Preparation method of ultraviolet-shielding transparent wood

An external shielding, wood technology, applied in the direction of wood treatment, wood impregnation, wood impregnation, etc., can solve the problem of no relevant articles or reports, and achieve the effect of improving social application value, reducing damage and increasing added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) First immerse the sample in 5% sodium hydroxide solution and react at 100℃ for 80min;

[0031] (2) Wash the sample after the pretreatment treatment to neutrality, put a sufficient mass fraction of 7% sodium chlorite, and treat it under acidic conditions (pH 4), the treatment time is 1h, and the lignin is measured The content is 6.68%;

[0032] (3) Wash the treated wood with distilled water to neutrality, and then use the organic solvent gradient method (40% ethanol, 60% ethanol, 80% ethanol, pure ethanol, ethanol: acetone 1:1, pure acetone, no polymerization initiated The monomer of the dipping liquid) is dehydrated;

[0033] (4) Then the decolorized wood is immersed in pre-polymerized methyl methacrylate (MMA) for 4 hours and cured at 50°C to obtain a UV-shielding transparent wood.

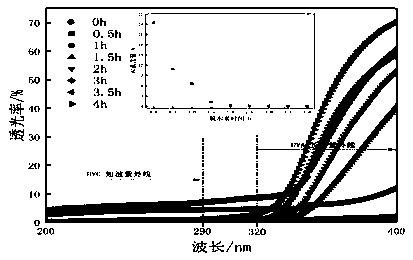

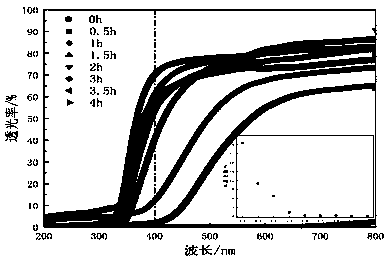

[0034] The obtained ultraviolet shielding transparent wood has a light transmittance of less than 5% in the short-wave and medium-wave ultraviolet region (200nm~320nm), and has a light transm...

Embodiment 2

[0036] The preparation of UV-shielding transparent wood includes the following steps:

[0037] (1) First immerse the sample in 5% sodium hydroxide solution and react at 100℃ for 80min;

[0038] (2) Wash the sample after pretreatment treatment to neutrality, put a sufficient mass fraction of 7% sodium chlorite, and treat it under acidic conditions (pH 4). The treatment time is 1.5h. The vegetarian content is 2.36%;

[0039] (3) Wash the treated wood with distilled water to neutrality, and then use the organic solvent gradient method (40% ethanol, 60% ethanol, 80% ethanol, pure ethanol, ethanol: acetone 1:1, pure acetone, no polymerization initiated The monomer of the dipping liquid) is dehydrated;

[0040] (4) Then the decolorized wood is immersed in pre-polymerized MMA for 4 hours and cured at 50°C to obtain a UV-shielding transparent wood.

[0041] The obtained UV-shielding transparent wood has a light transmittance of less than 5% in the short-wave and medium-wave ultraviolet region...

Embodiment 3

[0043] The preparation of UV-shielding transparent wood includes the following steps:

[0044] (1) First immerse the sample in 5% sodium hydroxide solution and react at 100℃ for 80min;

[0045] (2) Wash the sample after the pretreatment treatment to neutrality, put a sufficient mass fraction of 7% sodium chlorite, and treat it under acidic conditions (pH 4), the treatment time is 2h, and the lignin is measured The content is 0.23%;

[0046] (3) Wash the treated wood with distilled water to neutrality, and then use the organic solvent gradient method (40% ethanol, 60% ethanol, 80% ethanol, pure ethanol, ethanol: acetone 1:1, pure acetone, no polymerization initiated The monomer of the dipping liquid) is dehydrated;

[0047] (4) Then the decolorized wood is immersed in pre-polymerized MMA for 4 hours and cured at 50°C to obtain a UV-shielding transparent wood.

[0048] The obtained ultraviolet shielding transparent wood has a light transmittance of less than 5% in the short-wave and med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com