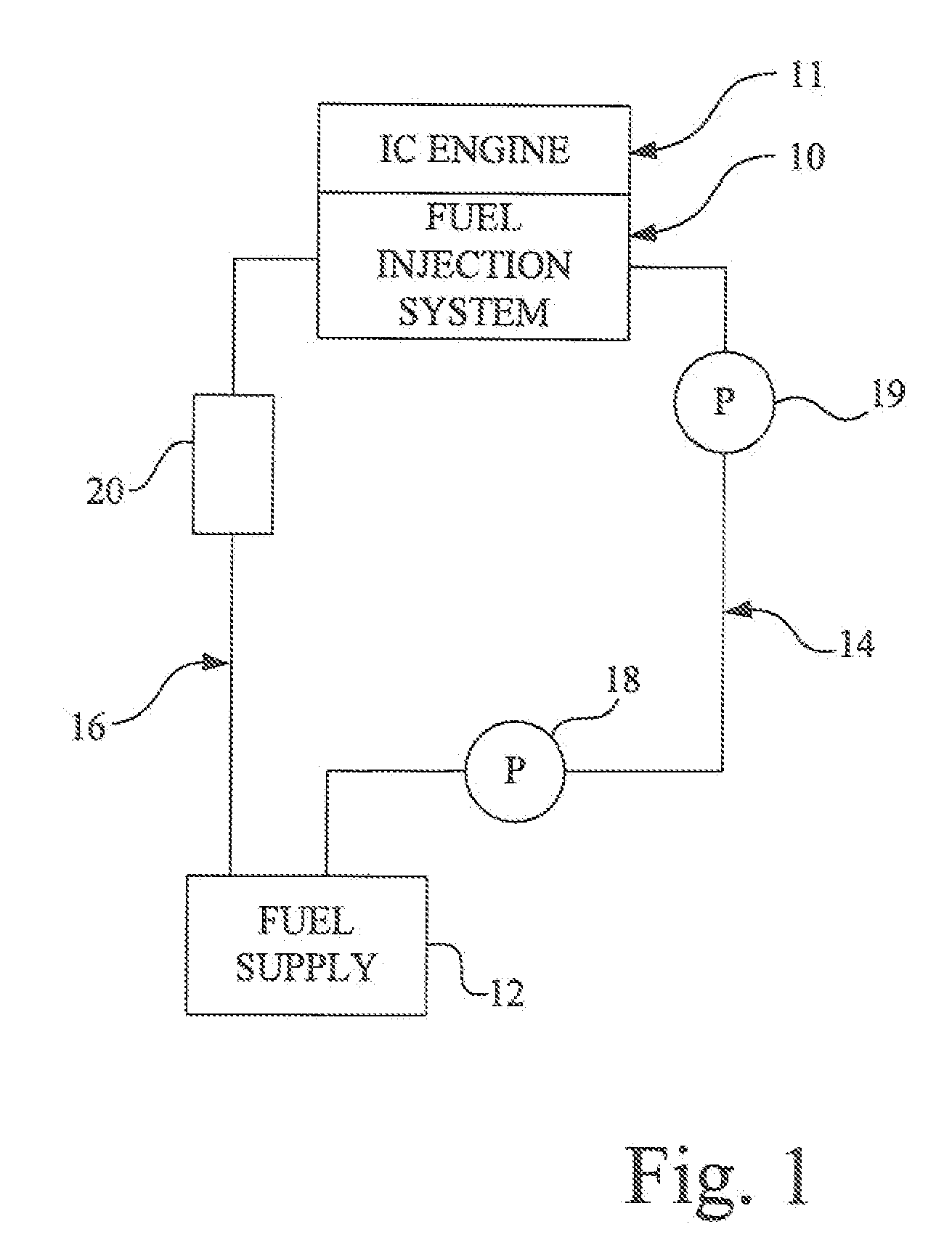

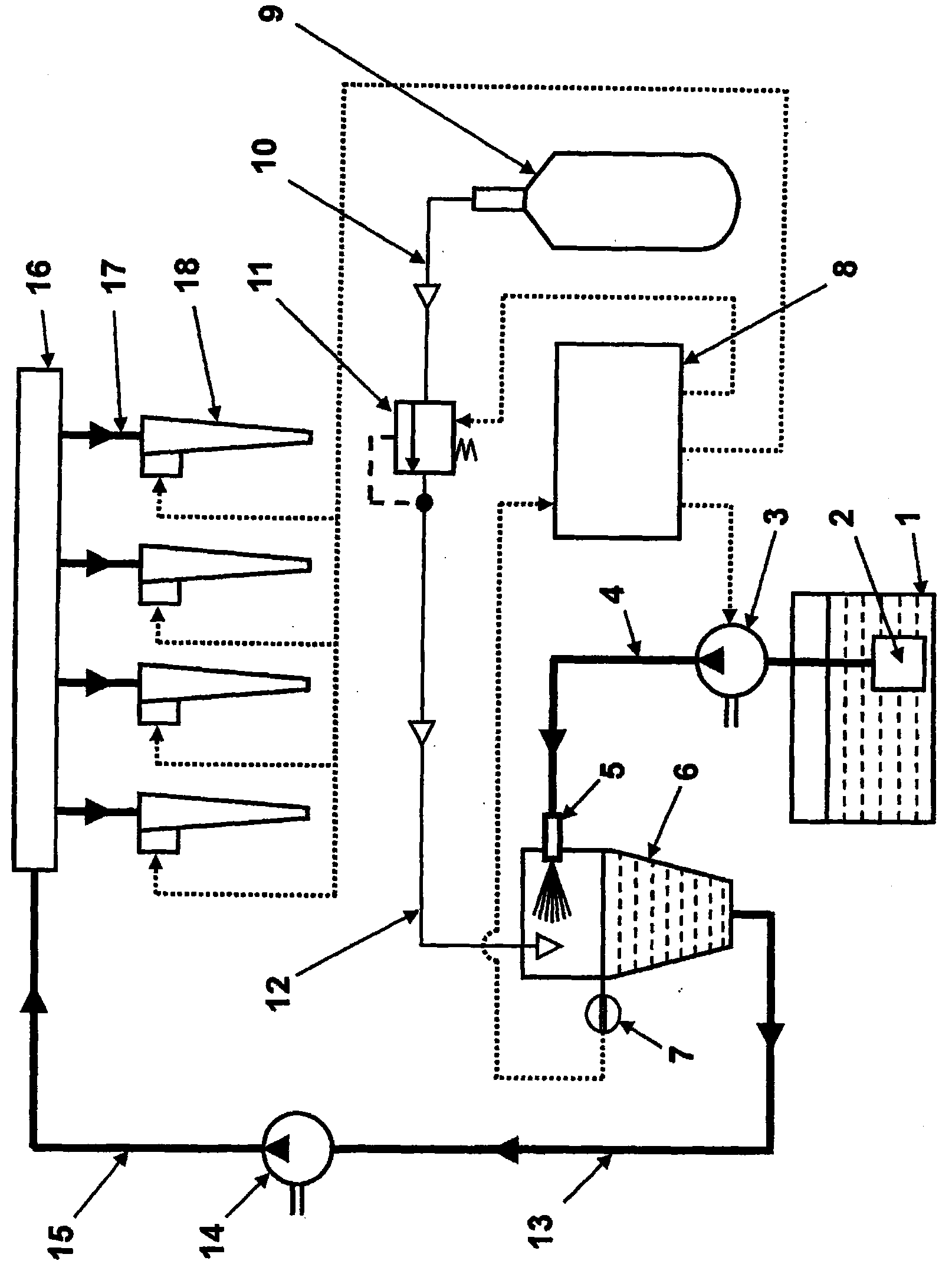

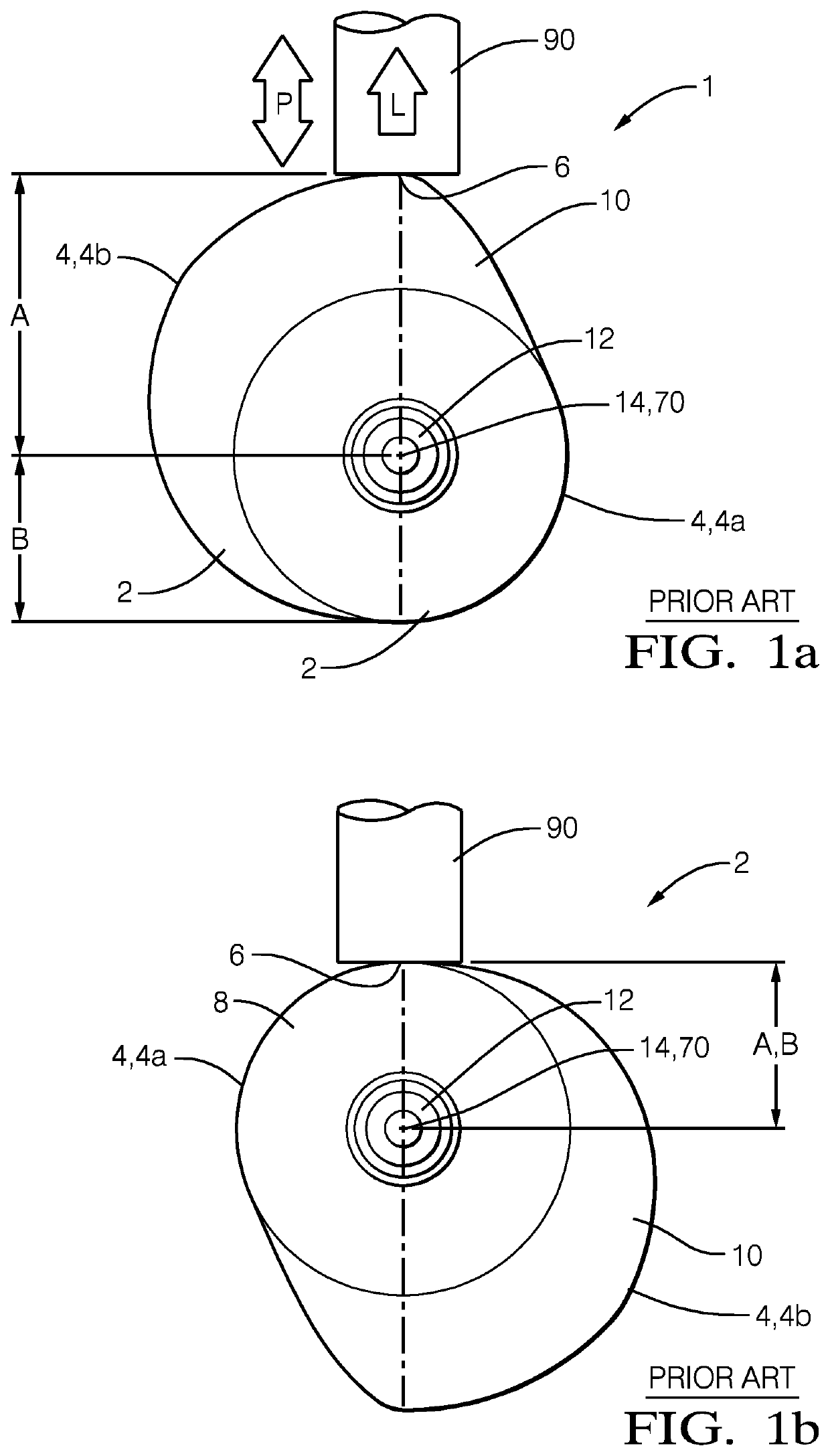

Method and system for liquid fuel conditioning

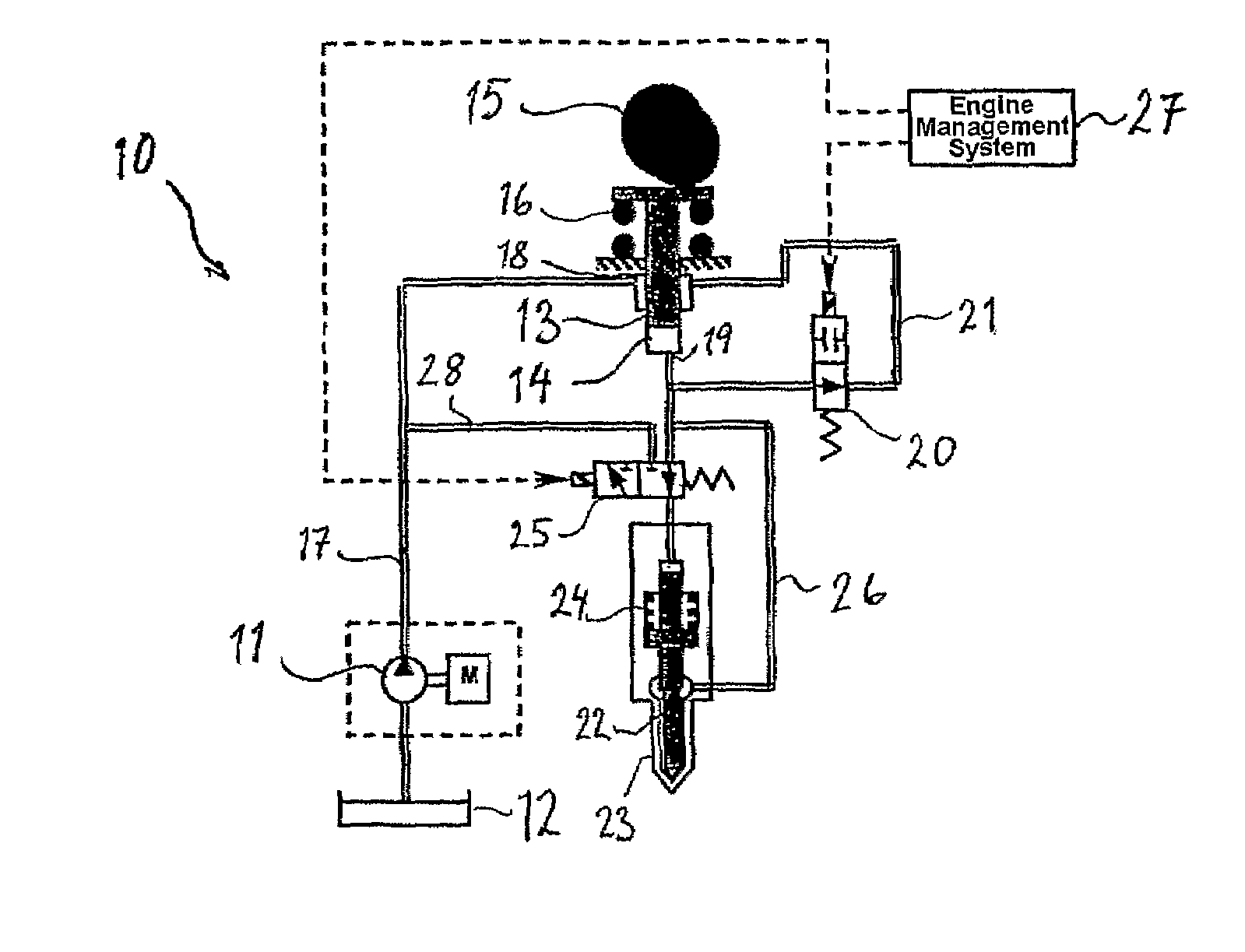

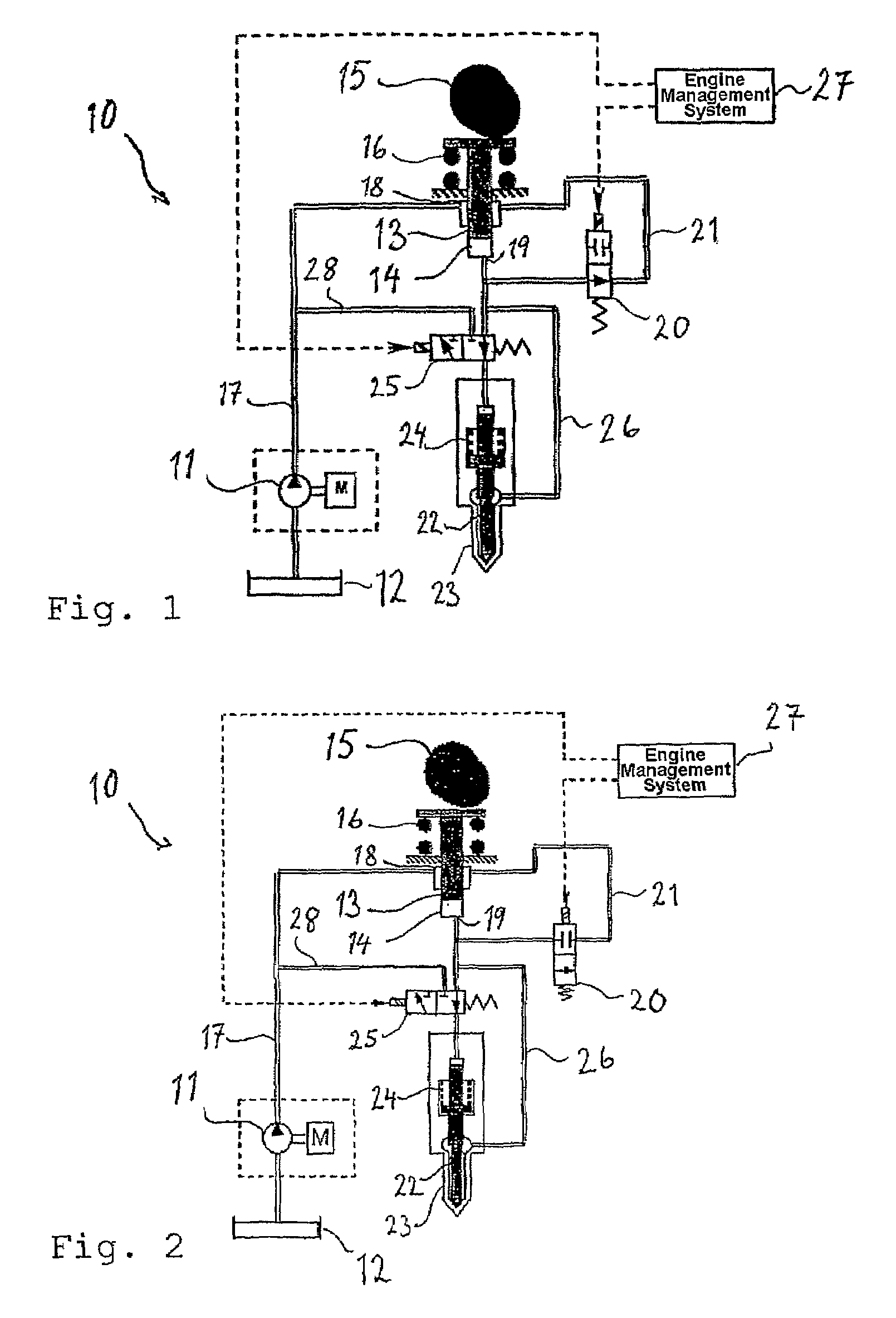

InactiveCN101981301AInternal combustion piston enginesNon-fuel substance addition to fuelCombustion chamberCommon rail

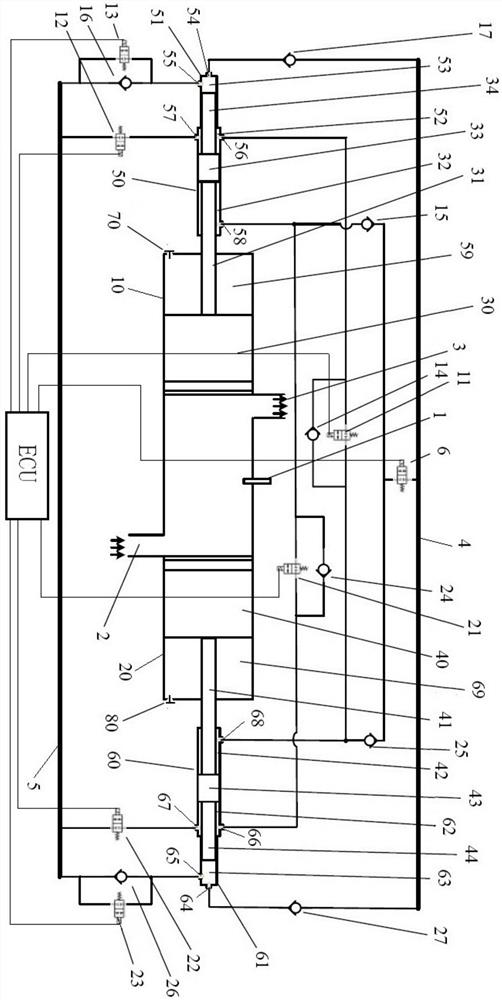

A fuel conditioning method is applicable to common rail direct injection or unit injector system. A liquid fuel is conditioned for higher-efficiency combustion in a combustion chamber. The conditioning system includes a fuel vessel (6) for fuel conditioning, at least one fuel dispersing nozzle (5) mounted for discharge into the fuel conditioning vessel (6), at least one gas inlet port (12), and at least one conditioned fuel outlet port (13) located in the vessel. A gas source (9) feeds a gas to the fuel conditioning vessel (6), wherein the gas is dissolved in the liquid fuel for forming a liquid / gas fuel solution. A low-pressure fuel pump (3) and a liquid fuel supply line (4) deliver liquid fuel from a fuel tank (1) to the at least one dispersing nozzle (5) of the fuel vessel (6) at pressure P1 higher than the gas pressure P2. A high-pressure fuel pump (14) feeds the liquid fuel / gas solution into a common rail (16) and further into fuel injectors (18), providing a pressure P4 higher than a pressure P5 in the combustion chamber at a moment of combustion.

Owner:极限燃烧公司

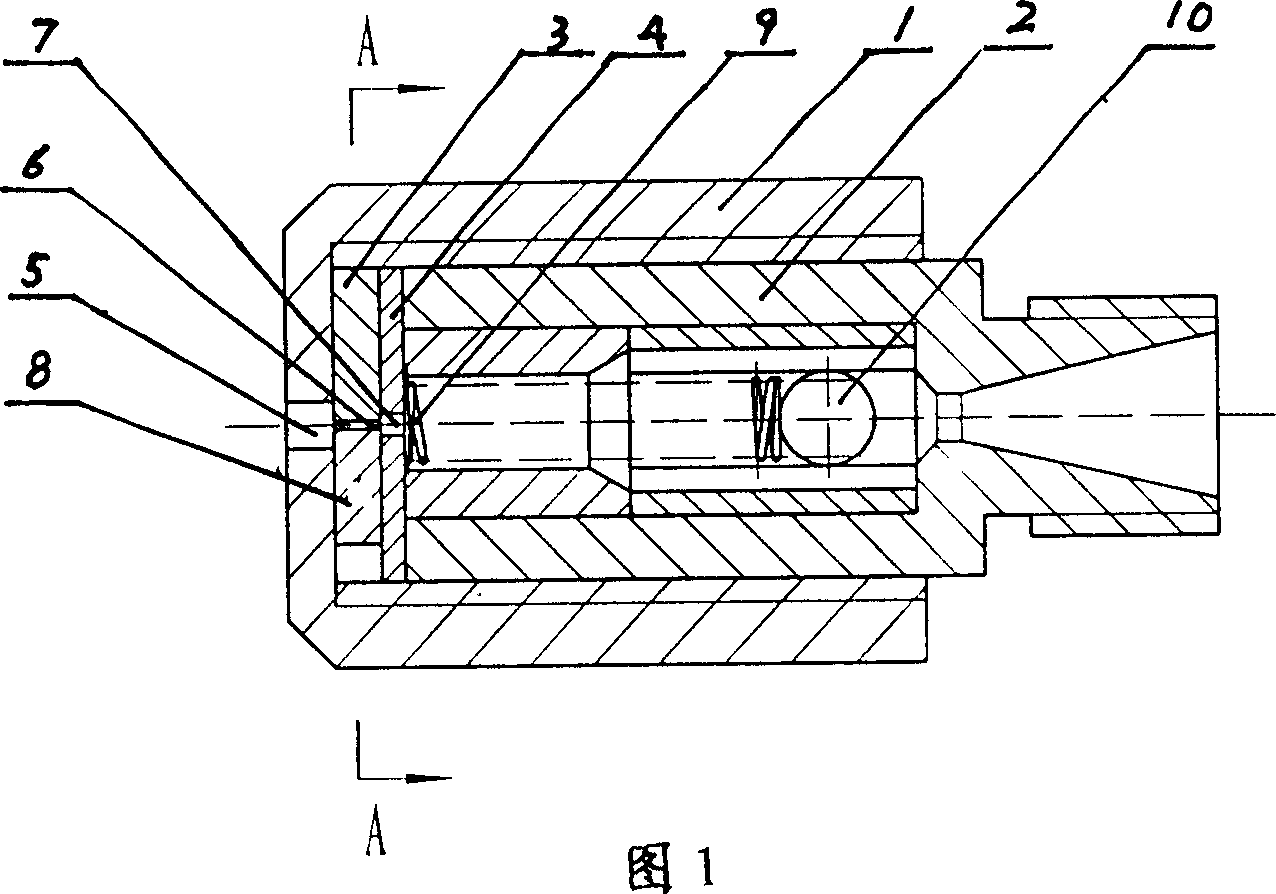

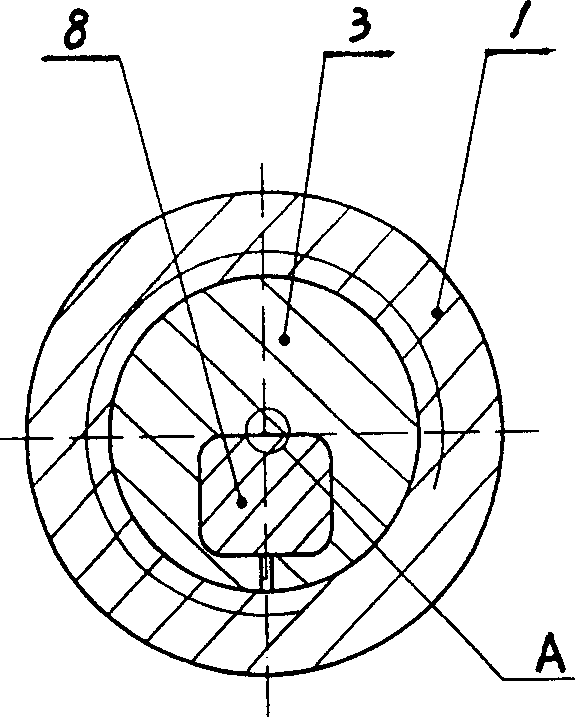

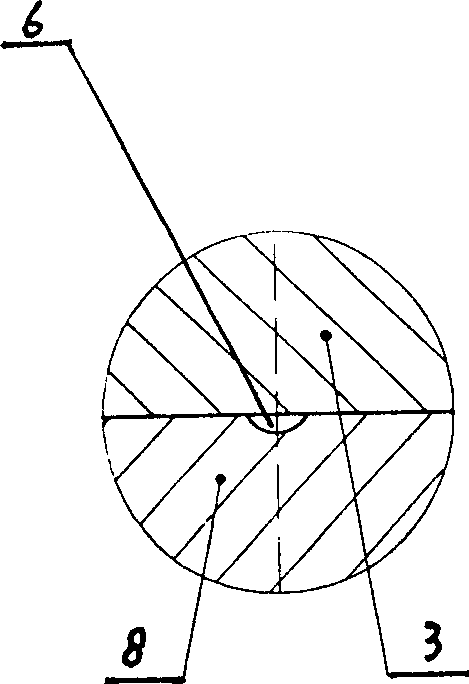

Inlaying-combination type oil sprayer

InactiveCN1815010ASave fuel injection pressureAdjust the fuel injection pressure in timeFuel injection apparatusMachines/enginesVena contracta diameterInlet channel

Present invention relates to an embedded unit injector including outer case, one-way valve, jet orifice plate and partition. It features in middle of jet orifice plate at least embedded a piece of restrictor plate, at least a micro interstice set between jet orifice plate and restrictor plate, said micro interstice is fuel injection hole, outer case oil outlet opposite with jet orifice plate fuel injection hole, jet orifice plate fuel injection hole opposite with partition through fuel hole, partition through fuel hole opposite with one-way valve. Said invention also refers to a embedded unit injector, one end in one-way valve oil inlet set with square opening vertical with fuel inlet channel, one end of one-way valve oil inlet vertical connected with valve body of oil pressure adjusting valve, square opening located upper of said communicated with oil pressure adjusting valve. It has simple structure, convenient for manufacture, precision controlling fuel feed, saving fuel, in time adjusting fuel injection pressure, raising fuel atomization quality.

Owner:SOUTHWEST UNIVERSITY

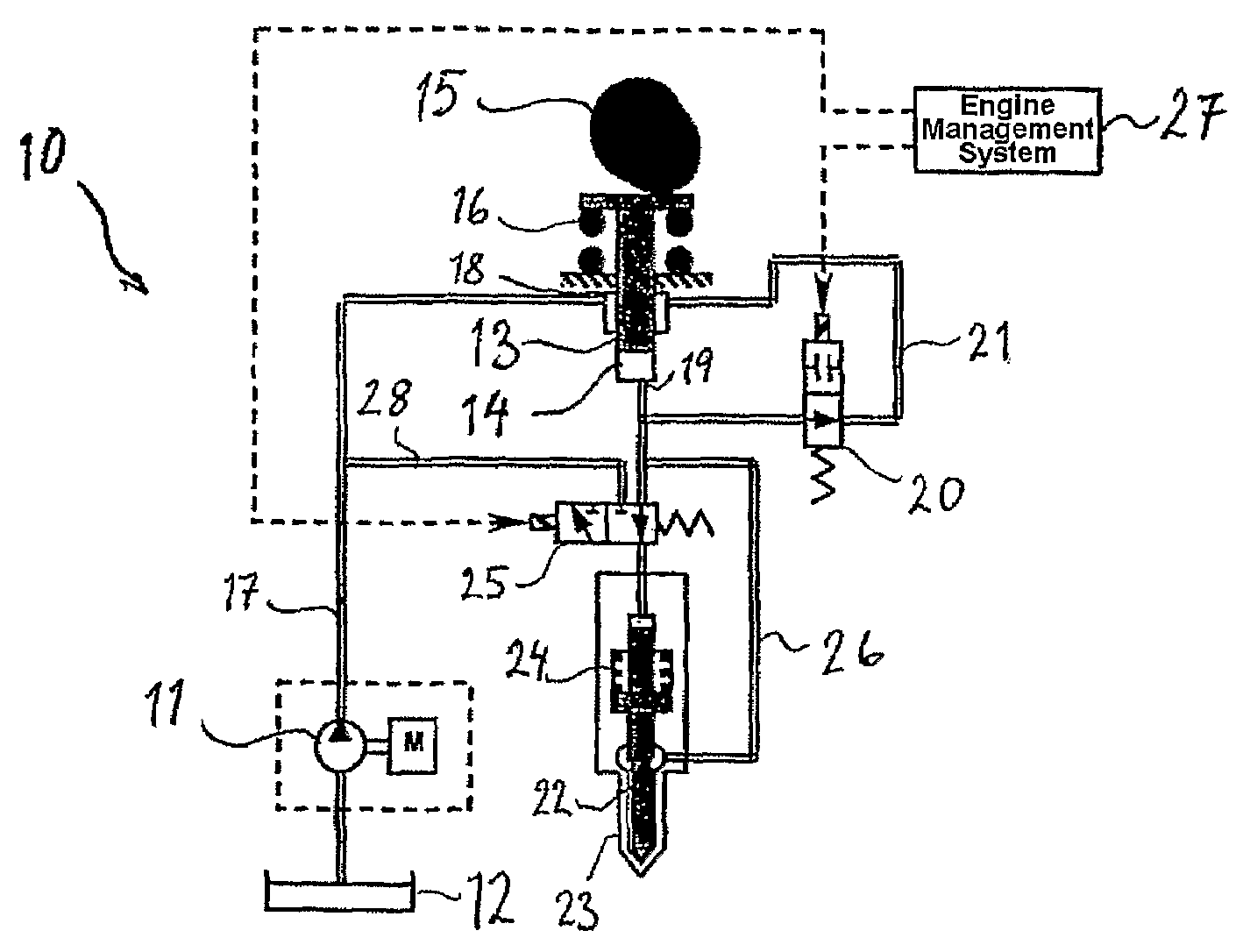

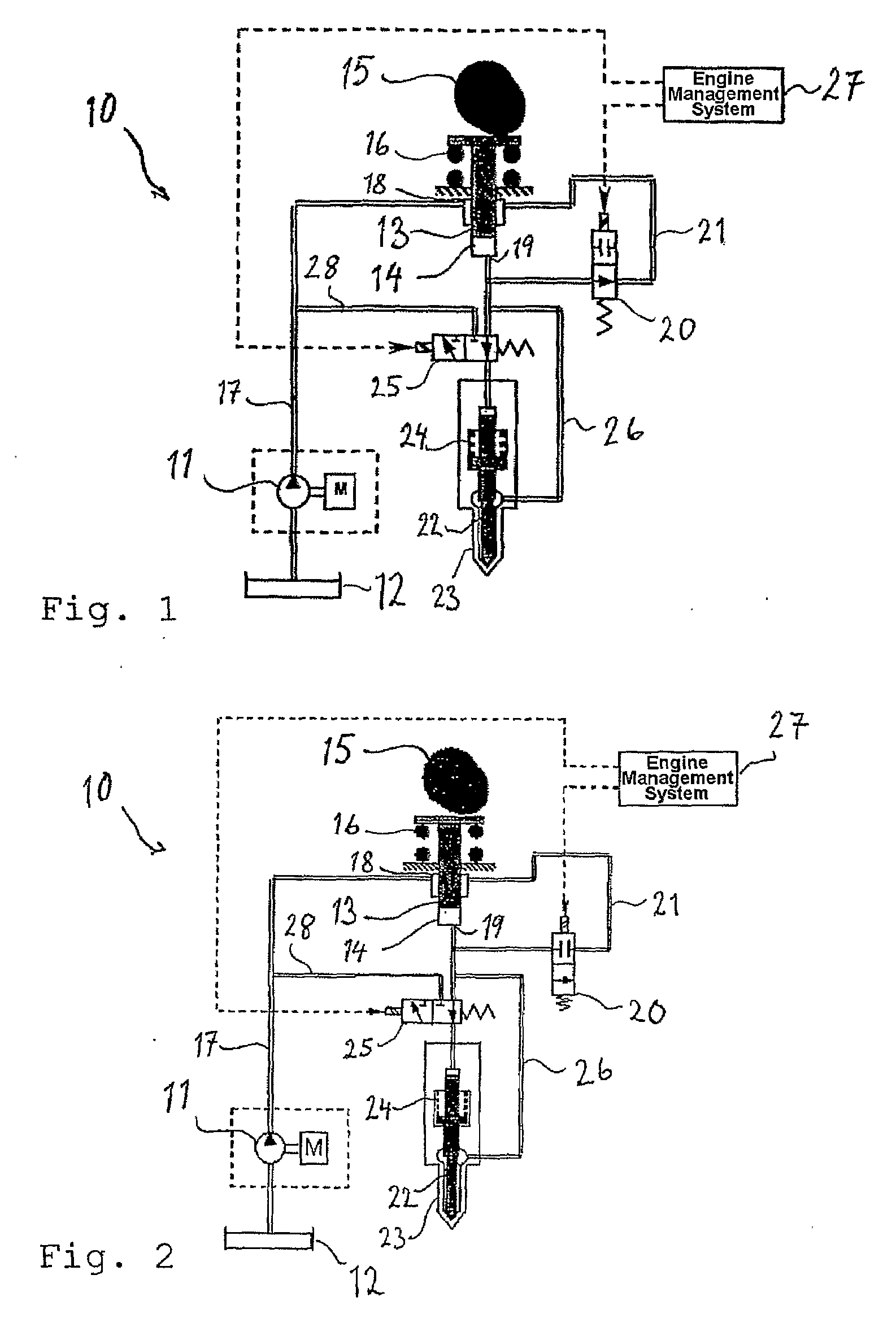

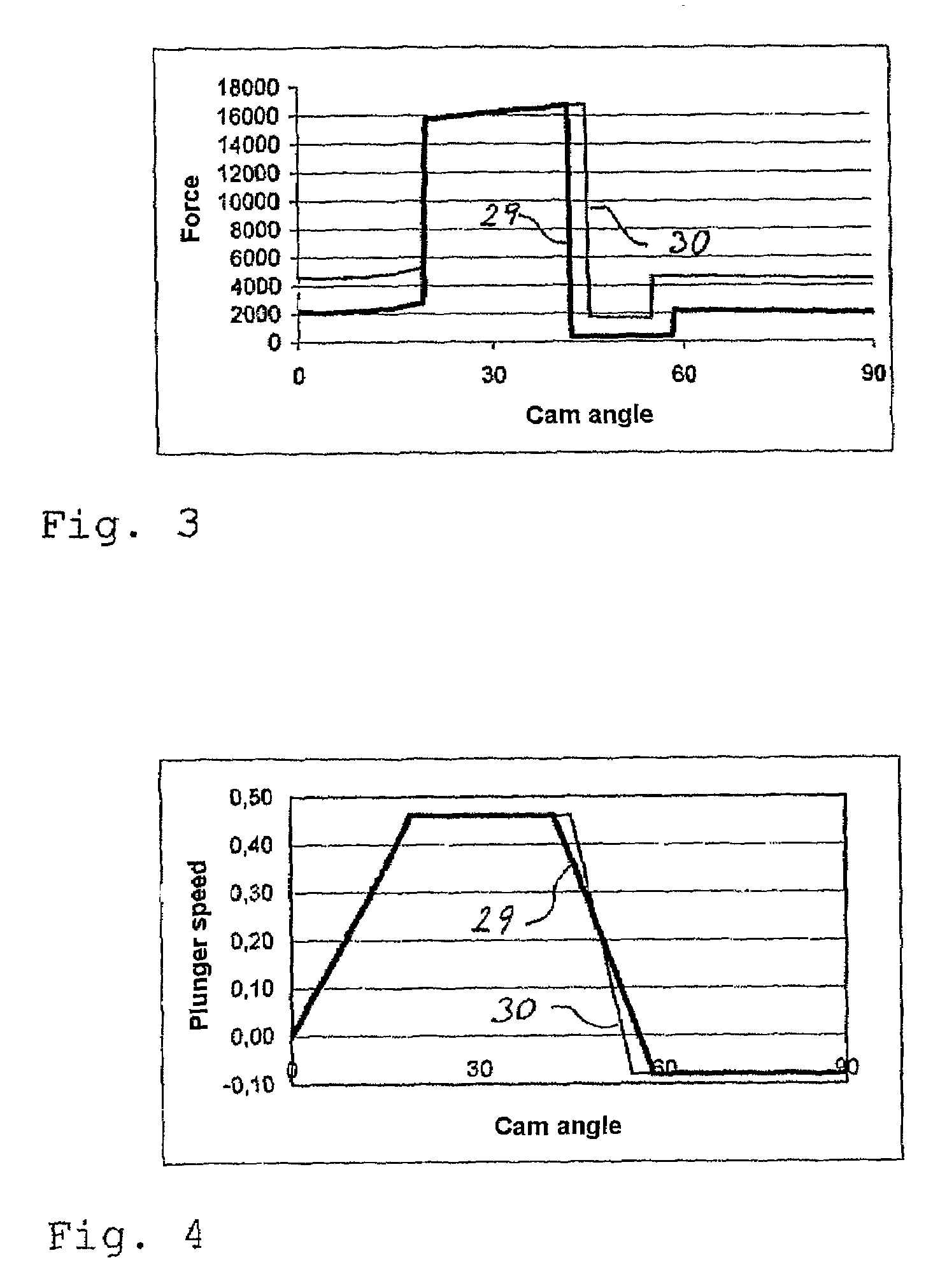

Method for Controlling a Fuel Injector

InactiveUS20080149741A1SpaceControl DimensionsElectrical controlInternal combustion piston enginesUnit injectorEngineering

A method in an internal combustion engine for controlling a fuel injector of the unit injector type which includes a plunger that is driven by a rotating camshaft and during a working stroke generates a hydraulic pressure increase in the fuel. Pressure build-up is regulated by a spill valve the injection sequence is regulated by a needle control valve. The spill valve and the needle control valve are regulated in such a way that additional plunger retardation force is produced in a part of a working stroke in addition to the normal retardation force that is produced by the plunger return spring and the flow resistance in the injector.

Owner:VOLVO LASTVAGNAR AB

Fluid injector with auxiliary filling orifice

InactiveUS20110220064A1Avoid fuel injectionLow pressure fuel injectionMachines/enginesMultiple injectionCommon rail

A common rail single fluid injection system including fuel injectors with the ability to produce multiple injection rate shapes. This is accomplished by including auxiliary filling orifices which selectively provide pressurized fluid to the check needle control chamber during injection events. In so doing, the speed and movement of the check needle is manipulated and differing injection rates may be achieved.

Owner:CATERPILLAR INC

Method for controlling a fuel injector

InactiveUS7559314B2Rapid retardationIncrease elasticityElectrical controlInternal combustion piston enginesEngineeringUnit injector

A method in an internal combustion engine for controlling a fuel injector of the unit injector type which includes a plunger that is driven by a rotating camshaft and during a working stroke generates a hydraulic pressure increase in the fuel. Pressure build-up is regulated by a spill valve the injection sequence is regulated by a needle control valve. The spill valve and the needle control valve are regulated in such a way that additional plunger retardation force is produced in a part of a working stroke in addition to the normal retardation force that is produced by the plunger return spring and the flow resistance in the injector.

Owner:VOLVO LASTVAGNAR AB

Internal combustion engine flow regulating valve

A flow regulating valve for a diesel engine in which a unitary valve element has three positions for controlling flow from a unit injector fuel injection system in response to valve inlet pressure. The valve has a first position wherein flow is blocked below about 10 psi, a second position between about 10 psi and 20 psi wherein flow is substantially unrestricted, and a third position above about 20 psi wherein flow is restricted to minimize return flow to a fuel supply and minimize fuel cooling requirements.

Owner:DEERE & CO

Noise-optimized device for injecting fuel

InactiveUS6874705B2Favorably affects noiseCavitation phenomenon can be avoidedCombustion enginesFuel injecting pumpsCombustion chamberUnit injector

The invention relates to a unit injector system for supplying the combustion chamber of a self-igniting internal combustion engine with fuel. The unit injector system has a high-pressure chamber that can be subjected to pressure via a pump piston. A storage piston is received inside a storage chamber and is acted upon via a compression spring disposed in a spring holder. A return flow throttle element, which delays the buildup of pressure in the storage chamber, is disposed between the high pressure chamber and the storage chamber of the storage piston.

Owner:ROBERT BOSCH GMBH

Inlaying-combination type oil sprayer

InactiveCN100408843CSave fuel injection pressureAdjust the fuel injection pressure in timeFuel injection apparatusMachines/enginesVena contracta diameterInlet channel

Present invention relates to an embedded unit injector including outer case, one-way valve, jet orifice plate and partition. It features in middle of jet orifice plate at least embedded a piece of restrictor plate, at least a micro interstice set between jet orifice plate and restrictor plate, said micro interstice is fuel injection hole, outer case oil outlet opposite with jet orifice plate fuel injection hole, jet orifice plate fuel injection hole opposite with partition through fuel hole, partition through fuel hole opposite with one-way valve. Said invention also refers to a embedded unit injector, one end in one-way valve oil inlet set with square opening vertical with fuel inlet channel, one end of one-way valve oil inlet vertical connected with valve body of oil pressure adjusting valve, square opening located upper of said communicated with oil pressure adjusting valve. It has simple structure, convenient for manufacture, precision controlling fuel feed, saving fuel, in time adjusting fuel injection pressure, raising fuel atomization quality.

Owner:SOUTHWEST UNIV

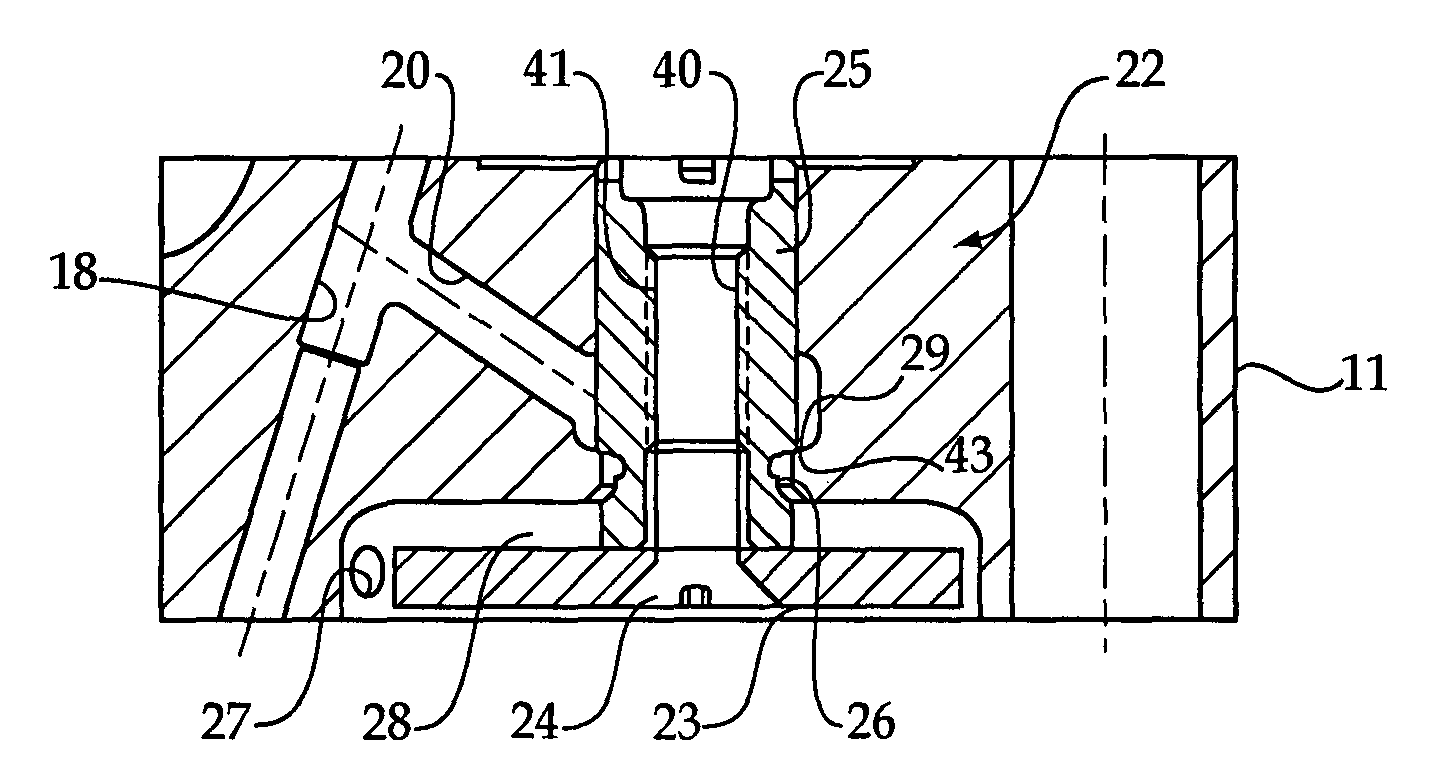

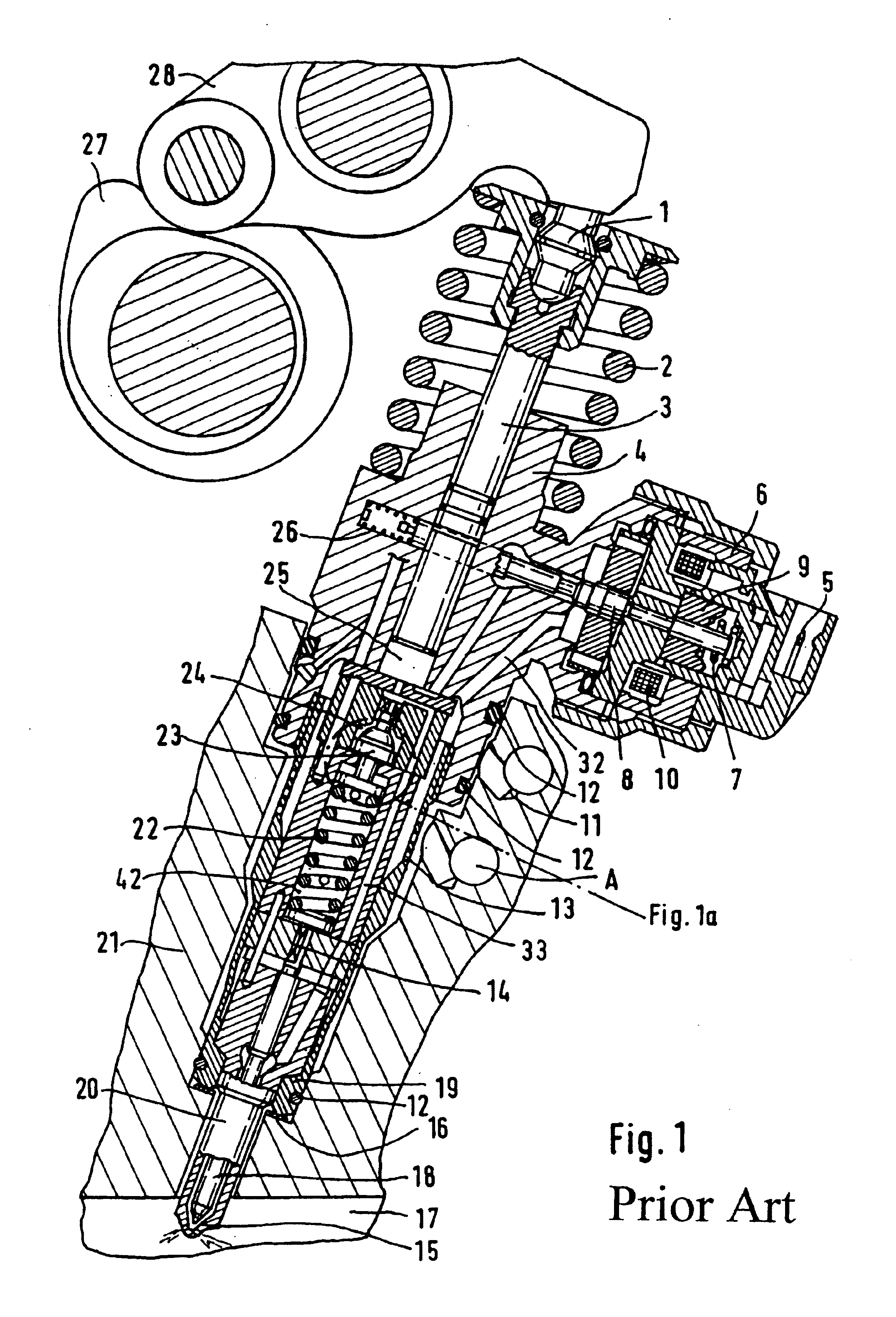

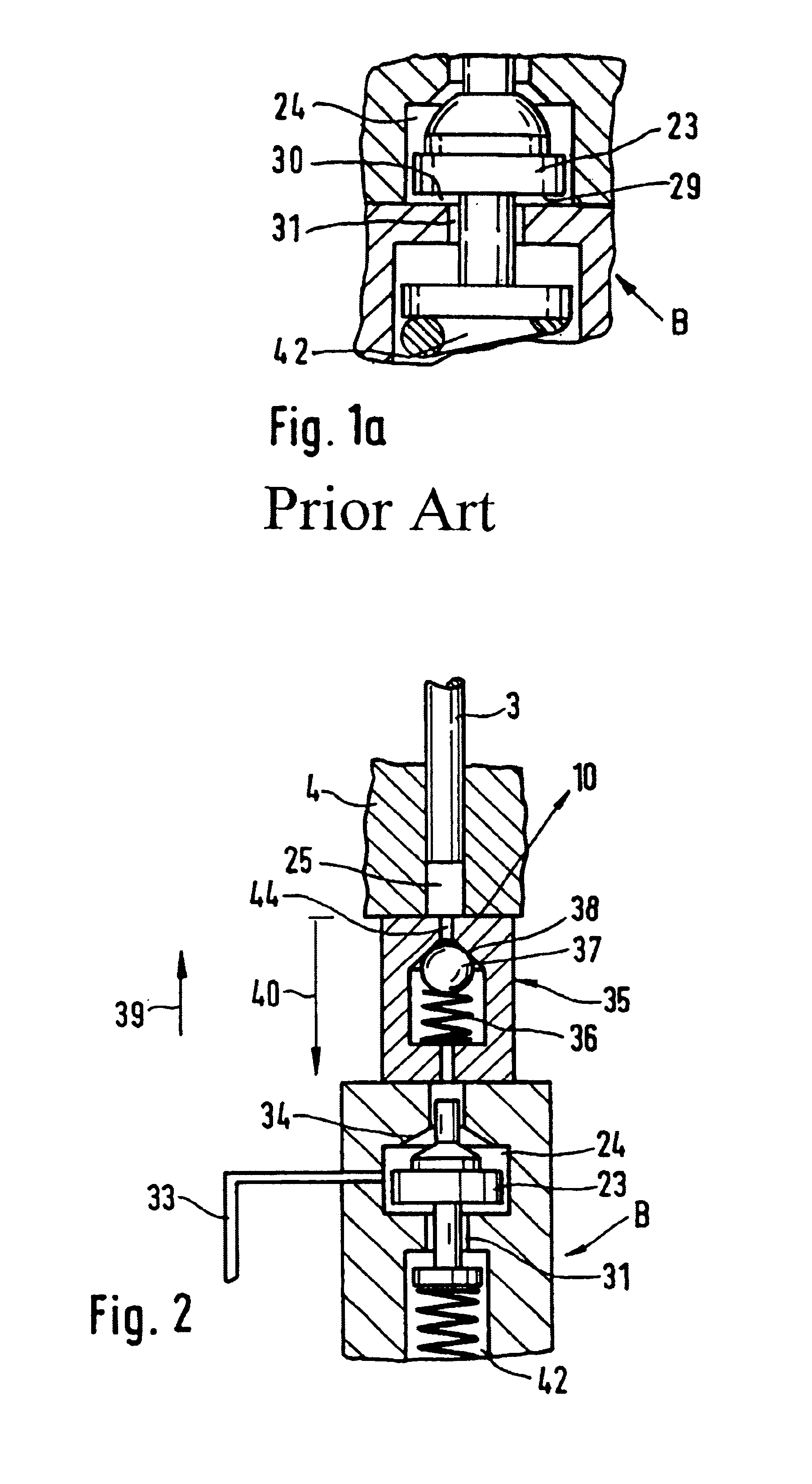

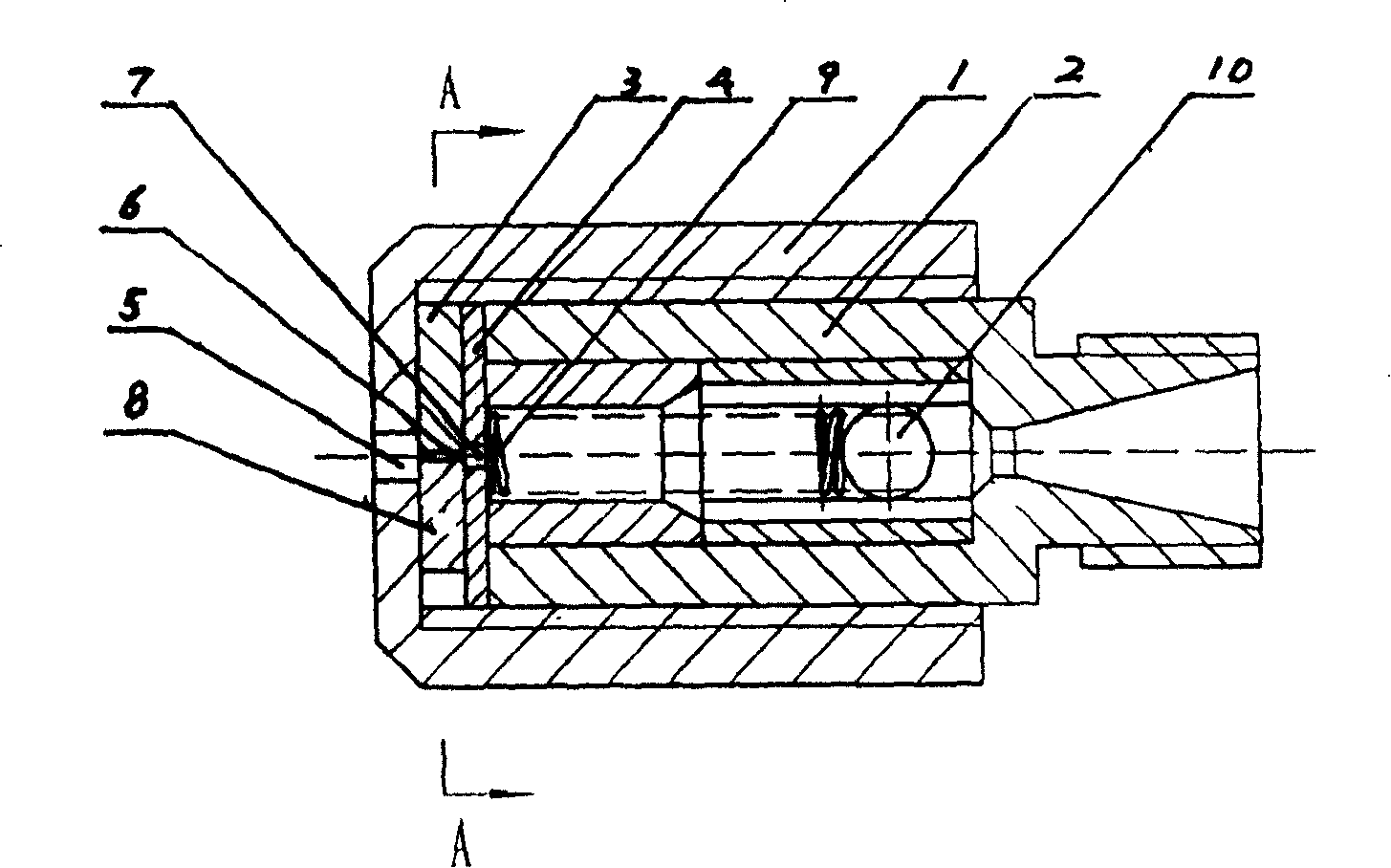

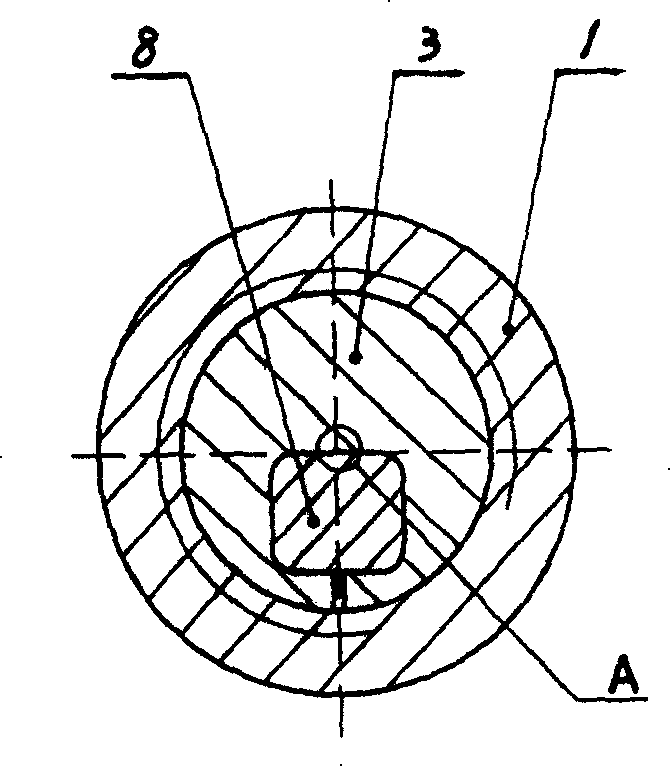

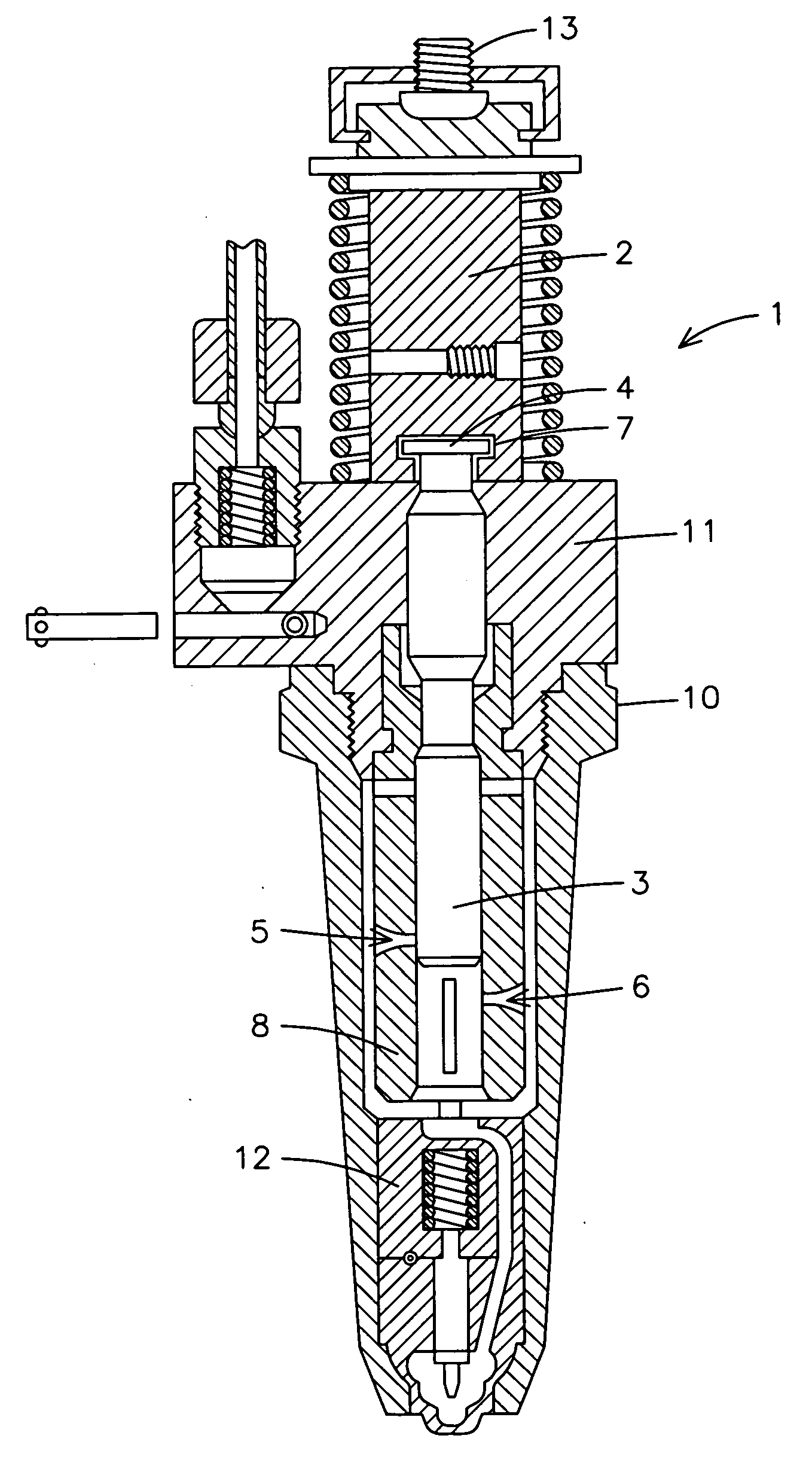

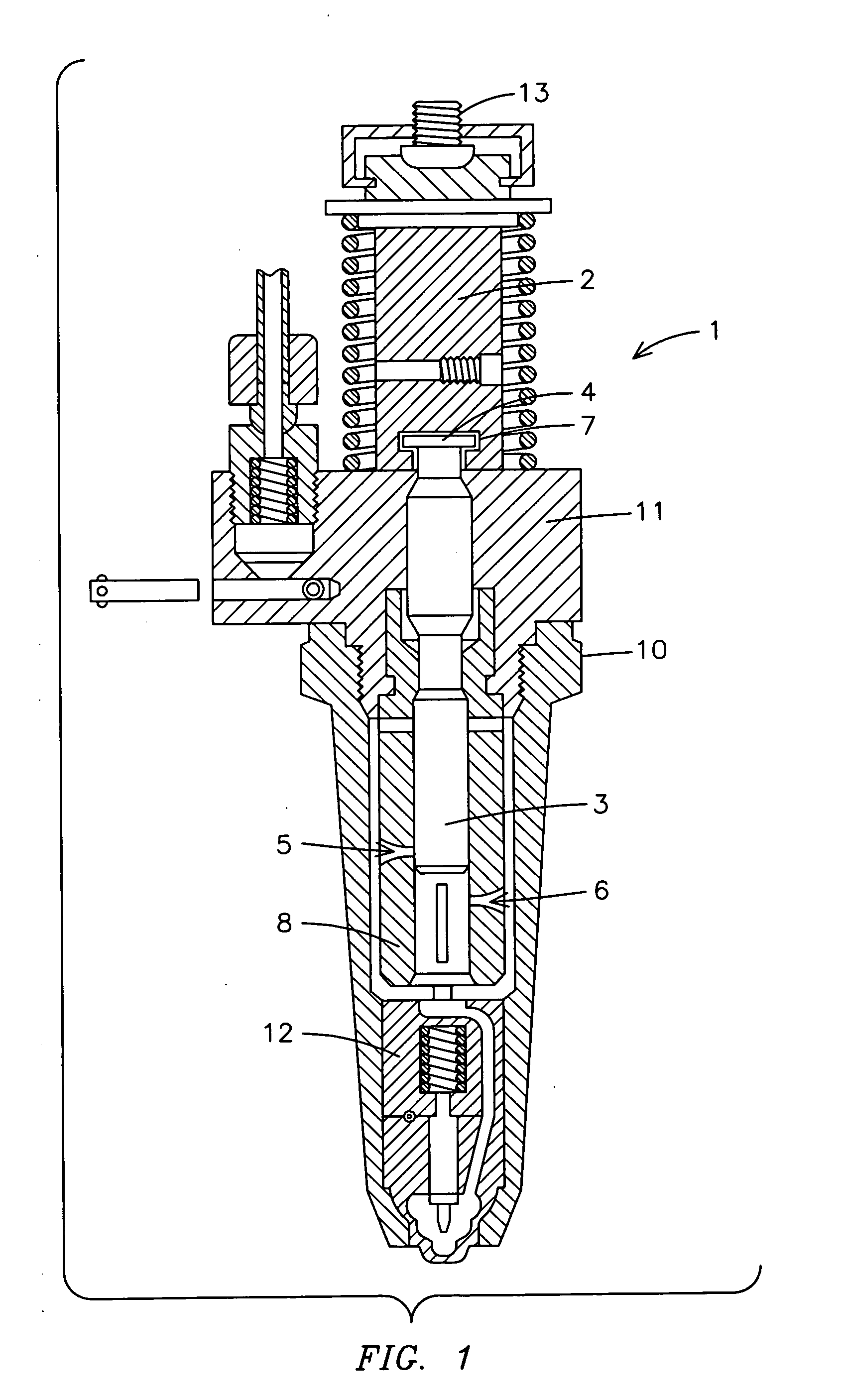

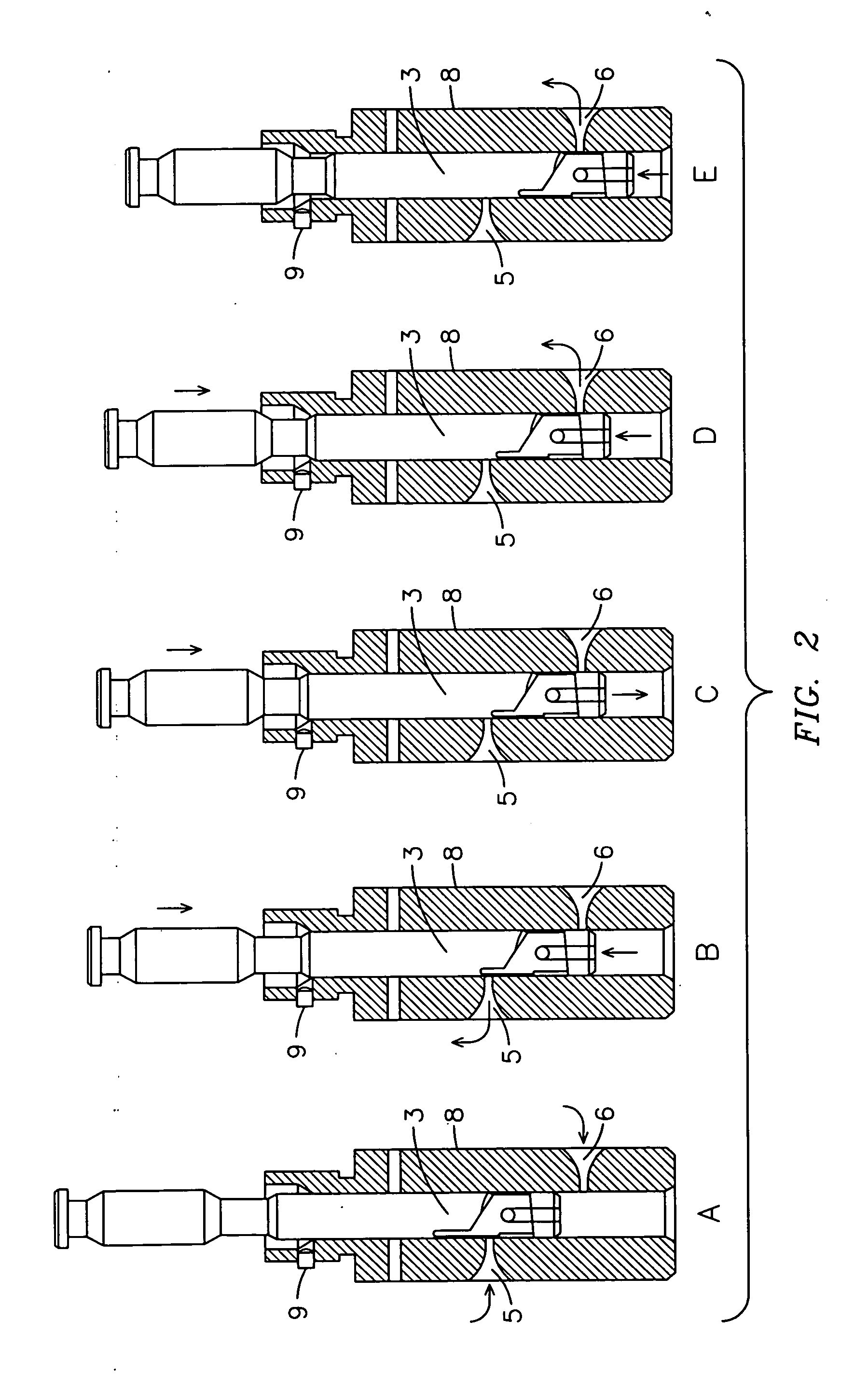

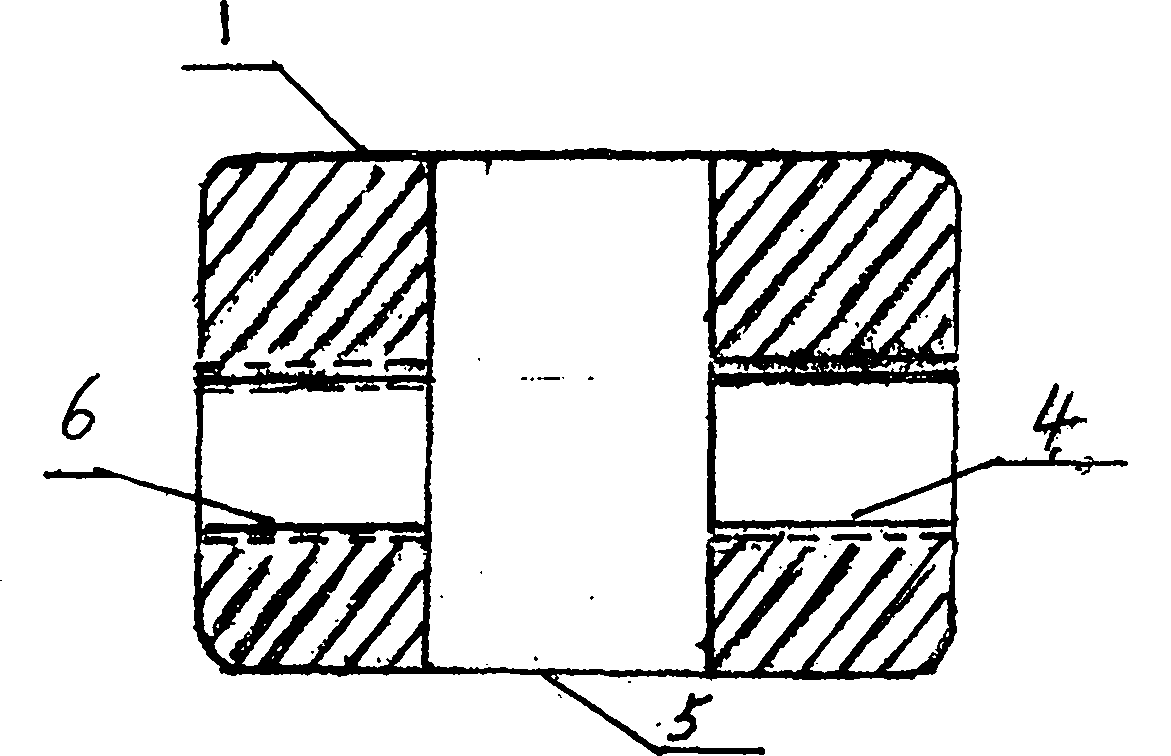

Method of retarding injection timing of mechanical unit injectors using a modified pump barrel

InactiveUS20070227508A1Reduce the amount requiredPositive displacement pump componentsFuel injecting pumpsUnit injectorEngineering

A modified barrel device (1) and method of retarding injection timing of EMD-type unit injectors by a desired amount of crank degrees includes the steps of providing a modified pump barrel (8) whose port locations differ, in their spacing from the top shoulder of the associated barrel, that corresponds to the spacing from the top face of the associated follower, from the spacing of the barrel port sealing location of the pump barrel of the original injector from the top shoulder of the associated barrel, that corresponds to the top face of the associated follower (2), such difference in spacing being by an amount equal to the amount of retardation, in linear units, that corresponds to the desired amount of retardation in crank degrees, and assembling the modified pump barrel (8) into an injector assembly.

Owner:HAYNES CORP

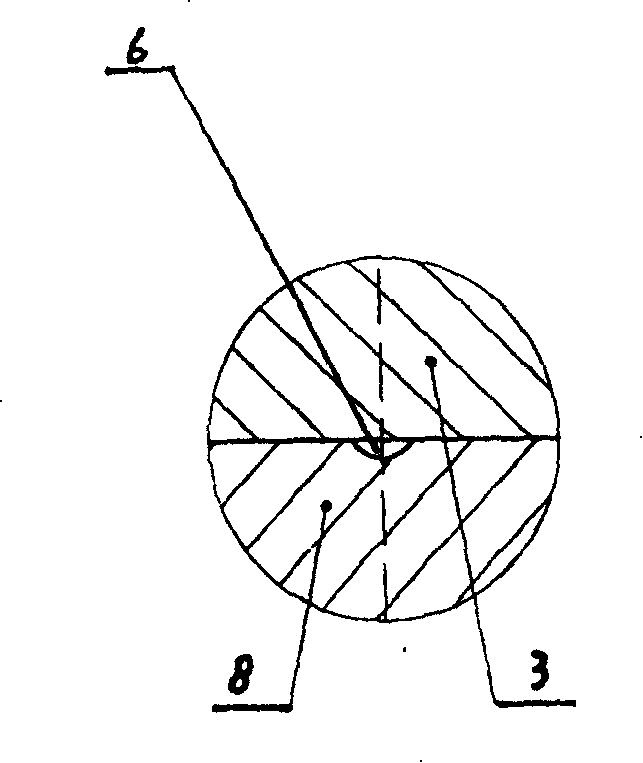

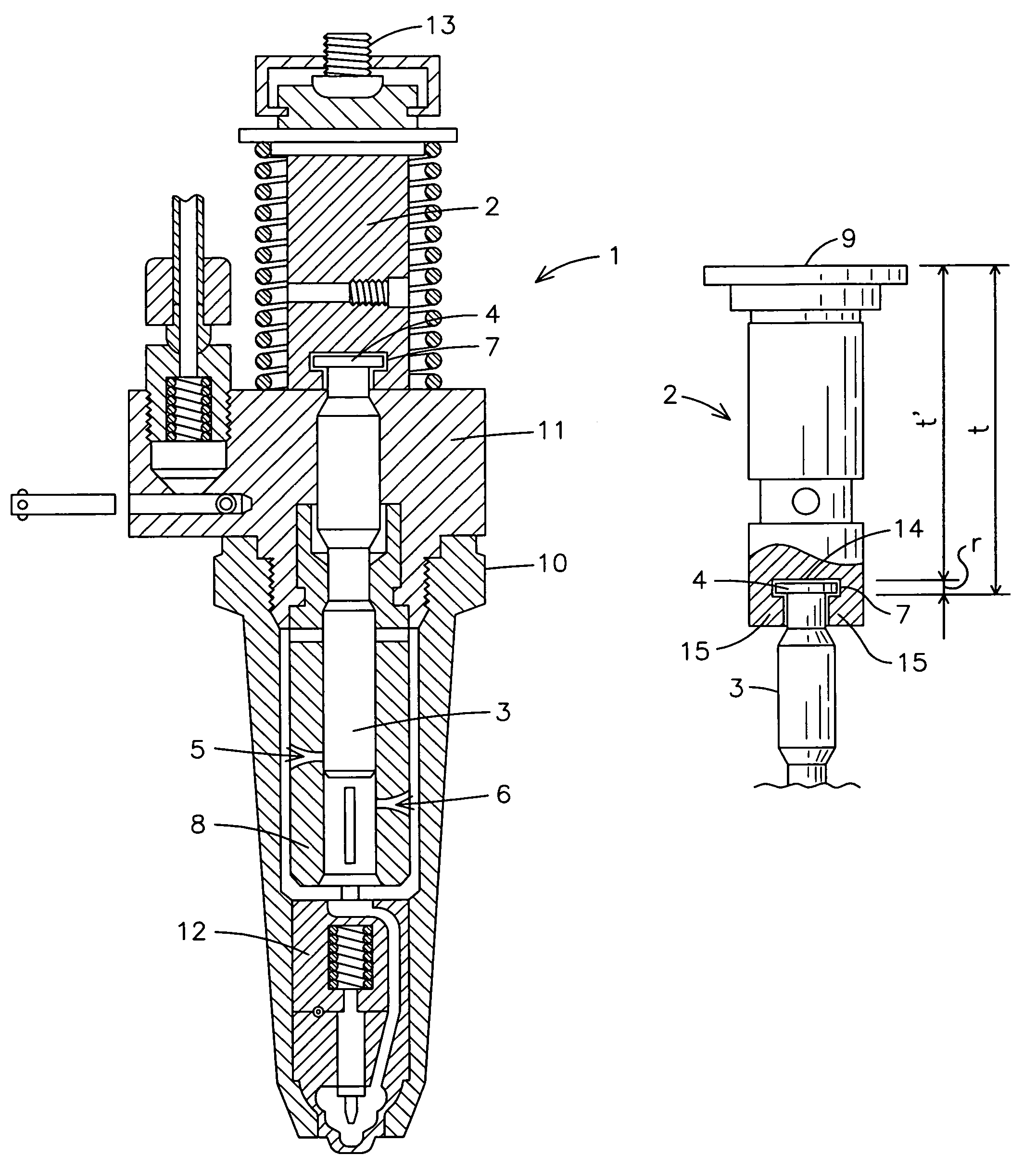

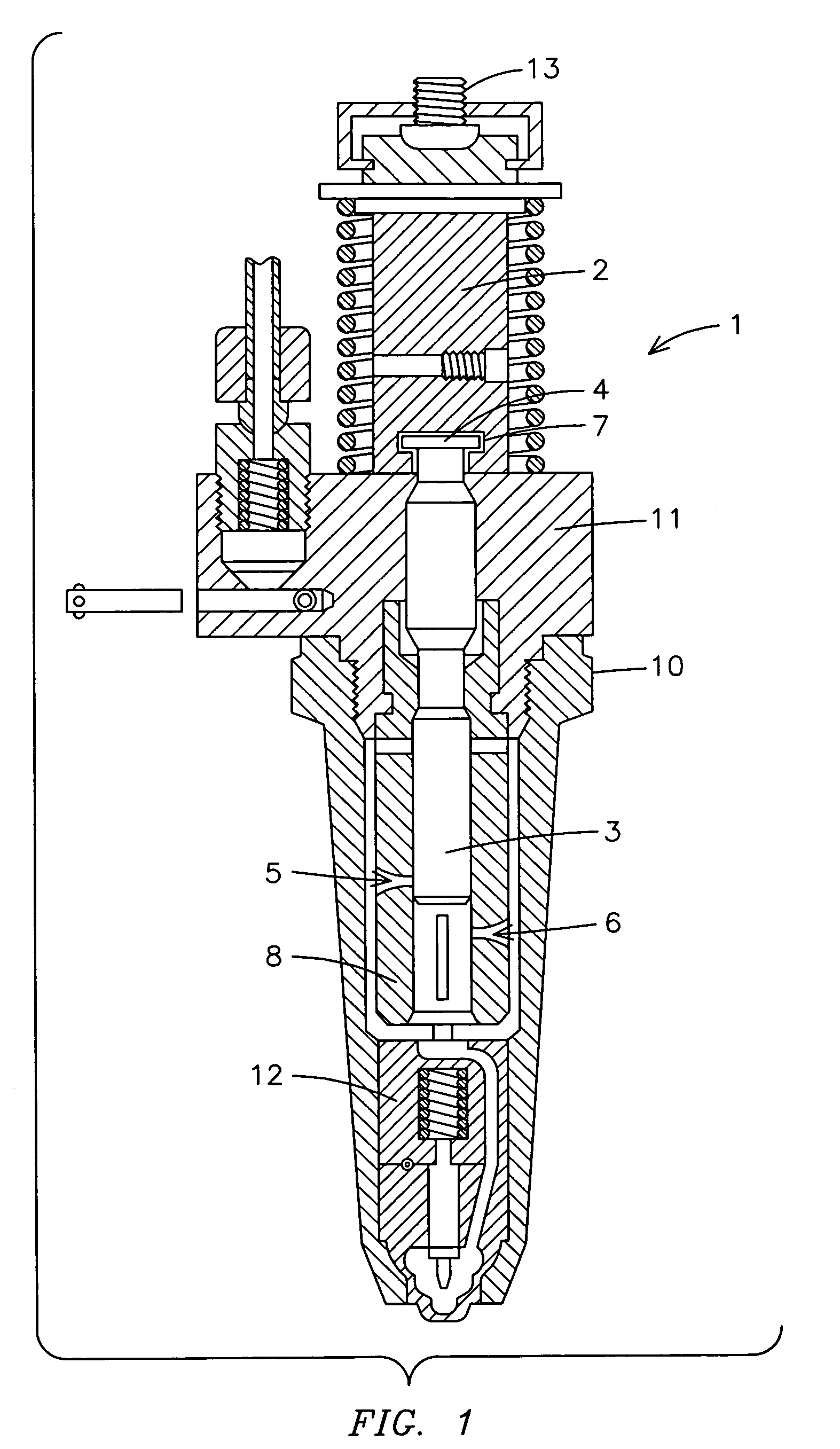

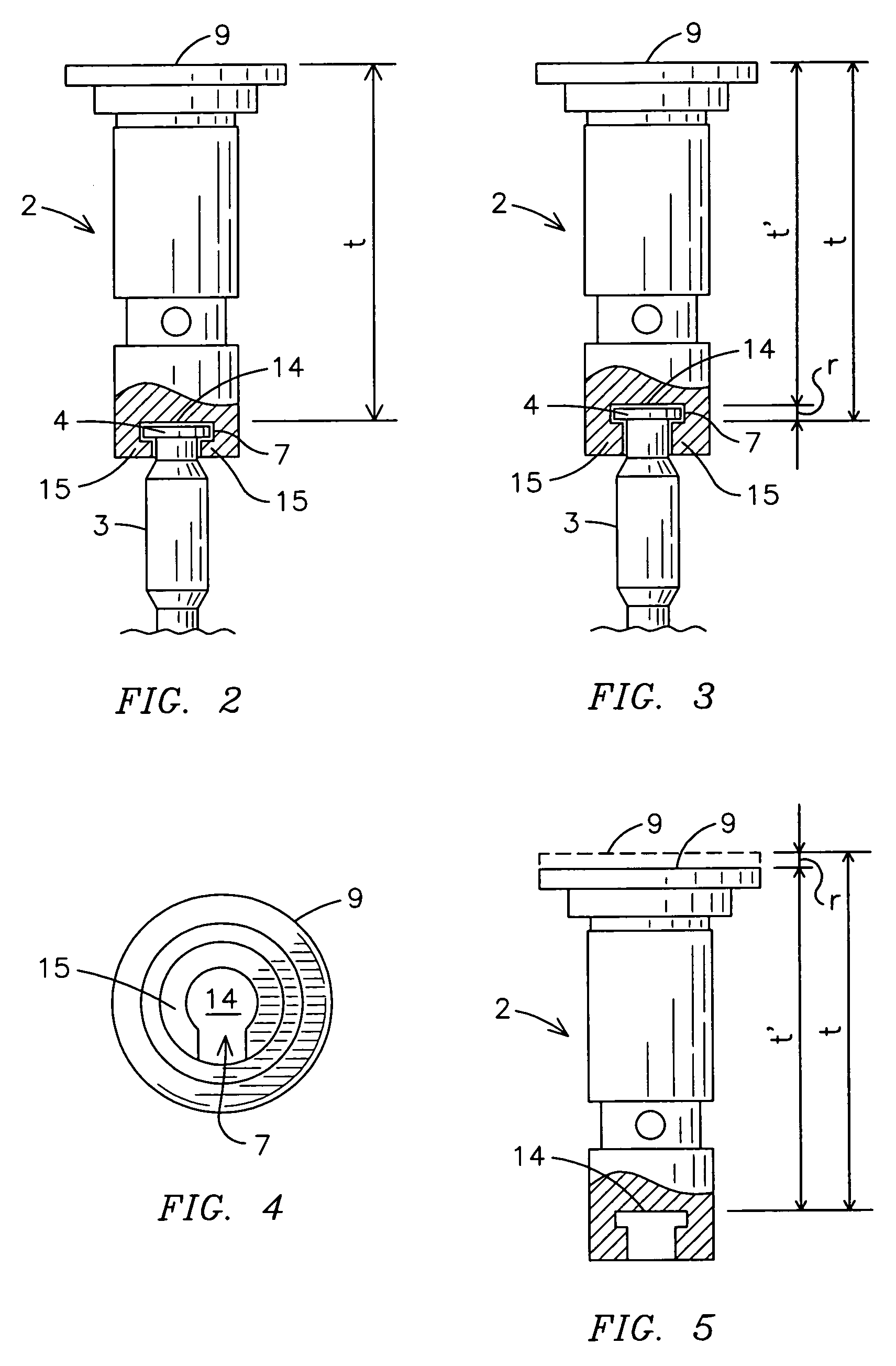

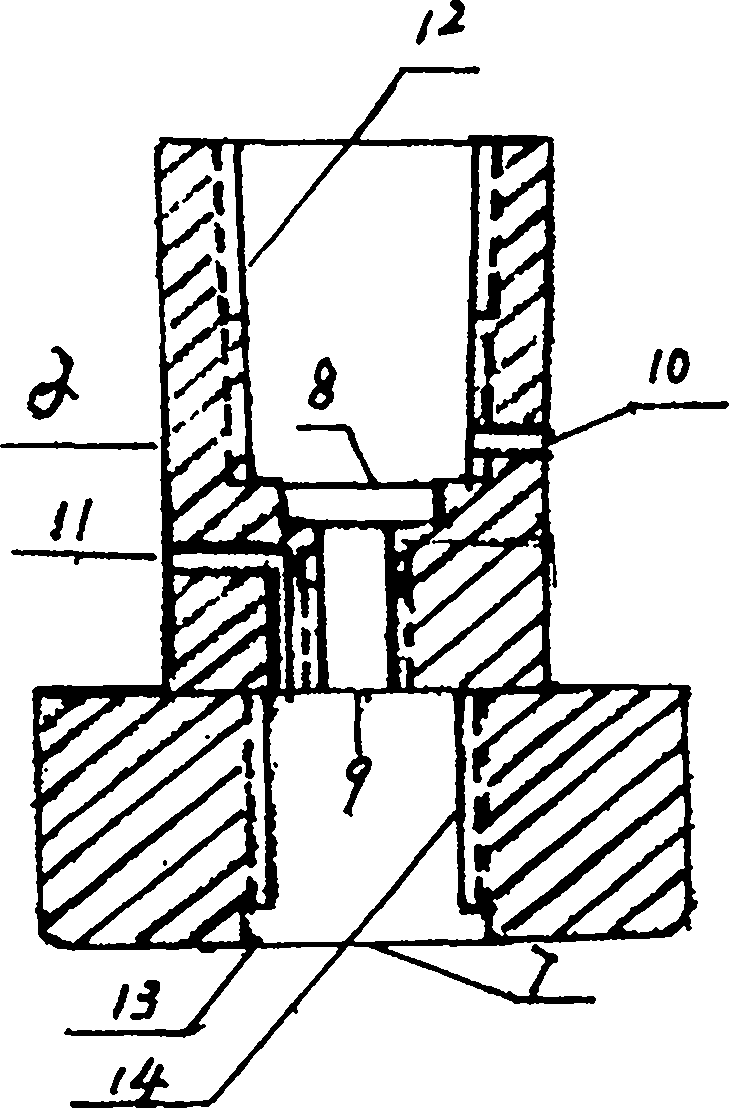

Methods of retarding injection timing of mechanical unit injectors using a modified pump follower

InactiveUS7191766B1Reduce the amount requiredCombustion enginesFuel injecting pumpsUnit injectorBiomedical engineering

A modified pump follower device (2) and method of retarding injection timing of EMD-type unit injectors by a desired amount of crank degrees includes the steps of providing a modified pump follower (2) whose plunger engagement location, also known as t-slot (7), varies depending on the desired amount of retarding. Specifically, the modified pump follower (2) has a t-slot (7) which has a predetermined distance t′ on the modified pump follower (2), as compared to conventional pump followers having a predetermined distance t, such that the t-slot (14) is closer to the top face (9) of the pump follower (2). The difference in spacing between the original timing t and the retarded timing t′ is r, which is an amount equal to the amount of retardation, in linear units, that corresponds to the desired amount of retardation in crank degrees.

Owner:HAYNES CORP

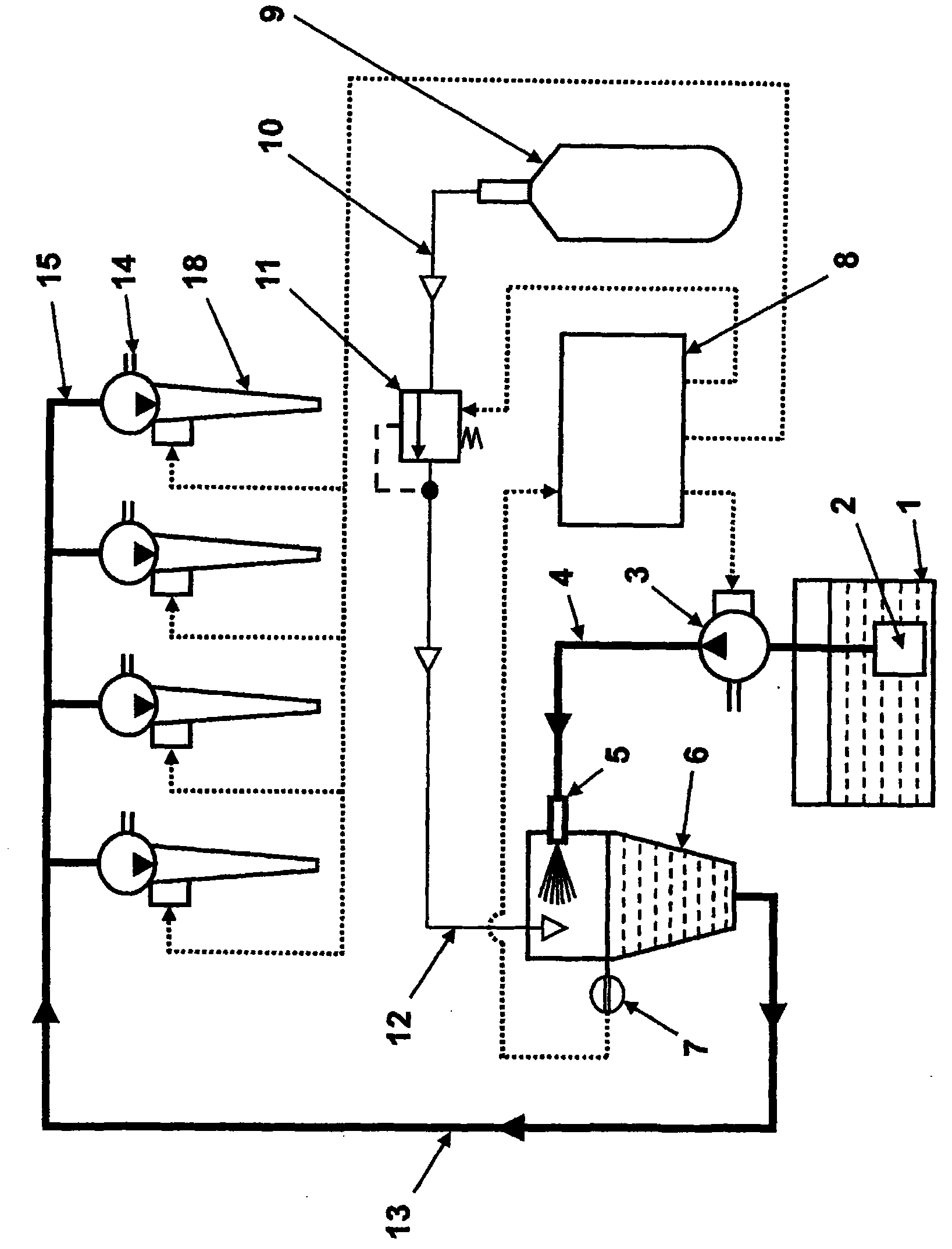

Fuel combined with carbon dioxide in elongate chamber

InactiveUS8677980B1Promote absorptionNon-fuel substance addition to fuelFuel supply apparatusCombustion chamberCommon rail

A fuel conditioning system is applied to common rail direct injection or unit injector diesel engines. A liquid fuel is conditioned with gas for combustion in the combustion chambers. The system includes an elongate conditioning vessel, at least one fuel dispensing inlet, at least one carbon dioxide inlet port, and at least one conditioned fuel outlet port on the vessel. Carbon dioxide and diesel fuel are fed into the inlet portion of the vessel. The mixture travels a path of at least ten feet in the vessel to the outlet portion to cause the carbon dioxide gas to dissolve in the liquid fuel for forming a liquid / gas fuel solution. At least one high-pressure fuel pump feeds the liquid fuel / gas solution into fuel injectors.

Owner:MUCCIACCIARO DOMENIC

Opposed hydraulic free piston engine with hydraulic synchronizing mechanism and driving method of opposed hydraulic free piston engine.

ActiveCN112031932AMotion synchronizationFlexible and convenient controlPositive displacement pump componentsCylinder headsFree-piston engineSprayer

The invention relates to an opposed hydraulic free piston engine with a hydraulic synchronizing mechanism and a driving method of the opposed hydraulic free piston engine. The opposed free piston engine comprises a high-pressure working medium liquid path, a low-pressure working medium liquid path, an electronic control unit, an oil sprayer, a gas inlet, an exhaust opening, a first cylinder sleeve, a second cylinder sleeve, a first piston matched with the first cylinder sleeve, a first piston rod connected with the first piston, a first high-pressure working medium output cavity connected withthe other end of the first piston rod, a second piston matched with the second cylinder sleeve, a second piston rod connected with the second piston, a second high-pressure working medium output cavity connected with the other end of the second piston rod, a high-pressure working medium liquid path, and the hydraulic synchronizing mechanism, wherein the first cylinder sleeve and the a second cylinder sleeve are coaxial and symmetrically distributed According to the opposed hydraulic free piston engine with the hydraulic synchronizing mechanism and the driving method of the opposed hydraulic free piston engine, a first synchronizing cavity and a fourth synchronizing cavity of the hydraulic synchronizing mechanism communicate, and a second synchronizing cavity and a third synchronizing cavity communicate, so that two synchronizing loops are formed; and due to the property that a liquid working medium is difficult to compress, mutual containing and mutual restraining are achieved, and the pistons on the two sides can synchronously move.

Owner:TIANJIN UNIV

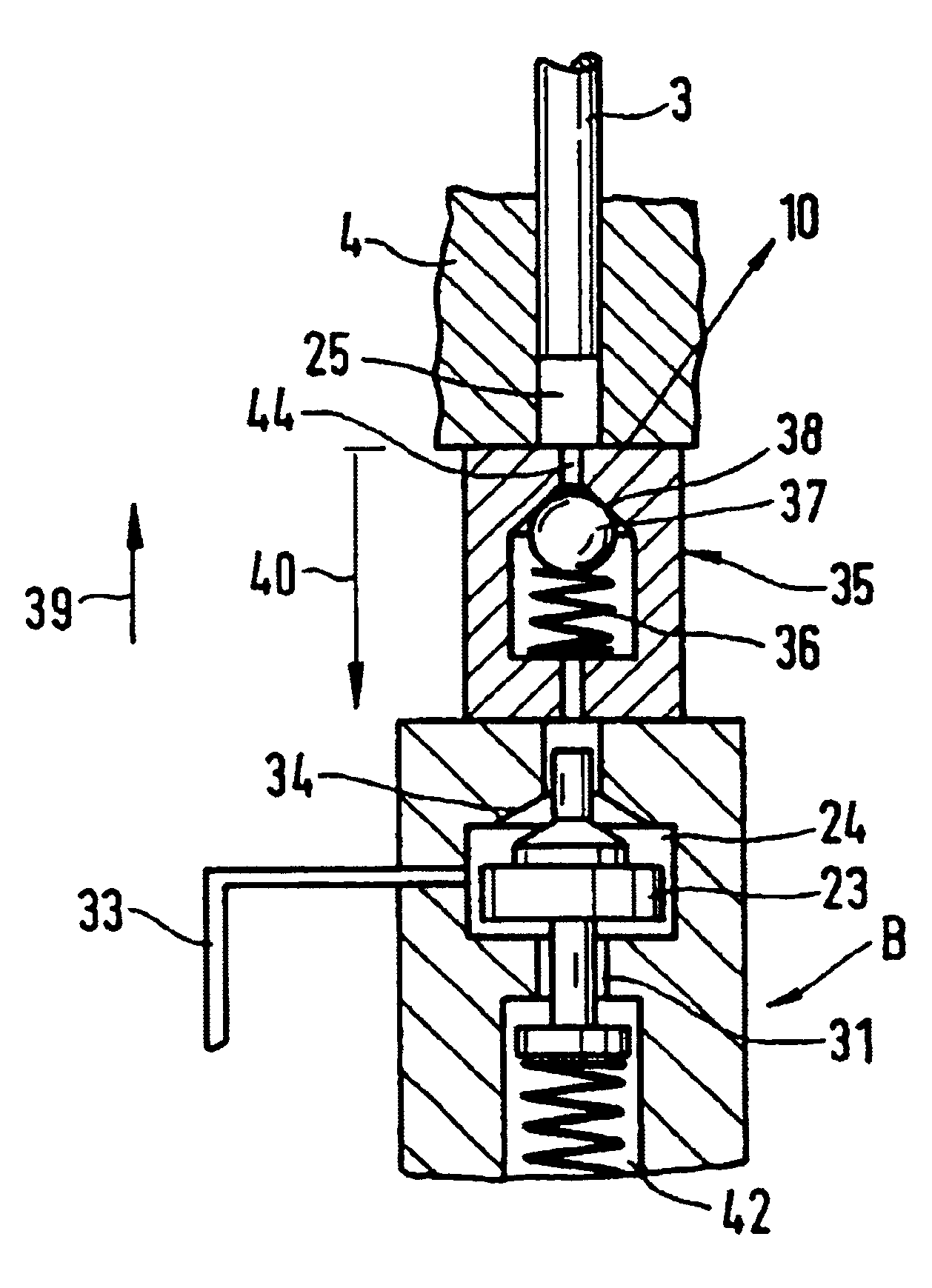

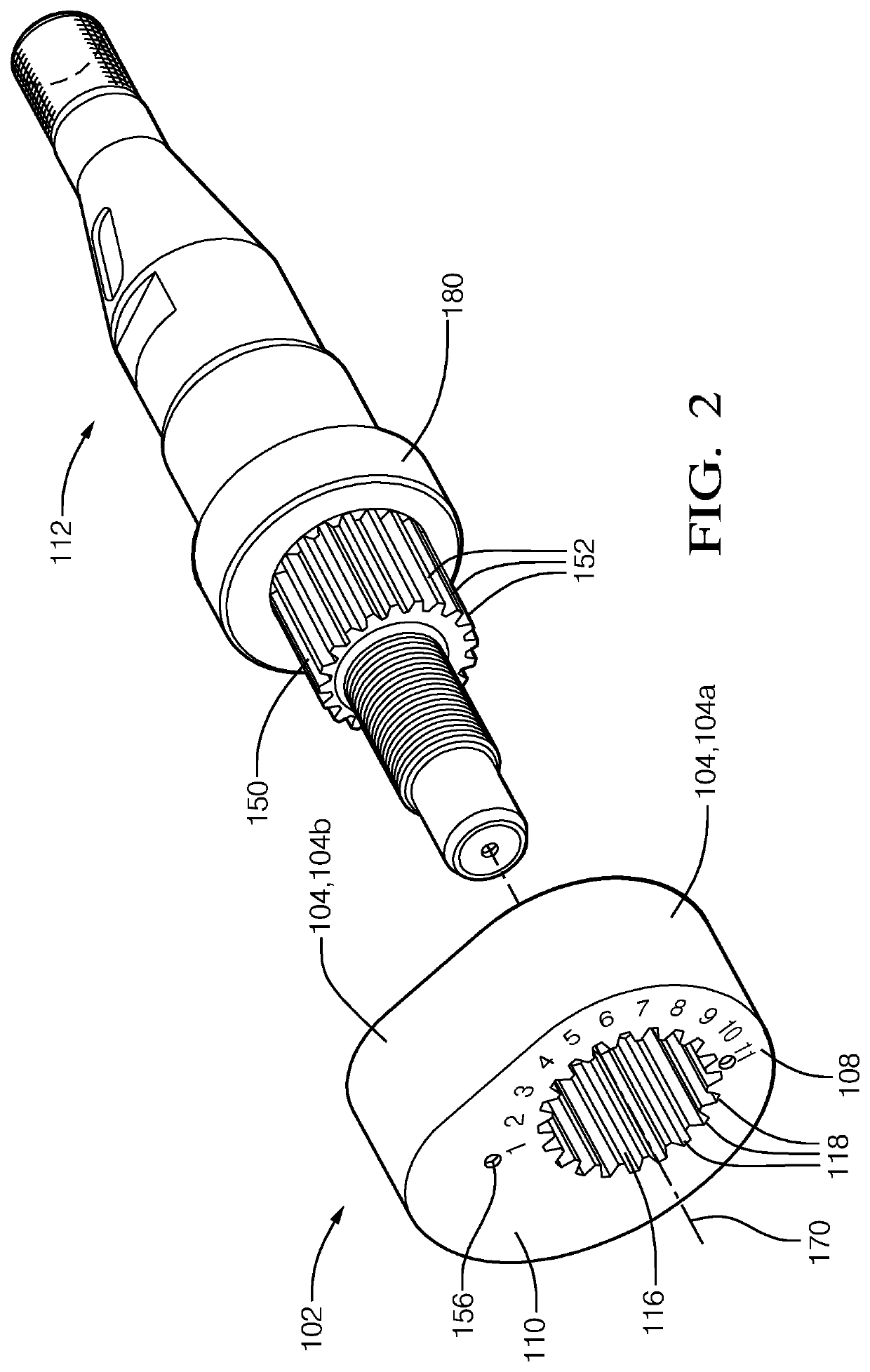

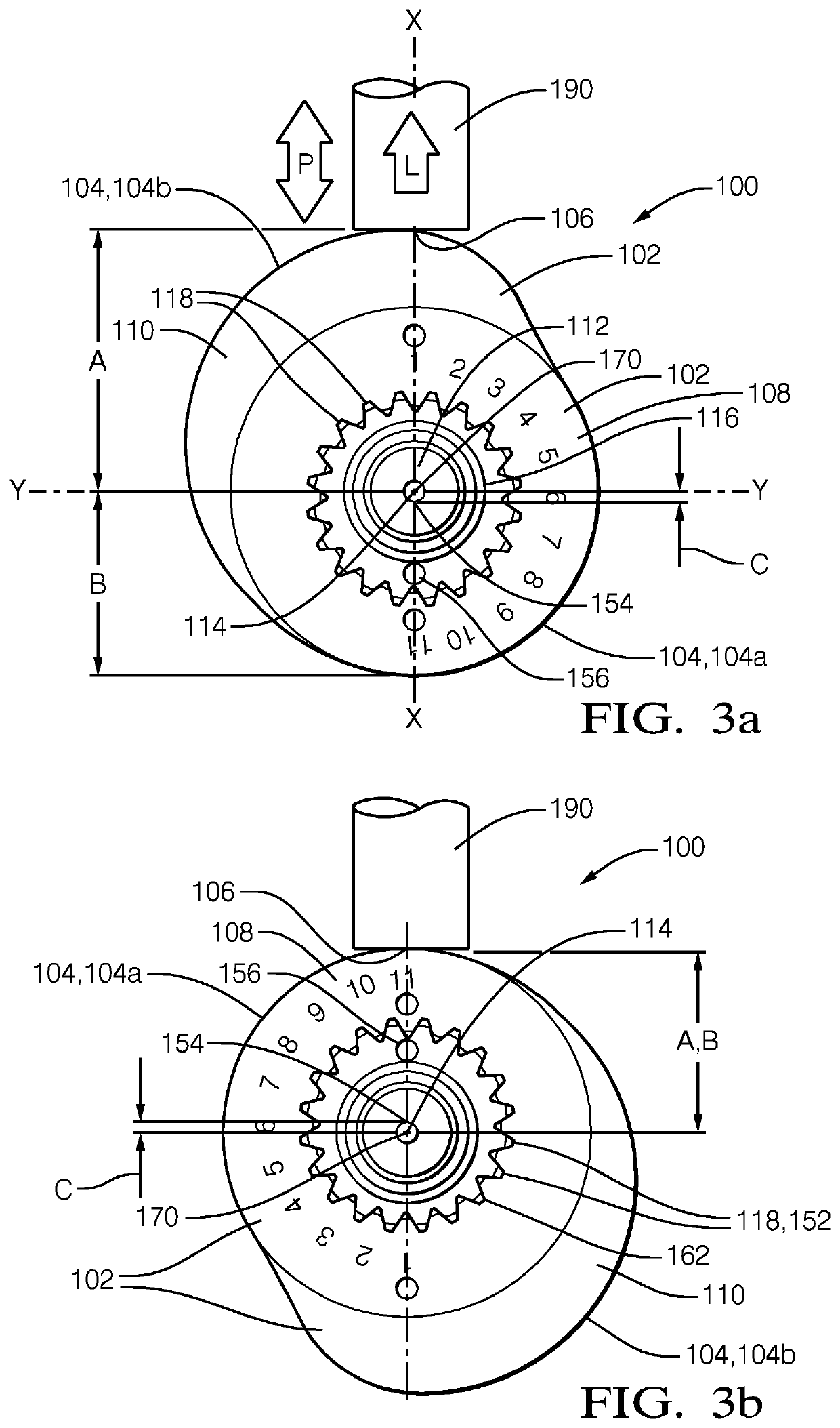

Servo control synchronous advancing device for unit pump or unit oil sprayer

A hydraulically actuated servo piston and hydraulic advance piston are integrated into the cam follower of a unit pump or injector to provide variable advance for an injection event produced by the pump or injector. The servo piston is nested in the advance piston with fluid passageways in the advance piston selectively opened or closed by movement of the servo piston. The full pressure of a hydraulic pump is available to the advance piston for powering the advance function, while stepwise reduced levels of hydraulic pressure from the same hydraulic pump are applied to control movement of the servo piston. A damping orifice restricts flow of hydraulic fluid to and from the servo piston.

Owner:斯塔纳迪恩公司

Driveshaft assembly with indexing means

A driveshaft assembly, for example in an Electronic Unit Injector, Unit Injector or Electronic Unit Pump testing machine, wherein an indexing arrangement, such as complementary external and internal splines, enables a cam to be mounted on a shaft at a number of discreet positions, each providing a different offset of a central axis of the base cylinder section from a central axis of the shaft, each position providing a different maximum lift value of a plunger in contact with the cam, directly or via a rocker arm.

Owner:DELPHI TECH IP LTD

Auto oil injector cleaning connector

An auto oil injector cleaning connector is classified into the mechanical engineering part according to the international patent classification (IPC). The auto oil injector cleaning connector is characterized in that: a stainless steel container is canceled on the basis of the original tool, which saves cost and material; when a factory produces an oil injector cleaning agent, a disposable sealing valve can be adopted without increasing the cost and transportation and storage are safer compared with a previous product; and the product is directly mounted on the auto oil injector cleaning connector, the cleaning agent does not need to be poured into the container, operation procedures are reduced and therefore safety, speed and strong practicability are promoted. The auto oil injector cleaning connector is simple to manufacture and has low cost. The auto oil injector cleaning connector comprises three parts of a valve seat, a valve core and a needle valve. The front end of the valve core is proved with a connecting thread of the oil injector cleaning agent product. An air inlet passage and the solution outlet are separated up and down. The air inlet passage is provided with a sealing hole. The front end of the needle valve can open the oil injector cleaning agent product to have the valve sealed, and the rear end of the needle valve seals the air inlet passage. Air through the air inlet passage of the needle valve is pressed into an oil injector cleaning agent tank. Air pressure makes the oil injector cleaning agent flow out from the solution outlet. During the whole cleaning process, an engine runs smoothly and operation is completed in one time and the connector can be promoted.

Owner:何秋生

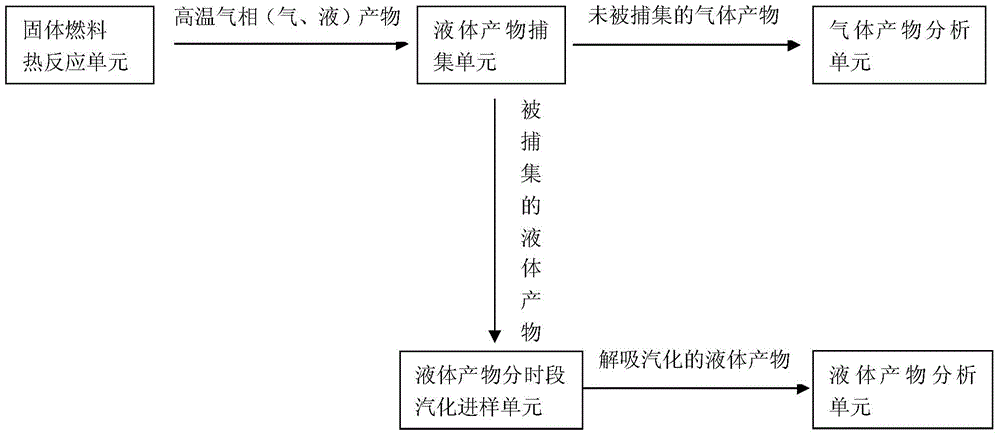

Device and method for on-line detection of composition of solid fuel thermal conversion gas and liquid products

An online detection device and detection method for the composition of solid fuel thermal conversion gas and liquid products in the thermal conversion process, the device is composed of a solid fuel thermal reaction unit, a gas product analysis unit, a liquid product analysis unit, a liquid product capture unit, and a liquid product The time-segmented vaporization sampling unit consists of five parts. The detection method of the present invention is performed using the device of the present invention. The device and method of the invention can continuously monitor the composition of gas products in the thermal conversion process of solid fuel, and carry out discontinuous periodical on-line analysis on the composition of liquid products.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com