Composite packaging film, packaging system and packaging method

A composite packaging film and composite material technology, applied in the field of packaging balsa wood and composite packaging film, can solve the problems of fan blade quality, moisture content can not meet the requirements, ordinary plastic packaging film is easily damaged, etc., to achieve excellent mechanical properties, excellent Water vapor barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

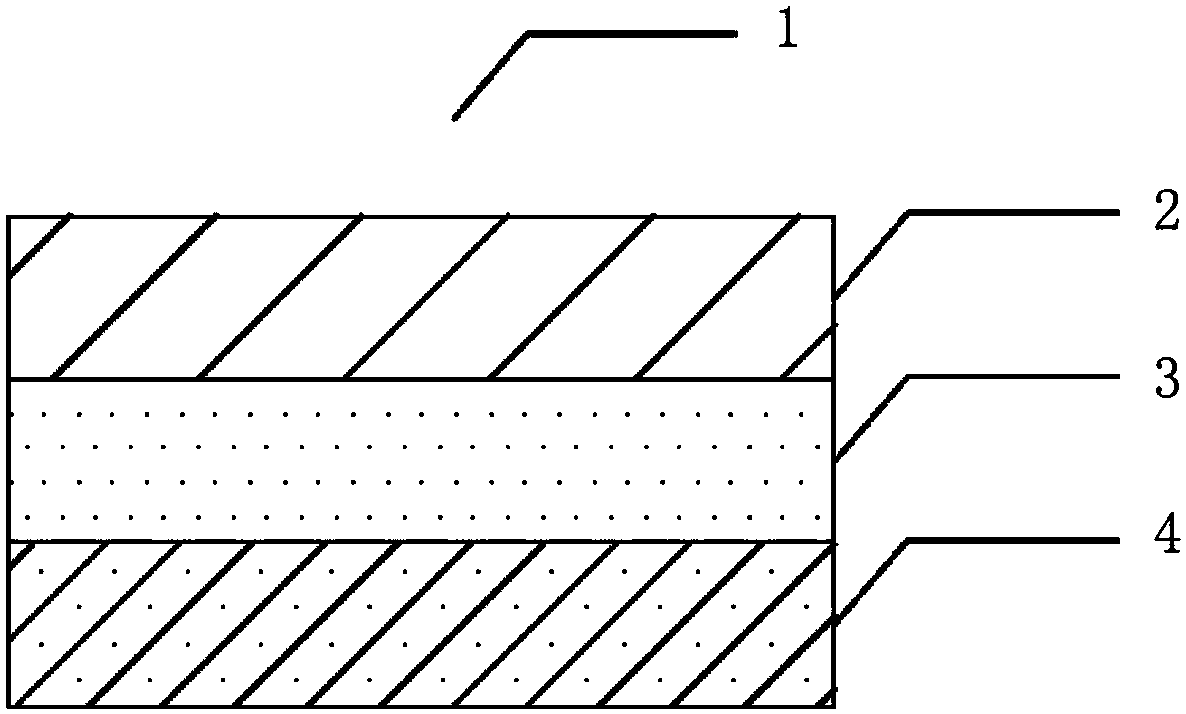

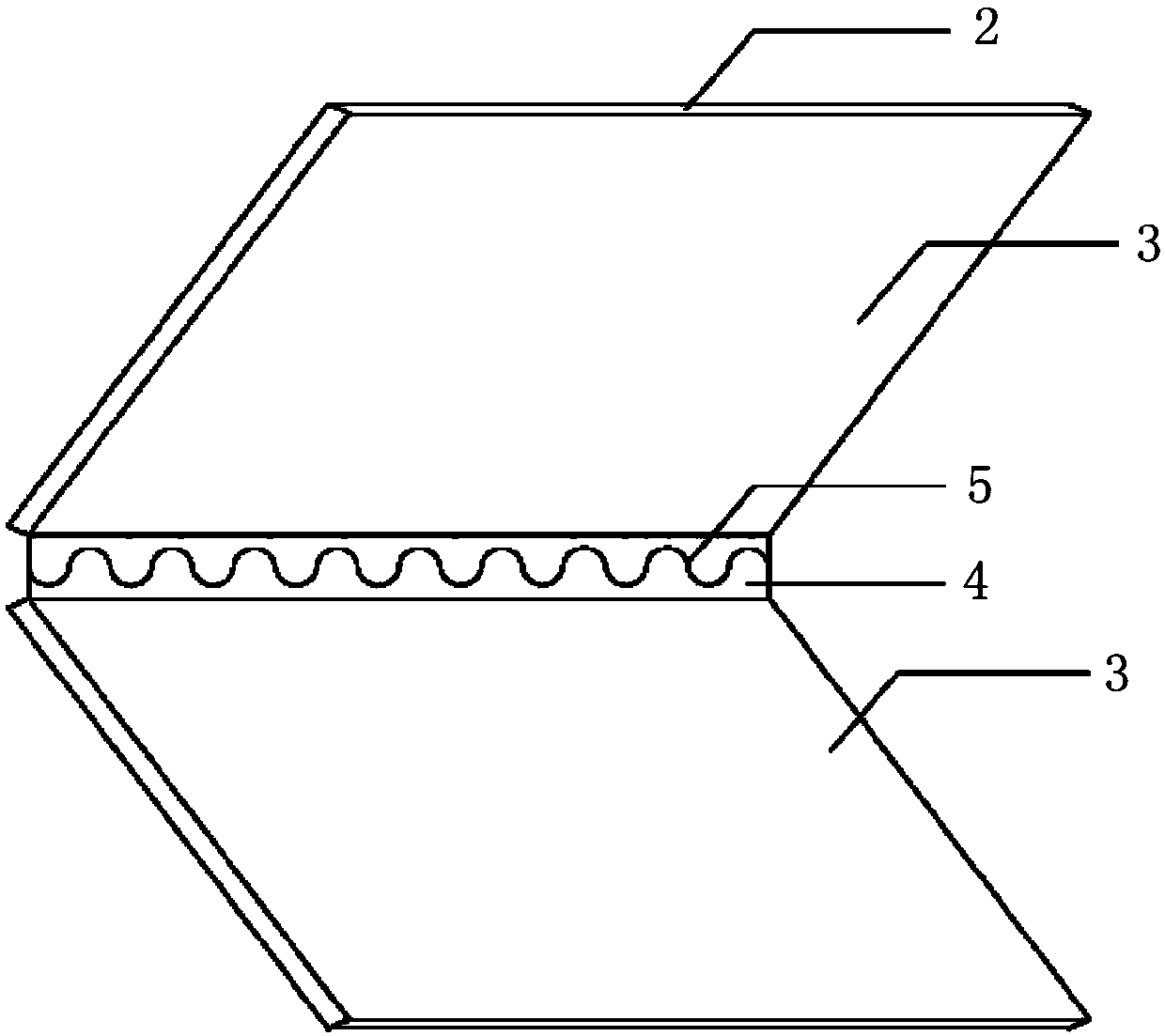

[0046] Such as figure 1 As shown, the composite packaging film 1 of Example 1 of the present application includes an inner layer 4 , an outer layer 2 , and an intermediate layer 3 located between the inner layer 4 and the outer layer 2 . The inner layer 4 is made of fiber-reinforced polyurethane elastomer composite material, and in the fiber-reinforced polyurethane elastomer composite material, the weight ratio of nylon mesh cloth to polyurethane elastomer is 20:80. The thickness of the inner layer 4 is 0.01 mm. The middle layer 3 is a silicone self-adhesive tape with a thickness of 0.2mm. The outer layer 2 is a 0.1 mm thick nylon membrane.

Embodiment 2

[0048] The structure of Example 2 of the present application is the same as that of Example 1, except that the inner layer 4 is made of fiber-reinforced polyurethane elastomer composite material, and in the fiber-reinforced polyurethane elastomer composite material, polyester grid cloth and polyurethane elastic The weight ratio of the body is 80:20, and the thickness of the inner layer 4 is 0.5mm. The middle layer 3 is a silicone self-adhesive tape with a thickness of 0.5mm. The outer layer 2 is a 0.4 mm thick polyethylene film.

Embodiment 3

[0050] The structure of Example 3 of the present application is the same as that of Example 1, except that the inner layer 4 is made of a fiber-reinforced polyurethane elastomer composite material, and in the fiber-reinforced polyurethane elastomer composite material, polyimide and polyurethane elastomer The weight ratio of the inner layer 4 is 40:60, and the thickness of the inner layer 4 is 0.8mm. The middle layer 3 is a silicone self-adhesive tape with a thickness of 0.3mm. The outer layer 2 is a 0.3 mm thick nylon membrane. In addition, in the inner layer 4, 2% by weight of n-butyl-phenylisothiazoline-trione is added with respect to the total weight of the inner layer 4, and in the inner layer 4, with respect to the total weight of the inner layer 4, weight, with the addition of 4% by weight of silica gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com