Energy-saving gas burner

A gas burner, gas technology, applied in heating fuel, climate sustainability, gaseous heating fuel, etc., can solve the problems of less obvious energy saving effect, insufficient gas combustion, large heat loss, etc., to overcome backfire The effect of sound, improving utilization, reducing gas loss and pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

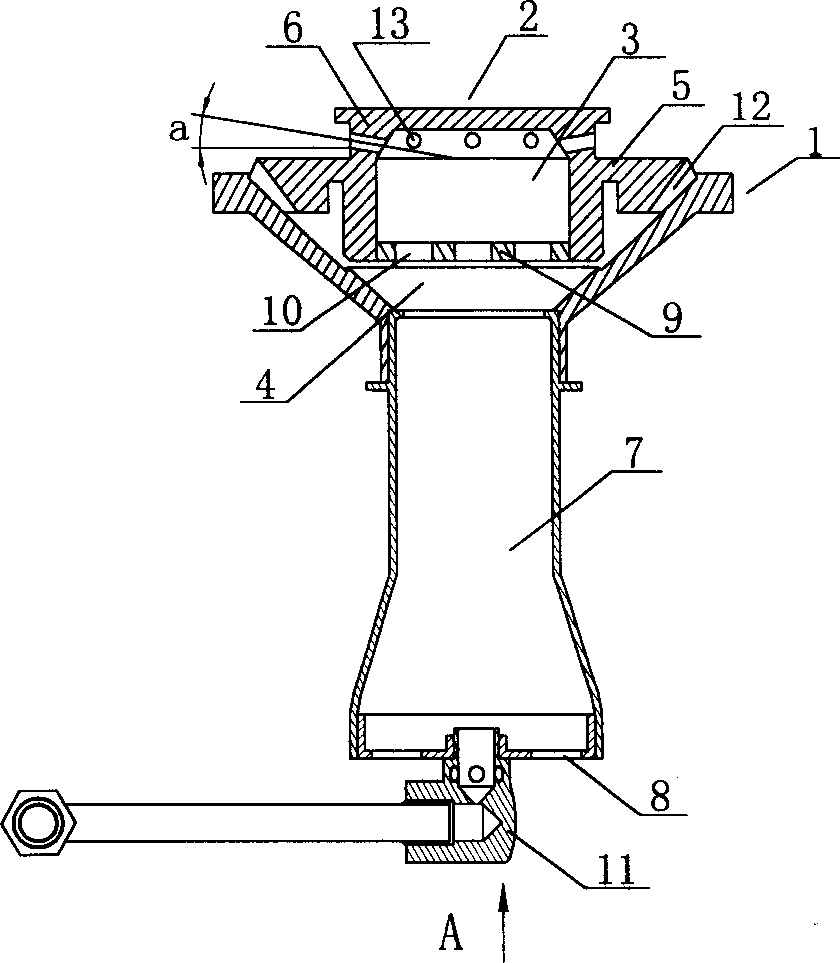

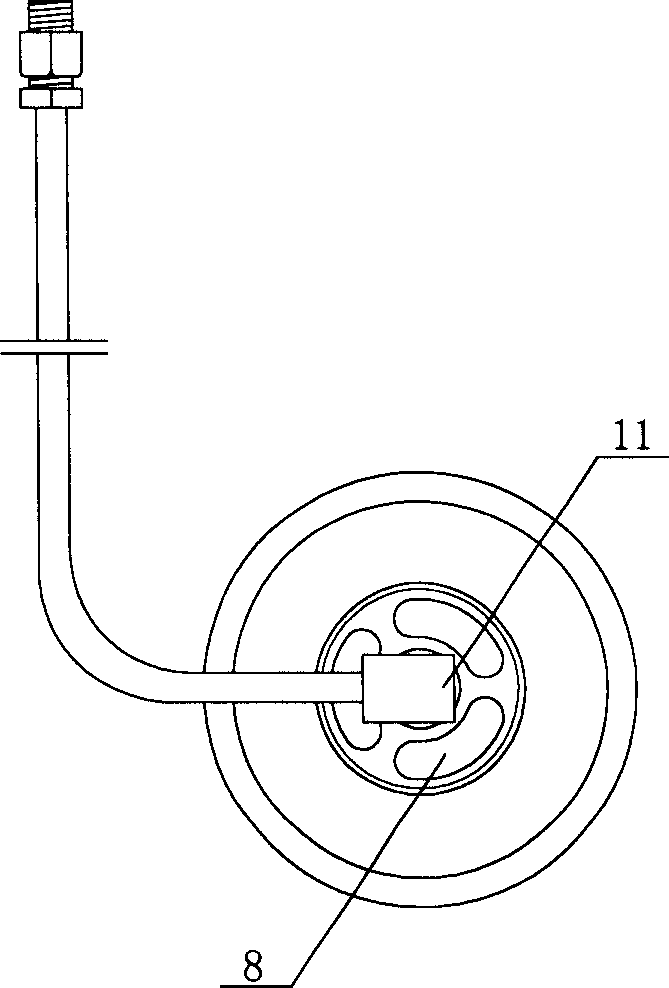

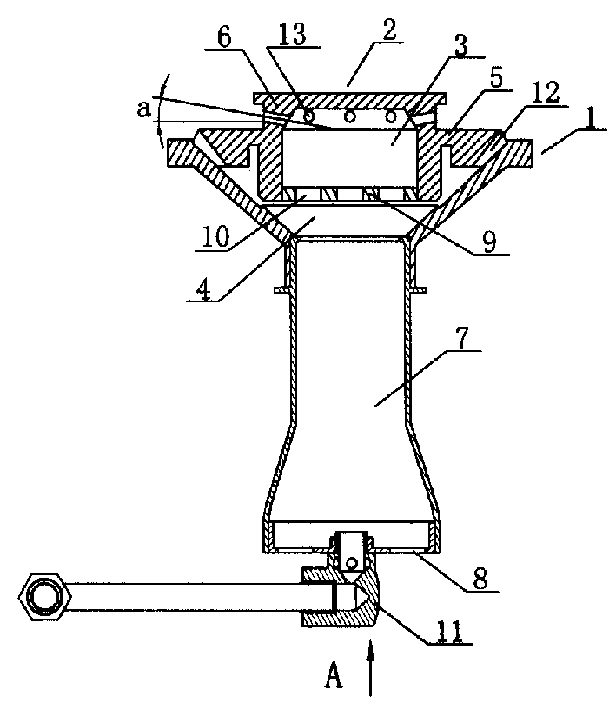

[0012] An energy-saving gas burner, such as figure 1 , figure 2 As shown, it includes a gas seat 1 with a fire cover 2 and an air mixing pipe 7 that is socketed with the bottom of the gas seat 1. The lower end of the air mixing pipe 7 is equipped with a nozzle facing the gas seat 1. The gas seat 1 There are internal and external gas chambers 3, 4 that are separated from each other and communicate with the fire cover 2.

[0013] In order to ensure that the gas from the nozzle 11 to the gas seat 1 can flow smoothly to the inner and outer gas chambers 3 and 4 and fully burn the gas, the outer gas chamber 4 is provided with upper and lower cone chambers, wherein the cone chamber of the lower cone chamber The height is 4-6 mm, preferably 5 mm. The diameter of the top of the upper cone cavity is 50-70mm, preferably 60mm, and the top of the upper cone cavity and the lower cone cavity are provided with a truncated cone, the thickness of which is 1-2.5mm, preferably 1.2mm; above the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com