Fastening element

A fastening element and fastening technology, applied in the direction of threaded fasteners, connecting components, screws, etc., can solve the problem of small loadability and achieve the effect of simplifying screw-in

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

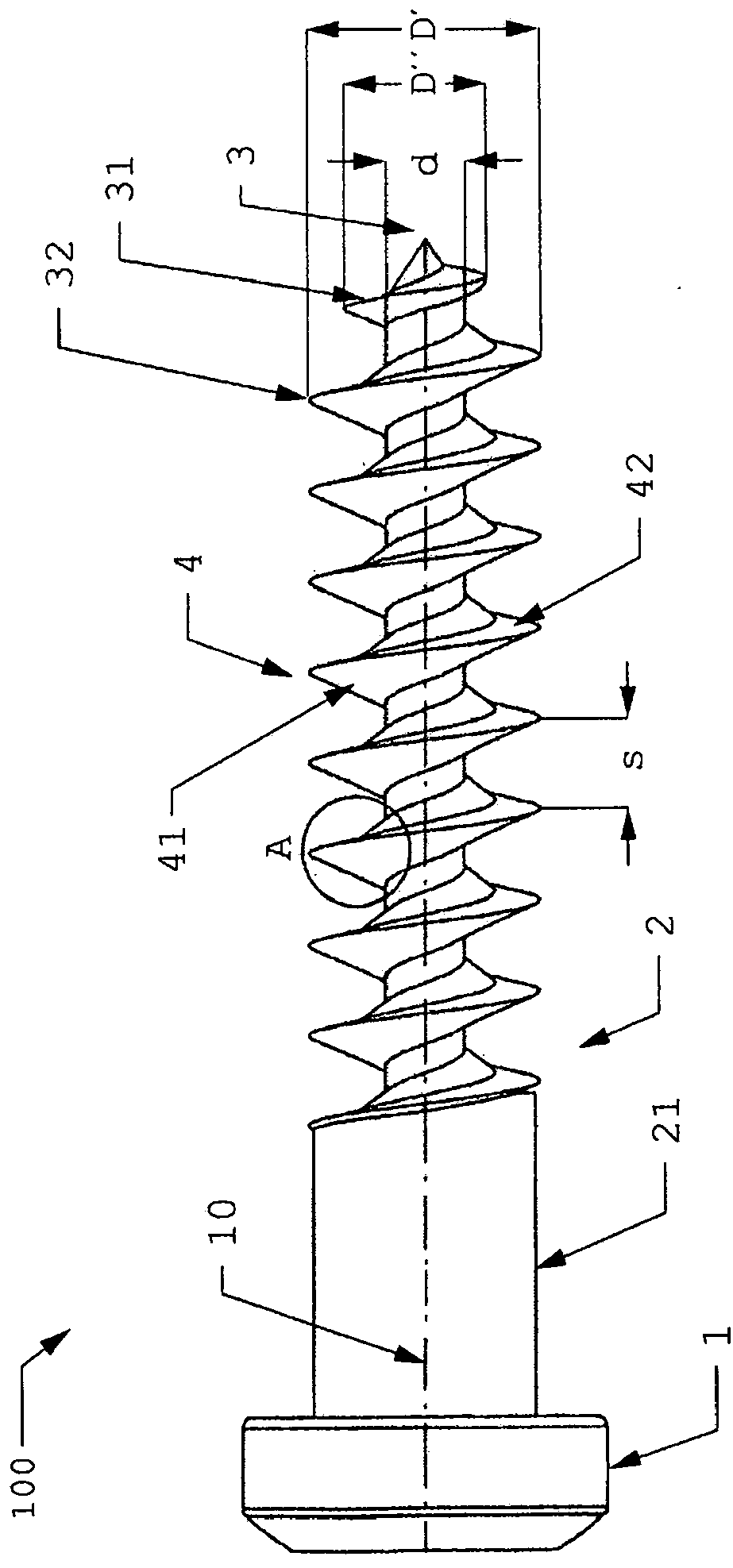

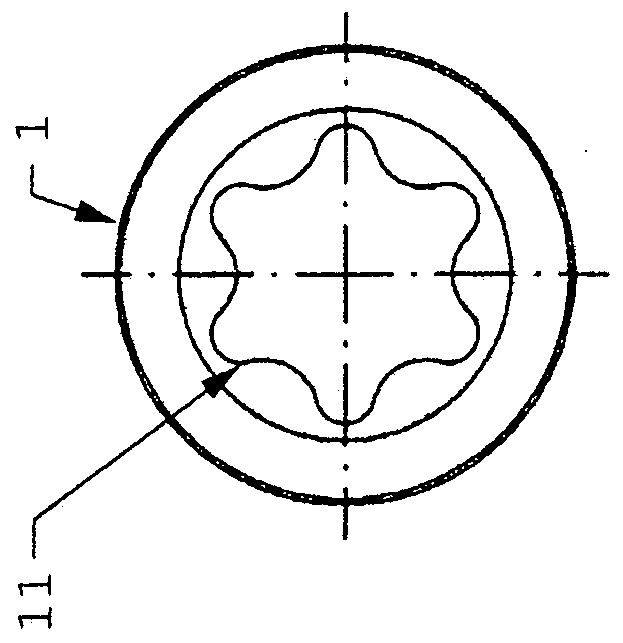

[0045] figure 1 An embodiment of a fastening element 100 according to the invention is shown, which has a fastening head 1 and a shank 2 which extends from the fastening head 1 in the direction of the main axis 10 and faces away from the The end of the fastening head 1 ends with a point 3 .

[0046] The length of the shank 2 extending from one end of the shank 2 , ie from the fastening head 2 up to the tip 3 , is preferably approximately 22 mm or approximately 25 mm.

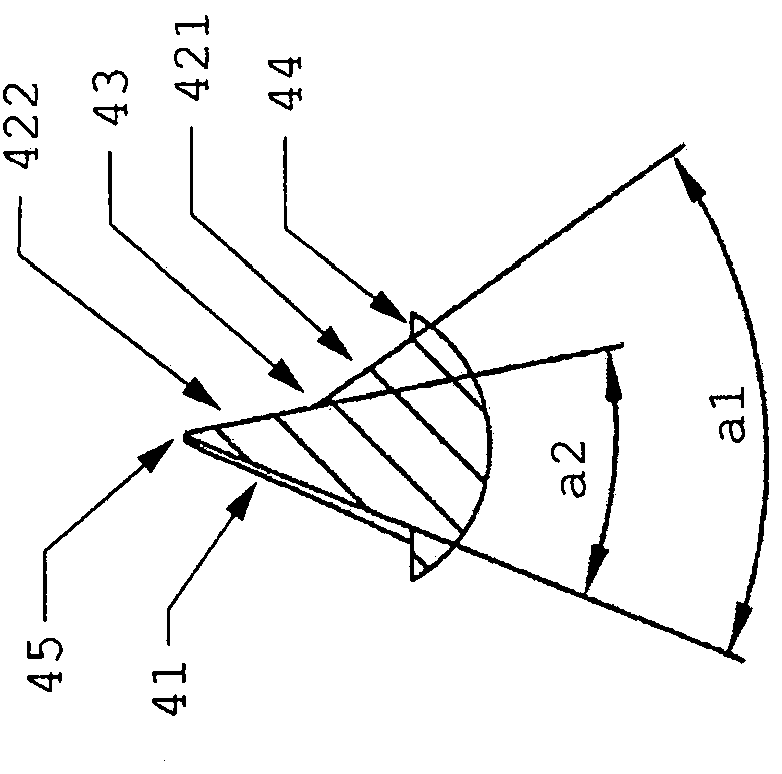

[0047] The shank 2 has an external thread 4 over a portion of its extent in the direction of the main axis 10 . In the embodiment shown, the external thread 4 is a right-handed thread, ie the thread line rises to the right in a plan view of the thread and the fastening element is thus screwed into the material in a clockwise direction. In another embodiment, however, the external thread 4 can also be a left-handed thread which is screwed into the material in a counterclockwise direction.

[0048]The diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com