Wood processing and arranging method

A wood and board technology, applied in the field of wood processing and finishing, can solve the problems of limited wood performance and easy cracking of wood, and achieve the effect of controlling gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

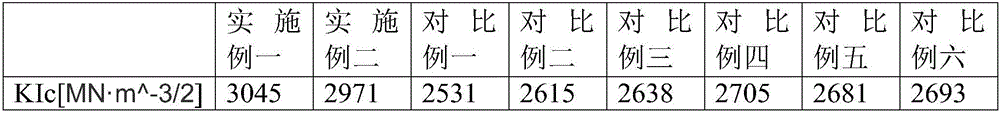

Examples

Embodiment 1

[0047] A method for wood processing and finishing, comprising the steps of:

[0048] Step 1: Cut the wood into boards with a thickness less than 5cm;

[0049] Step 2: drying the wood board at 50-80°C for 10-20 hours;

[0050] Step 3: Soak the wood in an aqueous solution of a composite loosening agent with a mass concentration of 20% for 10 to 20 hours;

[0051] Step 4: Put the loosened wood into the refrigerator, and refrigerate at -4°C for 12 hours;

[0052] Step 5: Place the frozen wood at room temperature to thaw naturally;

[0053] Step 6: configure the treatment solution, dissolve the treatment agent in the aqueous solution, the mass ratio of the treatment agent to solvent water is 1:4, and the treatment agent includes the following components by weight:

[0054] Nano silica sol: 100 parts

[0055] Glycerides: 10 parts

[0056] [4-[[[tert-butyl)dimethylsilane]oxy]methyl]phenylboronic acid: 1 part

[0057] 1,4-bis(hydroxydimethylsilyl)benzene: 5 parts

[0058] 3-(tr...

Embodiment 2

[0077] A method for wood processing and finishing, comprising the steps of:

[0078] Step 1: Cut the wood into boards with a thickness less than 5cm;

[0079] Step 2: drying the wood board at 50-80°C for 10-20 hours;

[0080] Step 3: Soak the wood in an aqueous solution of a composite loosening agent with a mass concentration of 20% for 10 to 20 hours;

[0081] Step 4: Put the loosened wood into the refrigerator, and refrigerate at -4°C for 12 hours;

[0082] Step 5: Place the frozen wood at room temperature to thaw naturally;

[0083] Step 6: configure the treatment solution, dissolve the treatment agent in the aqueous solution, the mass ratio of the treatment agent to solvent water is 1:4, and the treatment agent includes the following components by weight:

[0084] Nano silica sol: 100 parts

[0085] Glycerides: 10 parts

[0086] [4-[[[tert-butyl)dimethylsilane]oxy]methyl]phenylboronic acid: 1 part

[0087] 1,4-bis(hydroxydimethylsilyl)benzene: 5 parts

[0088] 3-(tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com