Preparing method for antibacterial and ultraviolet-resisting wood and obtained product

An anti-ultraviolet and wood technology, applied in the direction of wood treatment, impregnation of wood, wood impregnation, etc., can solve the problems of loss of modification effect, easy damage of the surface layer, complicated process, etc., and achieve excellent antibacterial performance, good antibacterial effect, and simple treatment process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

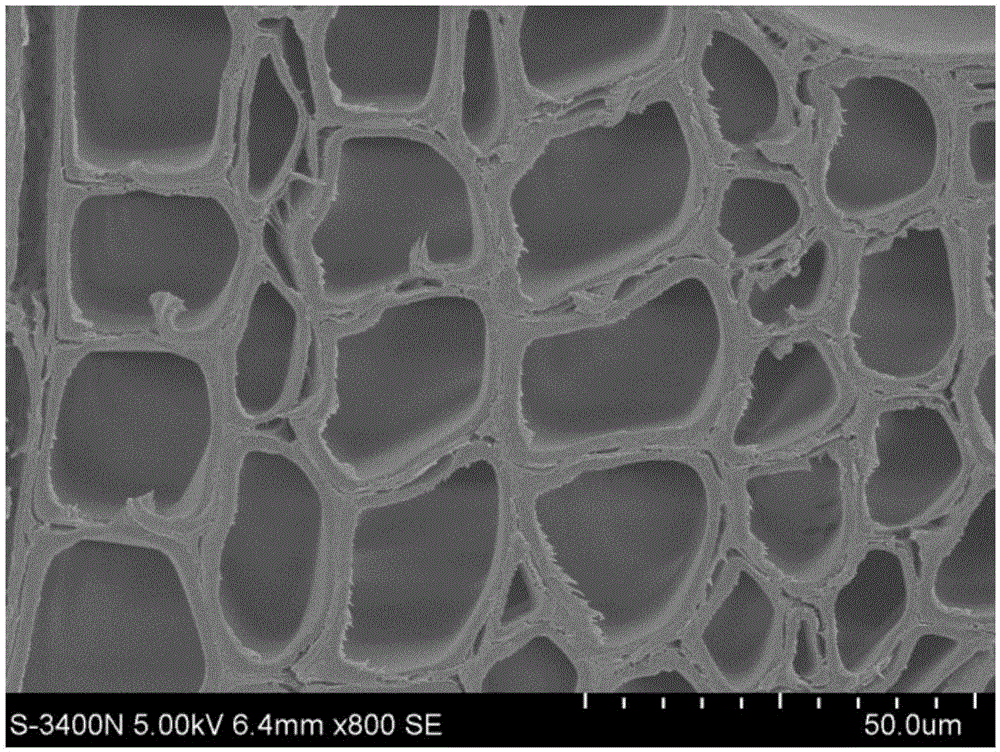

Embodiment 1

[0034] 1. Preparation of wood impregnation solution

[0035] Impregnation solution A: Add zinc nitrate to distilled water and stir until fully dissolved to obtain wood impregnation solution A; the content of the zinc nitrate solution is 0.6 mol / L.

[0036] Immersion solution B: prepare sodium hydroxide solution, and the mass fraction of the substance is 0.4mol / L.

[0037] 2. Wood impregnation treatment

[0038] Place the prepared wood blocks in a vacuum pressurized tank filled with impregnation solution A, and soak them in the wood impregnation solution, connect the vacuum equipment, vacuumize, and perform decompression impregnation treatment on the wood to make the wood absorb the impregnation solution A, to obtain impregnated wood; wherein the vacuum impregnation process is carried out at a temperature of 20° C., a vacuum of 0.095 Mpa, and a time of 20 minutes, followed by impregnation at normal pressure for 120 minutes.

[0039] 3. Curing treatment

[0040] Soak the impr...

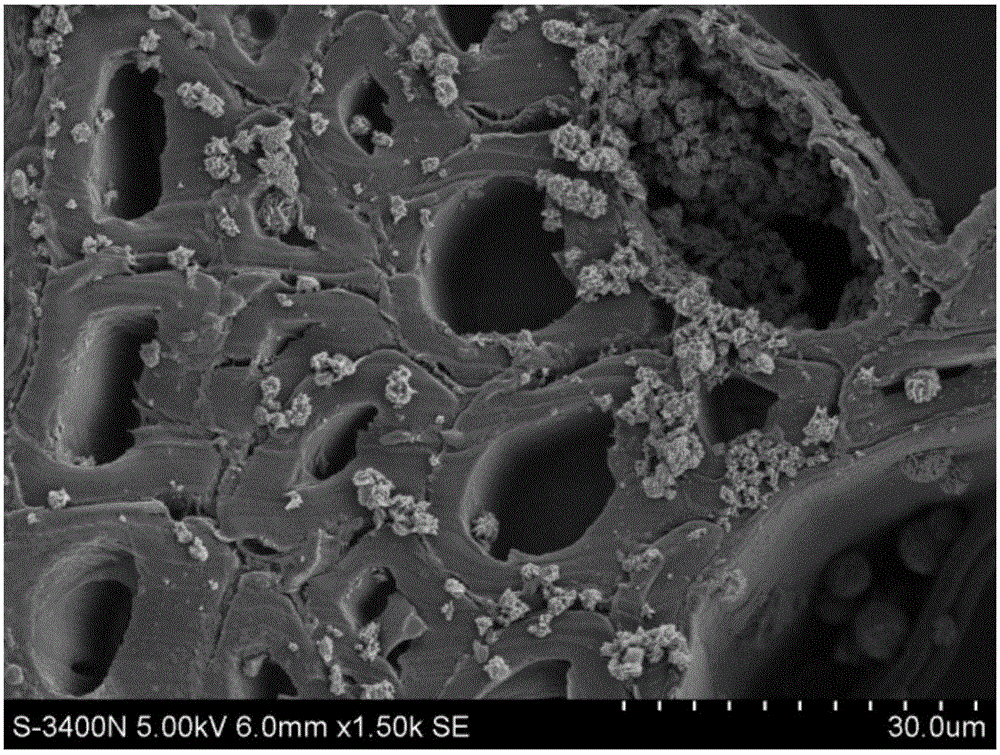

Embodiment 2

[0052] 1. Preparation of wood impregnation solution

[0053] Impregnation solution A: add zinc nitrate to distilled water, stir until fully dissolved, and obtain wood impregnation solution A; wherein the content of the zinc nitrate solution is 1.0 mol / L.

[0054] Immersion solution B: prepare sodium hydroxide solution, and the mass fraction of the substance is 0.4mol / L.

[0055] 2. Wood impregnation treatment

[0056] Place the prepared wood blocks in a vacuum pressurized tank filled with impregnation solution A, and soak them in the wood impregnation solution, connect the vacuum equipment, vacuumize, and perform decompression impregnation treatment on the wood to make the wood absorb the impregnation solution A, the obtained impregnated wood; wherein the vacuum impregnation process is carried out at a temperature of 20° C., a vacuum of 0.08 Mpa, and a time of 30 minutes, and then impregnated under normal pressure for 120 minutes.

[0057] 3. Curing treatment

[0058] Soak ...

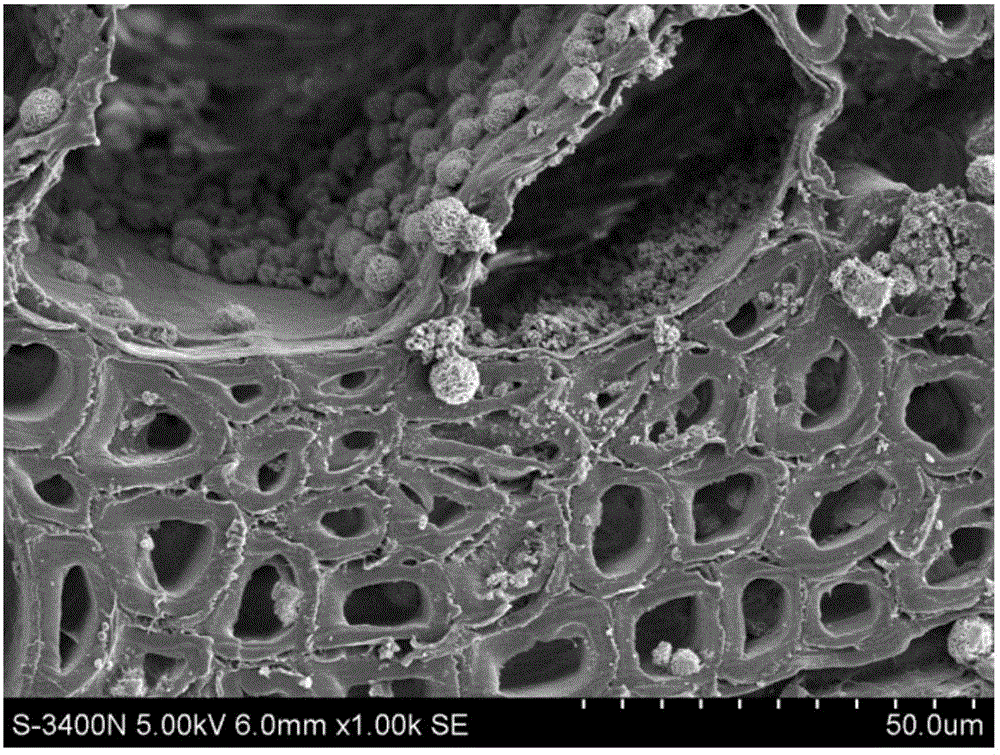

Embodiment 3

[0062] 1. Preparation of wood impregnation solution

[0063] Impregnation solution A: Add zinc nitrate to distilled water and stir until fully dissolved to obtain wood impregnation solution A; the content of the zinc nitrate solution is 0.6 mol / L.

[0064] Impregnation solution B: configure ammonia solution with a mass fraction of 25%.

[0065] 2. Wood impregnation treatment

[0066] Place the prepared wood blocks in a vacuum pressurized tank filled with impregnation solution A, and soak them in the wood impregnation solution, connect the vacuum equipment, vacuumize, and perform decompression impregnation treatment on the wood to make the wood absorb the impregnation solution A, to obtain impregnated wood; wherein the vacuum impregnation process is carried out at a temperature of 20° C., a vacuum of 0.095 Mpa, and a time of 20 minutes, followed by impregnation at normal pressure for 120 minutes.

[0067] 3. Curing treatment

[0068] Soak the impregnated wood in the impregna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com