Patents

Literature

153 results about "Sodium pentachlorophenate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium pentachlorophenate is an insecticide and herbicide that has also been used as a wood preservative. Pentachlorphenol is a widespread environmental pollutant.

Method of producing modified acrylic acid roofing waterproof paint

PendingCN101153180AWateryWaterproof and anti-seepageAntifouling/underwater paintsPaints with biocidesUltravioletCarvacryl acetate

The present invention discloses a preparation method of modifying acrylic acid waterproof dope for house face; 0.01 portion of sodium hexametahposphate is added into water for milling. 0.2 portion of sericite powder, 0.1 portion of silicon lime powder, 0.1 portion of titanium powder are added to be milled; after grinded for two times, 0.2 portion of pure acrylic acid ester latex, 0.1 portion of watercraft polyurethane latex, 0.2 portion of organic silicon latex, 0.1 portion of ethylene-polyvingl acetate emulsion, 0.01 portion of glycol, 0.01 portion of dibutyl phthalate and 0.001 portion of sodium pentachlorophenate are added for milling. And finally, 0.01 portion of organic silicon defoamer agent is added to be milled so as to obtain the present invention. The present invention has the advantages of innocuous, inodorous and non-pollution. The present invention has water-hating performance. The present invention can bear or endure the irradiation of ultraviolet radiation. In addition, the present invention is characterized in anti-aging, much stronger adhesion intension, waterproof, seepy-resisting, heat-resisting and cold-resisting. The present invention has much better extending ability; the present invention has the advantages of cool construction and can be coated directly.

Owner:ZHONGHONG (TIANJIN) IND CO LTD

Water-based paint of lost foam for iron casting, and production method of water-based paint

ActiveCN103447454ARaw materials are uniqueImprove securityFoundry mouldsFoundry coresWater basedSodium Bentonite

The invention relates to a water-based paint of lost foam for iron casting. The water-based paint is characterized by comprising the following raw materials: high bauxite, precious peal powder, brown aluminum oxide, sodium bentonite, polyacrylamide, a polyvinyl acetate emulsion, maltodextrin, silica sol, sodium hexametaphosphate, tributyl phosphate, sodium pentachlorophenate, OP-10 active agent and water. A production method of the water-based paint comprises the steps: pretreating the sodium bentonite, pretreating the polyacrylamide and the maltodextrin, adding the water, the sodium pentachlorophenate, the tributyl phosphate and the sodium hexametaphosphate into a high-speed dispersion kettle, stirring and then sequentially adding the sodium bentonite slurry and a polyacrylamide and maltodextrin pretreatment solution into the dispersion kettle, sequentially adding the polyvinyl acetate emulsion and the silica sol into the dispersion kettle, sequentially adding the OP-10, the high bauxite, the precious pearl powder and the brown aluminum oxide to the dispersion kettle under a stirring state, and conducting high-speed dispersion for 30 minutes after completing the feeding. The water-based paint is unique in the raw materials, environment-friendly, high in coating strength, anti-cracking, good in permeability, and free from carbon lack of castings.

Owner:共享新材料(山东)有限公司

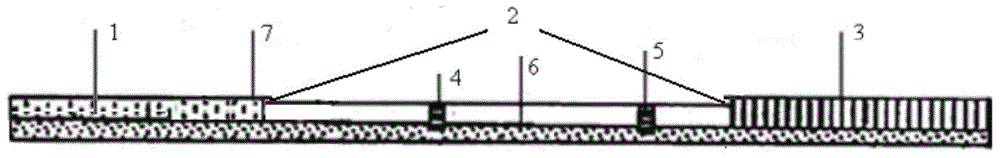

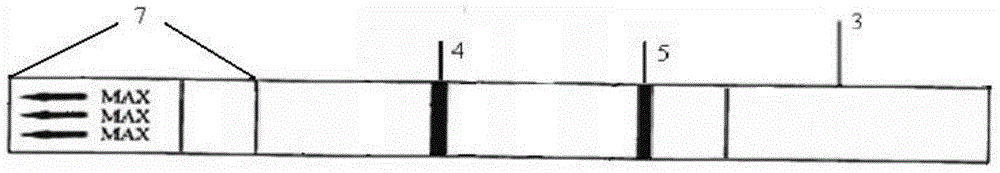

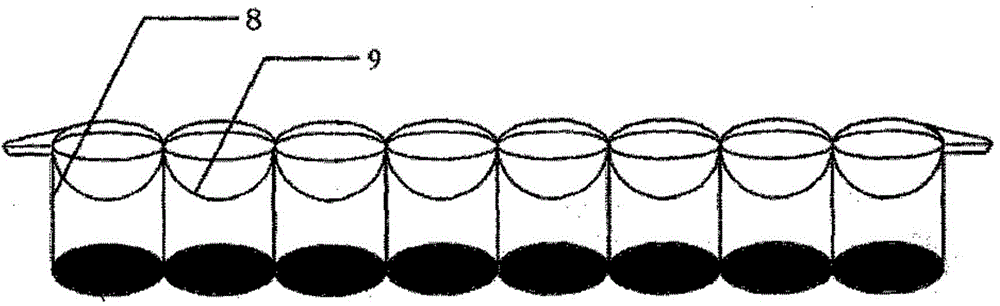

Test strip and method for detecting sodium pentachlorophenate

InactiveCN105116148AHigh sensitivityStrong specificityMaterial analysisFreeze-dryingMonoclonal antibody

The invention discloses a test strip and a method for detecting sodium pentachlorophenate. The test strip comprises a test paper and a micropore reagent, and the test paper comprises a sample absorption pad, a reaction membrane, a water absorption pad, a protection membrane and a base plate which are connected in order; the reaction membrane comprises a detection line and quality control line, the detection line is coated with a sodium pentachlorophenate semiantigen-carrier protein conjugate, the quality control line is coated with a goat anti-rat antiantibody, and the micropore reagent contains a freeze-dried sodium pentachlorophenate monoclonal antibody-colloidal gold label. The test strip provided by the invention for detecting sodium pentachlorophenate has the advantages of simple and convenience, rapid, visual sense, portability, wide application range, low cost, and easy popularization and usage.

Owner:BEIJING KWINBON BIOTECH

Acid-proof latex paint

InactiveCN107629565AImprove acid resistanceQuality improvementAnti-corrosive paintsEmulsion paintsPolystyrenePolyethylene glycol

The invention relates to an acid-proof latex paint, belonging to the technical field of coating. The latex paint contains the following components: polystyrene latex, polyvinyl acetate-ethylene emulsion, dispersing agent (sodium polymethacrylate), FCCHA, preservative (sodium pentachlorophenate), polyethylene glycol, polyurethane, hexanediol, diethylene glycol, pyrethroid, deionized water, titaniumdioxide and wollastonite in powder. The quality of the latex paint is improved, and the acid-proof property is better improved, so that the latex paint can completely resist the erosion of acidic substances of acid rain and the like.

Owner:王渊明

Preparation method of water-base spraying coating for large-size iron casting

ActiveCN103878303AImprove rheologyImprove spraying effectFoundry mouldsFoundry coresWater basedSpray coating

The invention relates to a production method of a fireproof coating for a sand mould casting and particularly relates to a preparation method of a water-base spraying coating for a large-size iron casting, which is used for a large-size thick-wall iron casting and is suitable for a spraying coating process. The method comprises the following steps: adding water into a high-speed dispersion kettle; starting electric agitation; slowly adding hydroxypropyl methyl cellulose; after adding the material, continuing to agitate; adding sodium pentachlorophenate, an organic silicon de-foaming agent and an activating agent into the dispersion kettle; starting the electric agitation and slowly adding attapulgite into the dispersion kettle while keeping high-speed agitation; after adding the material, dispersing; sequentially adding PVA (Polyvinyl Acetate), ethyl silicate and aluminum sulfate into the dispersion kettle; after adding the material, dispersing; sequentially adding bauxite and sillimanite into the dispersion kettle under an agitating state; after adding the material, finishing dispersion; discharging and packaging. The production method provided by the invention is unique in raw materials and process, high in environmental protection coefficient, excellent in coating rheological property and good in spraying performance; the coating is easy to sinter and is particularly suitable for the large-size iron casting.

Owner:共享新材料(山东)有限公司

Nano bacteria-killing paint

InactiveCN1515637AMake up for the singularityImprove securityAntifouling/underwater paintsPaints with biocidesCarboxymethyl celluloseWhite powder

The present invention relates to a nano bactericidal environment-protecting type paint. It is made up by using (wt%) 33%-38% of water-soluble latex using polyacrylic ester resin as base material, 4%-6% of microporous silver-carried bactericidal material, 21%-27% of superfine filling material, 9%-13% of rutile titanium white powder, 0.08%-0.2% of carboxymethyl cellulose, 0.05%-0.1% of sodium polymethacrylate, 0.1%-0.18% of sodium hexametaphosphate, 0.2%-0.4% of sodium pentachlorophenate and the rest water. It has fungusproof and antibacterial function.

Owner:SHANGHAI MINTAO IND DEV

Corrosion-proof ice-covering-proof coating

InactiveCN103788831AMeet the operating conditionsMeet the working conditions, acid and alkali resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsPolyesterPolymer science

The invention relates to the field of corrosion-proof ice-covering-proof coatings, and particularly relates to a corrosion-proof ice-covering-proof coating. The corrosion-proof ice-covering-proof coating comprises the following components in percentage by weight: 15%-30% of epoxy resin, 10%-15% of fluoroolefin resin, 15%-40% of nanometer silicon oxide, 10%-20% of solidifying agents, 1%-5% of toughening resin, 5%-10% of titanium dioxide blending agents, 15%-30% of fluorinated acrylate modified polyurethane resin and 5%-15% of organic solvents, wherein each titanium dioxide blending agent comprises polyurethane, biuret, polyester J4, butyl alcohol, ethanol ethyl ester, petroleum type dimethyl benzene, titanium dioxide, fine particle calcium carbonate, talcum powder, sodium pentachlorophenate and tri-butyl alcohol, and the weight ratio of polyurethane to biuret to polyester J4 to butyl alcohol to ethanol ethyl ester to petroleum type dimethyl benzene to titanium dioxide to fine particle calcium carbonate to talcum powder to sodium pentachlorophenate to tri-butyl alcohol is (1.5-2.5):(1-2):(1.5-2):(1.5-2):(1-1.5):(2-2.5):(1.5-2):(1-2):(1-1.5):(0.1-0.3):(0.3-0.5). The corrosion-proof ice-covering-proof coating disclosed by the invention has good adhesive force, can meet the requirements for use conditions of an oil drill rod in a using process in a cold place, and has the advantages of acid resistance, alkali resistance, corrosion proofing and ice-covering proofing.

Owner:南通新昱化工有限公司

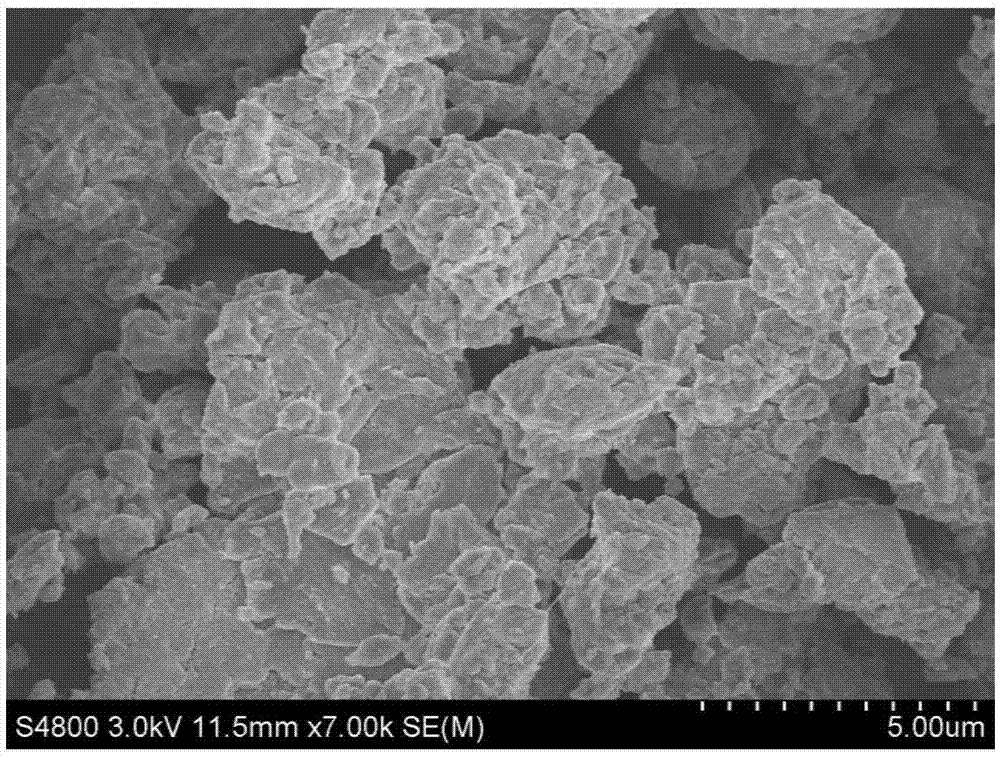

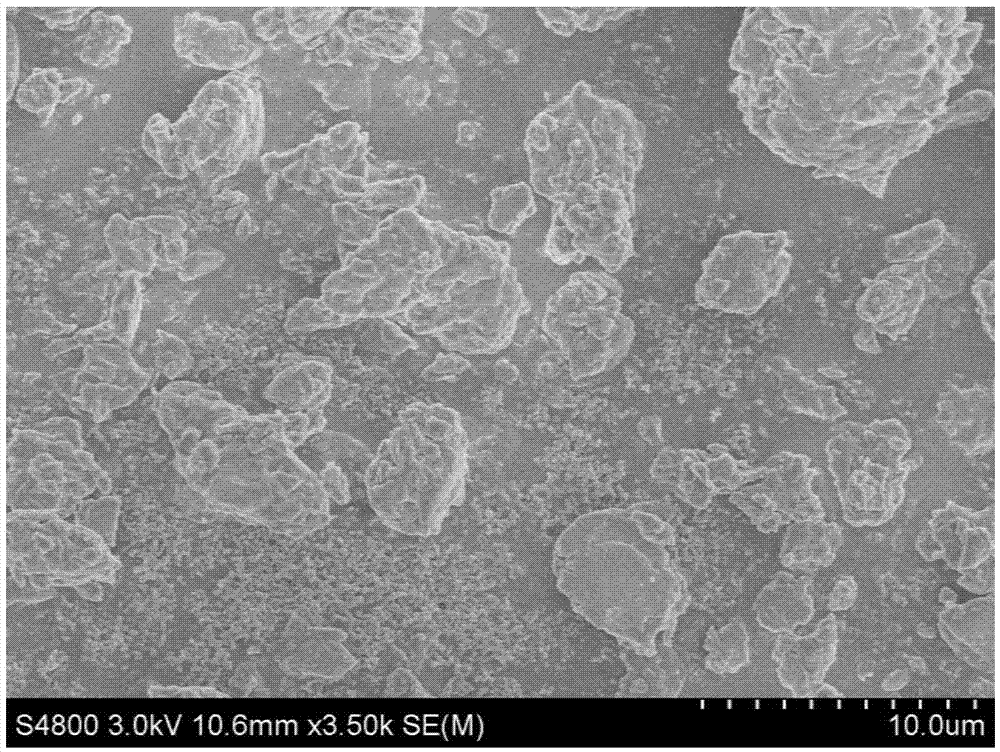

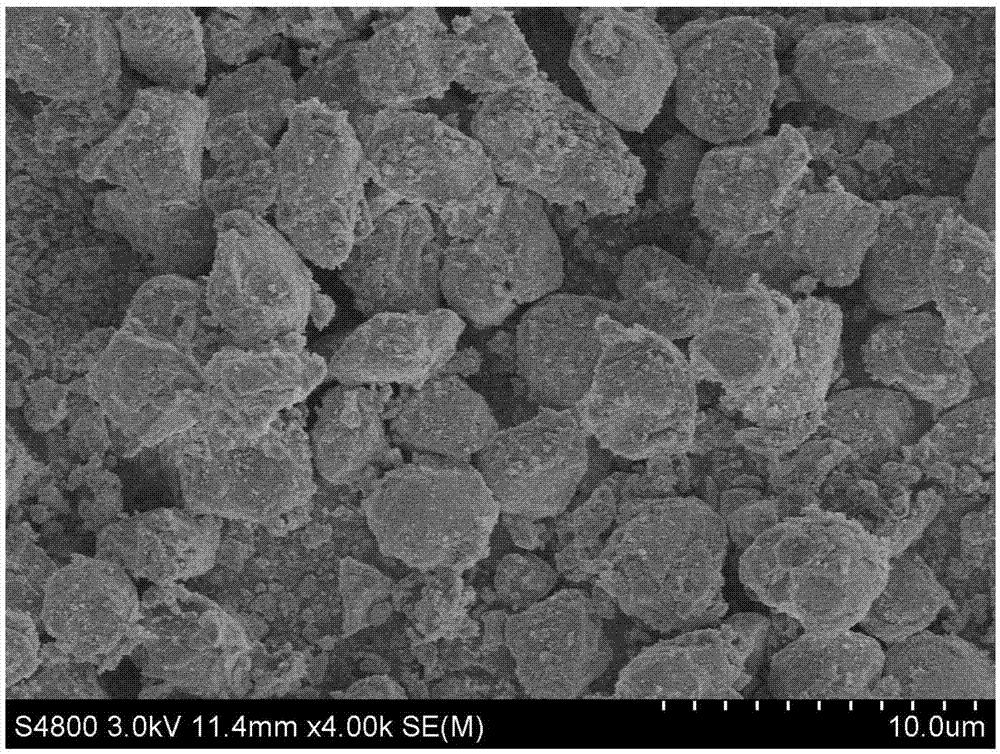

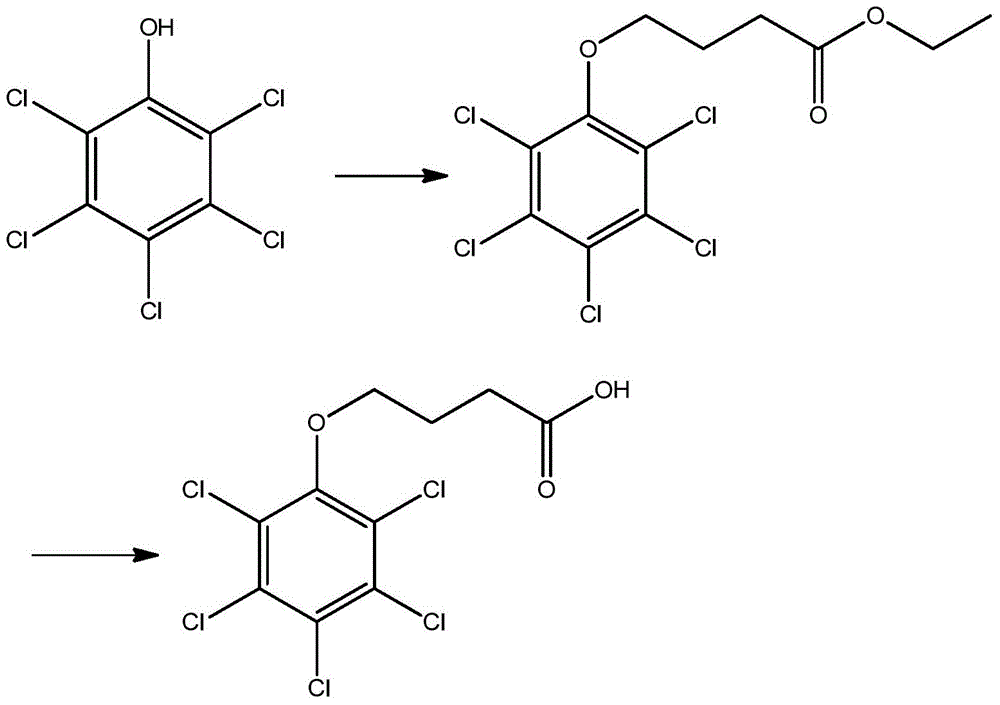

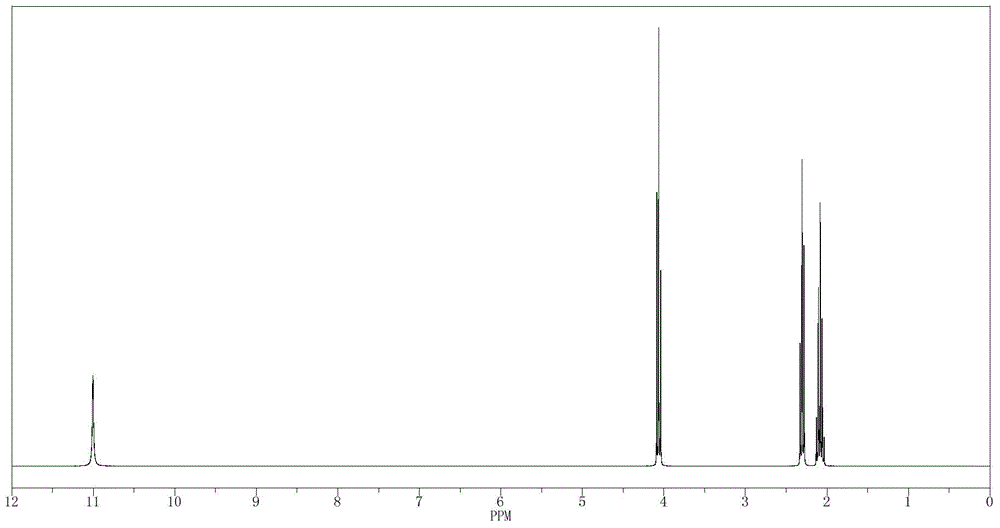

Preparation method of flower-like TiO2/graphene photocatalyst and application thereof

InactiveCN105435766APromote oxidationImprove microwave absorption performancePhysical/chemical process catalystsPentachlorophenolMicrowave method

The present invention relates to a preparation method of a flower-like TiO2 / graphene photocatalyst and application thereof. According to the photocatalyst disclosed by the present invention, titanium chloride (TiCl4) is taken as a titanium source, and a bromide N-butyl pyridine ionic liquid is taken as a shape control agent, so that the photocatalyst is prepared and formed through a hydrothermal microwave method; and the photocatalyst is specially applied to residual sodium pentachlorophenol in a vineyard, so that chemical toxic substances on grapes are reduced. In the preparation process, graphene oxide can be directly reduced into graphene by microwaves without the need of adding any other reducing agent, so that the purpose of green chemistry is achieved. The catalytic performance of the synthesized catalyst is greatly improved, the degradation of contaminants in industry is facilitated, and the synthesized catalyst has a good prospect in industrial applications.

Owner:CHANGAN UNIV

Pipe fitting processing lubricant

InactiveCN103602460AReduce roughnessExtended service lifeLubricant compositionPipe fittingBenzotriazole

Owner:QINGDAO HAIBAN PLASTIC IND & TRADE

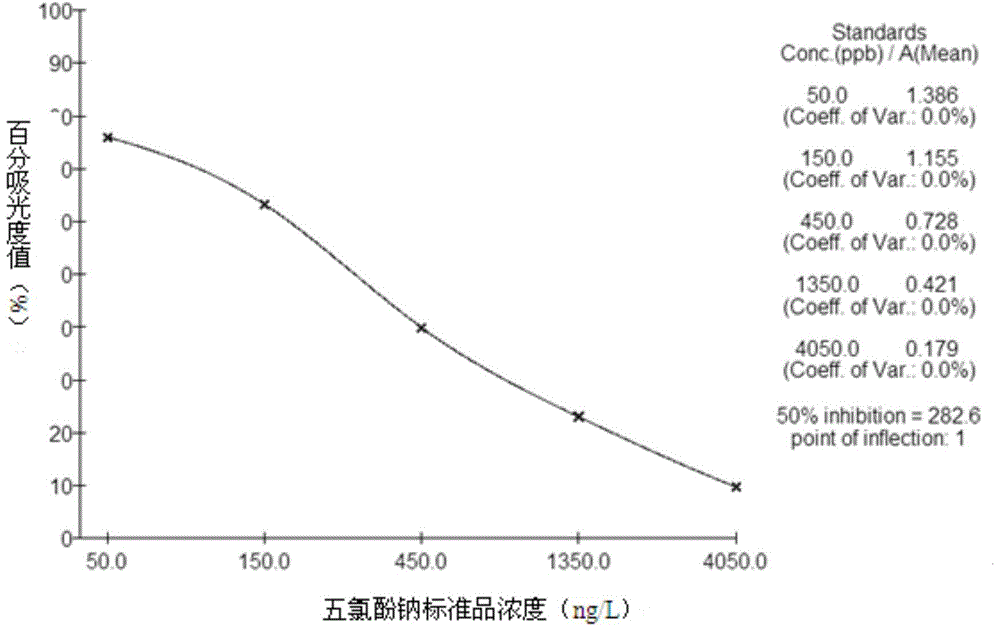

Enzyme linked immunosorbent assay kit detecting sodium pentachlorophenate and application of enzyme linked immunosorbent assay kit

The invention provides an enzyme linked immunosorbent assay kit detecting sodium pentachlorophenate. The enzyme linked immunosorbent assay kit detecting sodium pentachlorophenate comprises an elisa plate coated with coating antigens, a sodium pentachlorophenate standard product solution, HRP-conjugated antibodies, sodium pentachlorophenate specific antibodies, a substrate color developing solution, a stop solution, washing liquid and reconstruction fluid. The coating antigens are sodium pentachlorophenate coupling antigens. The HRP-conjugated antibodies are goat-anti-mouse antibodies labeled by enzyme. The invention further discloses a method applying the enzyme linked immunosorbent assay kit to detect sodium pentachlorophenate. The method includes the steps that firstly, samples are preprocessed; then; the kit is used for detection; finally, a detection result is analyzed. The enzyme linked immunosorbent assay kit can be used for detecting the content of sodium pentachlorophenate in shrimp mince, fish flesh, pork and water samples and is easy and convenient to operate, low in cost, high in sensitivity, capable of performing on-site monitoring and suitable for screening a large number of samples.

Owner:BEIJING KWINBON BIOTECH

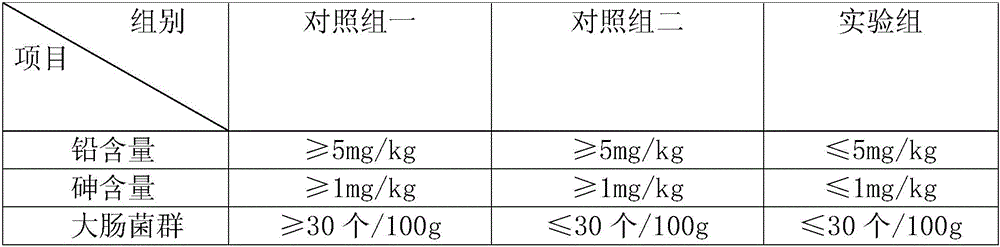

Mould-proof antibacterial food packaging paper and preparation method thereof

InactiveCN106436438AGood effectImprove adhesionFlexible coversWrappersCopper oxide8-Hydroxyquinoline

The invention discloses mould-proof antibacterial food packaging paper and a preparation method thereof. The mould-proof antibacterial food packaging paper is mainly prepared from main materials, mould-proof materials and antibacterial materials. The main materials include eucalyptus barks, heartleaf houttuynia herbs, cassava flour, cactus, cotton wadding, alginate, tragacanth gum, gelatin and fragrant plant essential oil. The mould-proof materials include sodium pentachlorophenate, sodium tribromophenol, alpha-bromocinnamaldehyde, zinc chlorphenol and copper 8-hydroxyquinoline. The antibacterial materials include zinc oxide, copper oxide, ammonium dihydrogen phosphate and lithium carbonate. The mould-proof antibacterial food packaging paper is good in toughness and capable of preventing damp and grease, has mould-proof antibacterial functions and can have mould-proof antibacterial effects on food when the food is packaged.

Owner:张日龙

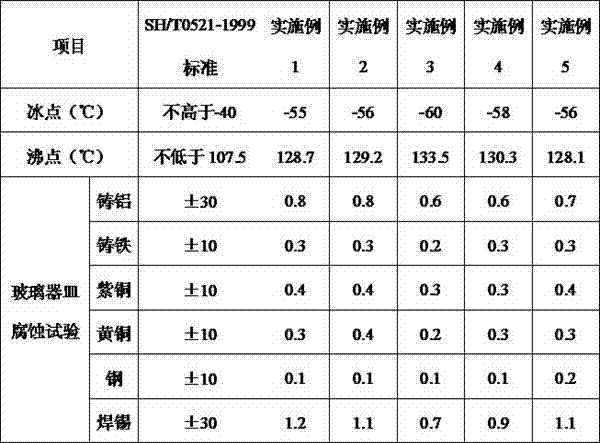

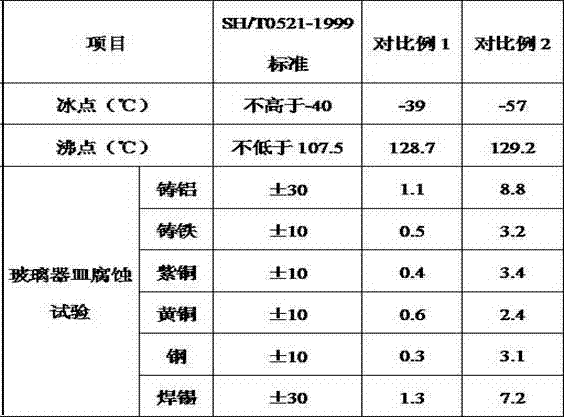

Preparation method of high-performance motor vehicle antifreeze fluid

InactiveCN104327804AMeet the use requirementsLowering the freezing pointHeat-exchange elementsAdipic acidSebacic acid

The invention discloses a preparation method of a high-performance motor vehicle antifreeze fluid. The motor vehicle antifreeze fluid is prepared from the following components in part by weight: 70-80 parts of ethylene glycol, 2-6 parts of adipic acid, 2-5 parts of sodium benzoate, 1-4 parts of sodium salicylate, 4-8 parts of crylic acid, 1-5 parts of sodium hydrogen sulfite, 3-6 parts of octoic acid, 5-10 parts of isopropyl alcohol, 2-5 parts of sebacic acid, 5-10 parts of glycerine, 0.5-2 parts of sodium pentachlorophenate, 0.2-1 part of antifoaming agent, 1-4 parts of sodium hexametaphosphate and 50-60 parts of deionized water. The preparation method comprises the following steps: mixing and dissolving ethylene glycol, deionized water and glycerine, adding the other components and fully mixing and dissolving, heating up and preserving heat for 30-45 minutes under the vacuum degree of 0.02-0.05 MPa. The motor vehicle antifreeze fluid has the characteristics of low freezing point, high boiling point and strong anti-corrosion property and can meet the using requirements of the motor vehicles in different conditions.

Owner:孟红琳

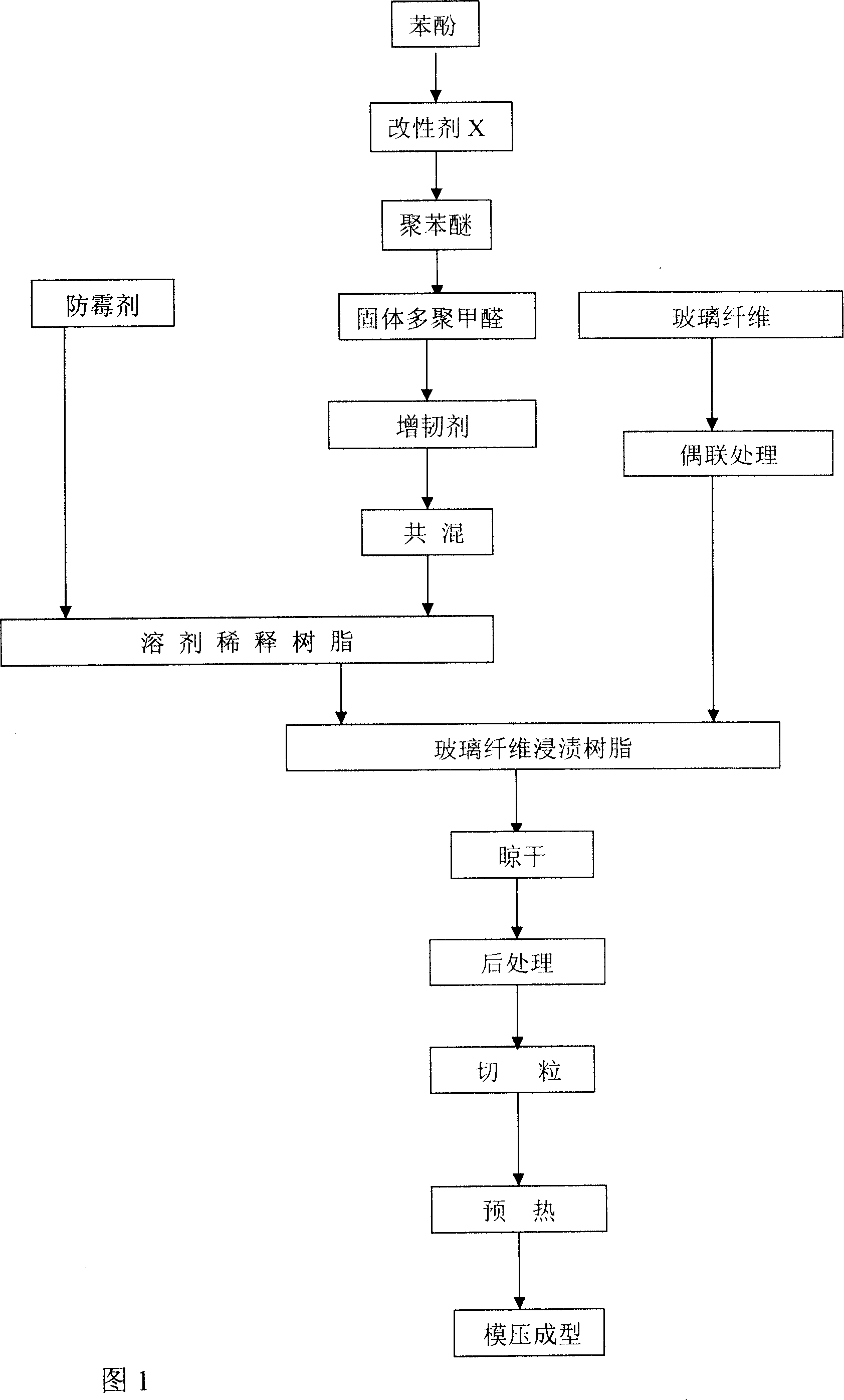

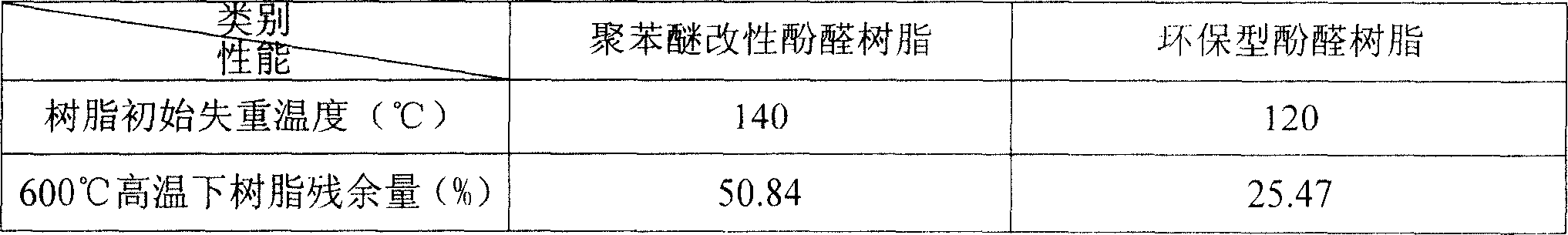

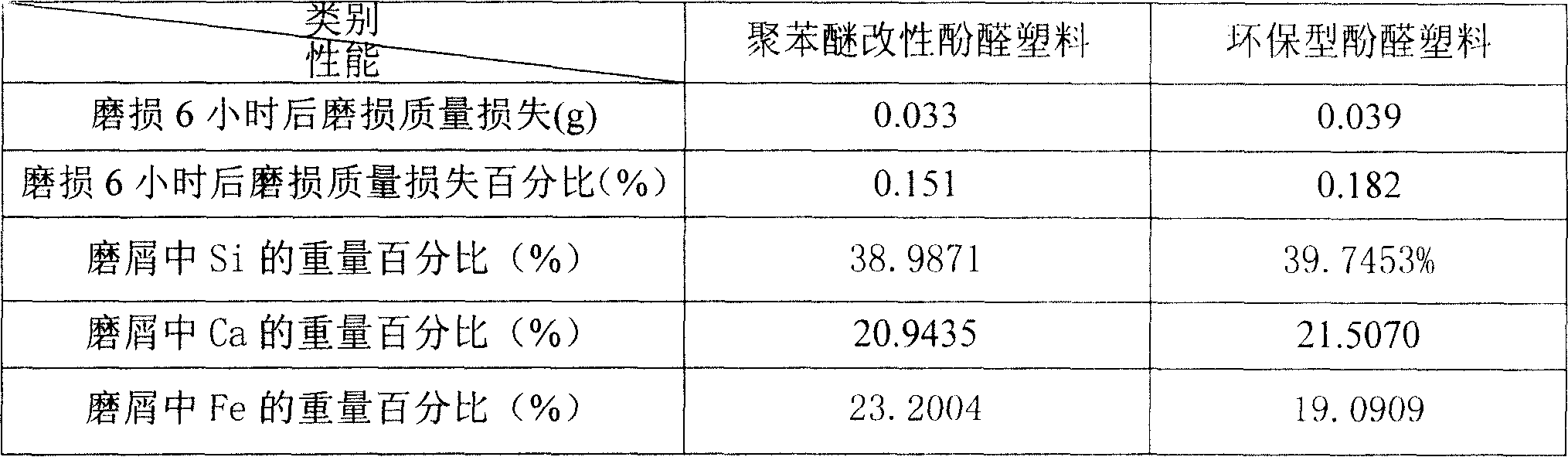

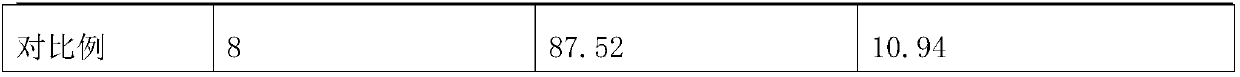

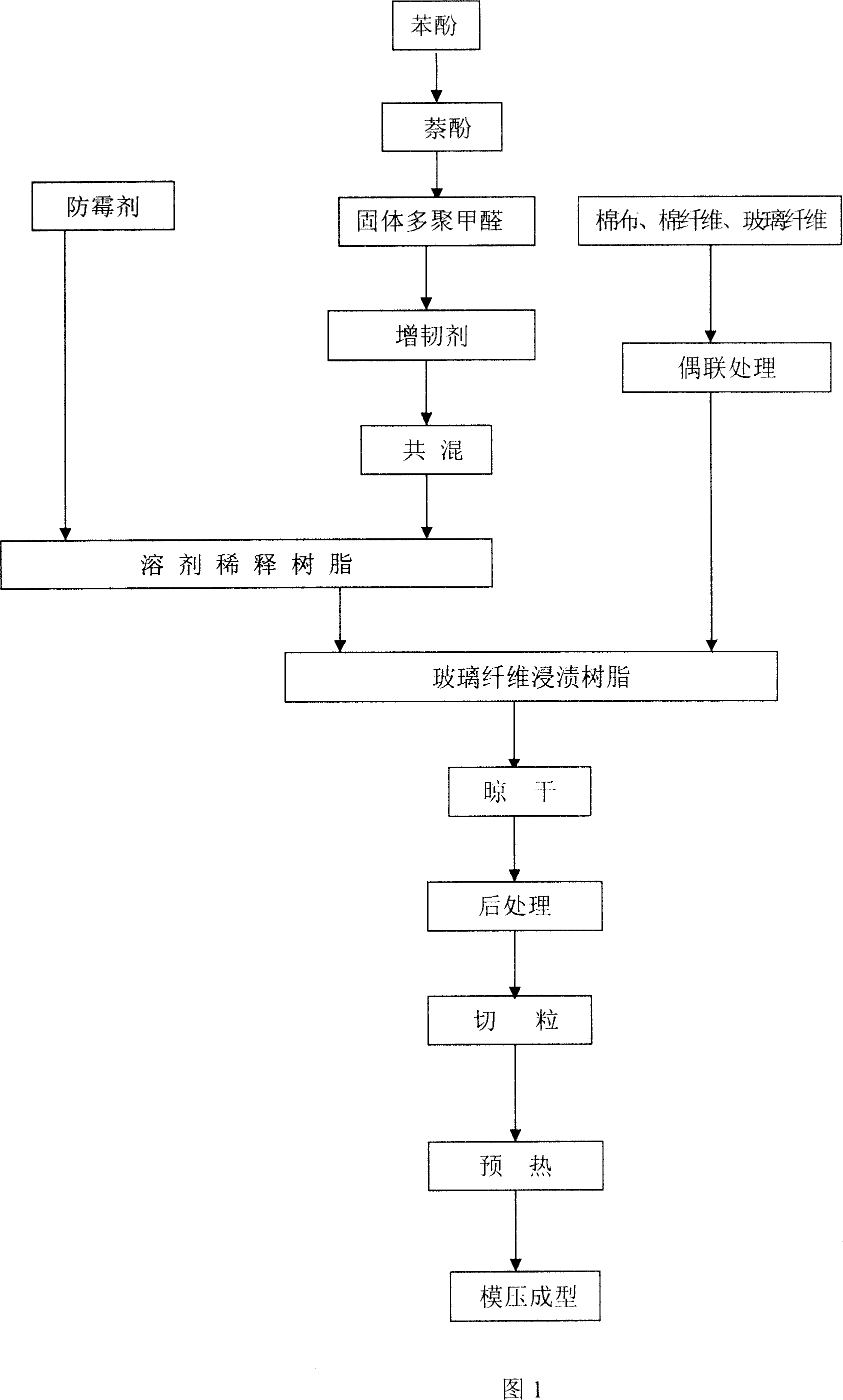

Polyphenylether modified phenolic resin, and its preparing method

This invention involves a naphthol modified phenolic resin and its preparation. The ratio of the components : Phenol 100, solid paraform 40 - 45, polyphenylene oxide ether10- 15, modifier X 10-15, fiberglass 55 - 60, polysulfone 10 - 20, while sodium pentachlorophenate 2 -5, solvents 94 -100. Through the stir conditions adding modifier X into phenol, adding certain proportion of the solid paraform and polysulfone. In reactor adding solvents, resin diluted, and joined the sodium pentachlorophenate; fiberglass couple treated then uniform impregnation, after drying, postbaking, processing pelletizing and molding.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Environment-friendly and low-carbon rotation rust paint and preparation method thereof

The invention discloses environment-friendly and low-carbon rotation rust paint prepared from a mixed solution and deionized water. The weight percentage ratio of the mixed solution to deionized water is between 19 to 3 and 21 to 1. The mixed solution is prepared from, by weight, 60%-70% of waterborne acrylic emulsion, 10%-20% of tartaric acid solutions, 5%-6% of polyvinyl alcohol solutions, 5%-8% of sodium pentachlorophenate solutions, 3%-5% of sodium nitrite solutions, 3%-5% of phosphoric acid and 0.2%-0.3% of tributyl phosphate. A preparation method of the paint includes the steps of evenly stirring tartaric acid solutions and sodium chlorite solutions, sequentially adding waterborne acrylic emulsion, polyvinyl alcohol resin, sodium nitrite solutions, phosphoric acid and tributyl phosphate to be evenly stirred, and finally conducting dilution. The environment-friendly and low-carbon rotation rust paint and the preparation method have the advantages that derusting does not need to be conducted on steel structure products before the rotation rust paint is coated, performance of an inertia coating formed after coating reaches the performance of a coating formed by solvent type paint, and the use requirements are met.

Owner:JIANGSU YICHENG BARRIER SCI & TECH

Rust-preventative oil for sealed storage in sea transportation

InactiveCN104726189AImprove adhesionImprove thermal stabilityLubricant compositionPhosphateWear resistant

The invention discloses rust-preventative oil for sealed storage in sea transportation. The rust-preventative oil is prepared from the following raw materials in parts by weight: 50-60 parts of 500sn base oil, 0.2-1 part of vitamin e acetate, 1-2 parts of para-toluenesulfonic acid, 1-2 parts of alkylphenol polyoxyethylene ether phosphate, 1-3 parts of sulphosodium succinate dioctyl ester, 1-2 parts of sodium pentachlorophenate, 0.5-1 part of diethylene glycol dibenzoate, 2-4 parts of petroleum ether, 2-5 parts of dodecenylsuccinic acid, 1-2 parts of calcium acetate, 0.5-1 part of polyethyleneimine and 3-5 parts of wear-resistant mechanical oil. The wear-resistant mechanical oil added into the rust-preventative oil disclosed by the invention can be used for forming a molecular directional adsorption membrane on a metal surface so as to reduce friction; the obtained modified terpene resin is good in cohesiveness, high in thermal stability, capable of promoting the compatibility between materials and capable of enhancing the adhesion force of a coating; as a generally used metal surface treating agent, zinc dihydrogen phosphate has a quite good rust-preventive and anticorrosive effect; the added rare-earth lanthanum ions can generate an insoluble complex with OH<-> generated during oxygen-uptake corrosion on the surface of a metal base material so as to alleviate corrosive electrode reaction and take a quite good slow-release effect.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

Starch size

InactiveCN103015180AImprove mechanical propertiesSave raw materialsFibre treatmentPotassium persulfatePolyamide

The invention discloses starch size which comprises the following components in part by weight: 30 to 40 parts of native starch, 2 to 5 parts of potassium persulfate, 10 to 15 parts of butyl methacrylate, 10 to 15 parts of acrylamide, 2 to 5 parts of emulsified oil, 3 to 6 parts of talcum powder, 1 to 5 parts of trisodium phosphate, 10 to 15 part of carboxymethylcellulose, 4 to 12 parts of sodium pentachlorophenate, 2 to 7 parts of formaldehyde ethyl phenol and 5 to 10 parts of polyamine polyamide epoxypropane. According to the starch size, the mechanical property of the starch size is improved obviously, the raw materials and the energy are saved, and the production cost is greatly reduced.

Owner:东莞建泰生物科技有限公司

Mildew-resistant and moth-proofing agent for bamboo rattan products

The invention is a bamboo and a rattan product antimold and repellant which prevents the bamboo and rattan products are mold or borer. It consists of sodium pentachlorophenate, zinc sulphate and water; it can be prepared to a corresponding bamboo and rattan product antimold and repellant after certain special production process. The invention not only play a distinctive antimold and repellant effect for the bamboo and a rattan product, but also cost low, convenient use and suitable for families preparation.

Owner:TIANJIN SHIXIONG TECH DEV

Gloss emulsion paint

The invention discloses gloss emulsion paint. The gloss emulsion paint comprises: by mass, 35 to 55% of an ethylene-propylene copolymer emulsion, 25 to 45% of titanium dioxide, 1.0 to 1.8% of sodium hexametaphosphate, 5 to 7% of glycol, 0.15 to 0.2% of tributyl phosphate, 1.5 to 2.5% of dibutyl phthalate, 0.05 to 0.08% of sodium benzoate, 0.03 to 0.06% of sodium pentachlorophenate, 0.01 to 0.03% of sodium nitrite, 1 to 2% of ammonia water and 15 to 30% of water. The gloss emulsion paint has the advantages of construction convenience, bright coating, strong color retention, good water resistance and good weatherability.

Owner:NANTONG HONGLIDA KNITTING

Cultivation method of selenium-enriched asparagus

The invention discloses a cultivation method of selenium-enriched asparagus, and belongs to the technical field of cultivation of traditional Chinese medicinal material. The cultivation method of theselenium-enriched asparagus comprises the following steps: step one, planting holes are dug, wherein the planting holes are dug according to a row spacing of 40-48 cm and a plant spacing of 22-28 cm;step two, transplanting is conducted, wherein 800-1000 g of miscellaneous manure are applied into the planting holes, a seedling is transplanted and soil covers the planting holes and is compacted; step three, weed control is performed, wherein three-time weed controls are performed each year, the first time is in March to April, the second time is in June to July, the third time is in September to October, the weed control should be 8-9 cm beneath the soil; step four, topdressing is performed, wherein compound fertilizer aqueous solution is sprayed once every three months after transplanting,and the compound fertilizer is composed of carbomite, potassium dihydrogen phosphate, potassium chloride, selenite, potassium naphthalene acetate, carbendazim and sodium pentachlorophenate. Comparedwith the current planting method, the planted asparagus has high selenium content, is more in line with human needs, as a traditional chinese medicinal material, the asparagus not only can treat related diseases, but also can supplement selenium to achieve the effects of regulating immunity, resisting cell mutations and avoiding cancer occurrence.

Owner:务川自治县红丝白马山茶叶种植加工厂

Waterproof coating material resistant to acid rain scouring

ActiveCN103602257AReduce pollutionWon't peel offPolyurea/polyurethane coatingsAcrylate esterUrethane acrylate

The invention discloses a waterproof coating material resistant to acid rain scouring. The waterproof coating material is prepared from the following raw materials in parts by weight: 5-10 parts of polyurethane acrylate resin, 2.3-4.4 parts of silane coupling agent, 3-7 parts of polyethersulfone, 2.3-3.6 parts of tourmaline powder, 1.1-2.3 parts of zinc chromate, 1.5-2.8 parts of sodium pentachlorophenate, 2.3-3.6 parts of N-alkyl sarcosinate and 0.9-1.8 parts of fatty-acid polyoxyethylene ester. Compared with the existing waterproof coating materials, the waterproof coating material has the advantages that the water resistance and waterproofing performance are higher, the tensile strength is high, the waterproof coating material is healthy and environmental-friendly, the environmental pollution is reduced, and wall body flaking caused by rainwater scouring can not occur during long-time use; the waterproof coating material can prevent acid rain scouring, and a coated film can not flake off after the coated film is subjected to rainwater scouring, so that the probability that loss is caused due to the fact that rainwater penetrates into wall faces and corrodes the wall faces is reduced.

Owner:中山市粤马科技有限公司

Control method for corylus heterophylla fisch dodder

The invention provides a control method for corylus heterophylla fisch dodder. The control method comprises the following steps that (1) the land outside corylus heterophylla fisch are ploughed depth in autumn, and the ploughing depth ranges from 5 cm to 8 cm, and dodder and the severely damaged portions of the corylus heterophylla fisch are removed manually; (2) thinning or intermediate felling is conducted on a corylus heterophylla fisch clump which is too dense so that the ventilation condition can be improved; (3) from April to late May, 200-fold to 400-fold 48% dibutalin (butralin) emulsifiable concentrate is sprayed three times; (4) from late May to mid June, a mixture of 40-fold to 600-fold 10% glyphosate and (0.3%-0.5%) ammonium sulfate and a mixture of 1.5% gyphosate solution and (0.3%-0.5%) ammonium sulfate are sprayed; (5) during each stage before July, a Zhenfeng Number three agent (the main ingredient is plant ash) is applied or a mixture of 1.5% sodium pentachlorophenate and 400-fold to 600-fold 2% prometryn liquid is applied. By the adoption of the control method, the quality of corylus heterophylla fisch products can be greatly improved; the method has the advantages of being efficient, safe, economical and the like.

Owner:铁岭市林业科学研究院

Energy-saving environment-friendly modified starch size

InactiveCN104928927AImprove permeabilityImprove wear resistanceFibre treatmentPotassium persulfatePhosphoric Acid Esters

An energy-saving environment-friendly modified starch size is made from, by weight, 8 to 14 parts of butyl methacrylate, 6 to 10 parts of sodium pentachlorophenol, 3 to 5 parts of formaldehyde ethyl phenol, 10 to 16 parts of polyvinyl alcohol, 0.5 to 0.7 part of 2-naphthol, 6 to 12 parts of phosphate starch, 2 to 5 parts of nano-silicon nitride, 4 to 7 parts of polyoxyethylene lauryl ether, 20 to 32 parts of native starch, 5 to 8 parts of cerium ammonium nitrate, 2 to 4 parts of potassium persulfate, 2 to 3.2 parts of acrylic acid, 3 to 7 parts of guar gum modified hydroxymethyl, 3 to 7 parts of guar endosperm, 6 to 9 parts of modified starch, and 4 to 6 parts of corn starch. The energy-saving environment-friendly modified starch size is higher in permeability and wear resistance and helps improve loom efficiency, reduce pollution and energy consumption and save energy.

Owner:QINGDAO JINGSHITONG PRECISION MACHINERY MFG

Dyeing and finishing process of knitted fabric

InactiveCN105421057AExcellent flame retardantExcellent mothproofHeat resistant fibresGrip property fibresIsothiazolinoneSodium acetate

The invention discloses a dyeing and finishing process of knitted fabric which comprises the following steps of firstly, pretreating; secondly, dying; thirdly, finishing: sequentially feeding 1 to 2 parts by weight of gamma-(methacryloyloxyethy) propyltrimethoxysilane, 0.4 part by weight of dimethylformamide, 1.3 parts by weight of 4,5-dichloro-2-n-octyl-3-isothiazolinone and 0.9 part by weight of sodium acetate into 15 parts by mass of deionized water and uniformly stirring; then simultaneously feeding 0.7 part by weight sodium pentachlorophenate, 0.5 part by weight of 1,3,5- triglycidylisocyanurate, 1,4 parts by weight of dimethyl terephthalate and 0.9 part by weight of octamethylcyclotetrasiloxane, and continuously stirring until the materials are fully and uniformly mixed to obtain a finishing liquid; subsequently performing padding treatment on fabric in the finishing liquid, taking out and then drying the treated fabric at constant temperature. According to the dyeing and finishing process of the knitted fabric, disclosed by the invention, the dyed and finished fabric has excellent flame-retardant, mothproof, mouldproof, antibacterial and antistatic properties; in addition, the dyed and finished fabric is high in washability and is soft in hand feeling.

Owner:常熟市大唐王子服饰厂

Wear-resisting interior wall waterproof coating

InactiveCN104559384AImprove breathabilityExcellent abrasion and tear resistanceFireproof paintsPolyvinyl chloridePolycarbonate

The invention discloses a wear-resisting interior wall waterproof coating. The wear-resisting interior wall waterproof coating is prepared from the following raw materials in parts by weight: 30-50 parts of deionized water, 15-25 parts of pottery clay, 5-10 parts of ferrous sulfate, 7-14 parts of texanol ester alcohol, 5-10 parts of polycarbonate, 7-14 parts of polytetrafluoroethylene wax, 2-6 parts of rigid polyvinyl chloride, 12-21 parts of hydroxyl butyl acrylate, 15-20 parts of isopropyl acrylate, 5-10 parts of hibiscus rosa-sinensis wood chips, 9-18 parts of calcium hydroxide water solution, 16-24 parts of hexyl acrylate, 3-6 parts of polyoxyethylene ether, 15-25 parts of silica sol, 3-9 parts of diethyl phthalate, 5-10 parts of sodium pentachlorophenate, and 15-30 parts of 2,4,6,8-tetravinyl-2,4,6,8-tetramethylcyclotetrasiloxane. The wear-resisting interior wall waterproof coating provided by the invention is non-toxic, environment-friendly, good in gas permeability, excellent in wear resistance, tearing resistance, heat resistance, flame retardance, and impact resistance, further good in scrubbing resistance, and quick in curing speed.

Owner:QINGDAO JIASHANG CREATIVE CULTURE

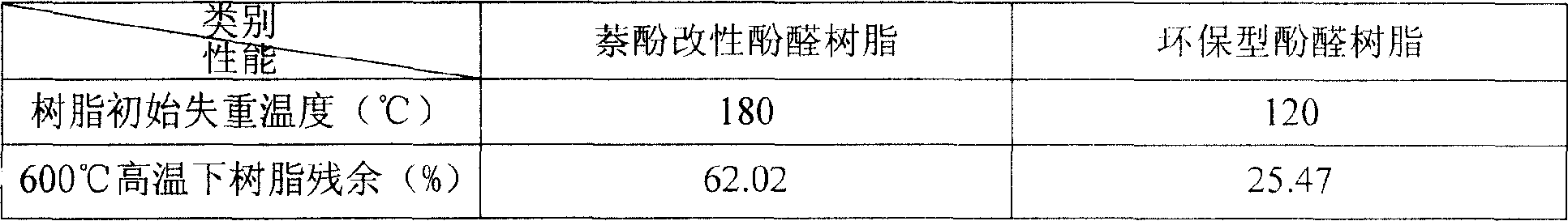

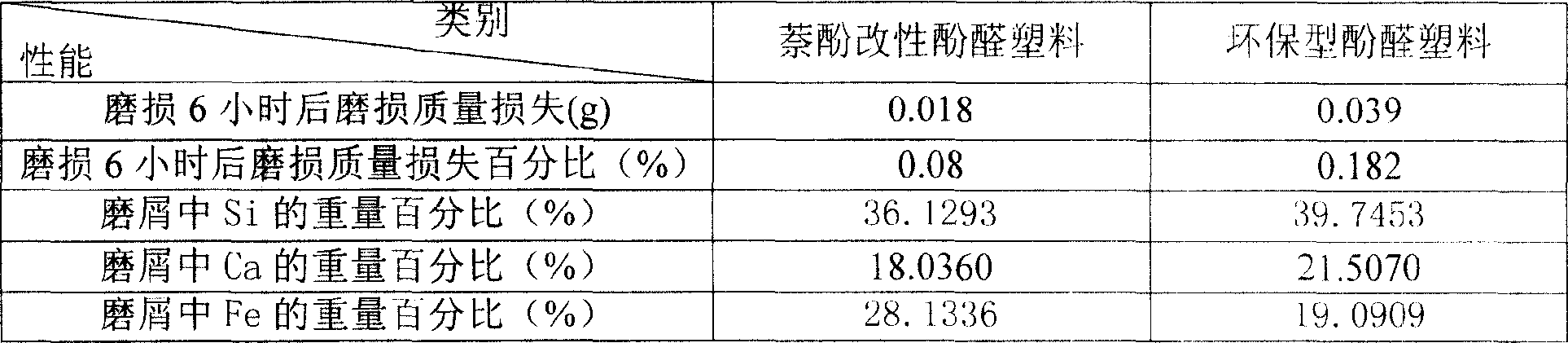

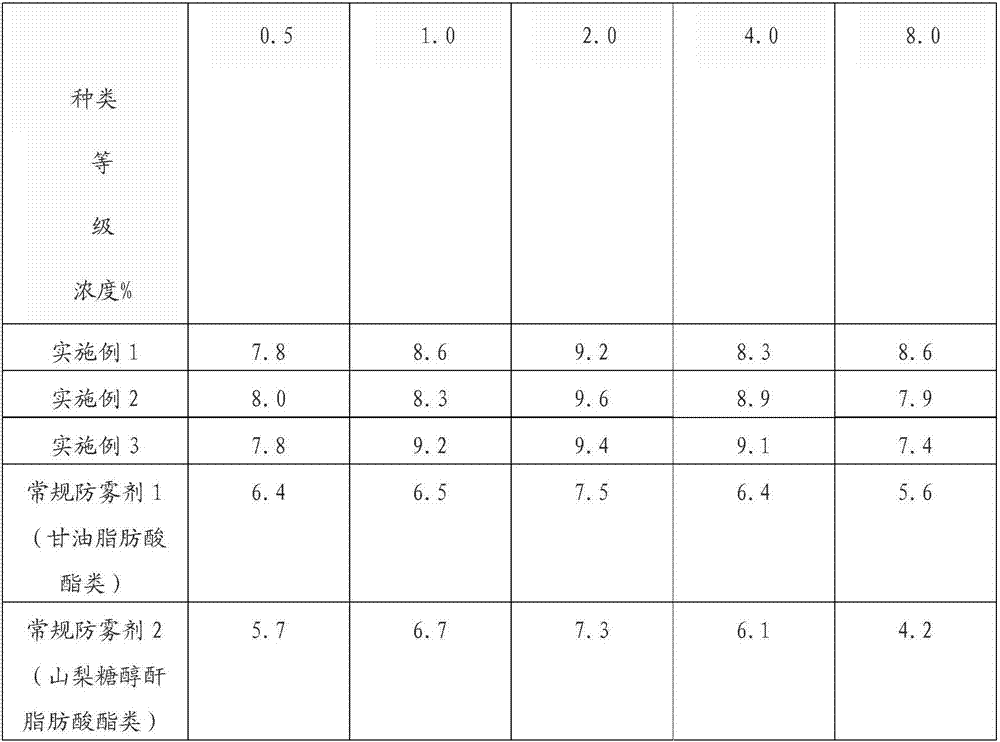

Naphthol-modified phenolic resin, and its preparing method

This invention involves a naphthol modified phenolic resin and its preparation. The technical characteristics lie on the ratio of the components: 100 phenol, solid paraform 40 - 45, naphthol 10 - 15 and fiberglass 55 -60, polysulfone 10- 20, sodium pentachlorophenate 2 - 5, solvents 94 -100. Through the stir conditions adding naphthol into phenol, adding certain proportion of the solid paraform and polysulfone. In reactor adding solvents, resin diluted, and joined the sodium pentachlorophenate; fiberglass couple treated then uniform impregnation, after drying, postbaking, processing pelletizing and molding.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Anticorrosion wood modifier

InactiveCN104816366AImprove anti-corrosion performanceExtended service lifeWood treatment detailsWood impregnation detailsCellulosePolymer science

The invention discloses an anticorrosion wood modifier. The anticorrosion wood modifier is prepared by, by weight, 3-6 parts of white spirit, 4-7 parts of nano tourmaline powder, 3-8 parts of lithium silicate, 6-8 parts of calcium sulfate, 4-9 parts of methyl sodium silicate, 6-10 parts of cellulose ether, 9-11 parts of sodium pentachlorophenate , 4-7 parts of hydroxypropyl methyl cellulose, 4-10 parts of sodium laureth sulfate, 5-8 parts of fatty alcohol polyoxyethylene ether, 4-6 parts of silica sol, 4-7 parts of borax and 2-5 parts of biuret . The anticorrosion wood modifier has the advantages of being capable of improving anticorrosion of wood well, prolonging service life of the wood and improving size stability and microorganism invasion resistance.

Owner:青岛百千川海洋生态科技有限公司

Metal cleaning liquid

The invention discloses a metal cleaning liquid which comprises the following components in parts by weight: 4-8 parts of sodium dodecyl sulfonate, 4-6 parts of trisodium phosphate, 8-12 parts of sodium carbonate, 4-8 parts of sodium pentachlorophenate, 2-6 parts of sodium benzoate, 4-8 parts of triethanolamine, 10-12 parts of ethanol, 2-8 parts of methyl acetate and 4-6 parts of sodium hydroxide. The metal cleaning liquid disclosed by the invention can effectively clean dirt on the surface of metal, can also improve the anti-rusting capability of a metal product, and is safe to use and low in price.

Owner:顾兴

Glass antifogging agent and preparation method thereof

InactiveCN107129875ACause some damagesSufficient surface strengthInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsAdhesivePolyvinyl alcohol

The invention discloses a glass antifogging agent and a preparation method thereof. The glass antifogging agent comprises a solution A and a solution B in a ratio of 5:1. The solution A comprises the following components in parts by weight: 7-18 parts of polyvinyl alcohol, 200-370 parts of water, 20-100 parts of diethanolamine, 10-50 parts of tallow alkyl propanolamine, 20-60 parts of isopropanol, 12-35 parts of 3 mol / L hydrochloric acid, 0.6-6.5 parts of 40 wt% acetaldehyde and 6-17 parts of potassium dichromate. The solution B comprises the following components in parts by weight: 7-16 parts of polyoxyethylene surfactant, 10-25 parts of sodium hexametaphosphate, 5-25 parts of sodium pentachlorophenate, 2-7 parts of soap flake adhesive, 8-19 parts of ethyl silicate, 7-22 parts of gamma-glycidoxypropyltrimethoxysilane, 11-32 parts of ethanol and 1.3-9.5 parts of glacial acetic acid. Thereby, after use, the glass antifogging agent has sufficient surface strength, is clean and harmless, can not do harm to the humans or livestock, is simple to use, and has the advantages of favorable antifogging effects, long technical effective time (up to half a year or more) and no environment pollution; and the manufacturing technique is simple, so the cost is lower.

Owner:JIANGSU FEIYA CHEM IND

Lubricant cutting fluid for metal processing

The invention discloses a lubricant cutting fluid for metal processing. The lubricant cutting fluid is prepared from the following raw materials by weight: 25-35 parts of a mixture of glycerol and water, 3-7 parts of trisodium phosphate, 3-7 parts of sodium pentachlorophenate, 4-9 parts of polyethylene glycol, 4-9 parts of sodium nitrite and 3-7 parts of sodium petroleum sulfonate. Compared with the cutting fluid of the prior art, an anionic surfactant in a large proportion and a nonionic surfactant in a small proportion are combined to greatly reduce the ratio of the nonionic surfactant, thereby improving defoaming performance. According to the invention, the contents of additives are adjusted to reach synergism of the components, so that the prepared cutting fluid combines the advantages of an emulsion and a total synthesis cutting fluid and has excellent lubrication, cooling performance, cleaning performance, corrosion resistance and long service life.

Owner:QINGDAO HAIBAN PLASTIC IND & TRADE

Methylcellulose multicolor coating

ActiveCN104073067AVariety of coating colorsLight and softPolyurea/polyurethane coatingsMulticolor effect coatingsCyclohexanoneLoss rate

The invention discloses a methylcellulose multicolor coating. The methylcellulose multicolor coating is prepared from the following raw materials in parts by weight: 100 parts of methylcellulose, 5-15 parts of zinc oxide, 10-20 parts of sodium pentachlorophenate, 30-40 parts of dimethylbenzene, 15-25 parts of montmorillonite, 25-35 parts of talcum powder, 70-90 parts of deionized water, 10-30 parts of cyclohexanone, 10-20 parts of pigment, 15-35 parts of trimethylolpropane, 20-30 parts of sodium orthophosphate, 5-25 parts of toluene diisocynate, 4-10 parts of plasticizer, 35-45 parts of aluminium stearate, 20-40 parts of polyving akohol and 25-45 parts of epoxidized soybean oil; the coating is multicolor and soft in gloss; the base of the coating is not exposed after the coating is scrubbed for 11,000-13,000 times; the content of solid accounts for 25-35%; when the coating is soaked in water at the temperature of 20 DEG C for 60-80 days, no bubble is formed and no powder is dropped; the surface is dried for 15-25 minutes and the solid is dried for 6-8 hours; and the loss rate of the coating in a coating reciprocating tester reaches 0.004-0.006g / cm<2> after running for 1000 times, so that the coating can be widely produced and used for continuously replacing the existing material.

Owner:WUJIANG HUACHENG COMPOSITE MATERIAL SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com