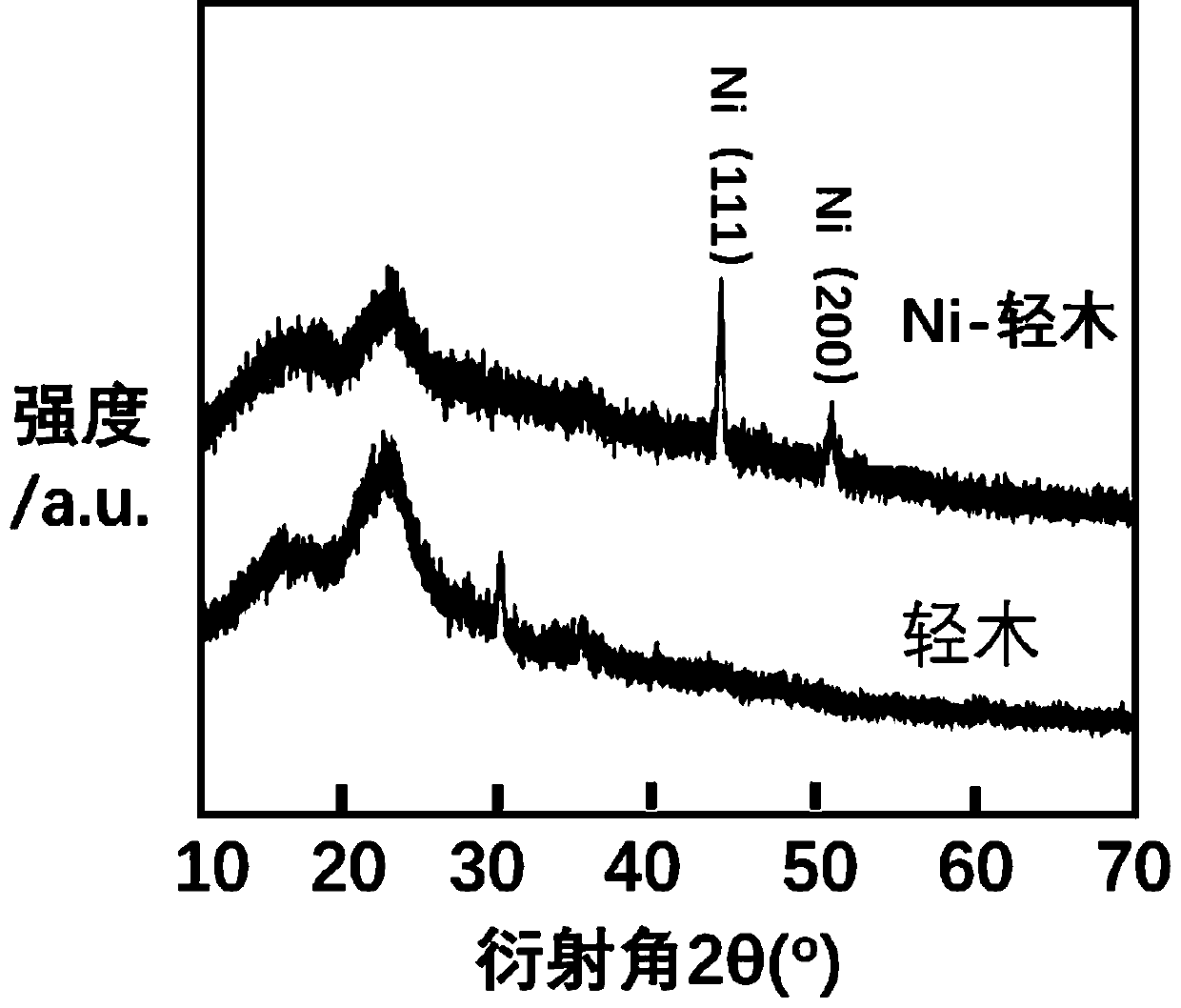

Preparation process for metallic nickel-balsa wood composite material

A composite material and preparation technology, applied in the direction of wood processing equipment, wood treatment, manufacturing tools, etc., to achieve the effect of convenient operation, safe and reliable processing, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] see figure 1 , the present invention provides following technical scheme: a kind of preparation technology of metallic nickel-balsa wood composite material, comprises the following steps:

[0020] A. First place the balsa wood in a drying oven for heat treatment;

[0021] B, then the balsa wood after heat treatment is placed in the suspension solution of nickel acetate and handles;

[0022] C, the finished balsa wood sample is placed in the blast dryer for drying treatment;

[0023] D. Finally dry until the weight of the sample remains unchanged.

[0024] In this embodiment, the processing temperature in step A ranges from 110° C., and the processing time is 12 hours.

[0025] In this embodiment, the treatment temperature in step B is 40° C., and the treatment time is 6 hours.

[0026] In the present embodiment, the suspension solution of nickel acetate described in step B comprises nickel acetate, sodium borohydride and deionized water, and the mass ratio of descri...

Embodiment 2

[0029] A kind of preparation technology of metallic nickel-balsa wood composite material, comprises the following steps:

[0030] A. First place the balsa wood in a drying oven for heat treatment;

[0031] B, then the balsa wood after heat treatment is placed in the suspension solution of nickel acetate and handles;

[0032] C, the finished balsa wood sample is placed in the blast dryer for drying treatment;

[0033] D. Finally dry until the weight of the sample remains unchanged.

[0034] In this example, the processing temperature in step A ranges from 100° C., and the processing time is 12 h.

[0035] In this embodiment, the treatment temperature in step B is 50° C., and the treatment time is 4 hours.

[0036] In the present embodiment, the suspension solution of nickel acetate described in step B comprises nickel acetate, sodium borohydride and deionized water, and the mass ratio of described nickel acetate, sodium borohydride and deionized water is 1:6:1, and then Add...

Embodiment 3

[0039] A kind of preparation technology of metallic nickel-balsa wood composite material, comprises the following steps:

[0040] A. First place the balsa wood in a drying oven for heat treatment;

[0041] B, then the balsa wood after heat treatment is placed in the suspension solution of nickel acetate and handles;

[0042] C, the finished balsa wood sample is placed in the blast dryer for drying treatment;

[0043] D. Finally dry until the weight of the sample remains unchanged.

[0044] In this embodiment, the treatment temperature in step A ranges from 95° C., and the treatment time is 7 hours.

[0045] In this embodiment, the treatment temperature in step B is 46° C., and the treatment time is 8 hours.

[0046] In the present embodiment, the suspension solution of nickel acetate described in step B comprises nickel acetate, sodium borohydride and deionized water, and the mass ratio of described nickel acetate, sodium borohydride and deionized water is 1:7:1, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Absolute dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com