Off-road vehicle composite trailing arm and manufacturing method thereof

A composite material and manufacturing method technology, applied in chemical instruments and methods, vehicle parts, wood-layered products, etc., can solve the problems of large trailing arm mass and reduce trailing arm mass, and achieve high safety factor and reduced mass. , to ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

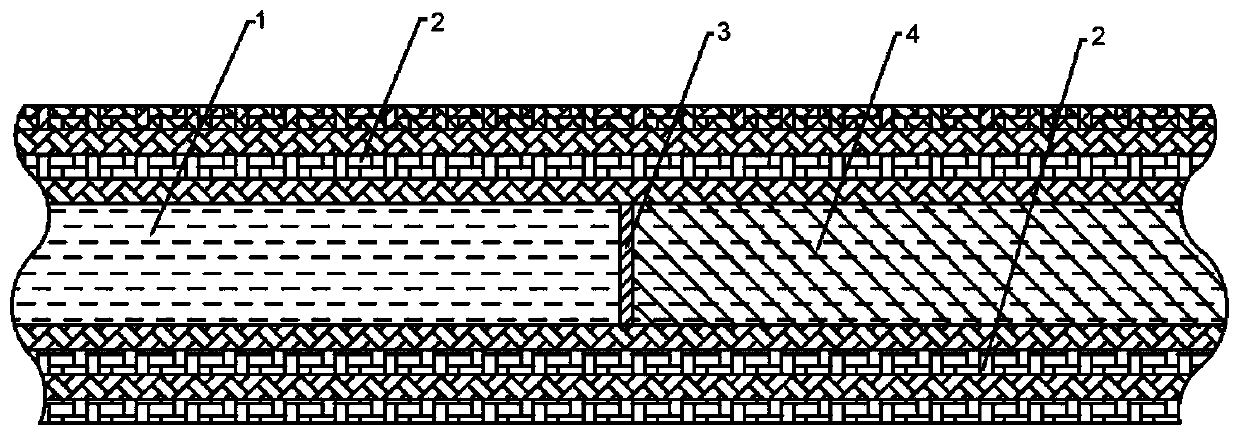

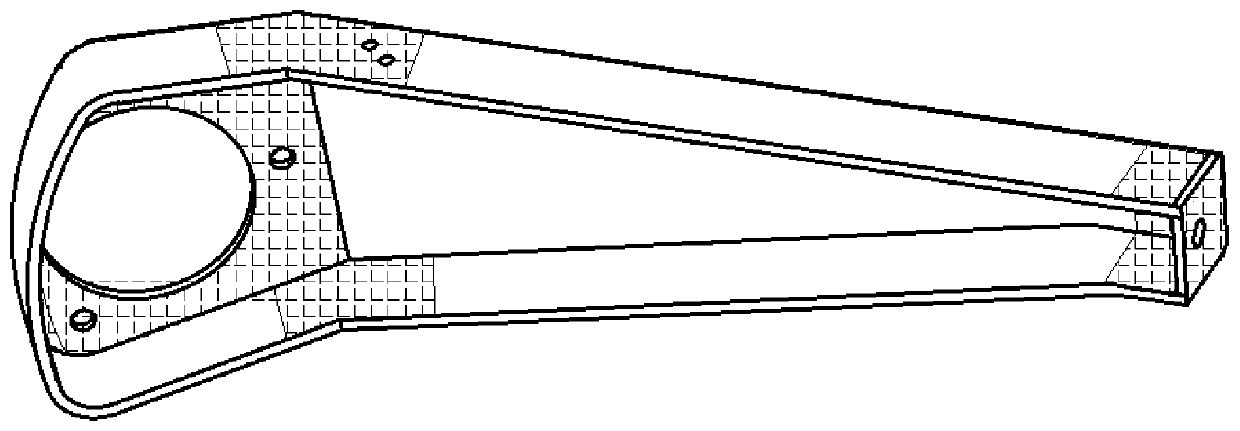

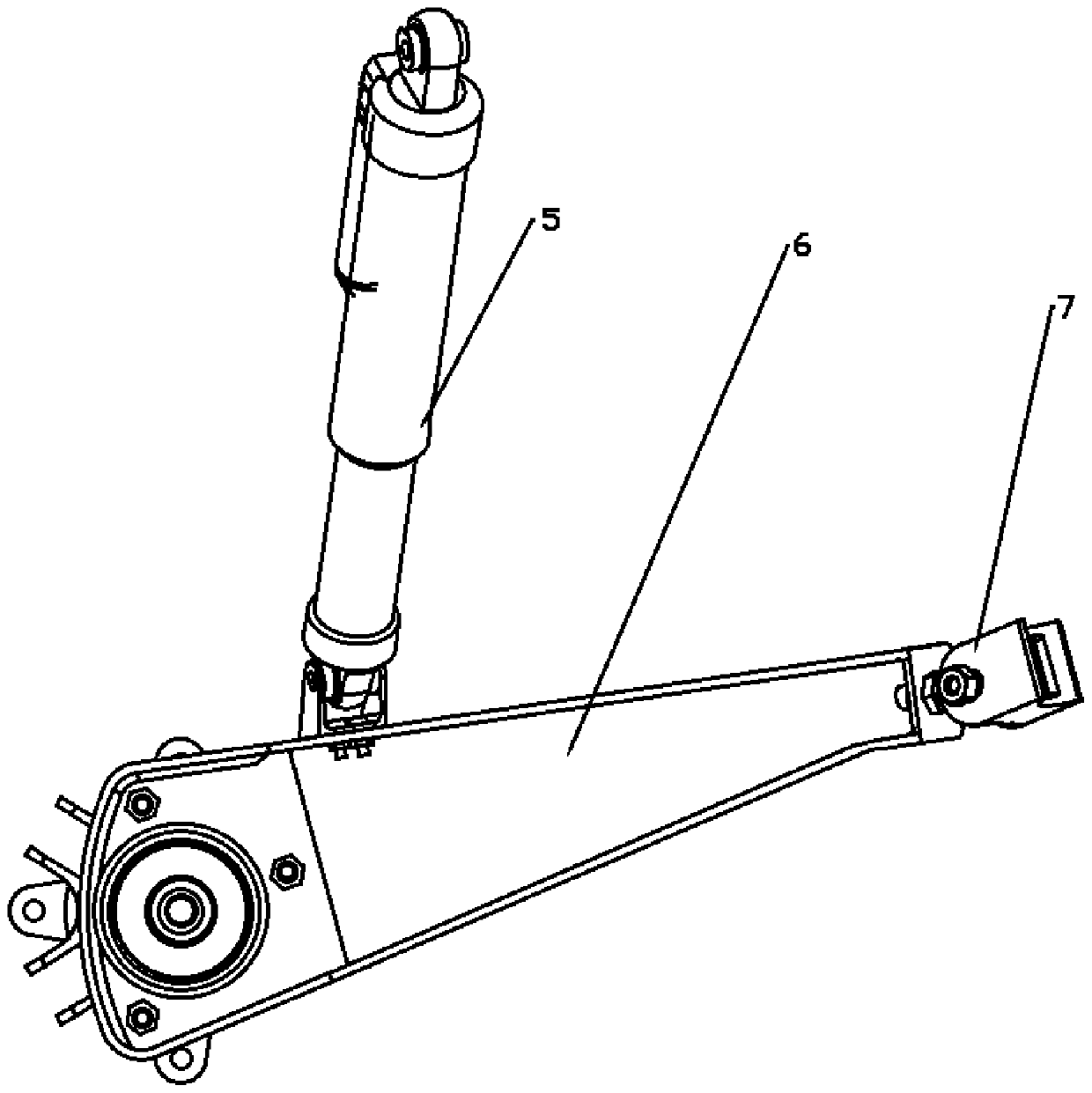

[0042] Refer to figure 1 , figure 2 , An off-road vehicle composite material trailing arm, the trailing arm 6 includes a support frame layer; the support frame layer is covered with an adhesive film layer; the outer side of the adhesive film layer is covered with a carbon fiber material layer 2.

[0043] The carbon fiber material layer 2 adopts a 45-degree alternately layered interwoven carbon fiber cloth, and the number of layers of the carbon fiber material layer 2 is 6-20.

[0044] The connecting portion of the trailing arm 6 and the wheel assembly 8, the connecting portion of the shock absorber lower ear piece 9 of the shock absorber 5, the connecting portion of the trailing arm front ear piece and the upper and lower corners of the trailing arm are made of aluminum material 4 is used as the core material; the remaining part uses the balsa material 1 as the core material to build the supporting frame of the trailing arm; the aluminum material 4 and the balsa material 1 are conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com