Nylon composite material for engineering machinery and preparation method thereof

A nylon composite material and construction machinery technology, applied in the field of construction machinery, can solve problems such as poor wear resistance, poor toughness, and limited applications, and achieve the effect of enhancing wear resistance and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

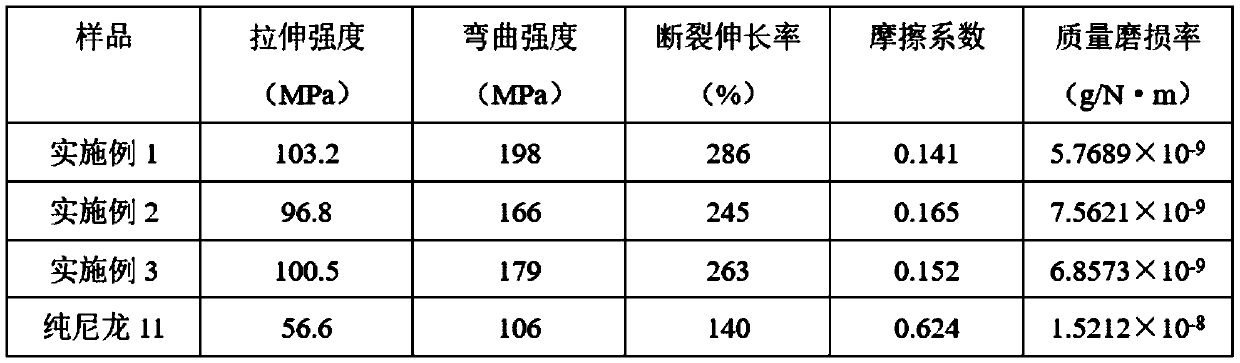

Examples

Embodiment 1

[0024] A kind of nylon composite material for construction machinery, its raw material is made up of the following components by weight:

[0025] 100 parts of aminoundecanoic acid, 10-20 parts of adipic acid, 0.05 parts of scandium chloride, 0.04-0.25 parts of silicon nitride hybrid.

[0026] Wherein, the preparation process of the silicon nitride hybrid is as follows:

[0027] (1) Add 2.0 g of silicon nitride with a particle size of 20 to 50 nm into 150 mL of toluene, and ultrasonically disperse at a temperature of 10 to 20 ° C for 1 hour to obtain a silicon nitride dispersion;

[0028] (2) Add 1.8g of toluene diisocyanate to the silicon nitride dispersion, raise the temperature to 90°C, stir and react for 3h under the protection of helium, add 2.1g of lauryl alcohol, and continue to stir and react for 6h under the protection of helium , cooled to room temperature to obtain a silicon nitride mixed solution; wherein, the stirring speed is 300-400rpm;

[0029] (3) Centrifuge ...

Embodiment 2

[0035] A kind of nylon composite material for construction machinery, its raw material is made up of the following components by weight:

[0036] 100 parts of aminoundecanoic acid, 10-20 parts of adipic acid, 0.05 parts of scandium chloride, 0.04-0.25 parts of silicon nitride hybrid.

[0037] Wherein, the preparation process of the silicon nitride hybrid is as follows:

[0038] (1) Add 2.0 g of silicon nitride with a particle size of 20 to 50 nm into 150 mL of toluene, and ultrasonically disperse at a temperature of 10 to 20 ° C for 1 hour to obtain a silicon nitride dispersion;

[0039] (2) Add 1.8g of toluene diisocyanate to the silicon nitride dispersion, raise the temperature to 90°C, stir and react for 3h under the protection of helium, add 2.1g of lauryl alcohol, and continue to stir and react for 6h under the protection of helium , cooled to room temperature to obtain a silicon nitride mixed solution; wherein, the stirring speed is 300-400rpm;

[0040] (3) Centrifuge ...

Embodiment 3

[0046] A kind of nylon composite material for construction machinery, its raw material is made up of the following components by weight:

[0047] 100 parts of aminoundecanoic acid, 10-20 parts of adipic acid, 0.05 parts of scandium chloride, 0.04-0.25 parts of silicon nitride hybrid.

[0048] Wherein, the preparation process of the silicon nitride hybrid is as follows:

[0049] (1) Add 2.0 g of silicon nitride with a particle size of 20 to 50 nm into 150 mL of toluene, and ultrasonically disperse at a temperature of 10 to 20 ° C for 1 hour to obtain a silicon nitride dispersion;

[0050] (2) Add 1.8g of toluene diisocyanate to the silicon nitride dispersion, raise the temperature to 90°C, stir and react for 3h under the protection of helium, add 2.1g of lauryl alcohol, and continue to stir and react for 6h under the protection of helium , cooled to room temperature to obtain a silicon nitride mixed solution; wherein, the stirring speed is 300-400rpm;

[0051] (3) Centrifuge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com