Method and system for liquid fuel conditioning

A fuel conditioning and gas fuel technology, which can be used in liquid fuel feeders, charging systems, fuel heat treatment devices, etc., and can solve problems such as complex designs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

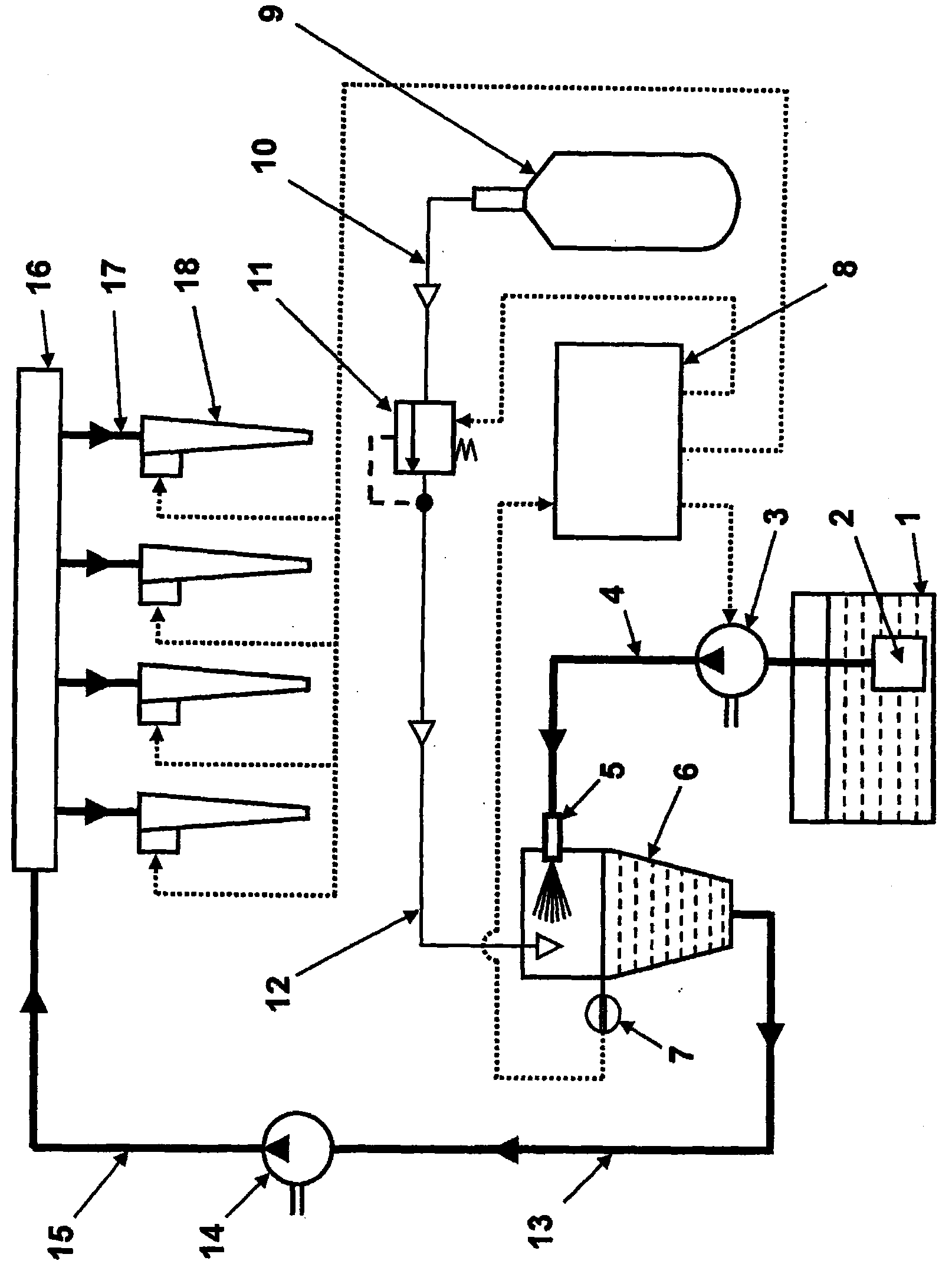

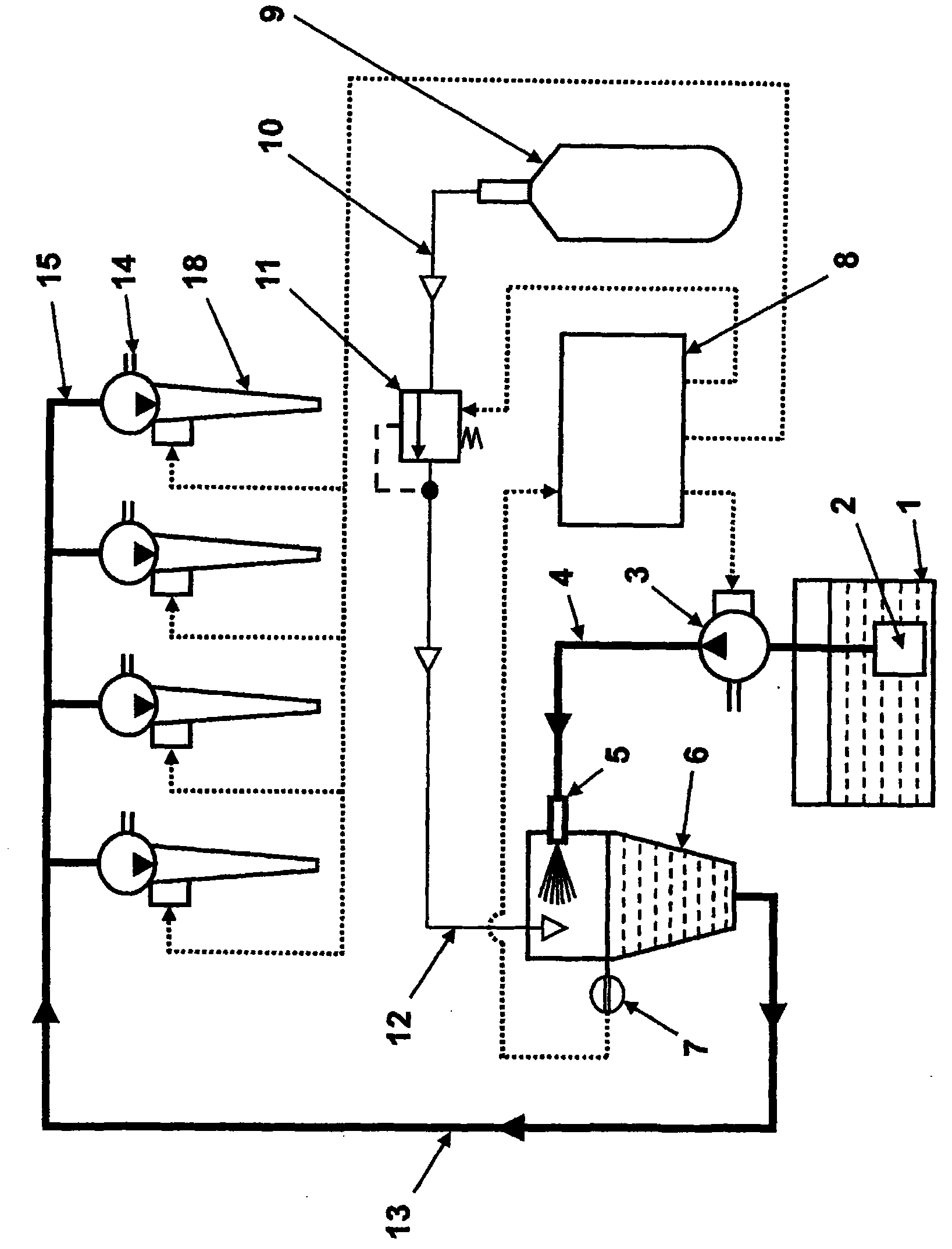

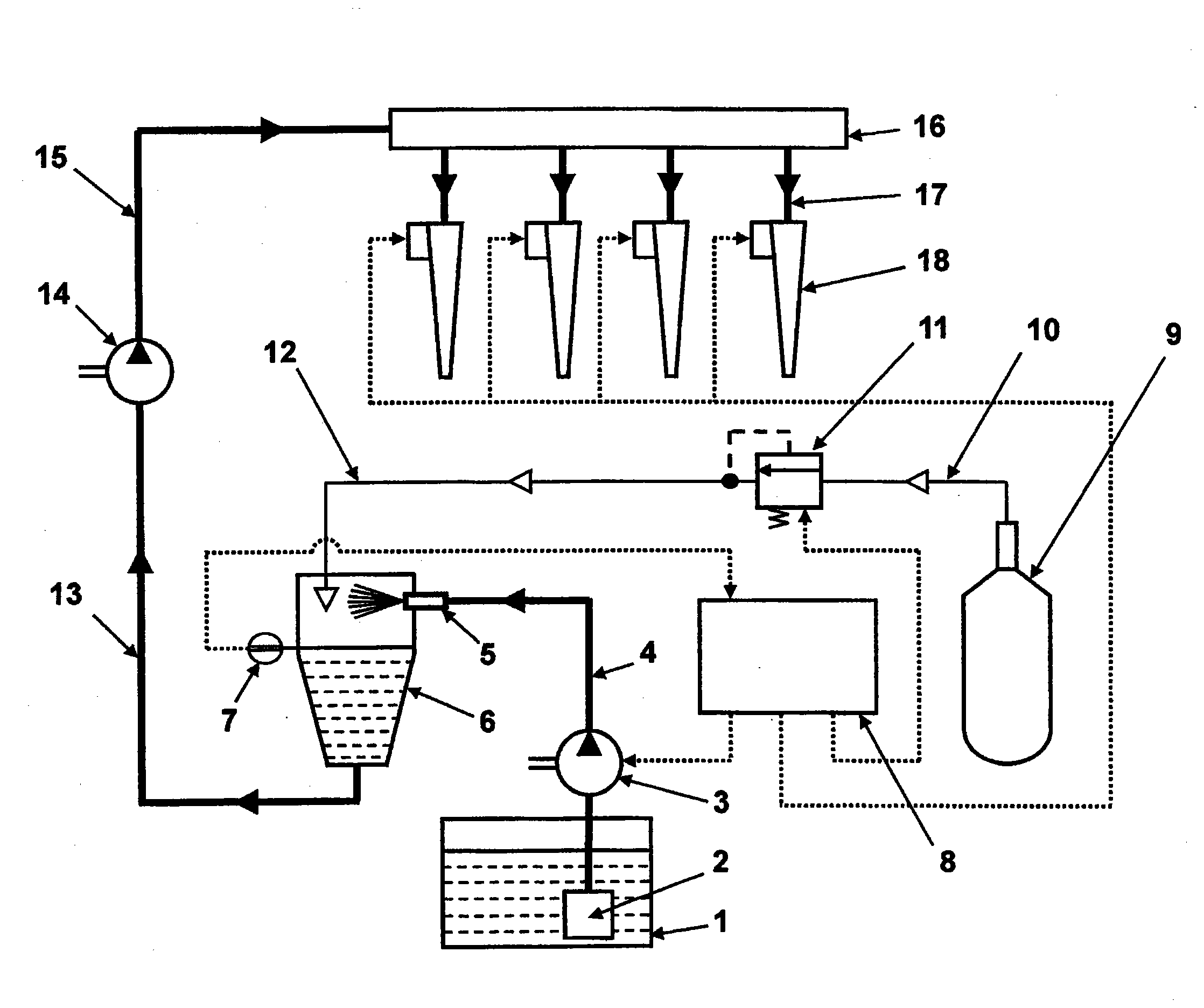

[0043] Referring now in detail to the attached figure 1 , the system consists of a fuel tank 1, a fuel filter 2, a low-pressure fuel pump 3 for delivering liquid fuel from the fuel tank 1 through a fuel line 4 to at least one diffuser nozzle 5 mounted in a fuel conditioning container 6 . Low-pressure fuel pump 3 provides fuel pressure P 1 . The level of fuel in the fuel regulating container 6 is controlled by a sensor 7 . Compressed gas 9 (e.g. air, CO 2 , oxygen, gas mixture, etc.) is jet-fluidically connected to the inlet of the pressure reducer 11 through the line 10, and the pressure reducer 11 controls the gas pressure downstream of the pressure reducer 11 in the line 12 at the level P 2 .

[0044] Pressure P 2 set to be lower than the fuel pressure P established by the low pressure fuel pump 3 at a level that provides satisfactory operating conditions for the nozzles 5 1 . Diffusion of the fuel in the gas achieves a sufficient amount of gas dissolved in the fuel....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com