Circulated fluid bed boiler and tangential firing method

A circulating fluidized bed and tangential combustion technology, which is applied to fluidized bed combustion equipment, combustion methods, and fuels burned in a molten state, etc. problem, to enhance the ability of penetrating disturbance, reduce the loss of impulse power, and enhance the effect of mixing and mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

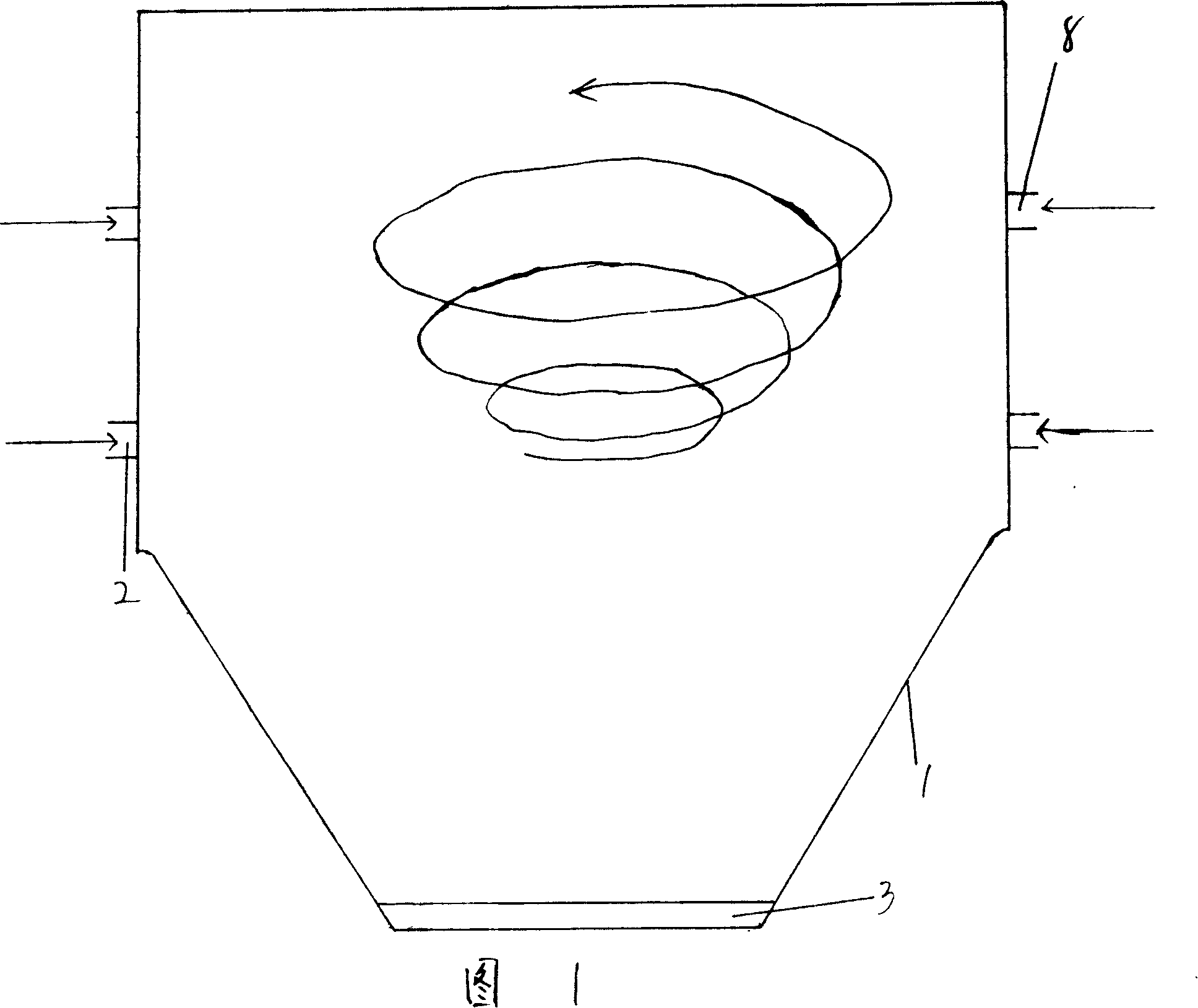

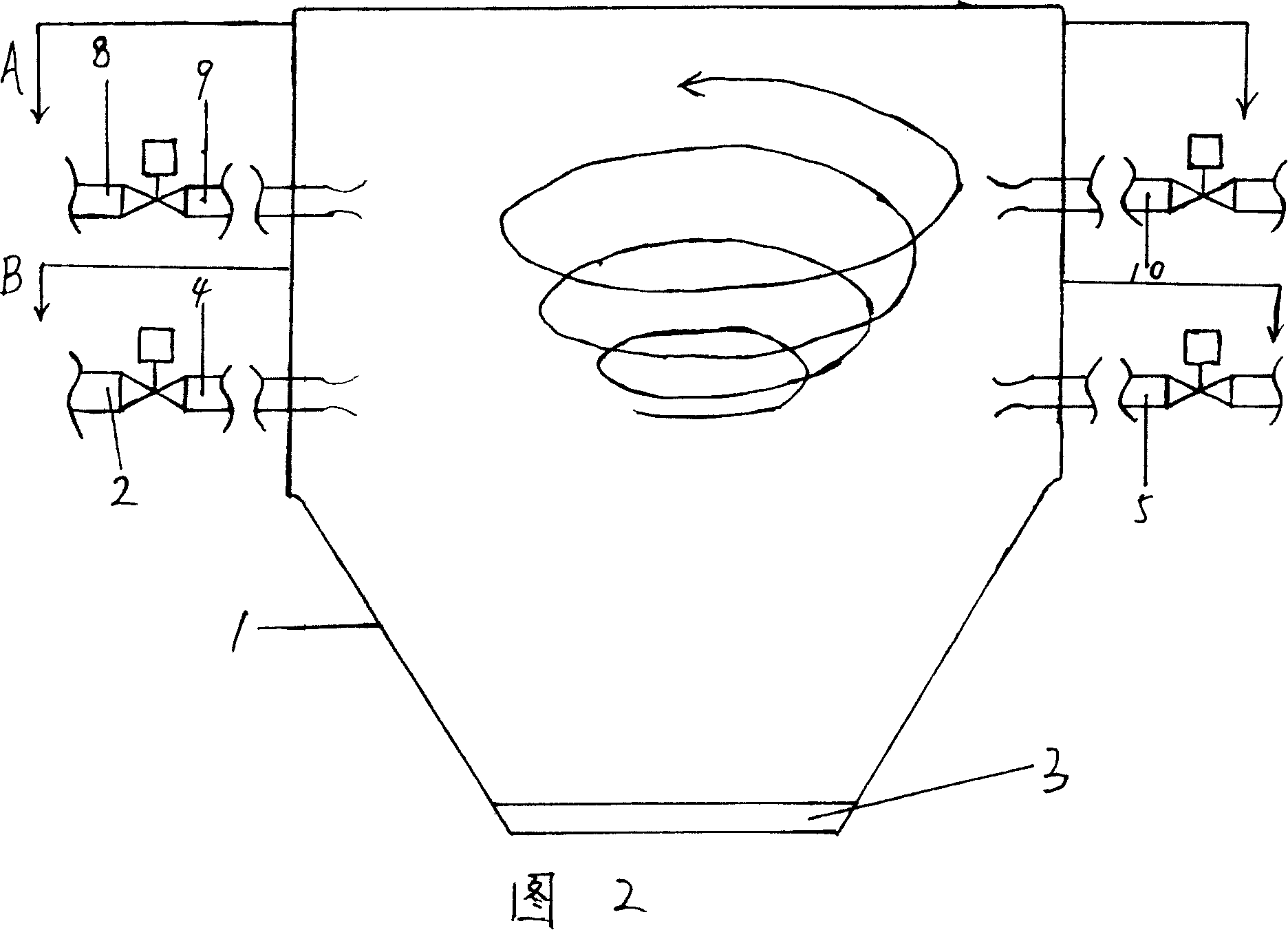

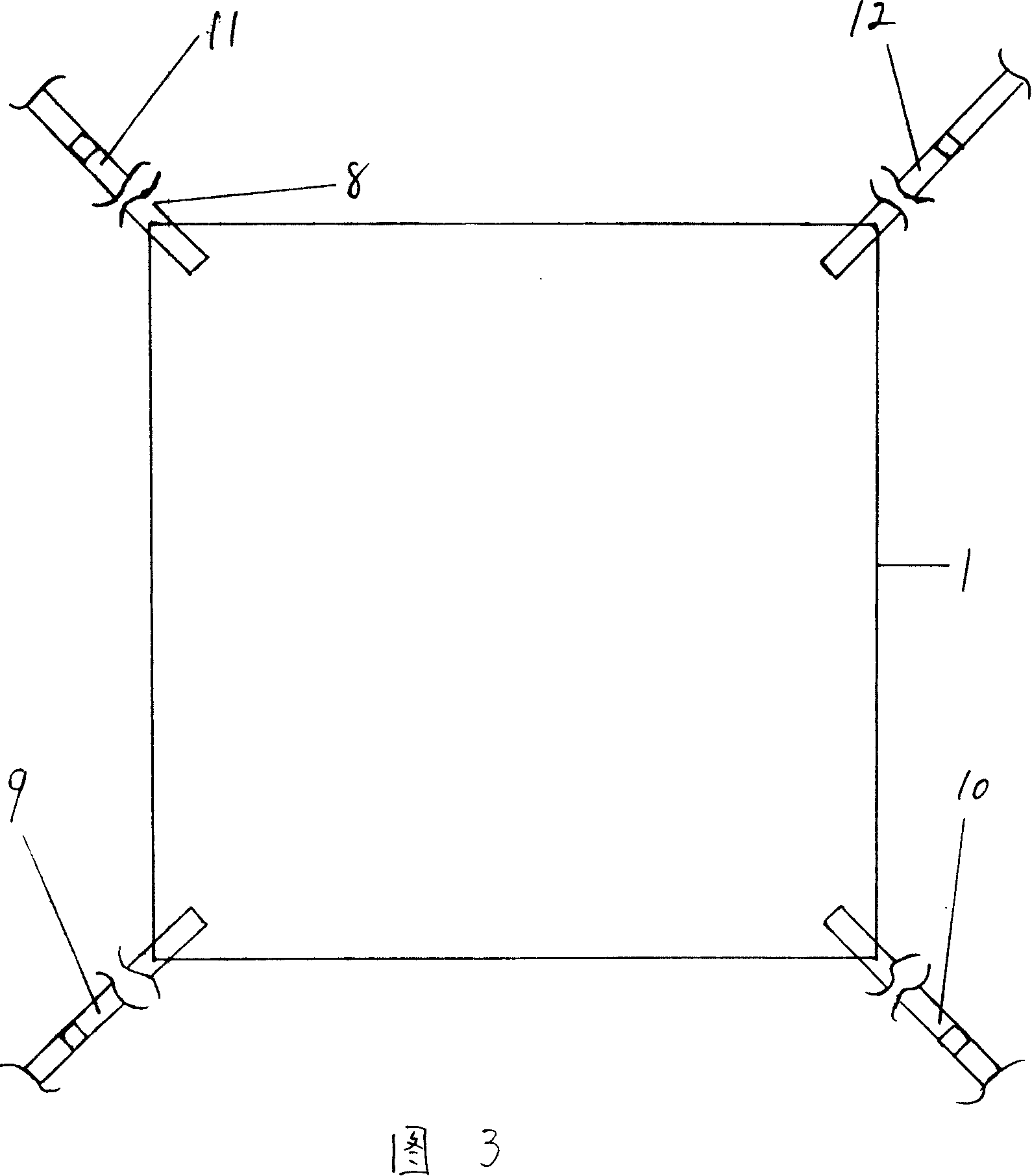

[0020] As shown in Figures 2, 3, 4, and 6, the present invention consists of a furnace body 1 and an air distribution plate 3. The air distribution plate 3 is arranged below the furnace body 1, and materials are placed on it. Above, the lower nozzle device 2 and the upper nozzle device 8 are provided, the lower nozzle device 2 is composed of the first nozzle 4, the second nozzle 5, the third nozzle 6, the fourth nozzle 7, and the upper nozzle device 8 is composed of the fifth nozzle 9, The sixth nozzle 10, the seventh nozzle 11, and the eighth nozzle 12 are composed. The lower nozzle device 2 and the upper nozzle device 8 nozzle devices are respectively arranged at the four corners of the horizontal section of the two furnace bodies, the lower nozzle device 2 is horizontally arranged, and the upper nozzle device 8 is inclined 5 downwards. On the same horizontal plane, the centerlines of the same group of nozzles arranged at four corners form a tangential circle in the furnace....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com