Novel damp-proof balsa wood material for wind power blade and preparation process of novel damp-proof balsa wood material

A technology of wind power blades and preparation technology, which is applied in the direction of manufacturing tools, grinding workpiece supports, metal processing equipment, etc., and can solve the problems of inconvenient moisture-proof balsa wood new material limit, moisture-proof balsa wood new material easy to shift, etc. , to achieve the effect of preventing the body from causing harm and preventing debris from polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

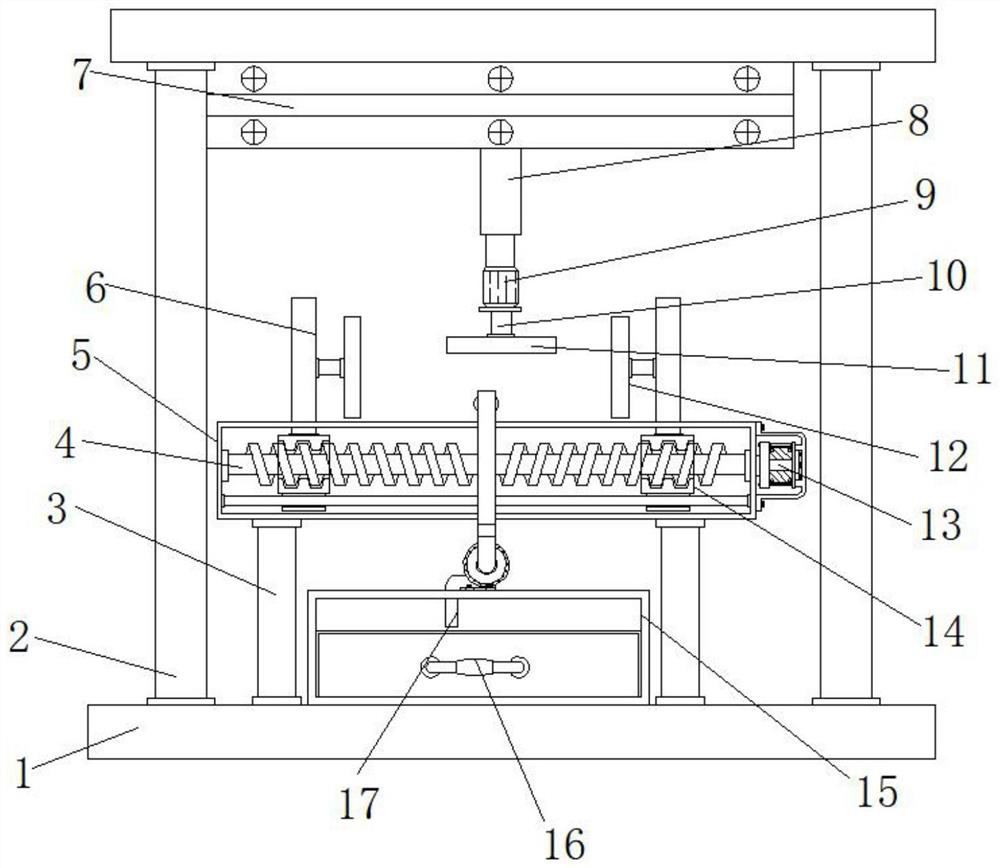

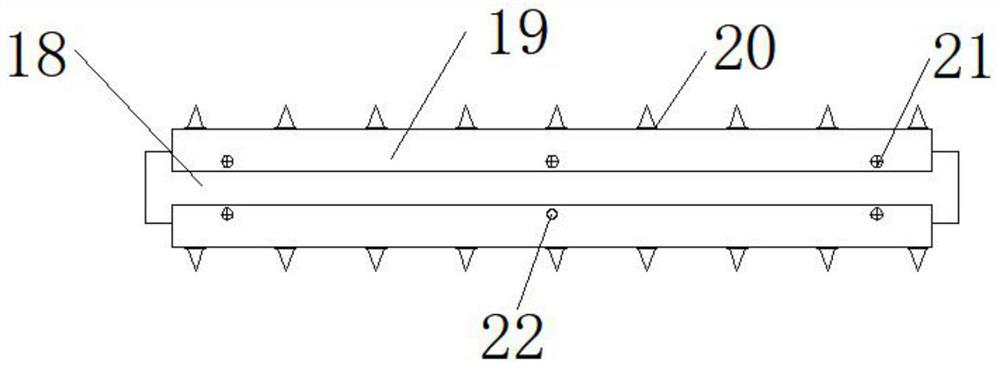

[0031] Example 1: See Figure 1-6 , a new moisture-proof balsa wood material for wind power blades and its preparation process, comprising a base 1 and a moisture-proof balsa wood main body 18, support frames 2 are provided on both sides of the top of the support frame 2, and electric sliding slides are installed on the top of the inside of the base 1 rail 7, the top of the base 1 is provided with a workbench 5, the four corners between the base 1 and the workbench 5 are fixedly connected with feet 3, one side of the workbench 5 is equipped with a servo motor 13, and the output end of the servo motor 13 The threaded rod 4 is fixedly connected, the two sides outside the threaded rod 4 and the limit slide rod 28 are provided with an adjustment sleeve 14, the top of the adjustment sleeve 14 is fixedly connected with a connecting plate 6, and one side of the connecting plate 6 is fixedly connected with the limit plate 12 , a connecting block 27 is fixedly connected between the con...

Embodiment 2

[0034] Embodiment 2: The bottom end of the threaded rod 4 is provided with a limit slide rod 28, the threads on both sides of the threaded rod 4 are opposite, the threaded rod 4 is movably connected to the inside of the workbench 5, and the two sides of the threaded rod 4 are provided with external threads , the interior of the adjustment sleeve 14 is provided with an internal thread, and the threaded rod 4 and the adjustment sleeve 14 cooperate with each other;

[0035] Specifically, such as figure 1 with Figure 4 As shown, the limit slide bar 28 is set at the bottom of the threaded rod 4, and the limit slide bar 28 can rotate the adjustment sleeve 14 to limit the rotation and prevent the adjustment sleeve 14 from turning over on the outside of the thread rod 4, so that the adjustment sleeve 14 can move left and right to adjust the limit. The diameter between the bit plates 12 can facilitate the clamping of timbers of different lengths.

Embodiment 3

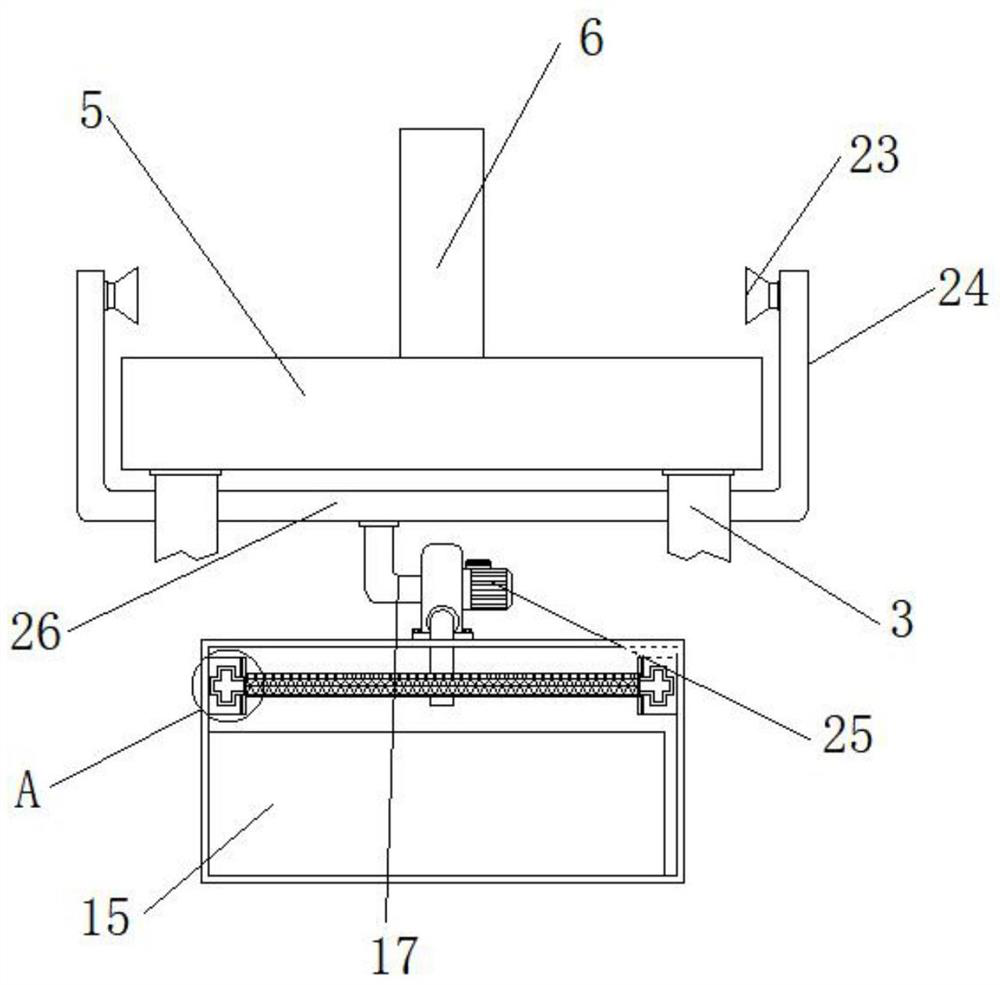

[0036]Embodiment 3: the top of the storage box 15 is equipped with an exhaust fan 25, the output end and the input end of the exhaust fan 25 are respectively fixedly connected with a connecting pipe 17, and the top of the connecting pipe 17 is fixedly connected with a branch pipe 26, and the two ends of the branch pipe 26 top are fixed. Connected with a dust suction pipe 24, one end of the dust suction pipe 24 is fixedly connected with a dust suction port 23, and the bottom end of the connecting pipe 17 runs through the top of the storage box 15;

[0037] Specifically, such as figure 1 , image 3 , Figure 5 with Image 6 As shown, the grinding disc 11 starts the exhaust fan 25 when grinding the moisture-proof balsa wood new material, and the exhaust fan 25 absorbs the debris generated by grinding to the inside of the storage box 15 through the connecting pipe 17 and the dust suction port 23, and through the grinding The generated debris is adsorbed to the inside of the sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com