Method for improving moisture-proof and waterproof performance of palm leaves

A palm leaf, high-performance technology, applied in wood treatment, can opening and impregnation, wood processing equipment, etc., can solve the problems of rot and mildew, short-term, poor moisture-proof and waterproof performance, etc., achieve long service life, promote uniform dispersion, improve The effect of moisture-proof and waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

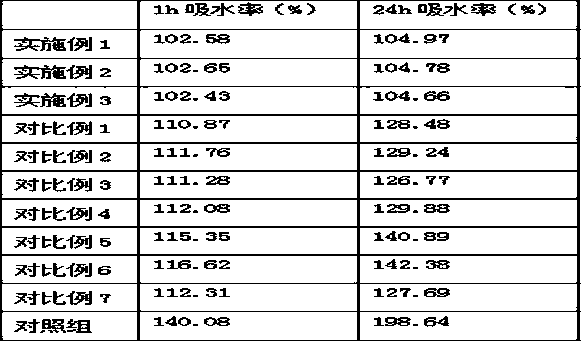

Examples

Embodiment 1

[0016] In an embodiment of the present invention, a method for improving the moisture-proof and waterproof performance of palm leaves, the specific method is as follows:

[0017] (1) Immerse the harvested palm leaves in a chitosan solution with a mass fraction of 4.1% and a temperature of 42°C for 32 minutes, then remove the filtrate, treat it with high-temperature and high-pressure steam, and cool it at a temperature of 0.2°C Processing 41min;

[0018] (2) Put the palm leaves treated in step (1) into the electric field for electric field treatment, immerse in the impregnating agent for 28 minutes, and remove the filter agent;

[0019] The impregnating agent is made of the following raw materials in parts by weight: 4.4 parts of propolis, 6.9 parts of alkyl glycosides, 2.2 parts of sodium alginate, 0.7 parts of curd polysaccharide, 3.4 parts of kaolin, 1.4 parts of sodium chloride, 2.6 parts of borax, 92 parts of water;

[0020] (3) The palm leaves treated in step (2) were p...

Embodiment 2

[0025] In an embodiment of the present invention, a method for improving the moisture-proof and waterproof performance of palm leaves, the specific method is as follows:

[0026] (1) Immerse the harvested palm leaves in a chitosan solution with a mass fraction of 4.4% and a temperature of 44°C for 35 minutes, take out the filtrate, treat it with high-temperature and high-pressure steam, and cool it at a temperature of 0.5°C Processing 44min;

[0027] (2) Put the palm leaves treated in step (1) into the electric field for electric field treatment, immerse in the impregnating agent for 31 minutes, and remove the filter agent;

[0028] The impregnating agent is made of the following raw materials in parts by weight: 4.6 parts of propolis, 7.3 parts of alkyl glycosides, 2.3 parts of sodium alginate, 0.8 parts of curd polysaccharide, 3.6 parts of kaolin, 1.5 parts of sodium chloride, 2.7 parts of borax, 95 parts of water;

[0029] (3) Put the palm leaves treated in step (2) into ...

Embodiment 3

[0034] In an embodiment of the present invention, a method for improving the moisture-proof and waterproof performance of palm leaves, the specific method is as follows:

[0035] (1) Immerse the harvested palm leaves in a chitosan solution with a mass fraction of 4.7% and a temperature of 46°C for 38 minutes, then remove the filtrate, treat it with high-temperature and high-pressure steam, and cool it at a temperature of 0.8°C Processing 47min;

[0036] (2) Place the palm leaves treated in step (1) into an electric field for electric field treatment, immerse in the impregnating agent for 34 minutes, and remove the filter agent;

[0037] The impregnating agent is made of the following raw materials in parts by weight: 4.8 parts of propolis, 7.7 parts of alkyl glycosides, 2.4 parts of sodium alginate, 0.9 parts of curd polysaccharide, 3.8 parts of kaolin, 1.6 parts of sodium chloride, 2.8 parts of borax, 98 parts of water;

[0038] (3) The palm leaves treated in step (2) were ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com