Filtrate flow-guiding silencer

A technology of a muffler device and a flow guide device is applied in the field of mining machinery manufacturing, which can solve the problems of easy wear and tear of the discharge pipe and high noise, and achieve the effects of reducing the degree of wear, eliminating noise, and reducing the speed of the liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

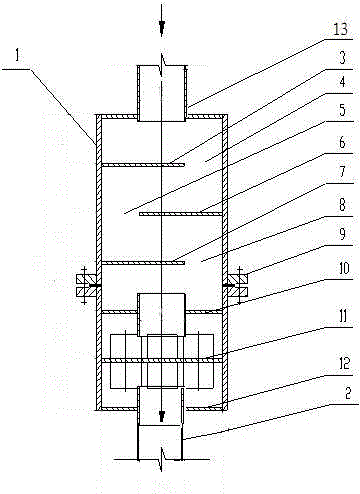

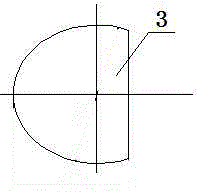

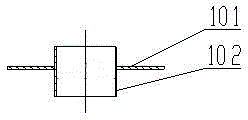

[0021] A filtrate diversion silencer device, comprising a cylinder body 1, the top of the cylinder body is connected with a liquid inlet pipe 13, the upper part of the cylinder body is equipped with a flow guide device, and the lower part of the cylinder body is equipped with a silencer device; the flow guide device consists of interlaced The filtrate baffles fixed on the inner wall of the cylinder are composed of three layers of interlaced filtrate baffles, which are the first-stage filtrate baffle 3, the second-stage filtrate baffle 6 and the third-stage filtrate baffle 7. Each filtrate The baffles have the same shape, and the circumferential surface of each filtrate baffle is adapted to the inner wall of the cylinder 1; the ratio of the area of each filtrate baffle to the cross-sectional area of the muffler is 0.73; the filtrate baffle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com