Glass antifogging agent and preparation method thereof

An anti-fogging agent and glass technology, applied in chemical instruments and methods, detergent compounding agents, other chemical processes, etc., can solve the problem that the anti-fogging effect cannot be maintained continuously, the anti-fogging effect has a short duration and requires repeated spraying, and the user's body Health damage and other problems, to achieve the effect of long effective technology, good anti-fog effect, and simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

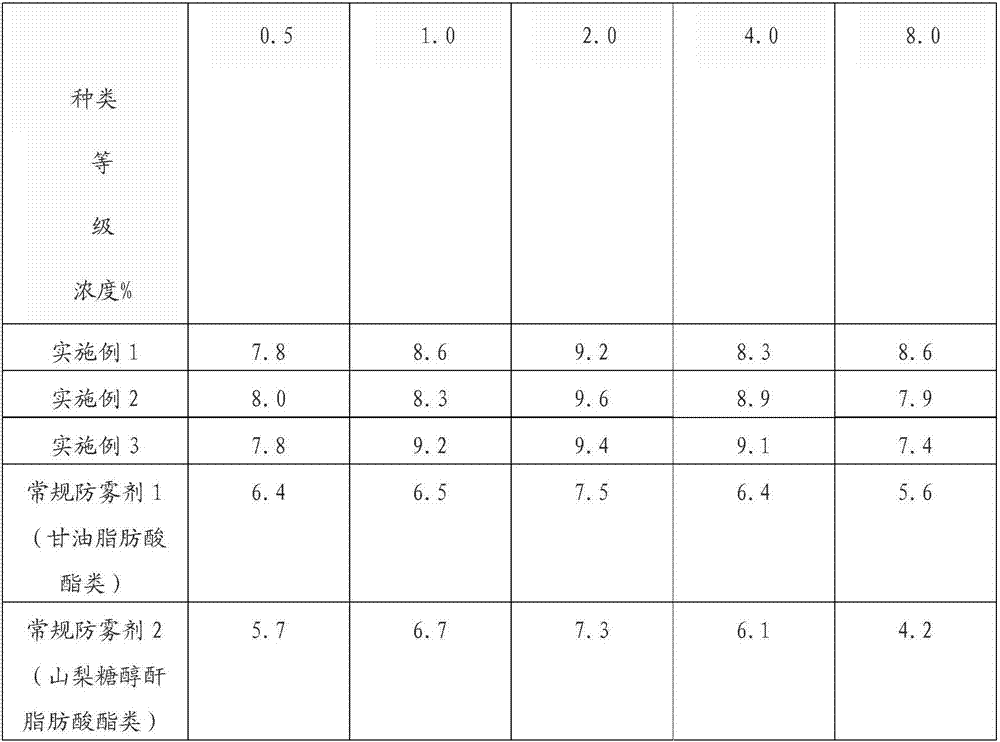

Examples

Embodiment 1

[0017] Glass anti-fogging agent, the composition is as follows:

[0018] Including solution A and solution B, the ratio of solution A to solution B is 5:1; wherein, solution A includes by weight: 10 parts of polyvinyl alcohol, 210 parts of water, 38 parts of diethanolamine, tallow alkyl propanolamine 22 parts, 55 parts of isopropanol, 12 parts of hydrochloric acid with a concentration of 3mol / L, 0.8 parts of acetaldehyde with a mass content of 40%, and 7 parts of potassium dichromate; solution B includes by weight: polyoxyethylene surfactant 7.5 parts, 15 parts of sodium hexametaphosphate, 11 parts of sodium pentachlorophenate, 2 parts of soap flake glue, 11 parts of ethyl silicate, 8 parts of γ-glycidyl etheroxypropyl trimethoxysilane, 13 parts of ethanol, ice 1.5 parts of acetic acid.

[0019] Wherein, the polyoxyethylene surfactant is any one of fatty alcohol polyoxyethylene ether, Tween or alkylphenol polyoxyethylene ether.

[0020] The preparation method of glass antifo...

Embodiment 2

[0025] Glass anti-fogging agent, the composition is as follows:

[0026] Including solution A and solution B, the ratio of solution A to solution B is 5:1; wherein said solution A includes by weight: 7 parts of polyvinyl alcohol, 200 parts of water, 20 parts of diethanolamine, tallow alkyl propanol 10 parts of amine, 20 parts of isopropanol, 12 parts of hydrochloric acid with a concentration of 3 mol / L, 0.6 parts of acetaldehyde with a mass content of 40%, and 6 parts of potassium dichromate; the solution B includes in parts by weight: polyoxyethylene 7 parts of surfactant, 10 parts of sodium hexametaphosphate, 5 parts of sodium pentachlorophenate, 2 parts of soap flake glue, 8 parts of ethyl silicate, 7 parts of γ-glycidyl etheroxypropyl trimethoxysilane, 11 parts of ethanol part, 1.3 parts of glacial acetic acid.

[0027] Wherein, the polyoxyethylene surfactant is any one of fatty alcohol polyoxyethylene ether, Tween or alkylphenol polyoxyethylene ether.

[0028] The prepa...

Embodiment 3

[0033] Glass anti-fogging agent, the composition is as follows:

[0034] Including solution A and solution B, the ratio of solution A to solution B is 5:1; wherein said solution A includes by weight: 18 parts of polyvinyl alcohol, 370 parts of water, 100 parts of diethanolamine, tallow alkyl propanol 50 parts of amine, 60 parts of isopropanol, 35 parts of hydrochloric acid with a concentration of 3mol / L, 6.5 parts of acetaldehyde with a mass content of 40%, and 17 parts of potassium dichromate; the solution B includes by weight: polyoxyethylene 16 parts of surfactant, 25 parts of sodium hexametaphosphate, 25 parts of sodium pentachlorophenate, 7 parts of soap flake glue, 19 parts of ethyl silicate, 22 parts of γ-glycidyl etheroxypropyl trimethoxysilane, 32 parts of ethanol part, 9.5 parts of glacial acetic acid.

[0035] Wherein, the polyoxyethylene surfactant is any one of fatty alcohol polyoxyethylene ether, Tween or alkylphenol polyoxyethylene ether.

[0036] The preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com