Converter alloy charging mechanism

A converter and alloy technology, applied in the manufacture of converters, etc., can solve problems such as easy splashing of red high-temperature steel slag, inhalation of heavy metal dust, personal safety injuries, etc., and achieve the effects of improving the working environment, ensuring safety, and reducing smoke and dust on the job

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

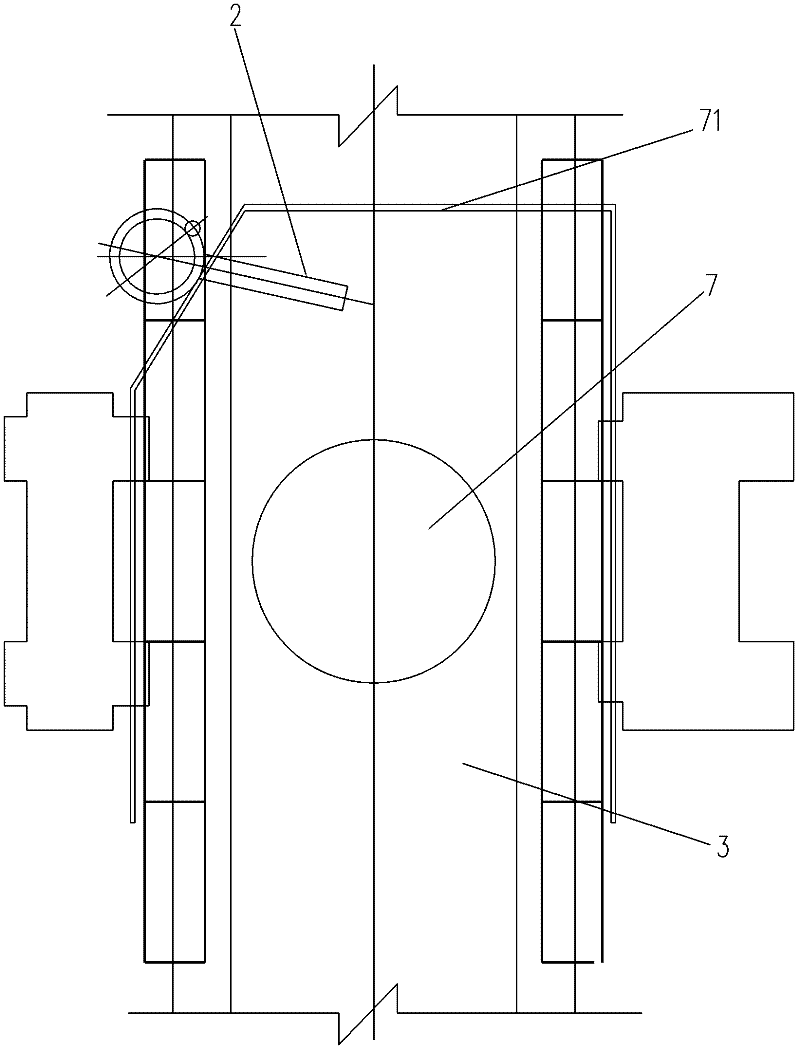

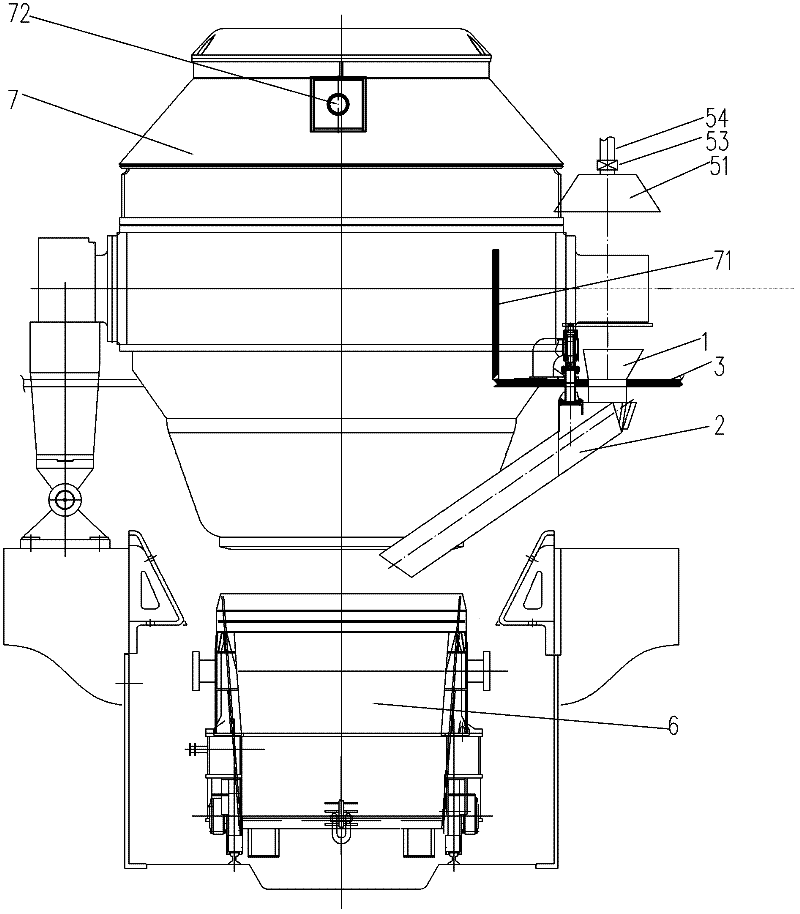

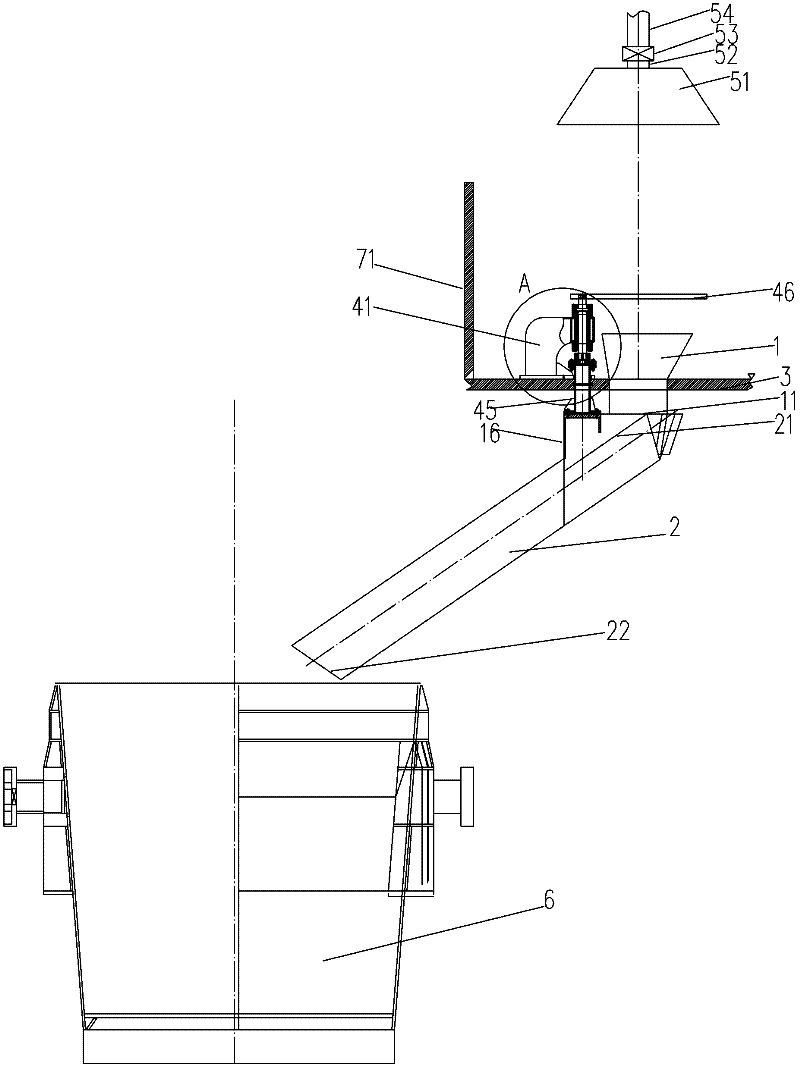

[0021] like Figure 1-3 As shown, the converter alloying mechanism of the present invention includes a converter 7, a steel putting operation platform 3, a molten steel tank 6, a receiving hopper 1, a lower hopper 2, a rocker rotating device, and a dust collection device. The steel putting operating platform 3 is arranged on the converter 7 Around, the rear side, the left side and the right side of the converter 7 are provided with water-cooled coamings 71 respectively, and the water-cooled coamings 71 are fixed on the steel-putting operation platform 3, and the molten steel tank 6 can be moved, and it is moved to the outlet of the converter 7 when blanking. Steel port 72 below.

[0022] The receiving hopper 1 is installed on the steel-putting operation platform 3 on the outside of the water-cooled coaming 71, and is located at the rear position on the left side of the converter 7, and the lower hopper 2 is a strip-shaped hopper. to combine Figure 4 As shown, the rocker rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com