Novel hockey goaltender stick and method of making the same

A production method and hockey technology, applied to rackets, manufacturing tools, sports accessories, etc., can solve the problems of hockey goalkeeper's clubs such as short service life, easy bending and deformation of goalkeeper boards, and poor shock resistance of goalkeeper boards, so as to increase shock absorption and durability. Playability, prevent breakage and bending deformation, and increase dexterity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

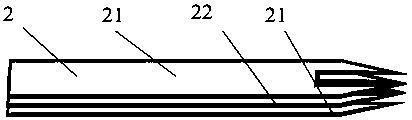

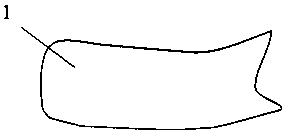

[0042] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, a new type of hockey goalkeeper club described in this embodiment includes a front filling plate, a middle filling plate, a plug filling plate and a handle, and the outer covering after the front filling plate, the middle filling plate and the plug filling plate are connected Three layers of glass fiber yarn materials form the gatekeeper board, wherein the middle filling board is composed of EPOXY, balsa wood and EPOXY three layers of materials sequentially, and the plug filling board in the gatekeeper board is inserted into the handle and the two are fixedly connected. The said balsa wood has a density of 80kg / m 3 Wooden material; said EPOXY has a density of 0.08g / cm 3 epoxy foam material.

Embodiment 2

[0044] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, a new type of hockey goalkeeper club described in this embodiment includes a front filling plate, a middle filling plate, a plug filling plate and a handle, and the outer covering after the front filling plate, the middle filling plate and the plug filling plate are connected Five layers of carbon fiber yarn materials form the goalkeeper board, wherein the middle filling board is composed of EPOXY, balsa wood, and EPOXY three-layer material sequentially. The plug filling board in the gatekeeping board is inserted into the handle and the two are fixedly connected. The balsa wood has a density of 135kg / m 3 Wooden material; said EPOXY is a density of 0.05g / cm 3 epoxy foam material.

Embodiment 3

[0046] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6As shown, a new type of hockey goalkeeper club described in this embodiment includes a front filling plate, a middle filling plate, a plug filling plate and a handle, and the outer covering after the front filling plate, the middle filling plate and the plug filling plate are connected Two layers of glass fiber yarn materials form the guard board, wherein the middle filling board is composed of EPOXY, balsa wood, and EPOXY three-layer material sequentially. The plug filling board in the gate guard board is inserted into the handle and the two are fixedly connected. The balsa wood has a density of 100kg / m 3 Wooden material; said EPOXY has a density of 0.06g / cm 3 epoxy foam material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com