Auto oil injector cleaning connector

A technology of fuel injectors and connectors, which is applied in the direction of machines/engines, engine components, mechanical equipment, etc., and can solve problems such as unsafe operation and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

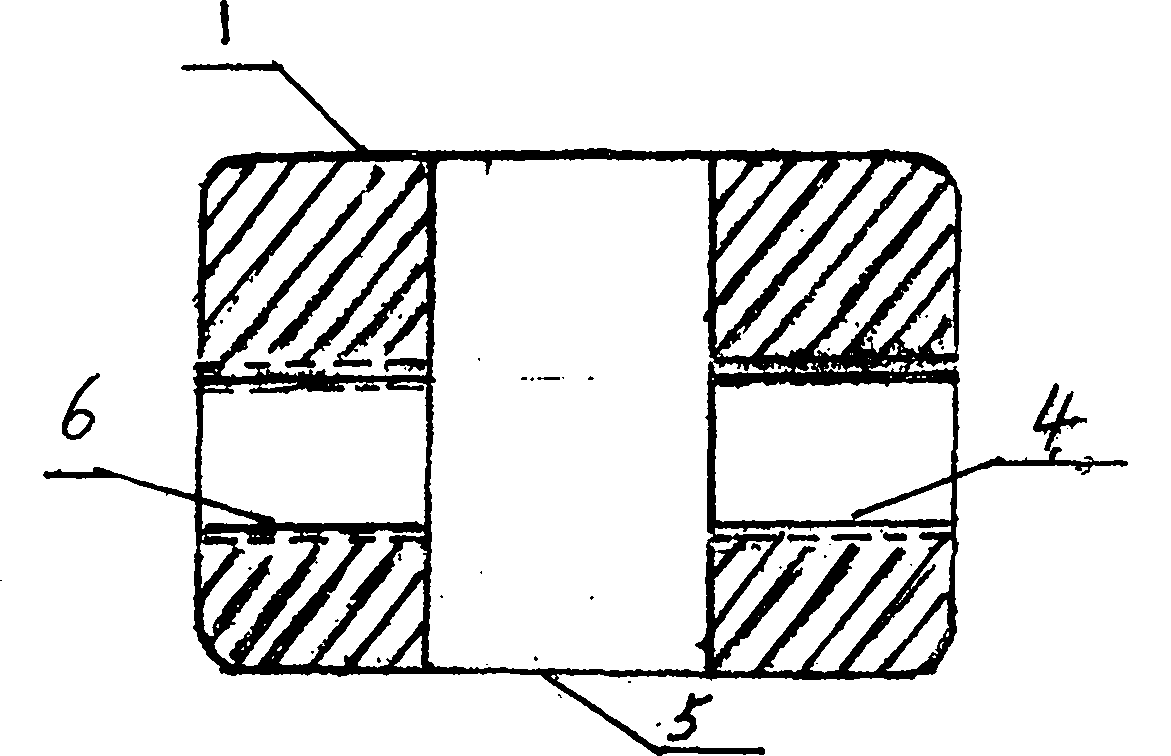

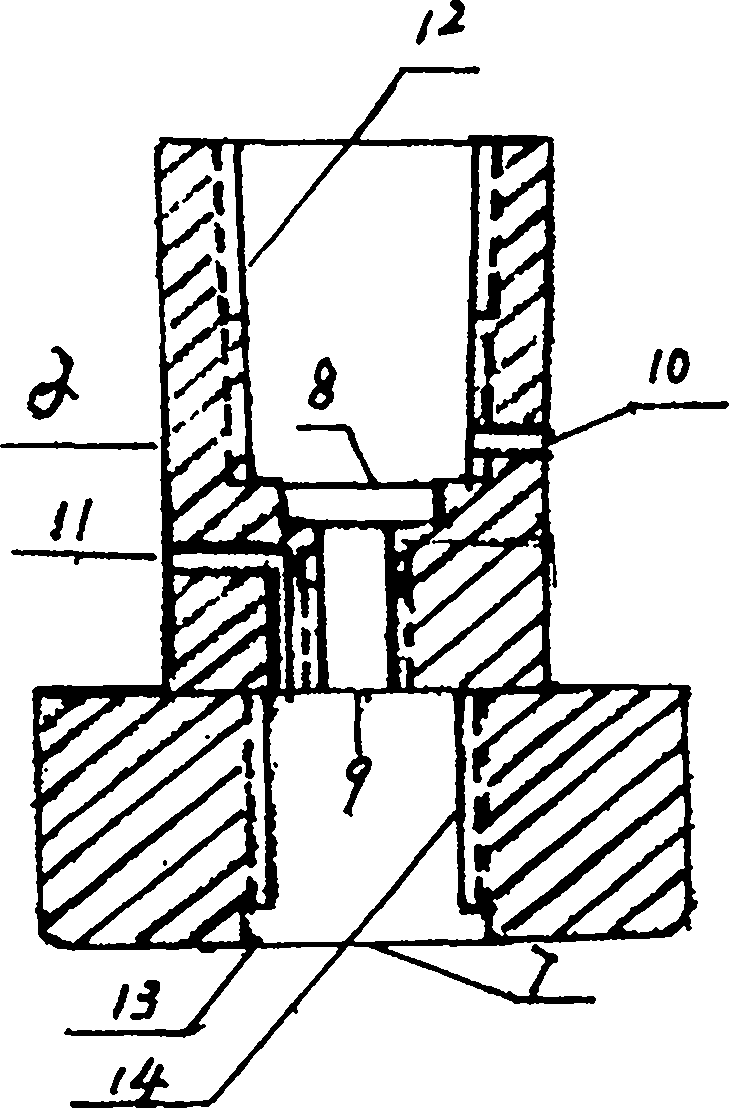

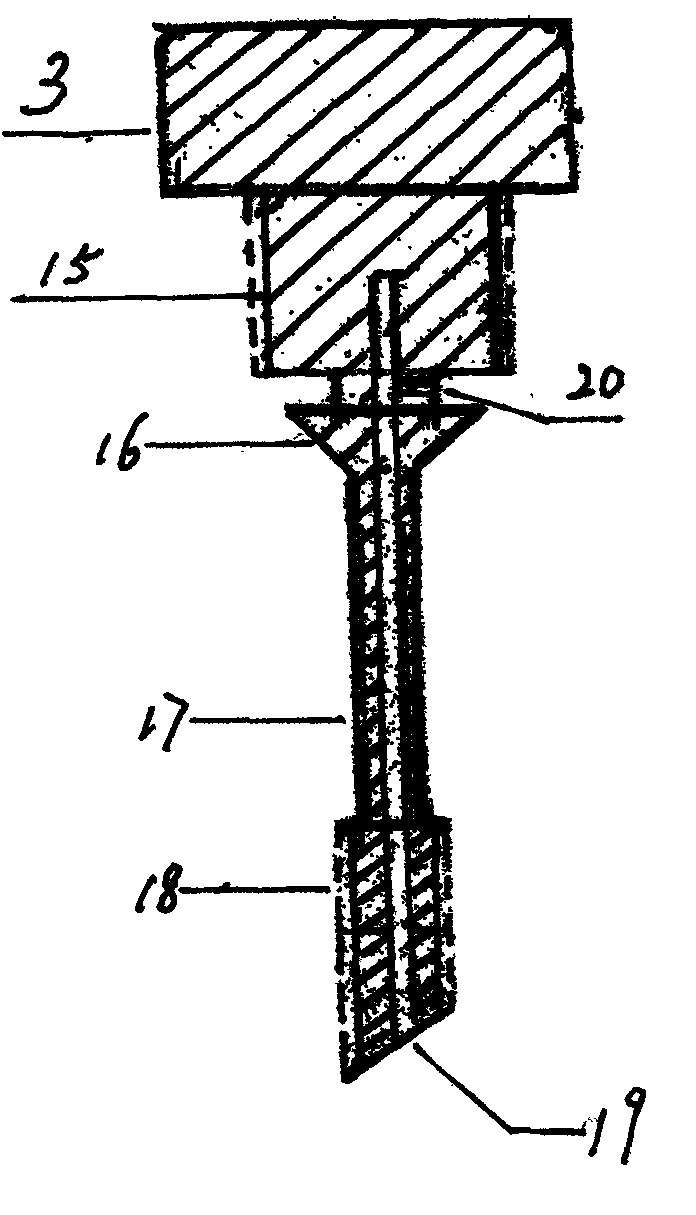

[0005] The embodiment of the automotive fuel injector cleaning connector invented by the utility model: the valve core (2) is pressed into the valve seat (1) to tightly fit into the connection hole (5), and one side of the valve seat (1) is connected to the pressure gauge (4) , the other side is connected to the intake switch (6), the valve needle (3) enters the valve core (2) through the connecting thread (12), the front end (18) of the valve needle (3) is threaded to the valve core (9), and the oil injection Nozzle cleaner product connection thread (14), turn the front end (18) of the needle valve (3) to open the product sealing valve, the air enters the spool channel (19) from the air intake channel (10), and enters the nozzle cleaner product bottle , at the same time, the needle valve (16) seals the sealing hole (8), the air intake channel (20) is separated from the solution outlet (11), and because the air intake channel is higher than the solution outlet, the air pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com