Polyester powder coating with sterilizing effect and preparation method and application thereof

A technology of polyester powder and bactericidal effect, applied in powder coatings, polyester coatings, paints containing biocides, etc., can solve the problems of product demulsification, mold, fermentation, etc., achieve low production cost, stable performance, and reasonable preparation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

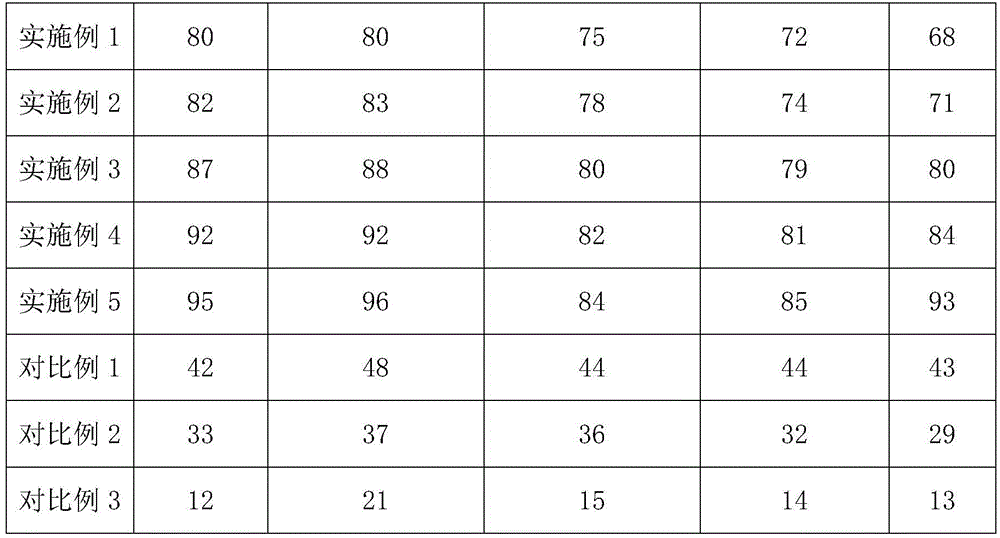

Embodiment 1

[0024] In the embodiment of the present invention, a polyester powder coating with bactericidal effect is made of the following components in parts by weight: 60 parts of hydroxyl polyester resin, 9 parts of aliphatic polyisocyanate, 20 parts of green bark extract, 5 parts of anatase nano-titanium dioxide, 1.5 parts of leveling agent SF-7, 0.5 parts of benzoin, 10102 parts of antioxidant, 1 part of ammonium salt, 10 parts of pigment, and 1 part of Abutilon seed extract.

[0025] The preparation method of the described polyester powder coating with bactericidal effect, concrete steps are as follows:

[0026] (1) The preparation of the green skin extract, the steps are as follows: wash the green skin, pulverize, pass through a 40-80 mesh sieve to obtain the green skin powder, then add the green skin powder to 7 times the water of its mass, stir evenly, and obtain a suspension liquid; the suspension is introduced into the ultrasonic extraction equipment for wall-breaking extracti...

Embodiment 2

[0030] In the embodiment of the present invention, a polyester powder coating with bactericidal effect is made of the following components in parts by weight: 55 parts of hydroxyl polyester resin, 12 parts of aliphatic polyisocyanate, 1 part of green bark extract, 10 parts of anatase nano-titanium dioxide, 1.0 parts of leveling agent SF-7, 1 part of benzoin, 10101 parts of antioxidant, 10 parts of ammonium salt, 20 parts of Abutilon seed extract.

[0031] The preparation method of the described polyester powder coating with bactericidal effect is the same as in Example 1.

Embodiment 3

[0033] In the embodiment of the present invention, a polyester powder coating with bactericidal effect is made of the following components in parts by weight: 58 parts of hydroxyl polyester resin, 9 parts of aliphatic polyisocyanate, 7 parts of green bark extract, 8 parts of anatase nano-titanium dioxide, 1.4 parts of leveling agent SF-7, 0.7 parts of benzoin, 10101.7 parts of antioxidant, 3 parts of ammonium salt, 6 parts of pigment, 7 parts of velvet hemp seed extract.

[0034] The preparation method of the described polyester powder coating with bactericidal effect is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com