Servo control synchronous advancing device for unit pump or unit oil sprayer

A servo and advancer technology, applied in fuel injection control, engine control, fuel injection pump, etc., can solve the problem of high fuel injection volume and achieve the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

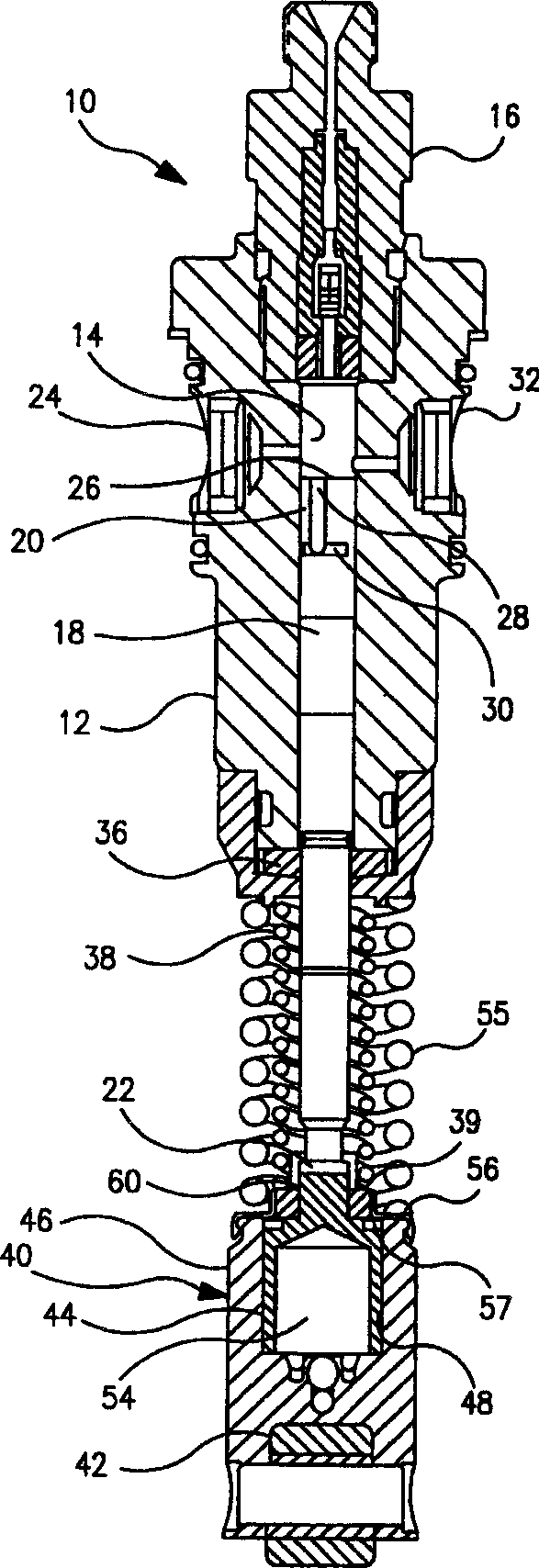

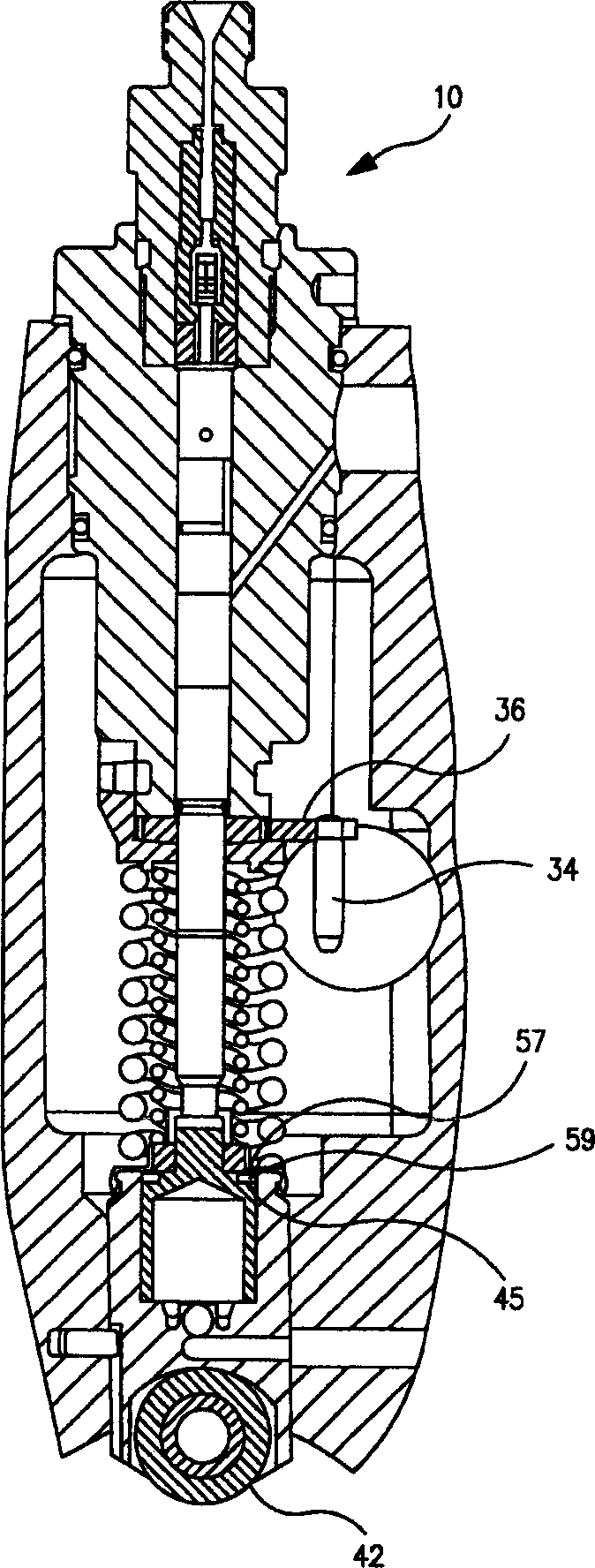

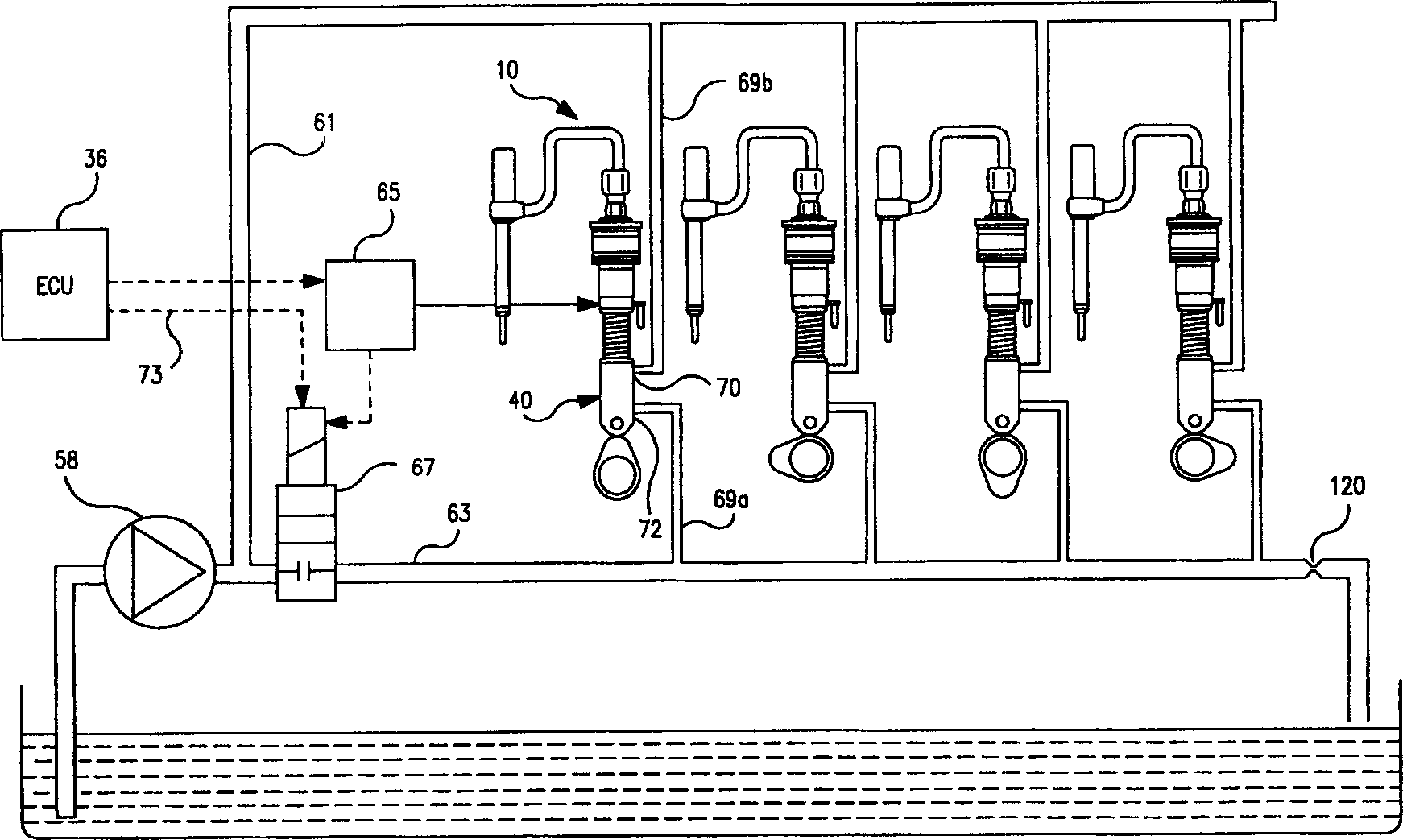

[0028] Figure 1A with 1BIllustrated is a fuel injection unit pump 10 or unit injector that can be modified by the present invention. Isocratic pump 10 includes a body 12 defining a longitudinal suction chamber 14, with a head 16 mounted at one end of the body coaxially with the suction chamber. A generally cylindrical suction plunger 18 is disposed within the suction chamber 14 for reciprocating movement therein. The suction plunger 18 has a suction end 20 disposed towards the head 16 and a counter-drive end 22 projecting from the unit pump body 12 . An infusion / overflow opening 24 is provided in the body 12, and movement of the leading edge 26 of the plunger suction end 20 past the infusion / overflow opening determines the start of the infusion process. The upper and lower channel portions 28 , 30 partially surround the outer diameter of the suction plunger 18 . The alignment of the lower passage portion 30 with the fill / overflow port 24 is used to determine the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com