Withdrawal tool of oil injector needle valve

A technology for disassembling tools and fuel injection nozzles, which is applied to fuel injection devices, engine components, machines/engines, etc. Simple, improve work efficiency, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

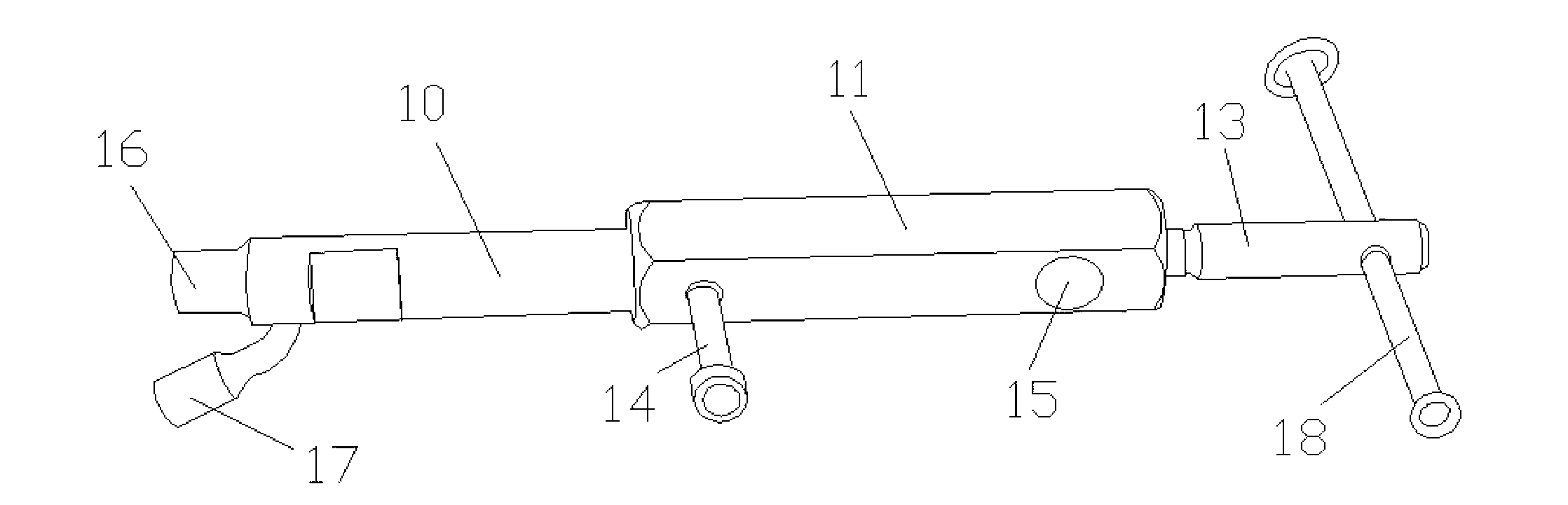

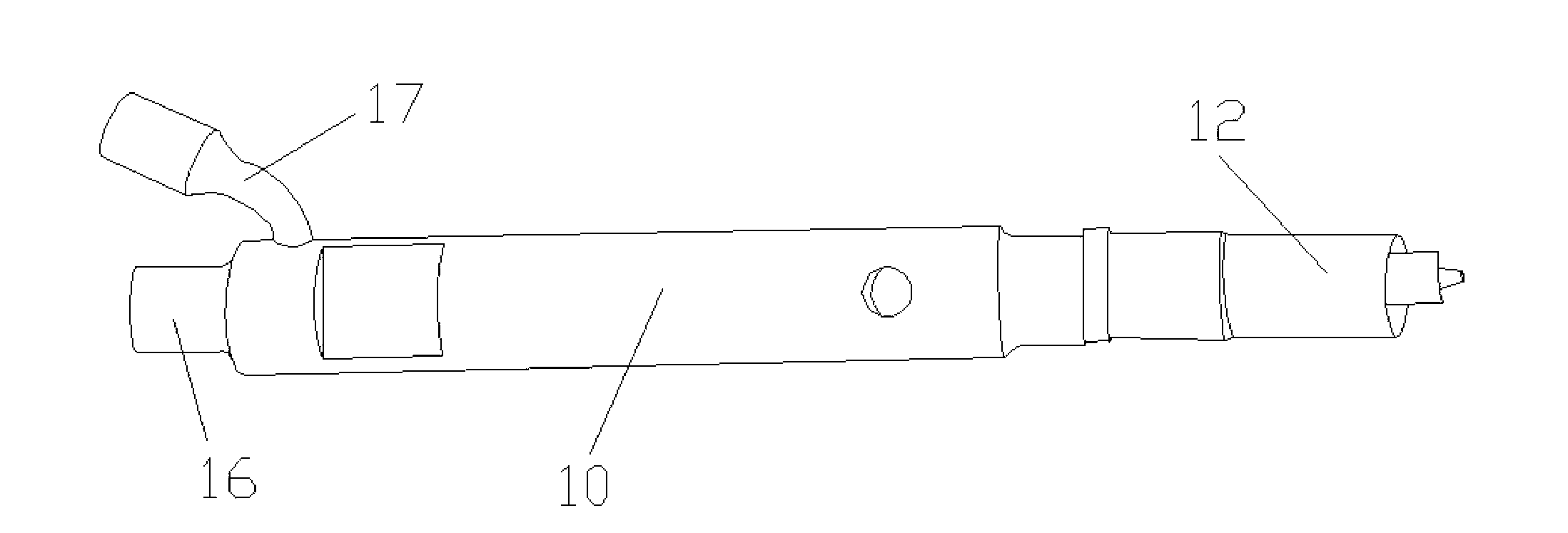

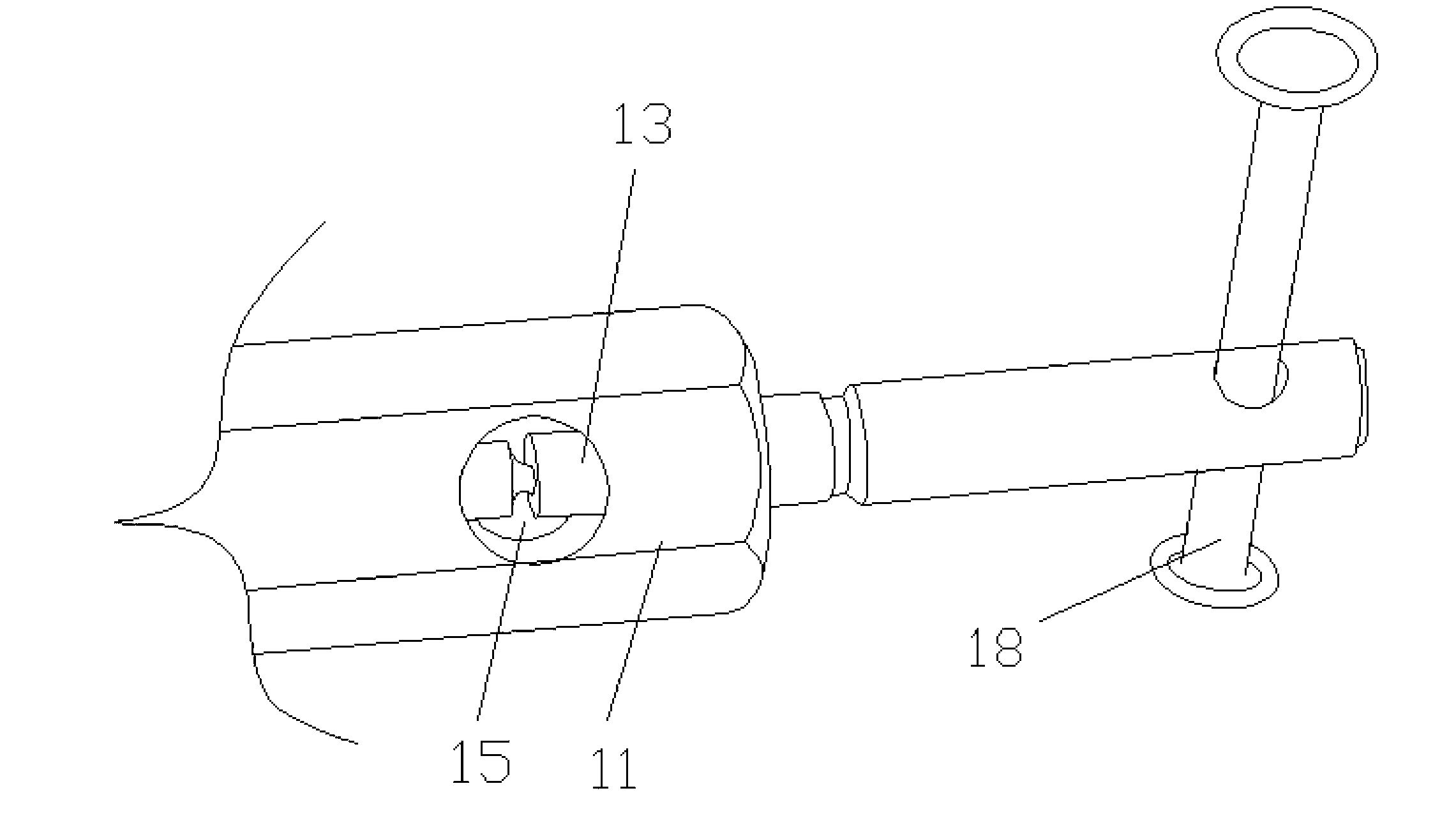

[0013] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —3: A tool for dismantling the needle valve of the fuel injector, including a fuel injector 10 without a nozzle and a bushing 11, wherein one end of the bushing 11 is connected to the head of the fuel injector 10 without a nozzle, and the bushing The other end of 11 is screwed with a fixed pin 13, and the outlet end of the fuel injector 10 without a nozzle in the shaft sleeve 11 is screwed with a fixed sleeve 12 that can be installed with a fuel injector inside, and the fuel injector 10 without a nozzle The tail is provided with a threaded interface 16 and an oil return joint 17.

[0014] According to the above-mentioned fuel injector needle valve removal tool, wherein, the specific structure that one end of the shaft sleeve 11 is connected to the head of the fuel injector 10 without nozzle is: the fuel injector 10 without nozzle and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com