Trickle falling film type evaporator device and use method

A falling film evaporator and dripping technology, which is applied in the field of dripping falling film heat exchange container devices, can solve the problems of uneven dripping, insufficient oil return, and reduced heat transfer performance, and improve heat transfer performance. , The gasification process is sufficient and the effect of reducing the charging amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

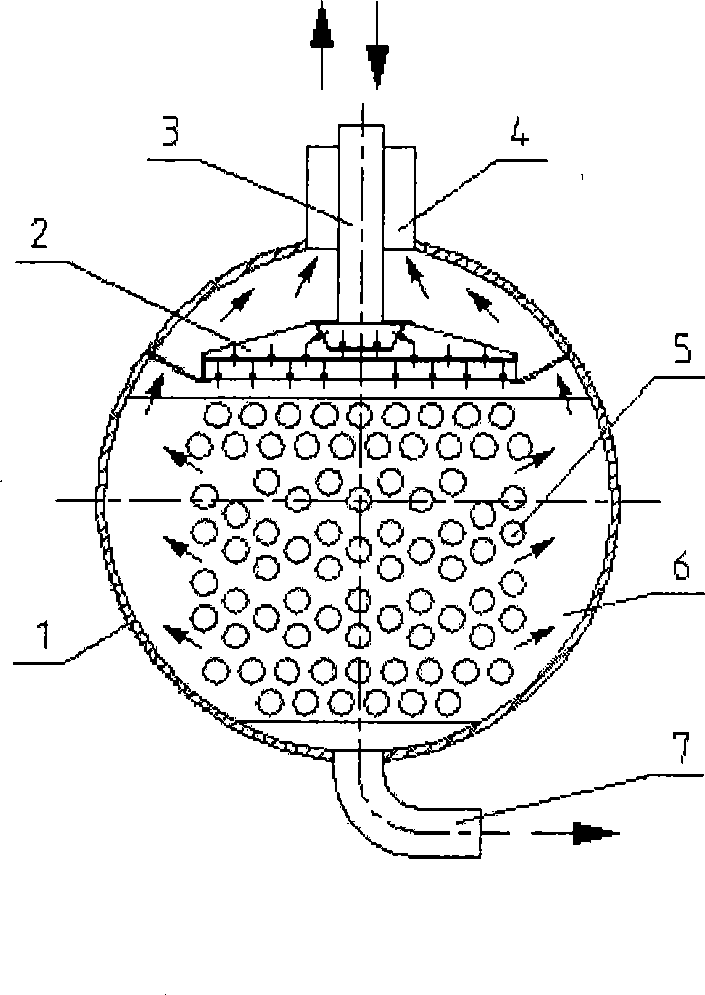

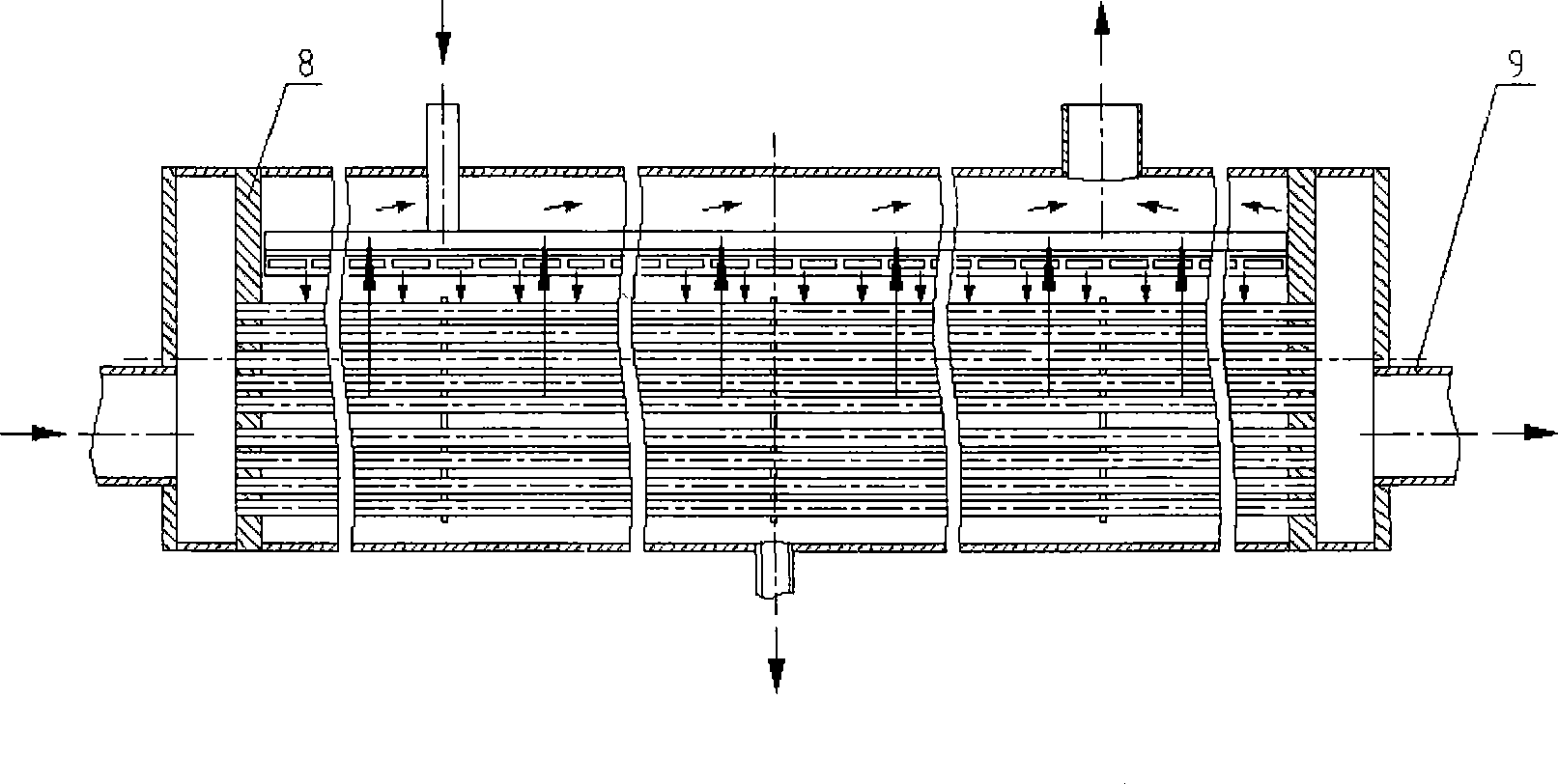

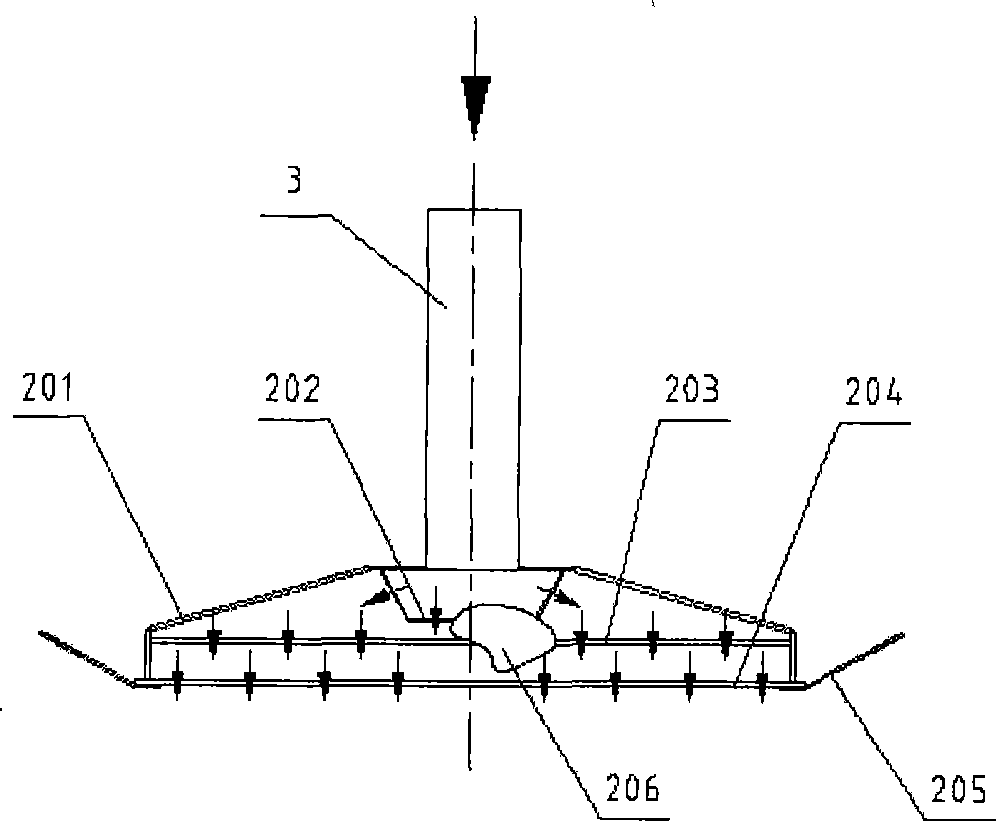

[0017] Attached below figure 1 , 2 , 3 and embodiment further illustrate the present invention:

[0018] This embodiment is a dripping falling film evaporator device used in refrigeration and air-conditioning units with a cooling capacity of 500kW and a model EJM26HJ. It is composed of a cylinder 1, a two-phase refrigerant distributor 2, a liquid inlet pipe 3, Suction pipe 4, evaporator tube bundle 5, support plate 6, oil return interface 7, tube plate 8 and brine inlet and outlet 9, trapezoidal shell 201, multi-directional distribution plate 202, primary distribution orifice plate 203, secondary distribution The orifice plate 204, the air suction distribution plate 205 and the end sealing plate 206 are composed of each part according to the attached figure 1 , 2 , 3 to install the structure given, wherein: the outer diameter of the cylinder 1 is Φ516mm, the length is 2600mm, and it is rolled by steel plate; Up and down in the steel cylinder 1, the two-phase refrigerant di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com