Inlaying-combination type oil sprayer

A fuel injector and combined technology, applied in the direction of machines/engines, fuel injection devices, engine components, etc., can solve problems such as increased fuel consumption, decreased fuel atomization quality, and affecting normal operation of the engine to achieve fuel saving, The effect of precise control of oil intake and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

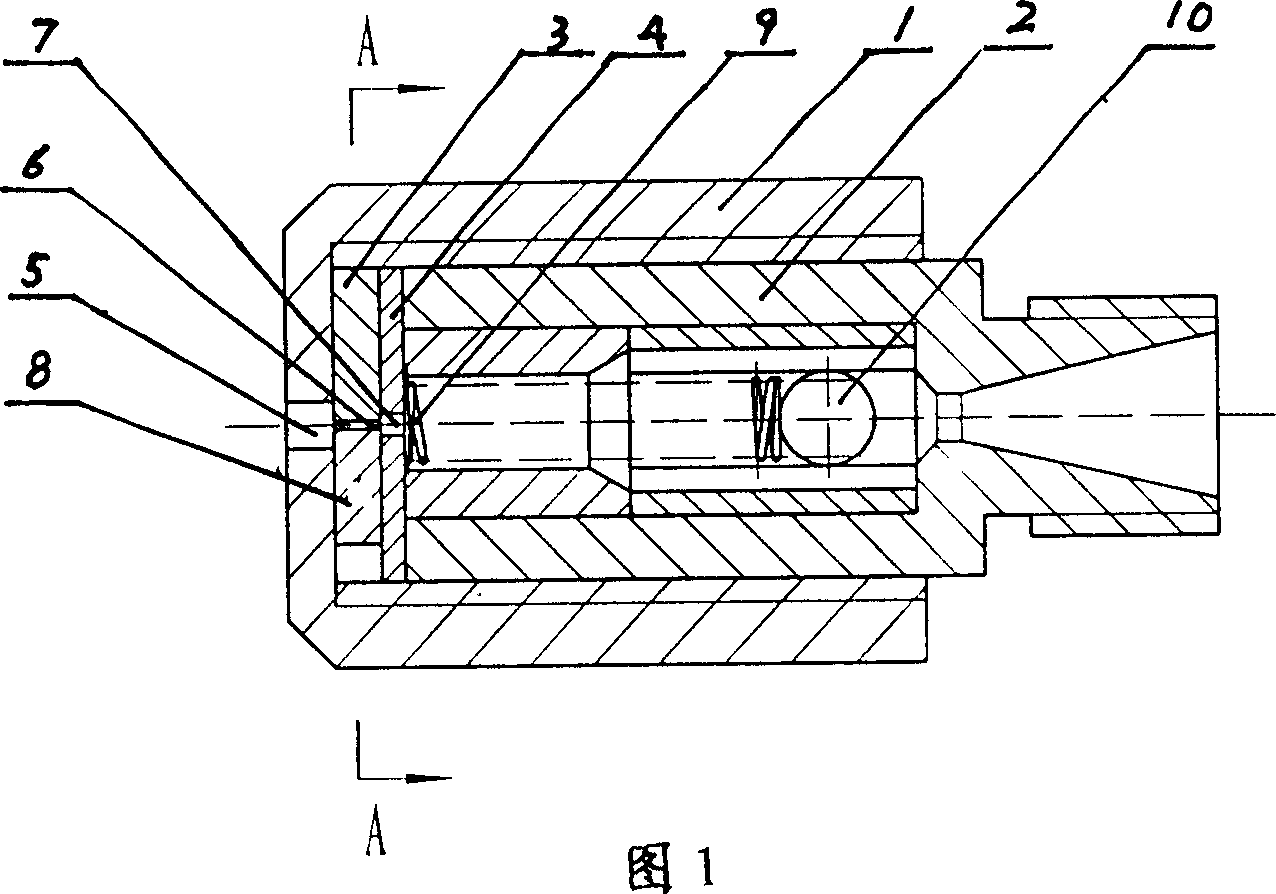

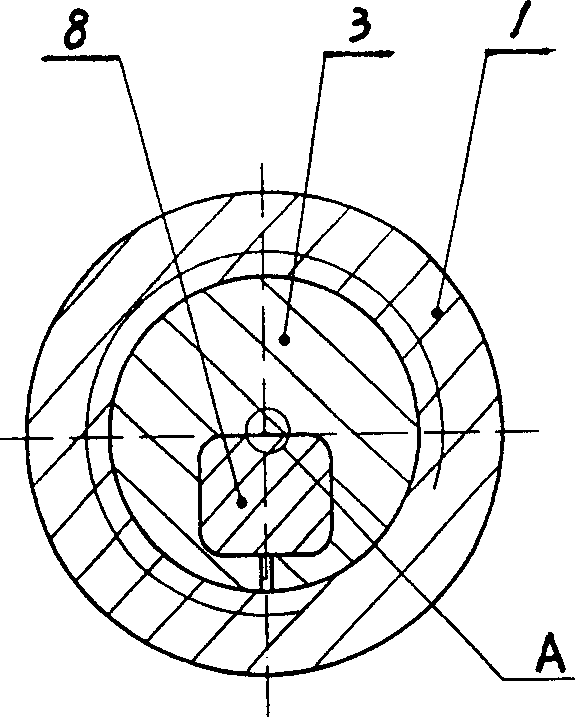

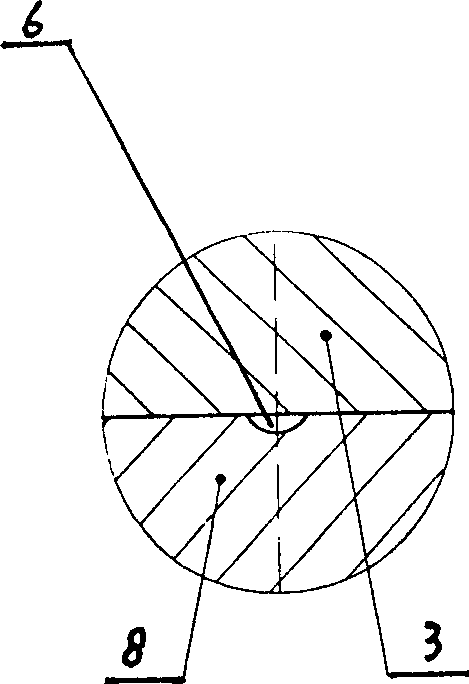

[0028] Embodiment one: the first scheme of the present invention. Referring to Fig. 1, Fig. 2 and Fig. 3, the steel ball 10 is installed in the oil inlet of the check valve 2, and one end of the compression spring 9 is close to the steel ball 10; a square restrictor plate 8 is embedded in the In the middle of the orifice plate 3, there is a micro gap between the orifice plate and the limiting plate, which is the injection hole 6; the limiting plate, the orifice plate and the injection hole can be cut by wire cutting machine processing;

[0029] Referring to Fig. 1, put the orifice plate 3 and the partition plate 4 inlaid with the flow limiting plate 8 into the casing 1, and connect the check valve 2 with the casing, and the orifice plate 3 and the partition plate 4 are located on the inner end surface of the casing Between and the front end of the one-way valve, the oil outlet 5 at the end of the jacket is opposite to the oil injection hole 6 on the orifice plate, and the oil...

Embodiment 2

[0031] Embodiment two: the second scheme of the present invention. see Figure 12 As shown in Fig. 15, the orifice plate 3 and the partition plate 4 embedded with the flow limiting plate 8 are put into the casing 1, and the one-way valve 2 is connected with the casing, and the orifice plate 3 and the partition plate 4 are located on the inner end surface of the casing Between and the front end of the one-way valve, the oil outlet 5 at the end of the jacket is opposite to the oil injection hole 6 on the orifice plate, and the oil injection hole on the orifice plate is opposite to the oil passage hole 7 on the separator, and the separator The oil hole on the top communicates with the one-way valve, and the other end of the compression spring 9 installed in the one-way valve is close to the separator 4; one end of the oil inlet of the one-way valve 2 is processed to be perpendicular to the oil inlet passage. A square hole 11, a pressure regulating seat 13 is installed in the squ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com