Main machine structure of simulation test machine for evaluating blockage ratio of electronically-controlled oil injector of gasoline engine

A simulation test, electronically controlled fuel injection technology, applied in the testing of machine/structural components, engine testing, machine/engine, etc., can solve the problem that the bench test does not have fast, online detection, time-consuming, and cannot express electronically controlled injection. Problems such as the state of deposits on the needle valve of the oiler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] According to the following detailed description of specific embodiments of the application in conjunction with the accompanying drawings, those skilled in the art will be more aware of the above and other objectives, advantages and features of the application.

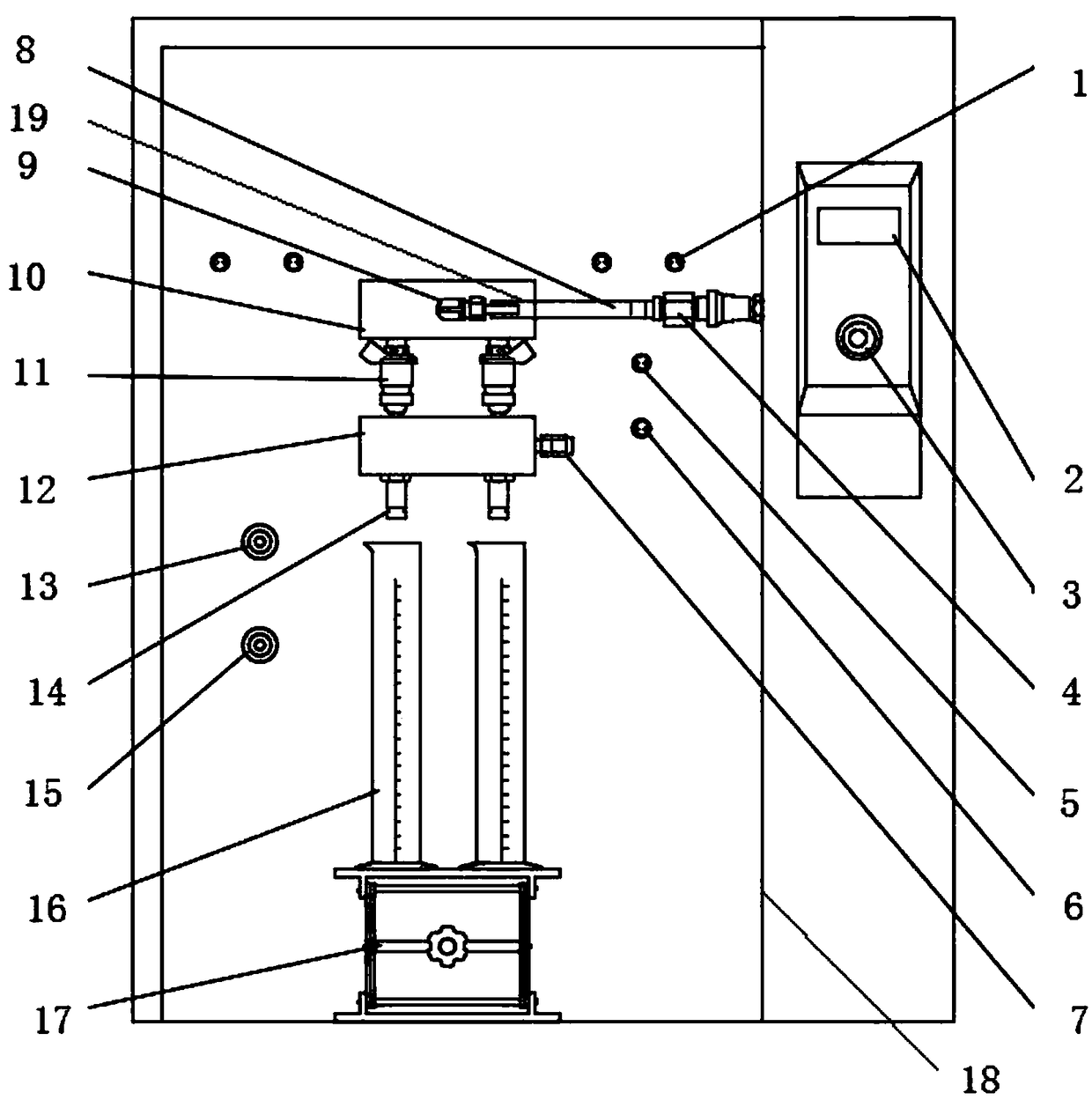

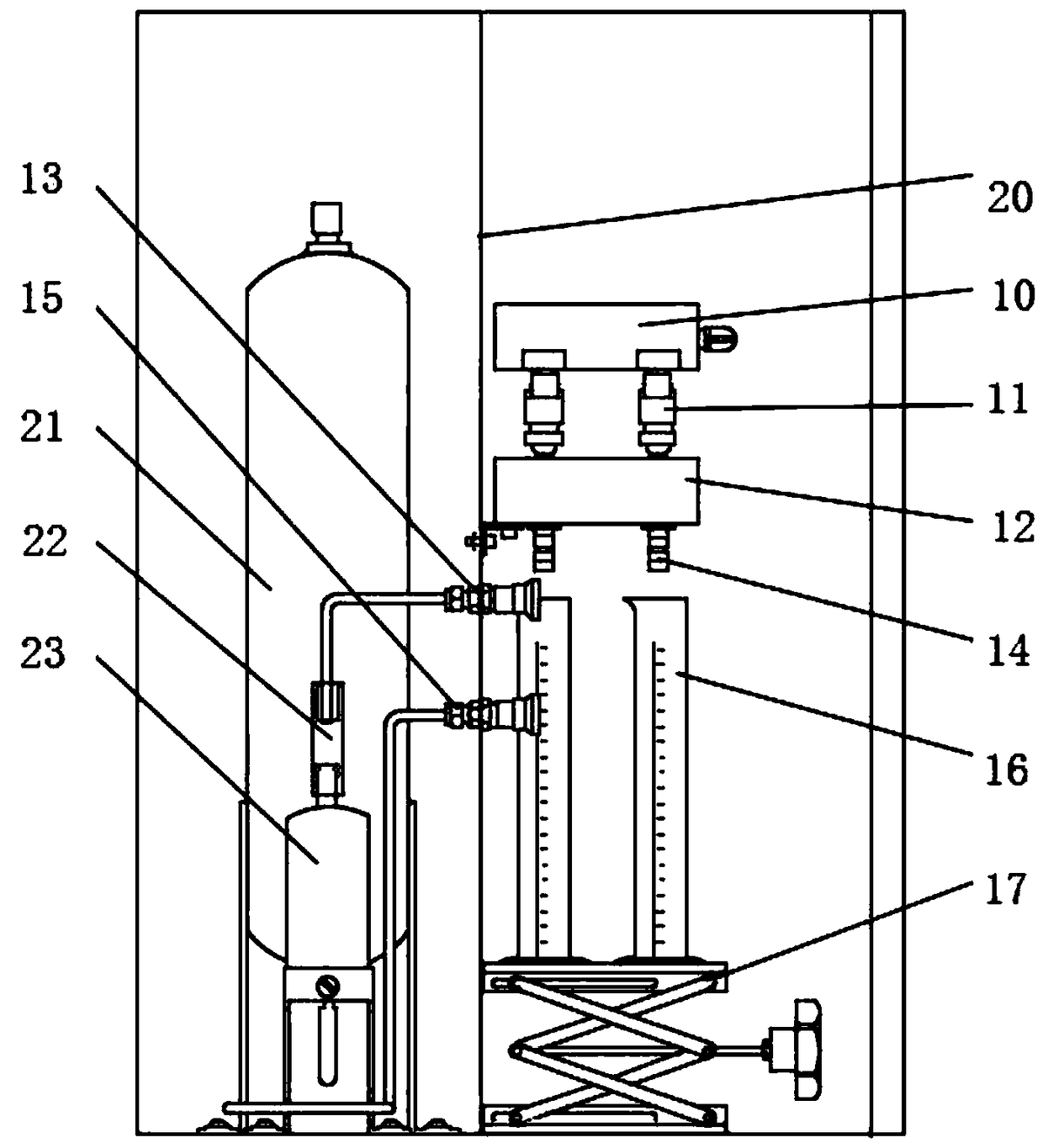

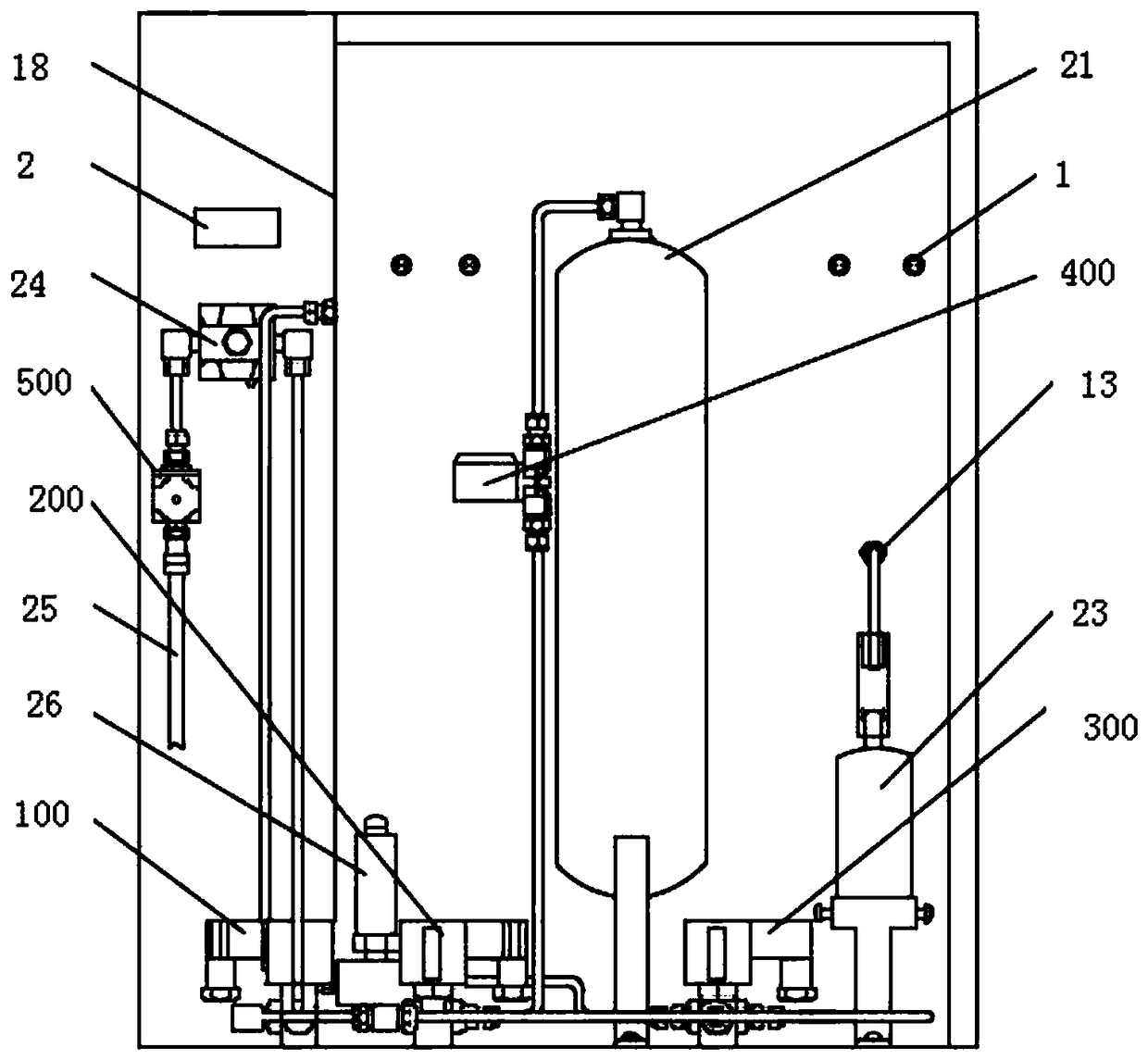

[0056] Figure 1 to Figure 3 One embodiment of the simulated test device of the present application is shown. This embodiment discloses a simulation test device for testing at least one electronically controlled fuel injector 11 . The simulation test device includes: a nitrogen pressure regulating device, a fuel storage device 21, a fuel distributor 10, a heating block 12 and a measuring device.

[0057] Wherein, the fuel storage device 21 is connected with the nitrogen pressure regulating device; the fuel distributor 10 communicates with the fuel storage device 21, and the lower end surface of the fuel distributor 10 is also connected with the electronic control injector 11 The heating device is used to heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com