Preparation method of solder for magnetron cathode assembly

A technology of magnetron cathode and configuration method, applied in welding/cutting medium/material, welding medium, welding equipment, etc., can solve problems such as difficulty in ensuring consistent filling, increased probability of filament deviation, unfavorable filling, etc. Waste, improved yield, improved field work environment effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

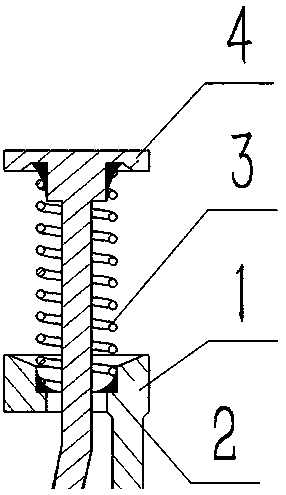

[0012] A method for configuring solder for a magnetron cathode assembly, the steps are as follows: (1) material selection: select molybdenum powder with an average particle size of 10 μm and silicon powder with an average particle size of 5 μm as solder raw materials; (2) proportioning: according to the weight ratio of 1: 11 Weigh 10g of silicon powder and 110g of molybdenum powder; (3) Grinding and mixing: Add silicon-molybdenum solder with a good ratio into a planetary ball mill for grinding for 36 hours. 10:1, the ball milling speed is set to 360r / min; (4) Configure the organic carrier: weigh 70g of epoxy resin, add 10g of epoxy resin diluent, stir and mix by mechanical stirring, the stirring speed is 1500r / min , Stirring time is 15min; add 45g of polyamide wax, continue to stir for 15min to prepare paste organic vehicle; (5) configure solder slurry: weigh 100g of ground silicon molybdenum powder, add 6g of prepared organic vehicle, add 8g of Ding Ester, stir and mix by mec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com