A kind of acrylate anticorrosion coating liquid which can be repaired automatically in sodium chloride aqueous solution and its preparation method and application

A technology of sodium chloride aqueous solution and acrylates, which is applied in the preparation of anti-corrosion coating liquid, intelligent anti-corrosion coating liquid and its preparation field, which can solve the problem of product protection and decoration discount, damage that cannot be repaired in time, and coating protection Function reduction and other problems, to achieve the effect of easy control of synthesis process, low cost and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

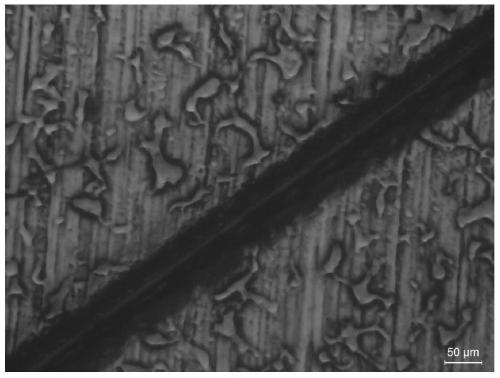

[0036] Embodiment 1 Preparation of an acrylic anticorrosion coating that can be automatically repaired in aqueous sodium chloride solution

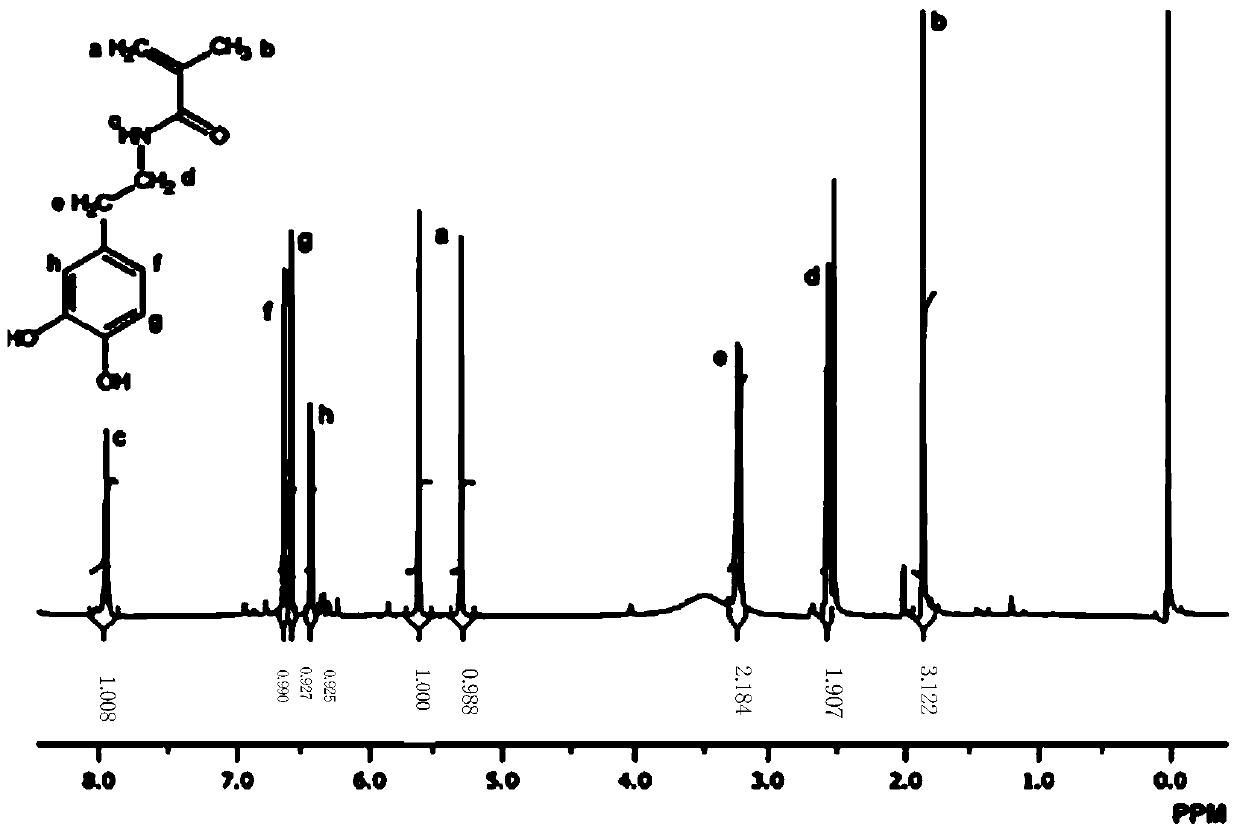

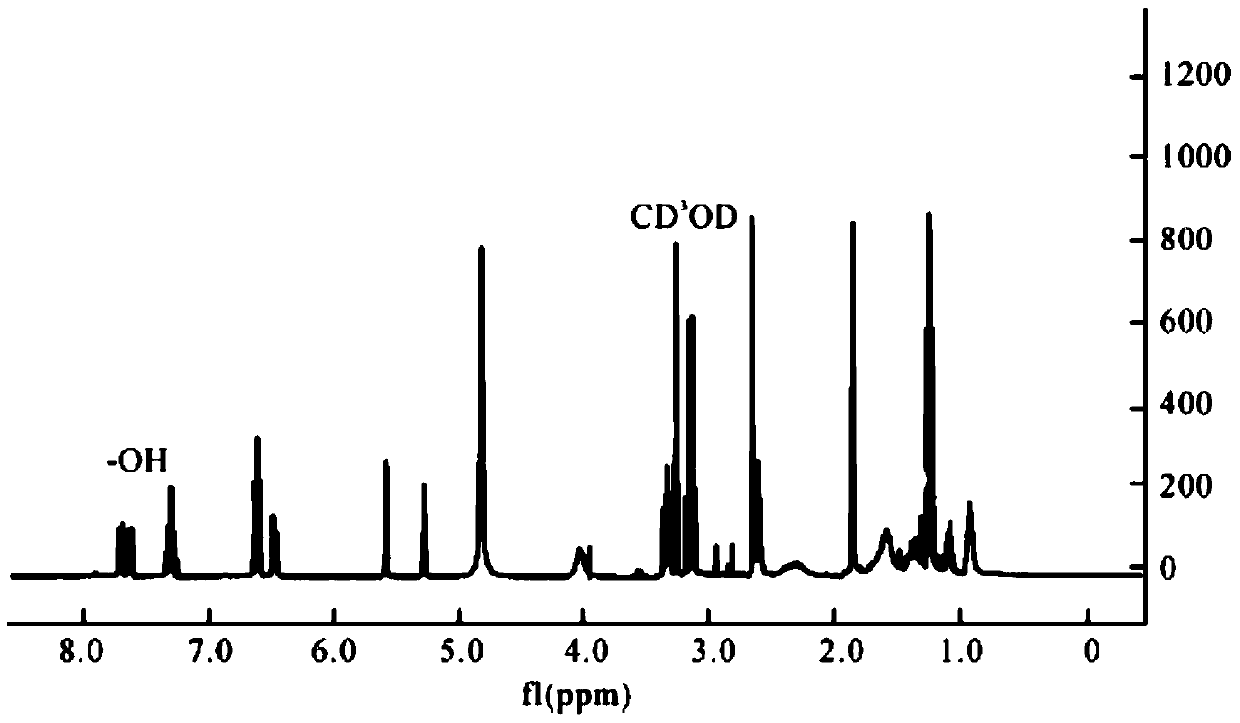

[0037] 1) Preparation of dopamine methacrylamide

[0038] Take by weighing 14.7g (77.7mmol) dopamine hydrochloride and be dissolved in 450ml water, then add borax decahydrate (Na 2 B 4 o 7 10H 2 O), stirred evenly under nitrogen protection at 0°C, and then gradually added 9ml (93.12mmol) of methacryloyl chloride dropwise in 10min using a constant pressure funnel. After reacting for 2 hours, stop the reaction and use Na 2 CO 3 Adjust the pH above 9.5. Then use acetic acid to adjust the pH value to 2, extract with ethyl acetate, take the organic phase part, anhydrous MgSO 4 Drying and removal of the solvent gave the crude product, which was recrystallized in ethyl acetate at -20°C and dried to give the fine product of dopamine methacrylamide in about 45% yield. The spectrogram of the H NMR spectrum of dopamine methacrylamide is as f...

Embodiment 2

[0044] Embodiment 2 Preparation of an acrylic anticorrosion coating that can be automatically repaired in aqueous sodium chloride solution

[0045] 1) Prepare dopamine methacrylamide functional monomer according to the same method as in Example 1, and set aside.

[0046] 2) Preparation of n-butyl acrylate, n-butyl methacrylate and dopamine methacrylamide terpolymer

[0047] in N 2 Under protection, weigh n-butyl acrylate 1.28g (10mmol), n-butyl methacrylate 1.41g (10mmol), dopamine methacrylamide 0.88g (4mmol) (the molar ratio of the three monomers is 5:5: 2) Put it into a polymerization bottle, dissolve it with 15g of dimethyl sulfoxide, add 1wt% (0.186g) of dimethyl azobisisobutyrate as an initiator, and then put the polymerization bottle into a constant temperature pot at 60°C for reaction 24h. The reaction mixture was washed three times with cyclohexane precipitation, and dried in a vacuum oven at 55°C.

[0048] 3) Dissolve 1 g of the terpolymer obtained in step 2) in ...

Embodiment 3

[0050] Embodiment 3 Preparation of an acrylic anticorrosion coating that can be automatically repaired in aqueous sodium chloride solution

[0051] 1) Prepare dopamine methacrylamide functional monomer according to the same method as in Example 1, and set aside.

[0052] 2) Preparation of n-butyl acrylate, n-butyl methacrylate and dopamine methacrylamide terpolymer

[0053] in N 2 Under protection, take 1.28g (10mmol) of n-butyl acrylate, 2.1g (15mmol) of n-butyl methacrylate, and 0.55g (2.5mmol) of dopamine methacrylamide. The molar ratio of these three monomers is 4:6: 1 Put it into a polymerization bottle, dissolve it with 15g of N,N-dimethylformamide, add 1wt% (0.189g) of azodicyclohexylcarbonitrile as an initiator, and then put the polymerization bottle into a constant temperature pot at 60°C Reaction 24h. The reaction mixture was washed three times with cyclohexane precipitation, and dried in a vacuum oven at 55°C.

[0054] 3) Dissolve 1 g of the terpolymer obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com