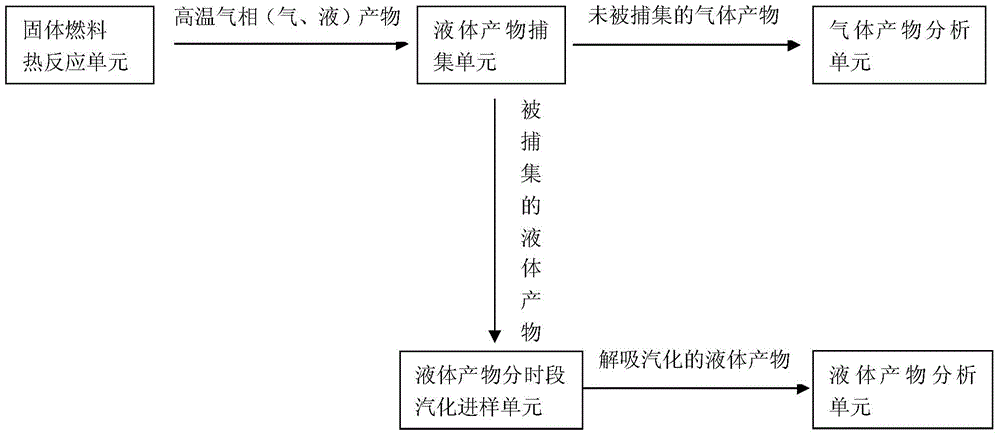

Device and method for on-line detection of composition of solid fuel thermal conversion gas and liquid products

A solid fuel and detection device technology, applied in the direction of fuel oil testing, material inspection products, etc., can solve the problems of reduced readability of IR spectrum, abnormally complex composition of pyrolysis products, difficult gas and effective detection of liquid product composition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation before the test: crush the Huolinhe coal dried at 120°C into pulverized coal with a diameter of less than 0.3mm, take 10mg of the pulverized coal sample and place it on a metal platinum plate, close the micro thermal conversion reactor (electric heating plate cracker), and open Helium (carrier gas) and control the flow rate of 30ml / min; the gas chromatography / mass spectrometer (Varian 3800-GC300-MS, Varian Company, USA) is in the power-on and stable state, and the analysis is performed in full scan mode, and the mass spectrum mass range is set 50-800; turn on the Raman spectrometer (HR800, laser 514nm, to sample power 6mW, scanning range 500-4300cm -1 ); the temperature of the liquid product trapping unit composed of 50 Tenax adsorption columns arranged in parallel in a disk shape is controlled at 40°C to condense the high-temperature gas phase liquid into liquid precipitation; the temperature of the high-temperature vaporizer is controlled at 300°C, and the ...

Embodiment 2

[0048] Preparation before the test: load the pine wood powder (24mg, particle size less than 0.4mm) dried at 120°C in a special ceramic crucible for a thermogravimetric analyzer, and place the dry pot after loading the sample on the balance support to seal the micro-thermal conversion reaction device (thermogravimetric analyzer furnace body), while feeding air (reaction gas doubles as carrier gas, 60ml / min); state, analyze in full scan mode, set mass spectrum mass range 50-800; turn on Raman spectrometer (HR800, laser 514nm, to sample power 6mW, scan range 500-4300cm -1 ); the temperature of the liquid product trapping unit composed of 50 self-made condensation adsorption columns (inner diameter 4mm, length 20mm, particle size <0.1mm silica gel packing) arranged in a disc shape is controlled at 0°C to condense the high-temperature gas phase liquid into a liquid state Precipitation; the temperature of the high-temperature vaporizer is controlled at 300°C, at which temperature t...

Embodiment 3

[0051] Preparation before the test: crush the Huadian oil shale dried at 120°C into a powder with a diameter of less than 0.3 mm, take 1.2 mg of the sample and place it in a quartz tube wrapped with a helical platinum wire, and close the miniature thermal conversion reactor (electric heating cracker), turn on the helium (carrier gas) and control the flow rate to 30ml / min; the gas chromatography / mass spectrometer (Varian3800-GC 300-MS, Varian Company, USA) is in a power-on and stable state, and analyzes in full-scan mode , set mass spectrum mass range 50-800; open Raman spectrometer (HR800, laser 514nm, to sample power 6mW, scan range 500-4300cm -1 ); the temperature of the liquid product trapping unit composed of 50 self-made condensation adsorption plates (a square glass plate with a side length of 10 mm, and a silica gel filler with a thickness of 0.5 mm on the surface) is controlled at -20 ° C. The high-temperature gas phase liquid is condensed into liquid precipitation; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com