Preparation method of porous structure functional wood base material

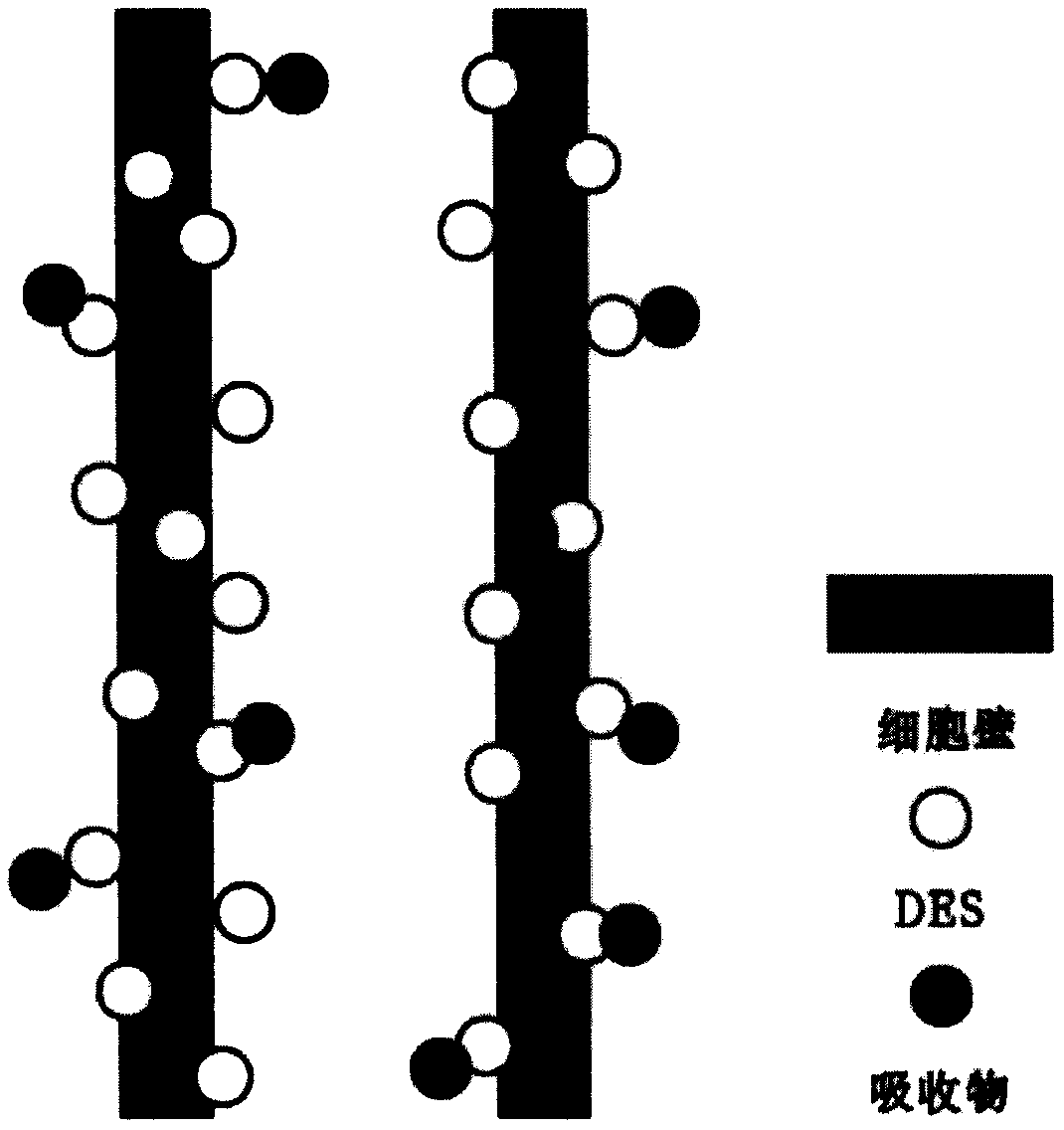

A wood-based, functional technology, applied in wood heating, wood impregnation, wood treatment, etc., can solve problems such as environmental pollution, achieve environmental friendliness, uniform pores, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

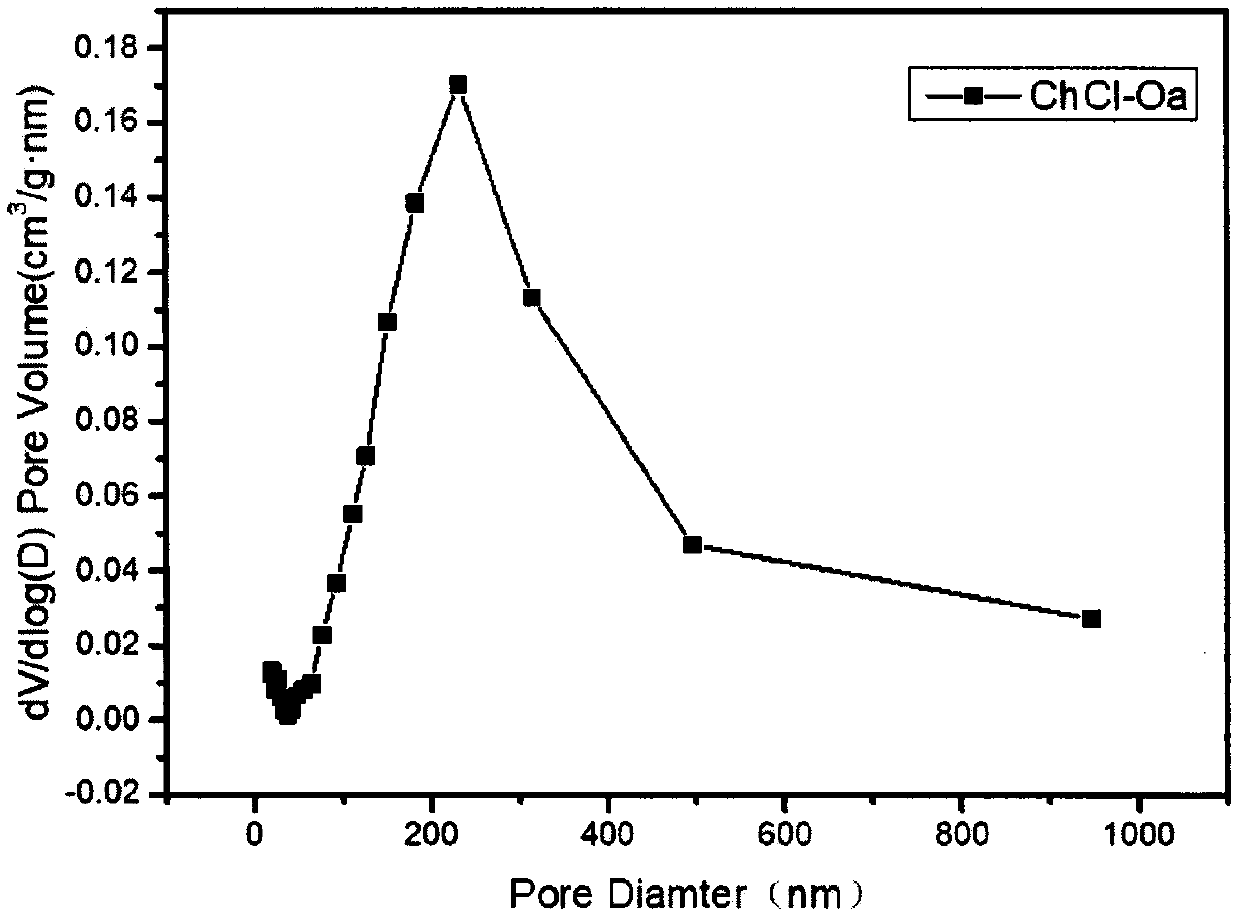

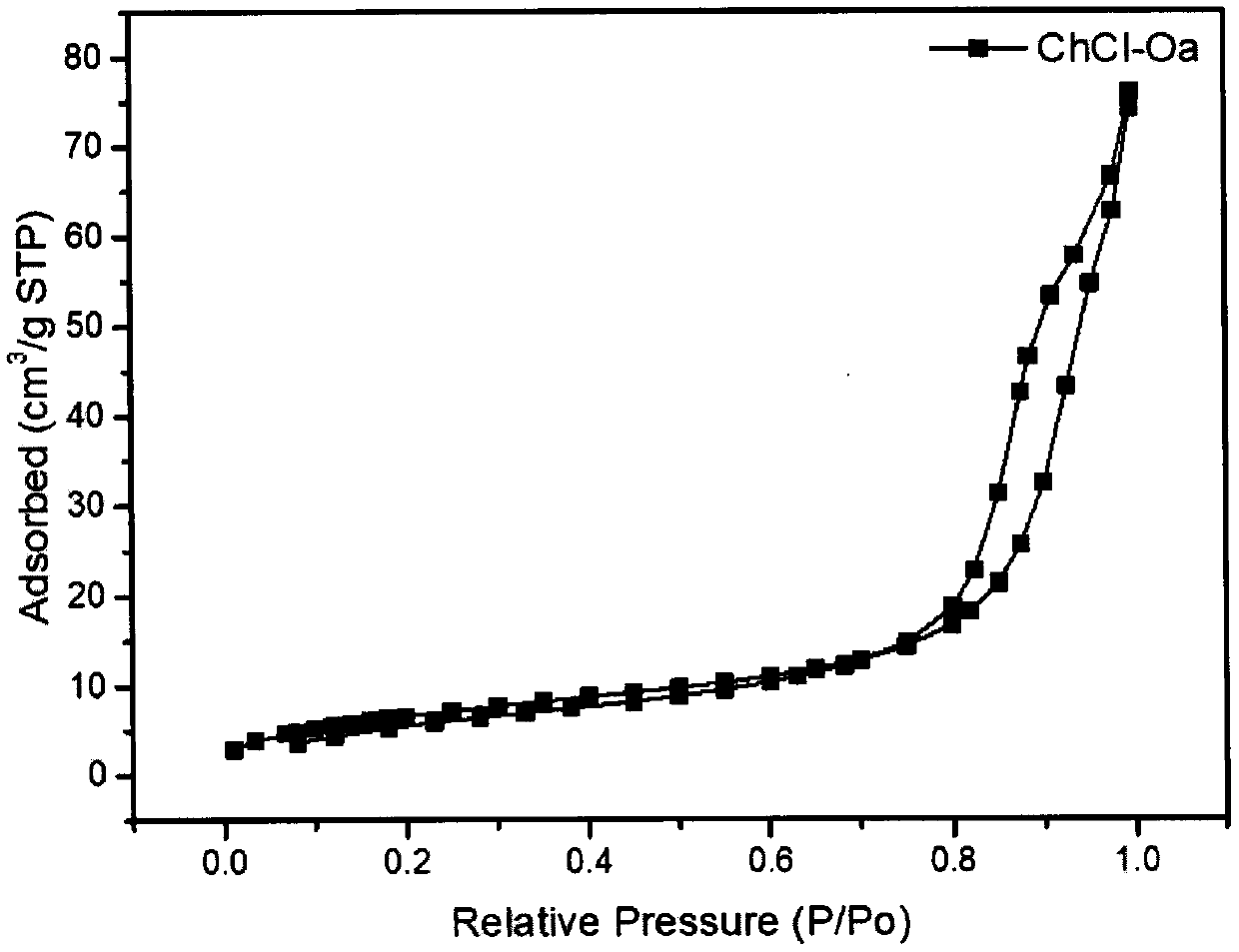

[0036] (1) Heating choline chloride and oxalic acid at a molar ratio of 1:1 at 90°C for 0.5h to prepare a DES solution;

[0037] (2) Put poplar wood into the 500mL beaker of DES solution prepared in step (1), the bath ratio is 1: 20, the heating temperature is 90°C, and the heating time is 6h;

[0038] (3) Take out the wood sample treated with DES in step (2), and after natural cooling, first clean the DES on the surface with deionized water, then soak the wood in absolute ethanol to remove the remaining reaction solution, and the soaking time is 2h;

[0039] (4) add 10% H to the wood obtained in step (3) to remove a large amount of lignin and hemicellulose 2 o 2 solution, and then slowly dropwise add NaOH solution to pH 9, and heat the above solution at a reaction temperature of 80°C for 6h;

[0040] (5) Soak the wood prepared in step (4) in absolute ethanol with a solid-to-liquid ratio of 1:5 for 2 hours, and exchange the remaining reaction solution in the wood;

[0041] ...

Embodiment 2

[0045] (1) heating choline chloride and formic acid at 60° C. for 2 hours at a molar ratio of 1:2 to obtain a DES solution;

[0046] (2) put the balsa wood into the 500mL beaker of the DES solution prepared in the step (1), and immerse completely, the bath ratio is 1: 20, the heating temperature is 120 ℃, and the heating time is 4h;

[0047] (3) The wood sample treated with DES in step (2) is taken out, after natural cooling, the DES on the surface is cleaned with deionized water, and then soaked in acetone to remove the remaining reaction solution. The soaking time is 4h;

[0048] (4) add 30% H to the wood obtained in step (3) to remove a large amount of lignin and hemicellulose 2 o 2 solution, and then slowly dropwise add 10% NaOH solution to pH 11, and heat the above solution at a reaction temperature of 120°C for 2 hours;

[0049] (5) Soak the wood prepared in step (4) in an acetone solution with a solid-to-liquid ratio of 1:5 for 4 hours, and exchange the remaining reacti...

Embodiment 3

[0054] (1) heating choline chloride and lactic acid at a molar ratio of 1:1 at 80°C for 1.5h to prepare a DES solution;

[0055] (2) Put Paulownia wood into the DES solution 500mL beaker that makes in step (1) and submerge completely, bath ratio is 1: 20, and heating temperature is 60 ℃, and heating time is 10h;

[0056] (3) Take out the wood sample treated with DES in step (2), and after natural cooling, first clean the DES on the surface with deionized water, then soak the wood in a mixed solution of absolute ethanol and acetone to remove the remaining reaction solution, and the soaking time is 6h;

[0057] (4) add 20% H to the wood obtained in step (3) to remove a large amount of lignin and hemicellulose 2 o 2 solution, and then slowly drop NaOH solution dropwise until the pH is 10.5, and heat the above solution at a reaction temperature of 100°C for 4h;

[0058] (5) Soak the wood prepared in step (4) in a mixed solution of absolute ethanol and acetone with a solid-to-li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com