Preparation method of superhydrophobic wood sponge

A water wood and sponge technology, applied in the field of preparation of super-hydrophobic wood sponge, can solve the problems of poor environmental compatibility, complicated preparation process, secondary pollution, etc., and achieve the effects of low cost, improved hydrophobic performance, and good oil absorption characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 prepares superhydrophobic wood sponge (1)

[0032] 1. Preparation of Experimental Materials and Reagents

[0033] Balsa wood, balsa wood, density 83.85 mg / cm 3 , sawn into small pieces of 15mm (L) * 15mm (W) * 15mm (H), the lignin content is 27.2%, and the hemicellulose content is 15.1%. Dry at 60°C until its mass does not change, and the mass of each piece is about 0.283g.

[0034] Prepare 2.5mol / L NaOH solution, 0.4mol / L NaOH solution 2 SO 3 solution and a 1% sodium chlorite aqueous solution. Wherein, the pH of sodium chlorite is adjusted to 4.6 with 30% acetic acid after the preparation is completed, and the pH meter is used for monitoring, and the preparation is sealed with a plastic wrap for preservation.

[0035] 2. Vacuum the balsa wood block with a vacuum drying oven for 10 minutes, and then mix the prepared NaOH solution with Na 2 SO 3 The solutions were mixed at a volume ratio of 1:1, and the test materials were treated with an electric fur...

experiment example 1

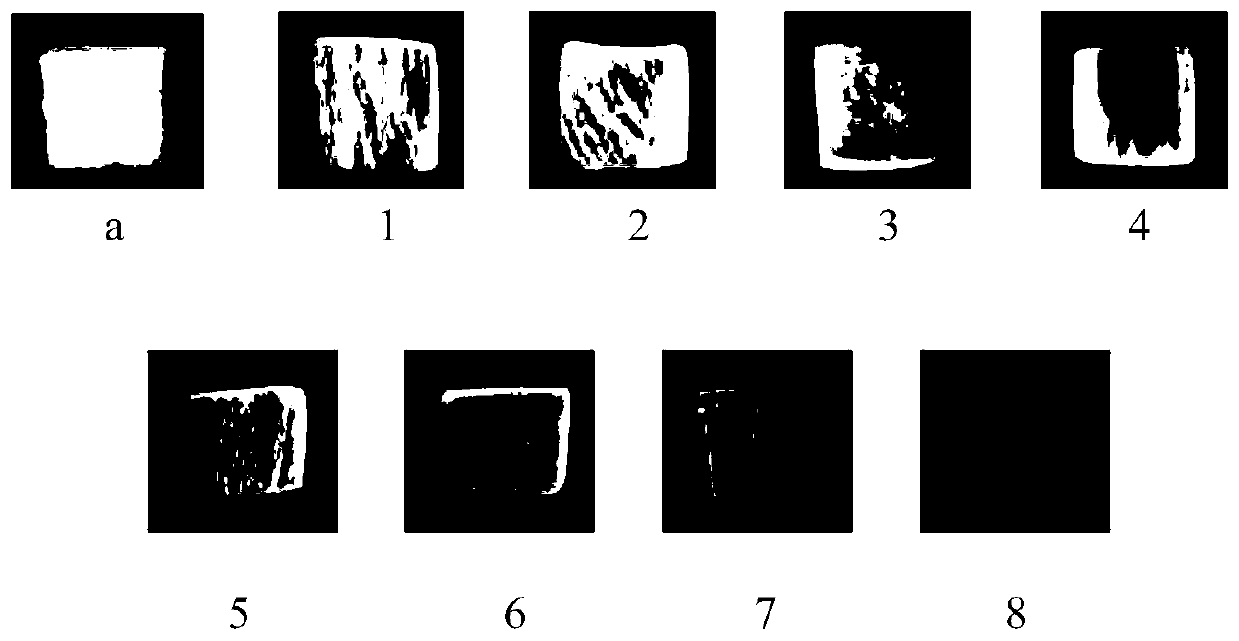

[0042] Experimental example 1 Performance testing of balsa wood before and after hydrophobic modification

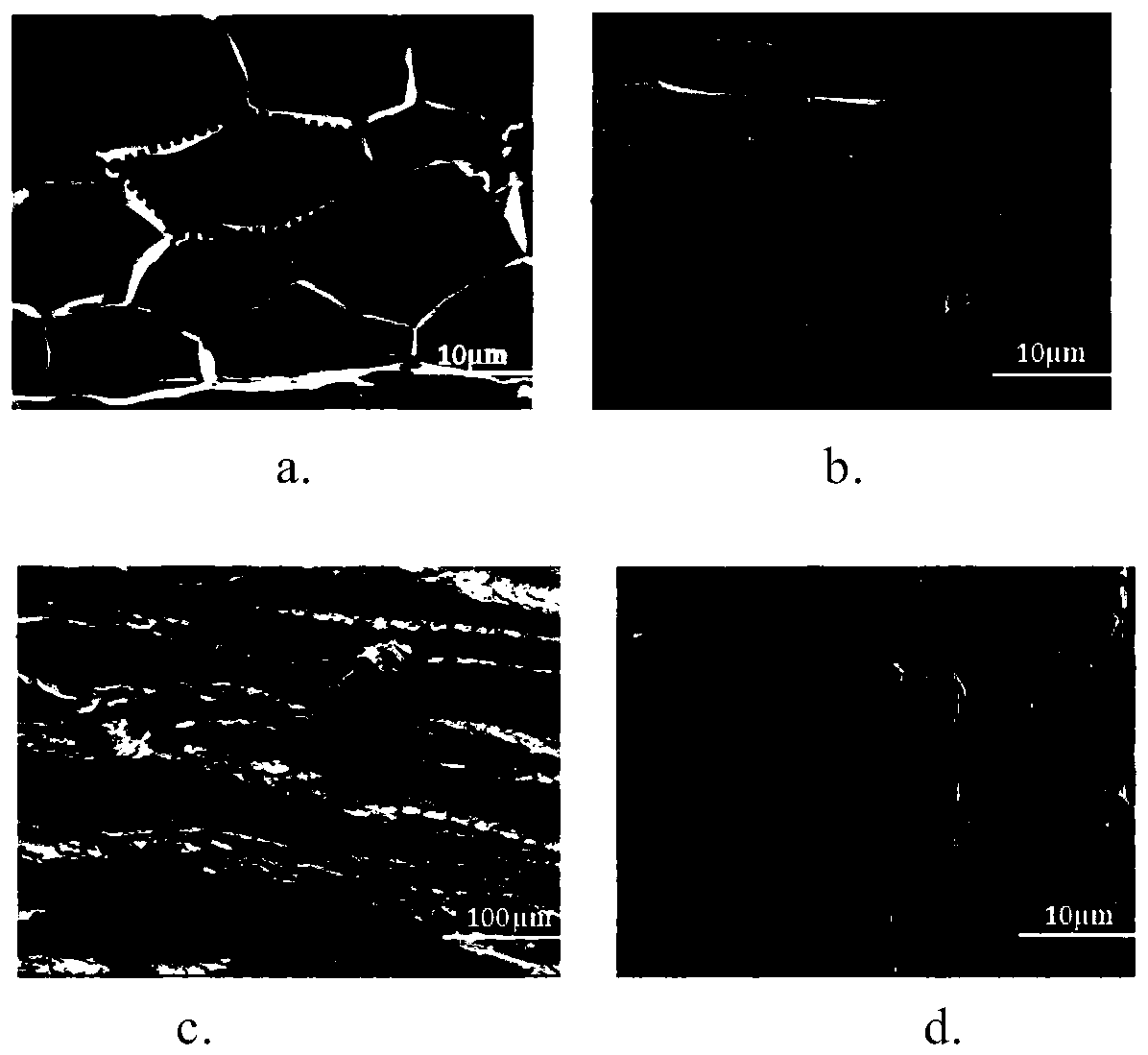

[0043] (1) Morphological changes of balsa wood materials during delignification treatment

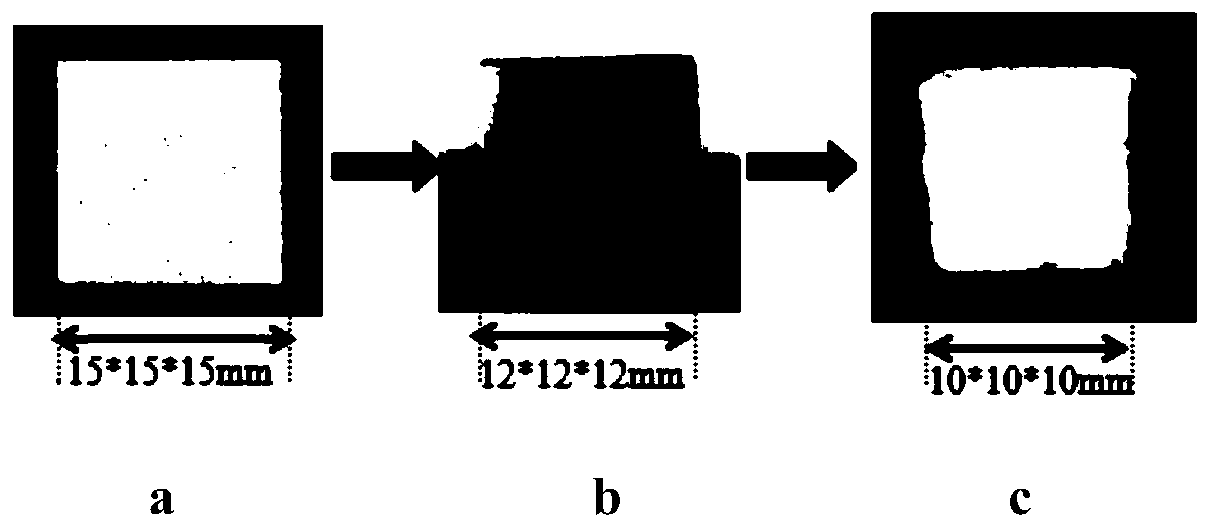

[0044] figure 1 It is the photo of the balsa wood material in each step of delignification in Example 1: a. the original wood block, b. the wood block after step 2 treatment, c. the wood block after step 3 treatment.

[0045] Such as figure 1 a. figure 1 b and figure 1 As shown in c, use NaOH / Na 2 SO 3 After the mixed solution is used to delignify the original balsa wood block, it can be found that the color of the wood block is darker than the light yellow color of the original wood block. NaClO 2 After the treatment of the aqueous solution, the color of the wood block gradually changed to milky white.

[0046] It can be seen from the figure that after the lignin removal treatment, the size of the wood block is reduced by about 33%, and the shape is basically kept good, w...

Embodiment 2

[0072] Embodiment 2 prepares superhydrophobic wood sponge (two)

[0073] 1. Preparation of Experimental Materials and Reagents

[0074] Balsa wood, balsa wood, density 83.85 mg / mm 3 , sawn into small pieces of 15mm (L) * 15mm (W) * 15mm (H), the lignin content is 27.2%, and the hemicellulose content is 15.1%. Dry at 60°C until its mass does not change, and the mass of each piece is about 0.283g.

[0075] Prepare 2.5mol / L NaOH solution, 0.4mol / L NaOH solution 2 SO 3 solution and a 1% sodium chlorite aqueous solution. Wherein, the pH of sodium chlorite is adjusted to 4.6 with 30% acetic acid after the preparation is completed, and the pH meter is used for monitoring, and the preparation is sealed with a plastic wrap for preservation.

[0076] 2. Vacuum the balsa wood block with a vacuum drying oven for 10 minutes, and then mix the prepared NaOH solution with Na 2 SO 3 The solutions were mixed at a volume ratio of 1:1, and the test materials were treated with an electric f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com