Mould-proof antibacterial food packaging paper and preparation method thereof

A food wrapping paper, anti-mildew and anti-bacterial technology, applied in wrapping paper, wrapping paper, packaging, etc., can solve the problems of increased production cost, low moisture-proof and oil-proof performance, complicated process, etc., to improve the overall bonding performance, oil-proof Good moisture resistance and strong antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

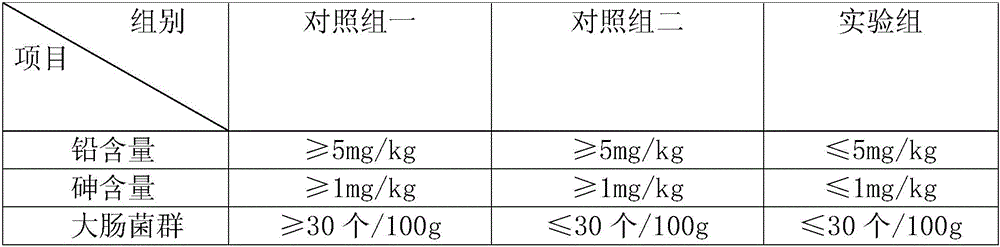

Examples

Embodiment 1

[0022] An anti-mold and anti-bacterial food wrapping paper, made of main materials, anti-mold materials and anti-bacterial materials, including the following main materials in proportions by weight: 160 parts of eucalyptus bark, 50 parts of Houttuynia cordata, 40 parts of cassava flour, cactus 70 parts, 30 parts of cotton wool, 20 parts of alginate, 20 parts of tragacanth gum, 20 parts of gelatin and 30 parts of plant aromatic essential oil, including the anti-mold material with the following parts by weight ratio: 10 parts of sodium pentachlorophenate, three 9 parts of sodium bromophenate, 8 parts of a-bromocinnamaldehyde, 10 parts of zinc chlorophenate and 7 parts of 8-hydroxyquinone copper, including antibacterial materials in the following proportions by weight: 8 parts of zinc oxide, 7 parts of copper oxide , 10 parts of ammonium dihydrogen phosphate and 11 parts of lithium carbonate.

[0023] A method for preparing anti-mildew and antibacterial food packaging paper, comp...

Embodiment 2

[0034]A mildew-proof and anti-bacterial food packaging paper, made of main materials, anti-mold materials and anti-bacterial materials, made of the following main materials, anti-mold materials and anti-bacterial materials, including the main materials in the following proportions by weight: eucalyptus bark 100 80 parts, 80 parts of Houttuynia cordata, 70 parts of cassava flour, 90 parts of cactus, 50 parts of cotton wool, 40 parts of alginate, 40 parts of tragacanth gum, 40 parts of gelatin and 50 parts of plant aromatic essential oil, including the following parts by weight Ratio anti-mold materials: 16 parts of sodium pentachlorophenate, 13 parts of sodium tribromophenate, 12 parts of a-bromocinnamaldehyde, 14 parts of zinc chlorophenate and 9 parts of 8-hydroxyquinone copper, including the following parts by weight Specific antibacterial materials: 14 parts of zinc oxide, 15 parts of copper oxide, 16 parts of ammonium dihydrogen phosphate and 15 parts of lithium carbonate. ...

Embodiment 3

[0046] A mildew-proof and anti-bacterial food wrapping paper, made of main materials, anti-mold materials and anti-bacterial materials, made of the following main materials, anti-mold materials and anti-bacterial materials, including the main materials in the following proportions by weight: eucalyptus bark 130 65 parts, 65 parts of Houttuynia cordata, 55 parts of cassava flour, 85 parts of cactus, 40 parts of cotton wool, 30 parts of alginate, 30 parts of tragacanth gum, 30 parts of gelatin and 40 parts of plant aromatic essential oil, including the following parts by weight Ratio anti-mold materials: 13 parts of sodium pentachlorophenate, 11 parts of sodium tribromophenate, 10 parts of a-bromocinnamaldehyde, 12 parts of zinc chlorophenate and 8 parts of 8-hydroxyquinone copper, including the following parts by weight Specific antibacterial materials: 11 parts of zinc oxide, 11 parts of copper oxide, 13 parts of ammonium dihydrogen phosphate and 13 parts of lithium carbonate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com