A method for making aeroelastic wind tunnel test model of wind turbine blade

A technology for wind turbine blades and aeroelastic models, which is applied in the field of wind tunnel testing, can solve problems such as large differences in production methods, and achieve the effects of short cycle, high precision and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

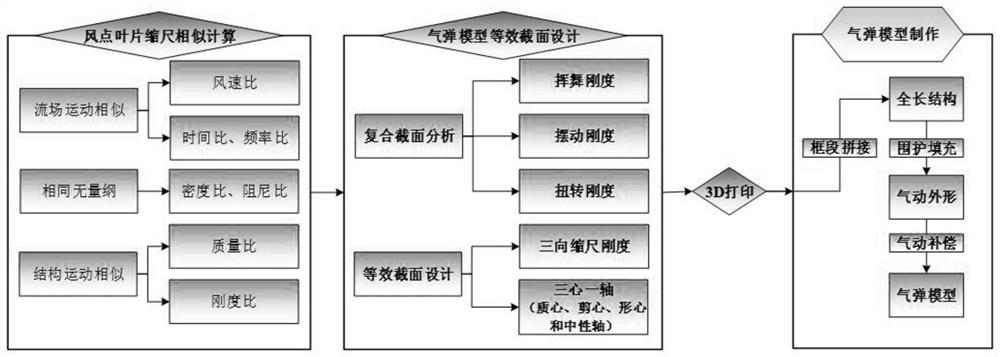

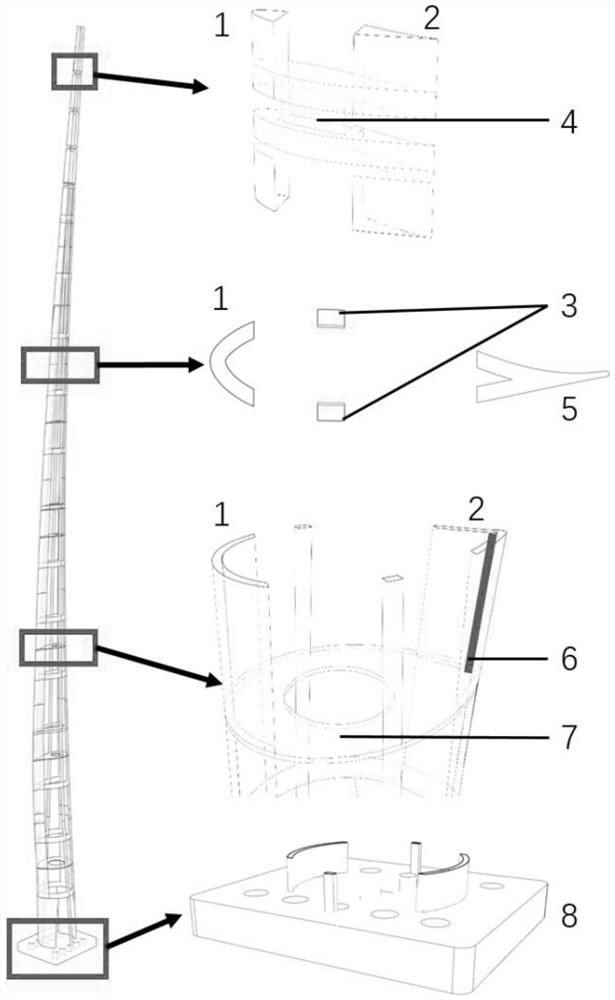

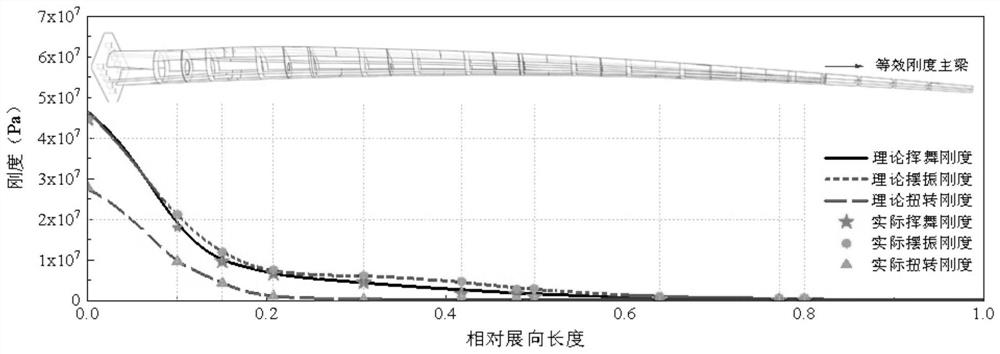

[0046] The present invention provides a wind turbine blade aeroelastic wind tunnel test model and a manufacturing method, including a reasonable simplification similarity criterion for the wind turbine blade aeroelastic model, a design method for the equivalent section of the aeroelastic model, and a method for making a frame segment / coat of the aeroelastic model. Firstly, based on kinematic equivalence, a reasonable simplification similarity criterion for the aeroelastic model of wind turbine blades is derived. Then, the variational asymptotic equivalent section method (VPES) is proposed to design a high-precision equivalent wind turbine blade model with special-shaped section, and realize the aero-elastic model of blade aero- Aeroelastic model design based on stiffness-mass scale mapping; finally, relying on high-precision 3D printing to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com