Balsa wood-derived binder-free self-standing carbon foam negative electrode material and preparation method thereof

A negative electrode material, binder-free technology, applied in the field of binder-free self-supporting carbon foam negative electrode material and its preparation, can solve the problems of unfavorable electrolyte infiltration, small contact area, electrode crushing, etc., and achieve enhanced electron transfer , Improve energy density, improve wettability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

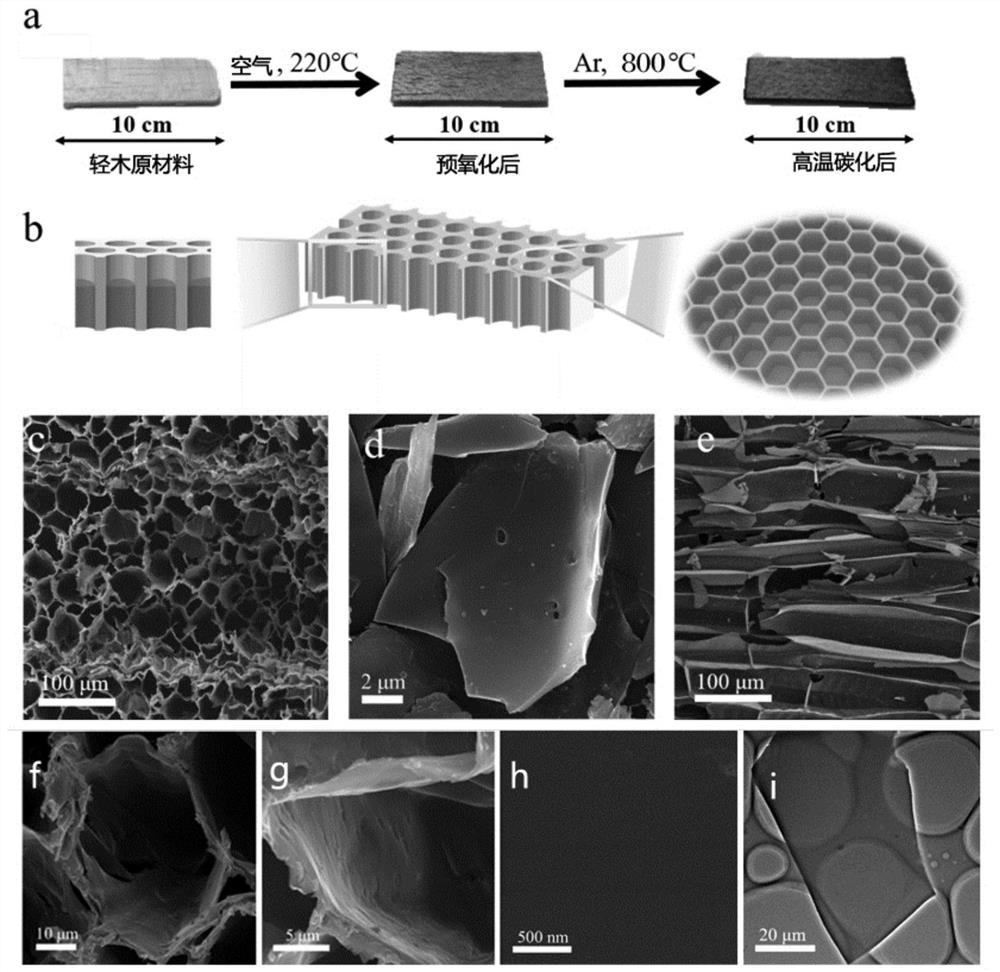

[0035] First, clean and dry the balsa wood precursor: cut the balsa wood into small pieces, put them in a petri dish, and then wash them repeatedly with deionized water; then put the cleaned balsa wood into a petri dish at 70°C to fully dry;

[0036] Secondly, pre-oxidize the balsa wood: put the dried balsa wood into an air atmosphere muffle furnace, -1 Raise the temperature to 220°C at a certain rate, and heat it at this temperature for 30 minutes;

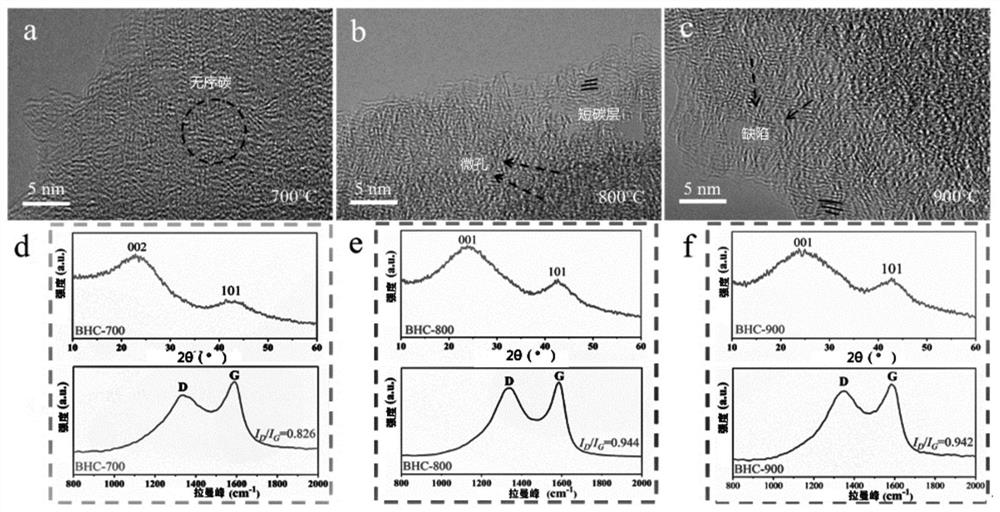

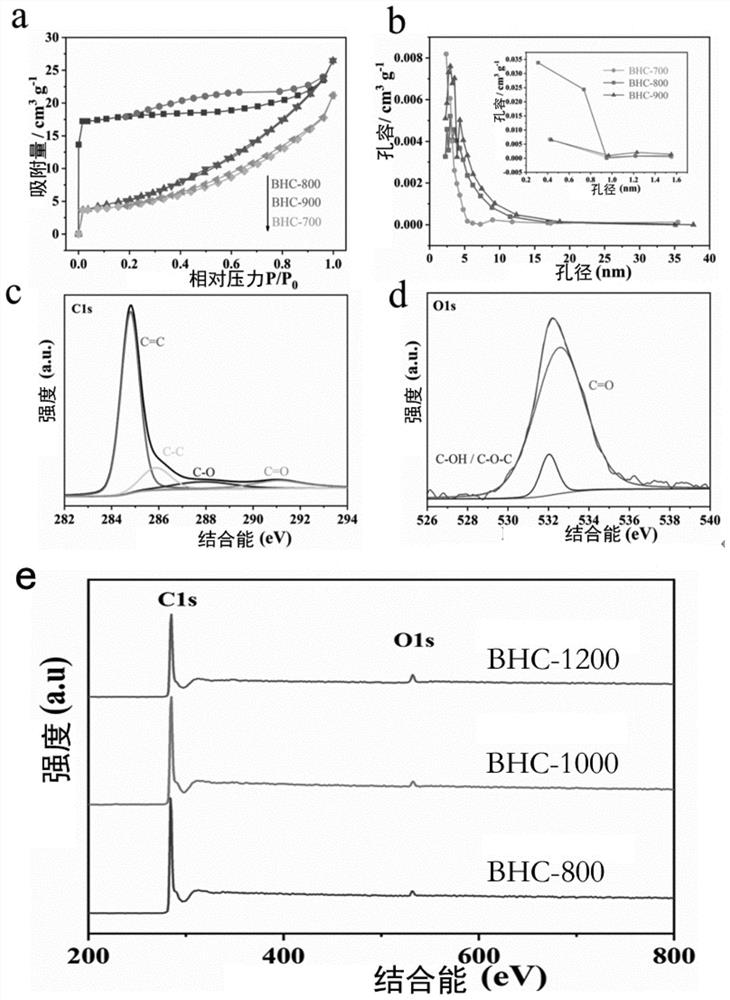

[0037] Finally, high-temperature carbonization treatment: put the pre-oxidized material into a reaction furnace with an argon atmosphere, and heat it at 5°C min -1 The temperature was raised to 800°C at a high temperature, and annealed and carbonized at this high temperature for 2 hours to obtain a binder-free self-standing carbon foam negative electrode material (BHC-800);

Embodiment 2

[0039] The high-temperature carbonization temperature of embodiment 2 is 700 ℃, and others are consistent with embodiment 1, obtain non-binder free-standing carbon foam negative electrode material (BHC-700);

Embodiment 3

[0041] The high-temperature carbonization temperature of embodiment 3 is 900 ℃, and others are all consistent with embodiment 1, obtain non-binder free-standing carbon foam negative electrode material (BHC-900);

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com