Preparation method of high-performance bamboo steel composite material

A composite material, high-performance technology, applied in wood compression, wood impregnation, manufacturing tools, etc., can solve the problems of weak mechanical properties, easy rebound of size, low bamboo fiber content, etc., to achieve transverse tensile strength improvement and waterproof performance The effect of improving and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1, bamboo material selection and pretreatment: select the 5-year-old Moso bamboo that has no mildew, wormholes, and cracks in appearance, and process it into 5mm thick bamboo chips.

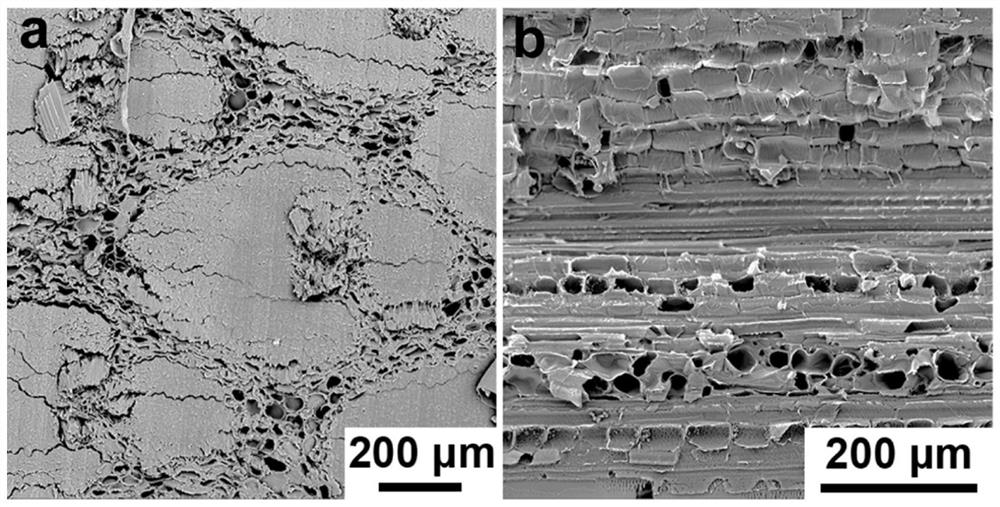

[0035] Step 2. Bamboo drying: place the bamboo chips in Step 1 at 80° C. for 72 hours. The microstructure of bamboo, such as figure 1 shown.

[0036] Step 3, two-step method to remove lignin and hemicellulose: first, place the bamboo chips obtained in step 2 in a mixed solution of 2mol / L sodium hydroxide and 0.4mol / L sodium sulfite, and soak them at 110°C for 14h; then Place in 5mol / L hydrogen peroxide solution, soak at 80°C for 4 hours, and then wash away the residual chemical reagents.

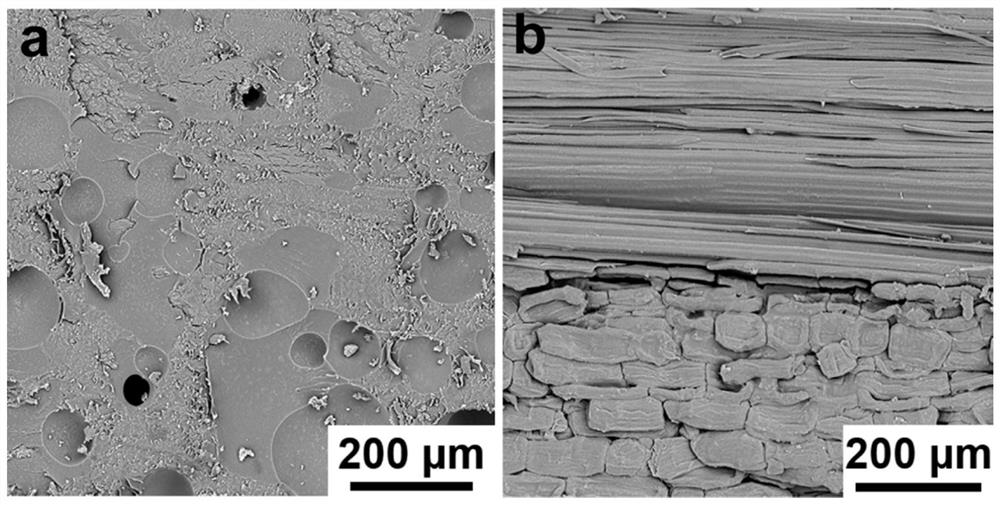

[0037] Step 4, freeze-drying: Place the bamboo chips obtained in step 3 vertically on a cold source at -25°C along the growth direction to control the growth of ice crystals along the growth direction of the bamboo; then freeze-dry at -40°C to obtain the natural orientation and Gradient structure...

Embodiment 2

[0042] Step 1, bamboo material selection and pretreatment: select the 5-year-old Cizhu that has no mildew, wormholes, and cracks in appearance, and process it into 3mm thick bamboo chips.

[0043] Step 2. Bamboo drying: place the bamboo chips in Step 1 at 80° C. for 72 hours. The microstructure of bamboo, such as figure 1 shown.

[0044] Step 3, two-step method to remove lignin and hemicellulose: first place the bamboo chips obtained in step 2 in a mixed solution of 2.5 mol / L sodium hydroxide and 0.5 mol / L sodium sulfite, soak at 105°C for 8 hours; then Then put it in 8mol / L hydrogen peroxide solution, soak it at 60℃ for 2.5h, and then wash away the residual chemical reagents.

[0045] Step 4, freeze-drying: Place the bamboo slices obtained in step 3 vertically on a cold source at -15°C along the growth direction to control the growth of ice crystals along the growth direction of the bamboo; then freeze-dry at -55°C to obtain the natural orientation and Gradient structure o...

Embodiment 3

[0048] Step 1, bamboo material selection and pretreatment: select the 5-year-old mottled bamboo that has no mildew, wormholes, and cracks in appearance, and process it into 4mm thick bamboo chips.

[0049] Step 2. Bamboo drying: place the bamboo chips in Step 1 at 80° C. for 72 hours. The microstructure of bamboo, such as figure 1 shown.

[0050] Step 3, two-step method to remove lignin and hemicellulose: first place the bamboo chips obtained in step 2 in a mixed solution of 3 mol / L sodium hydroxide and 0.8 mol / L sodium sulfite, soak at 100°C for 10 hours; then Place in 2mol / L hydrogen peroxide solution, soak for 6 hours at 80°C, and then wash off residual chemical reagents.

[0051] Step 4, freeze-drying: Place the bamboo chips obtained in step 3 vertically on a cold source at -10°C along the growth direction to control the growth of ice crystals along the growth direction of the bamboo; then freeze-dry at -45°C to obtain the natural orientation and Gradient structure of b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com