Patents

Literature

61results about How to "Has a natural antibacterial" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

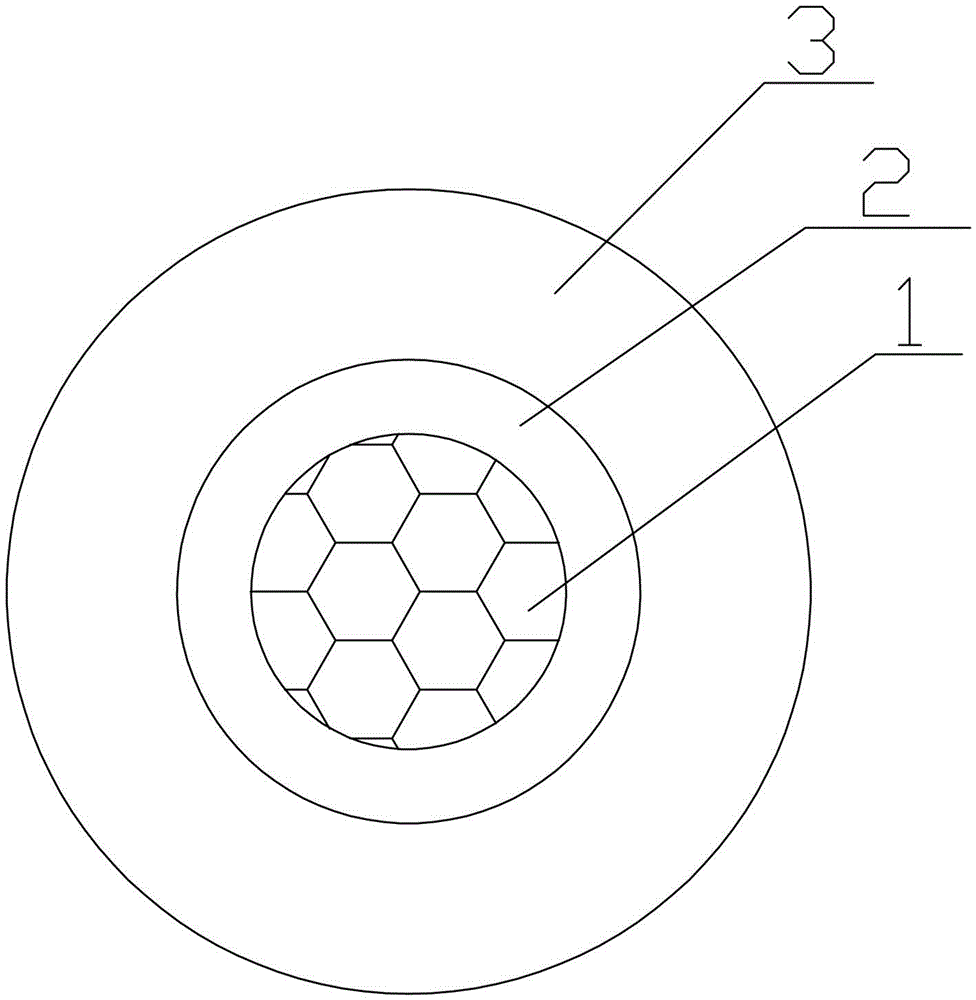

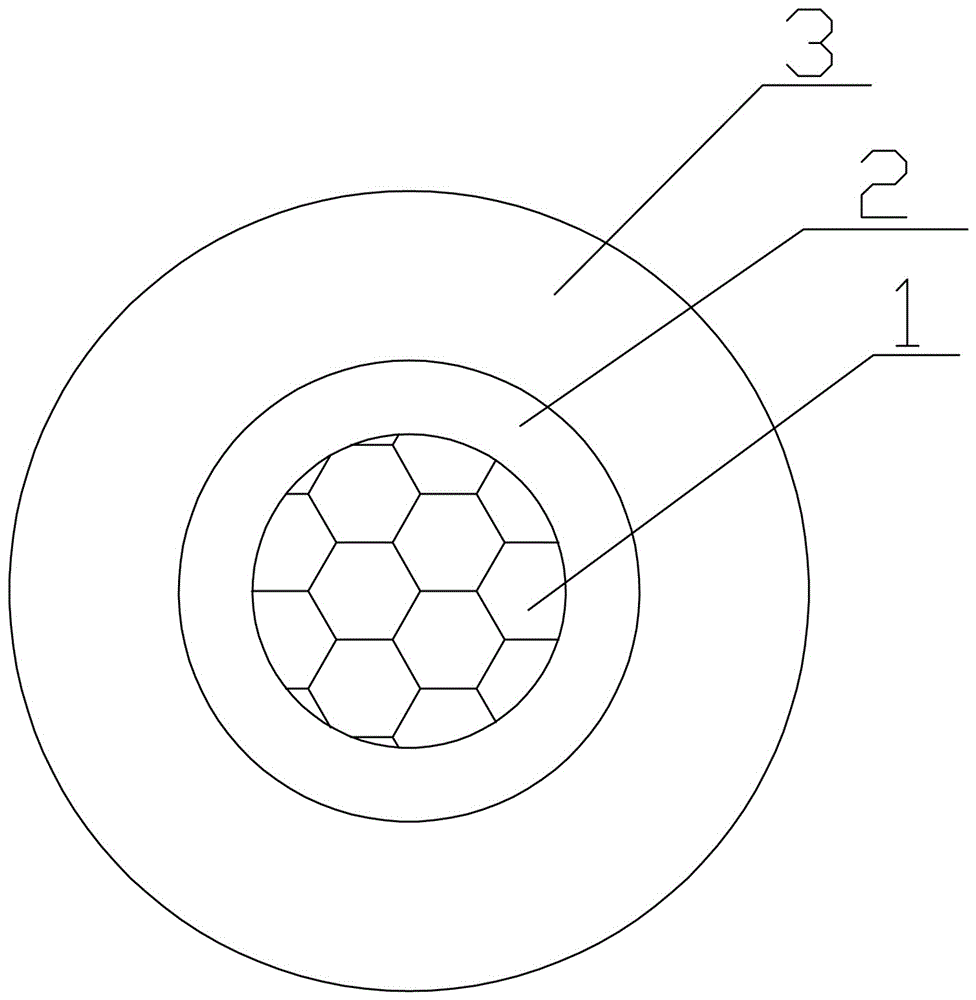

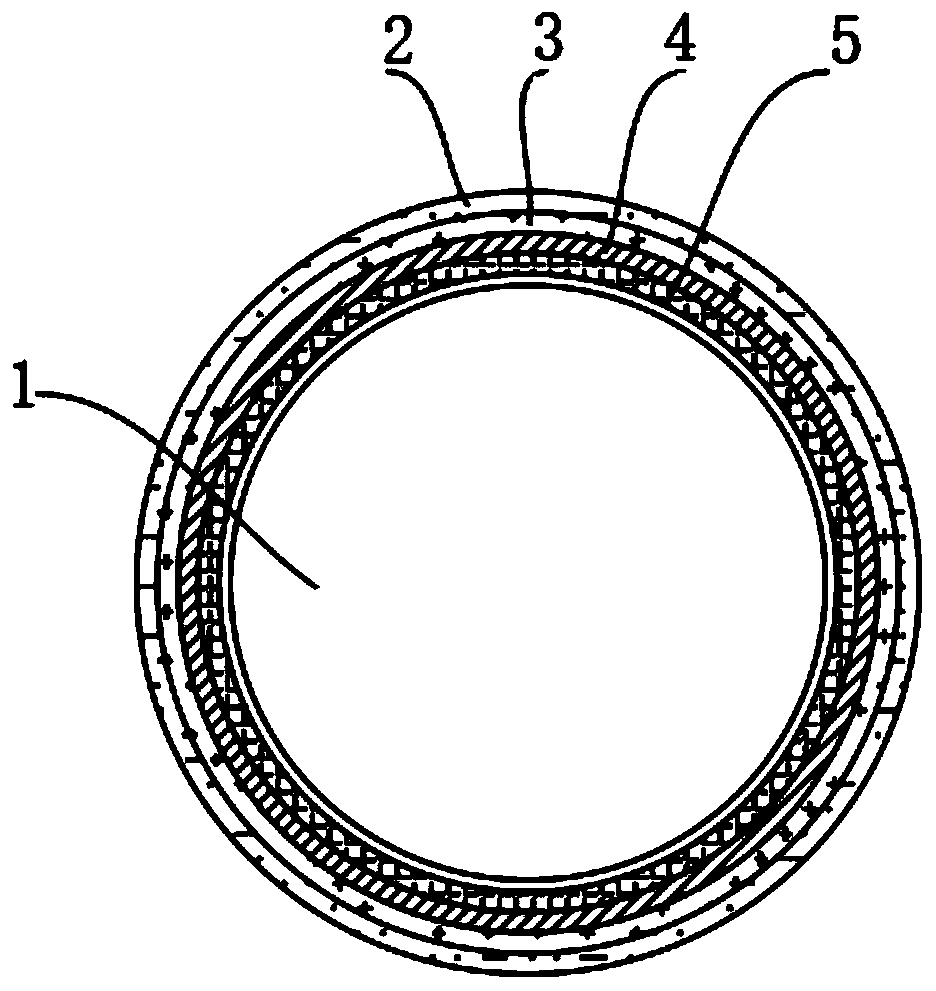

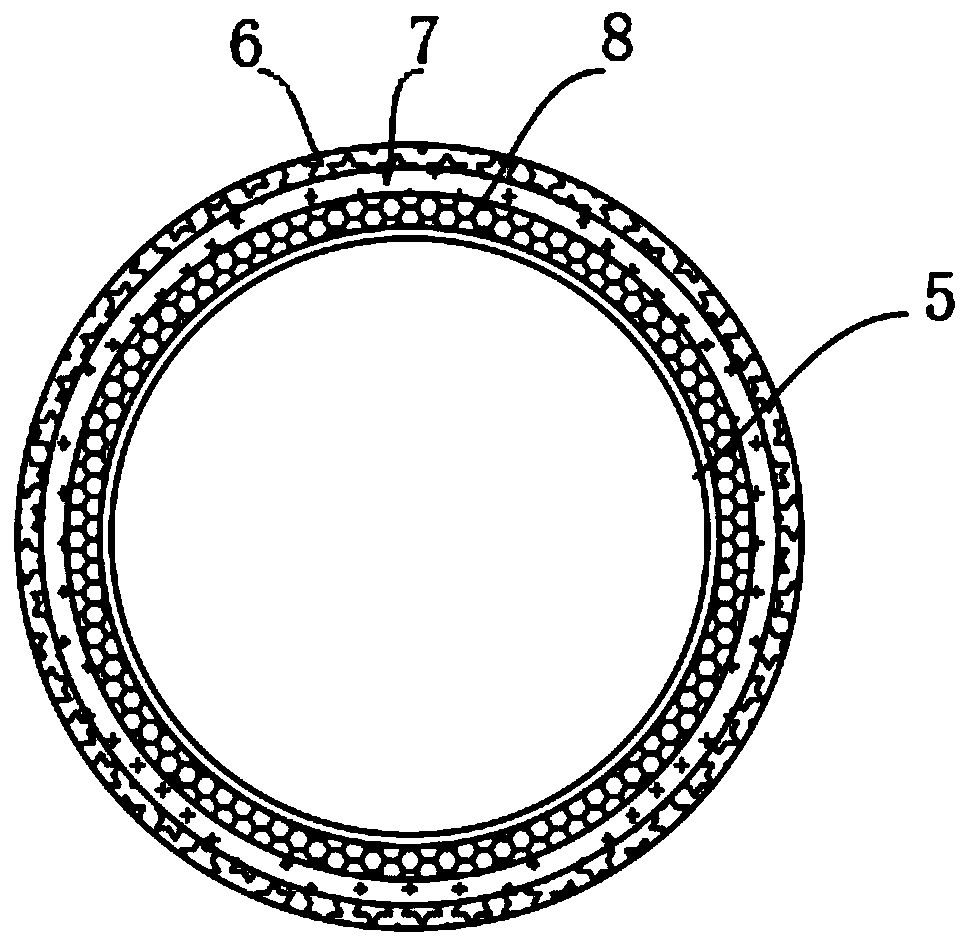

Anti-icing cable

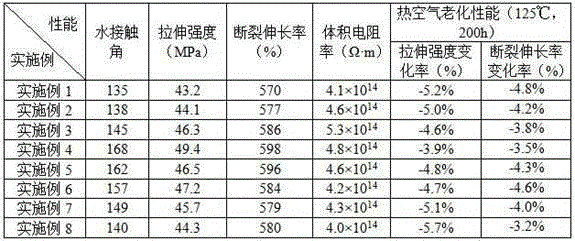

ActiveCN105390189AAchieving Hydrophobic PropertiesAchieve strengthPower cables with screens/conductive layersInsulated cablesGlass fiberAntioxidant

The invention discloses an anti-icing cable. The cable comprises a core, a shielding layer and an anti-icing layer arranged in sequence from inside to outside, wherein the anti-icing layer comprises the following raw materials by weight: 60-75 parts of fluorosilicon resin, 20-30 parts of methyl vinyl silicone rubber, 10-15 parts of SiO2-glass fiber gel, 5-8 parts of polypropylene fiber powder, 3-5 parts of nano SiO2, 4-6 parts of nano TiO2, 0.5-1 part of a dispersing agent, 0.5-1.5 parts of a flame retardant, 1-2 parts of a silane coupling agent and 1-2 parts of an antioxidant. The anti-icing cable has excellent hydrophobic property and anti-icing performance, and is excellent in insulating performance, high in compressive strength, high in flexibility and anti-aging; and the anti-icing layer of the anti-icing cable can replace the insulating layer in the cable and a sheath outside the cable, so that the cable mass is lowered and the service life of the cable is prolonged.

Owner:STATE GRID HENAN DENGZHOU POWER SUPPLY CO

Terylene, bamboo fiber and milk protein fiber blended yarn

The invention provides a terylene, bamboo fiber and milk protein fiber blended yarn which comprises the following components in parts by weight: 55-65 parts of terylene, 20-30 parts of bamboo fiber, and 10-20 parts of milk protein fiber. According to the blended yarn provided by the invention, the characteristics of the terylene, the bamboo fiber and the milk protein fiber are integrated, so as to play the advantages of the the terylene, the bamboo fiber and the milk protein fiber.

Owner:HAIAN COUNTY BROS SYNTHETIC FIBER

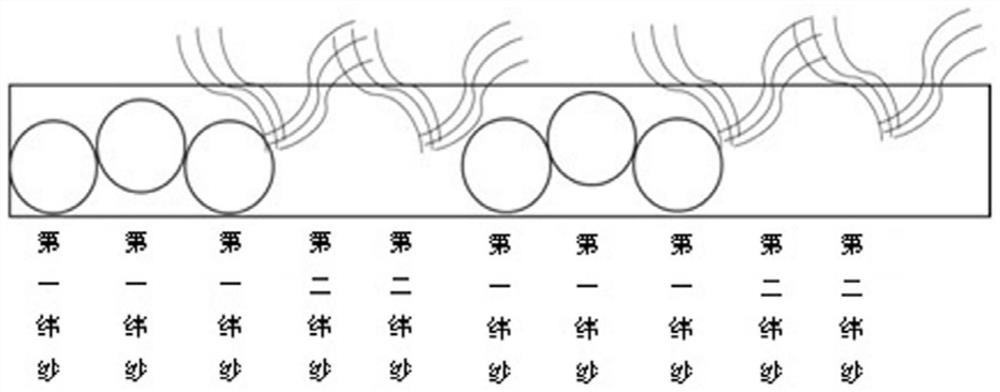

High-count high-density jacquard China hemp bedding fabric and product

InactiveCN102121155AWith comfortRetain comfortBiochemical fibre treatmentDry-cleaning apparatus for textilesHigh densityEngineering

The invention discloses a high-count high-density jacquard China hemp bedding fabric. Warps are selected from tightly spun 50S China hemp yarns, and wefts are selected from vortex spun 40S China hemp yarns; the specification of the fabric is 136' tightly spun China hemp 50S * Murata vortex spinning (MVS) China hemp 40S / 173 *110; the number of total warps is 23,520; a second consecutive realistic / abstract single flower of traditional Chinese ink painting skill is applied and spread on the whole ground, wherein the flower breadth is 74 centimeters, and the flower length is 255 centimeters; at least 20 different fabric tissues are applied in the circulation of a pattern; and the heald lifting proportion is controlled at 30 to 35 percent. The fabric has necessary comfort, function and environmental friendliness of high-grade bedding fabrics. Not only main natural properties of bacteria resistance, ultraviolet resistance, moisture absorption, quick dryness and the like of China hemps are kept, but also softness and compactness of the fabric and jacquard weaving luxury reach the requirements of the high-grade fabrics. The prepared bedding also has all excellent properties of the fabric.

Owner:JIANGSU YUEDA HOME TEXTILE

Novel tussah silk composite fiber

InactiveCN103215711AHas a natural antibacterialMoisture-absorbing and breathableYarnYarnMoisture absorption

The invention discloses a novel tussah silk composite fiber. The novel tussah silk composite fiber is a blended yarn applied to the weaving industry and is formed by blending the following components in percentage by mass: 45 to 55 percent of tussah silk, 15 to 20 percent of Sunn crotataria fiber, 8 to 15 percent of ramie fiber and 10 to 32 percent of china-hemp fiber, and the specification of the tussah silk composite fiber is 33 to 52 counts. In such way, the novel tussah silk composite fiber has the advantages of natural antibacterial effect, moisture absorption property, ventilating property, luster and elegance, is particularly proper for preparing shirt fabrics, and has the advantages of comfort in wearing, health and elegance.

Owner:张寰宇

Bamboo fiber plush printed blanket and preparation method thereof

The invention discloses a bamboo fiber plush printed blanket and a preparation method thereof. The blanket is knitted by a double-needle-bed warp knitting machine; and the plush yarn of the blanket is a yarn obtained by blended knitting of bamboo fibers and acrylic fibers, wherein the double-yarn specification of the yarn obtained by the blended knitting is 32 double-strands or 16 single strands; the base elater of a base material terylene is warped, and then the coiled head is used as the knitting yarn and weft insertion yarn of the blanket; and the bamboo fibers account for 60-70% of the weight of the double-yarn. The preparation method comprises the following steps: starching and high-temperature setting of a white grey cloth, carding, lustering, shearing, plush cutting, flat screen printing, aging and fixation, washing, dehydrating and drying, fuzzing, lustering, shearing, binding and packaging and warehousing. The bamboo fiber plush printed blanket disclosed by the invention not only has good air permeability, instantaneous water absorbability, relatively strong abrasive resistance, but also has the functions of natural antibacterium, bacteriostasis, mite removal, deodorization and ultraviolet resistance at the same time.

Owner:JIANGSU QIYING HOME TEXTILE

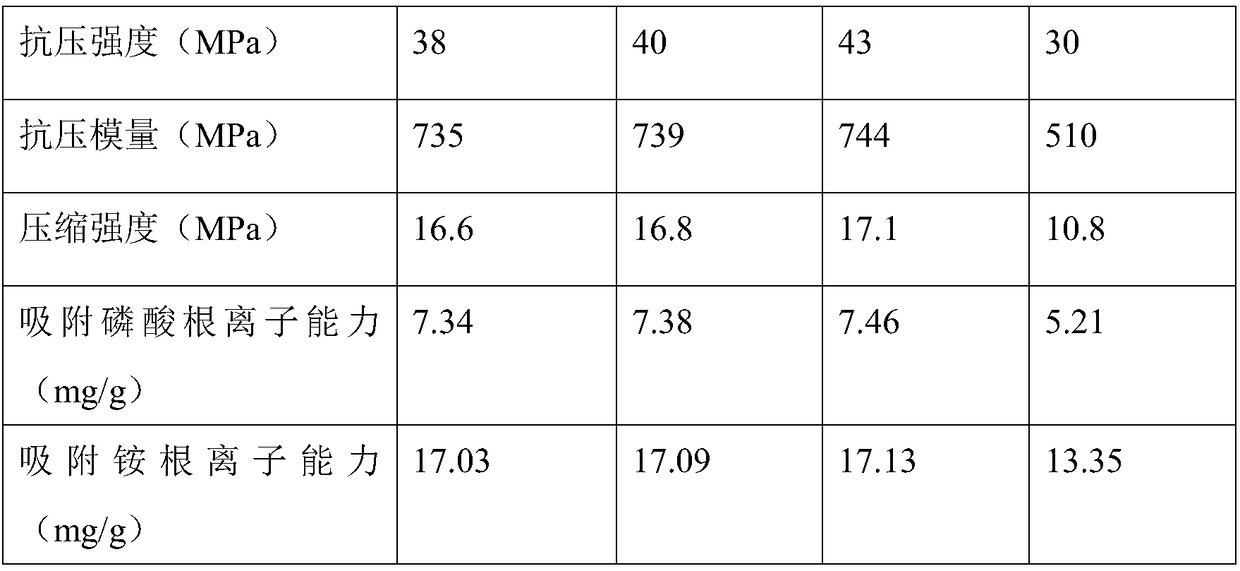

Preparation method of high-toughness and high-adsorption biomass-based foamed carbon

InactiveCN109250715AImprove toughnessUniform pore sizeSilicaCarbon compoundsUltravioletCarbonization

The invention relates to the technical field of preparation of foamed carbon, and concretely relates to a preparation method of high-toughness and high-adsorption biomass-based foamed carbon. The preparation method comprises the following steps: preparing active carbon from camphor tree leaves, preparing nano-silica from sodium silicate, combining the nano-silica to the surface of the camphor treeleaf active carbon, preparing bamboo charcoal fibers from bamboo skins, and carrying out mixing and high-temperature carbonization on the bamboo charcoal fibers and the camphor tree leaf active carbon to obtain the high-toughness and high-adsorption biomass-based foamed carbon. The camphor tree leaf active carbon has uniform pore sizes and a high adsorption rate, the silica is a flocculent and netted quasi-particle structure, the camphor tree leaf active carbon combined with the nano-silica can be used as a template for the biomass-based foamed carbon, the addition of the bamboo charcoal fibers improves the toughness, the antibacterial property and the ultraviolet resistance of the foamed carbon, and the bamboo charcoal fibers are combined into apertures of the camphor tree leaf active carbon, so the obtained high-toughness and high-adsorption biomass-based foamed carbon has a broad application prospect.

Owner:CHANGZHOU UNIV

An anti-icing cable

ActiveCN105390189BImprove toughness and strengthHigh impact strengthPower cables with screens/conductive layersPower cables for overhead applicationGlass fiberAntioxidant

The invention discloses an anti-icing cable. The cable comprises a core, a shielding layer and an anti-icing layer arranged in sequence from inside to outside, wherein the anti-icing layer comprises the following raw materials by weight: 60-75 parts of fluorosilicon resin, 20-30 parts of methyl vinyl silicone rubber, 10-15 parts of SiO2-glass fiber gel, 5-8 parts of polypropylene fiber powder, 3-5 parts of nano SiO2, 4-6 parts of nano TiO2, 0.5-1 part of a dispersing agent, 0.5-1.5 parts of a flame retardant, 1-2 parts of a silane coupling agent and 1-2 parts of an antioxidant. The anti-icing cable has excellent hydrophobic property and anti-icing performance, and is excellent in insulating performance, high in compressive strength, high in flexibility and anti-aging; and the anti-icing layer of the anti-icing cable can replace the insulating layer in the cable and a sheath outside the cable, so that the cable mass is lowered and the service life of the cable is prolonged.

Owner:STATE GRID HENAN DENGZHOU POWER SUPPLY CO

Tujia saddlebag

The invention provides a Tujia saddlebag, belonging to the technical field of articles for daily life. The Tujia saddlebag is characterized in that mixed yarns are taken as raw materials, and a production method of the saddlebag comprises the steps of weaving the mixed yarns by a Tujia weaving method and soaking the yarn raw material in impregnating liquid with full and lasting aroma, bacterium resistance and virus resistance, so that the saddlebag not only has the national features of the Tujia, but also has original functions and new functions of aroma distributing, bacterium resistance and epidemic prevention. Therefore, the life quality and the health level of people can be improved, and the Tujia saddlebag is suitable for popularization and application on a large scale.

Owner:重庆市黔江区澳特尔服装皮具有限责任公司

Medical rubber gloves with antibacterial function and preparation method thereof

The invention provides medical rubber gloves with an antibacterial function and a preparation method thereof and relates to the field of medical products. The medical rubber gloves are prepared from natural rubber, modified carbon black, modified white carbon black, dialdehyde pullulan, sericin, sulfur, dibutyl adipate, zinc oxide, stearic acid, dioctyl phthalate, light calcium carbonate, diatomaceous earth, silver nitrate, rosin, potassium hydroxide, calcium chloride, zinc N-ethyl-N-phenyldithiocarbamate, micro-silica gel, didecyldimethylammonium bromide, bamboo fibers, saponin extract, an antiager, a vulcanization accelerator and an appropriate of water. The medical rubber gloves have a strong antibacterial function and excellent comprehensive performances, prevent the transfer of poisonous and harmful substances among patients and medical personnel, improve the safety and well protect the medical personnel and patients.

Owner:王维维

Novel burn-out fabric and burn-out technology thereof

Owner:LILANG CHINA

Blended yarn of milk protein fibres, natural bamboo fibres and cotton fibres

The invention provides a blended yarn of milk protein fibres, natural bamboo fibres and cotton fibres. The blended yarn comprises the following components in parts by weight: 20 to 30 parts of the milk protein fibres, 25 to 35 parts of the natural bamboo fibres and 35 to 45 parts of the cotton fibres. According to the blended yarn provided by the invention, the characteristics of the three fibres, namely, the milk protein fibres, the natural bamboo fibres and the cotton fibres, can complement one another, and the advantages of the three fibres can be played.

Owner:NANTONG DOUBLE GREAT TEXTILE

Preparation method of nano-antibacterial fiber mixed fabric

InactiveCN107675290AHas a natural antibacterialDeodorantWoven fabricsConjugated synthetic polymer artificial filamentsPolyesterFiber

The inventio discloses a preparation method of a nano-antibacterial fiber mixed fabric. The nano-antibacterial fiber mixed fabric is prepared from the following raw materials in parts by weight: 75 to85 parts of copper modified polyester fiber, 5 to 10 parts of wheat starch, 2 to 5 parts of aloe, 10 to 20 parts of alginate fiber, 2 to 4 parts of nano-zinc oxide, 1 to 2 parts of nanometer silver powder, 1 to 3 parts of pearl powder, 2 to 3 parts of M82 emulgator, 2 to 5 parts of propylparaben, 2 to 3 parts of polyhexamethylene guanidine, 2 to 4 parts of olive oil, 3 to 5 parts of synthesized silk oil, 1 to 3 parts of sodium hyaluronate, 2 to 5 parts of root of rauvolfia verticillate, 2 to 4 parts of folium artemisiae argyi, 1 to 2 parts of bitter herbs, 1 to 2 parts of root of sophora alopecuroide, 1 to 3 parts of tea tree, 1 to 3 parts of herba thymi and 1 to 2 parts of pearl essence. The nano-antibacterial fiber mixed fabric prepared by the invention has the function characteristicsof natural antibacterial ability, deodorization, ultraviolet protection and the like, and is widely applicable to the fields of clothing and home textile preparation.

Owner:广东樱兰智能服装有限公司

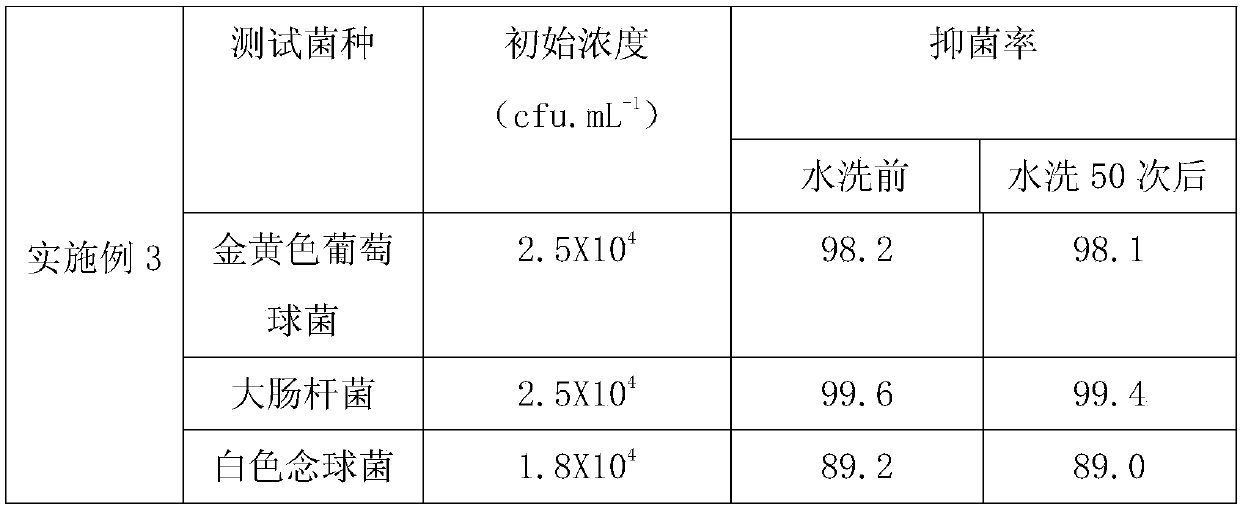

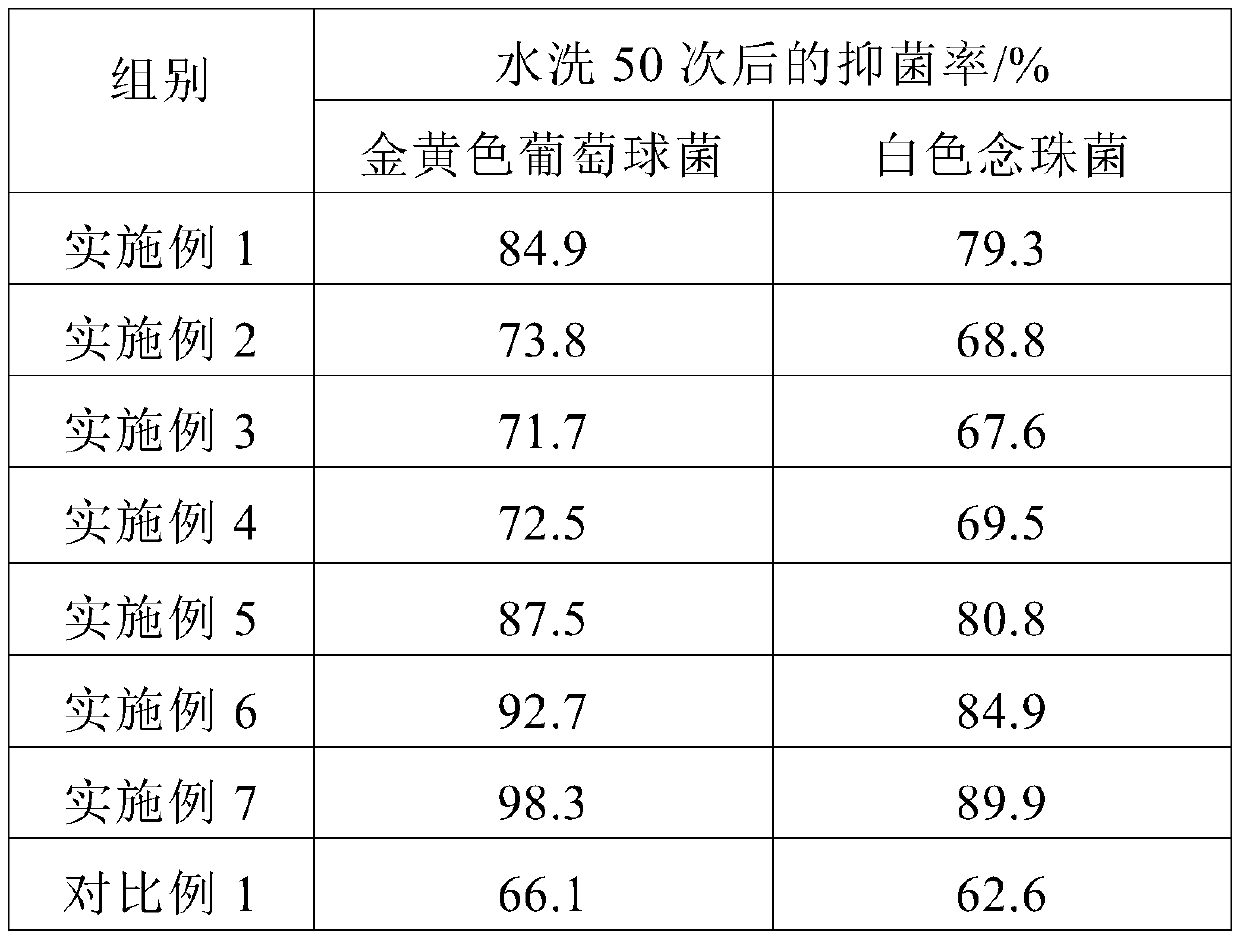

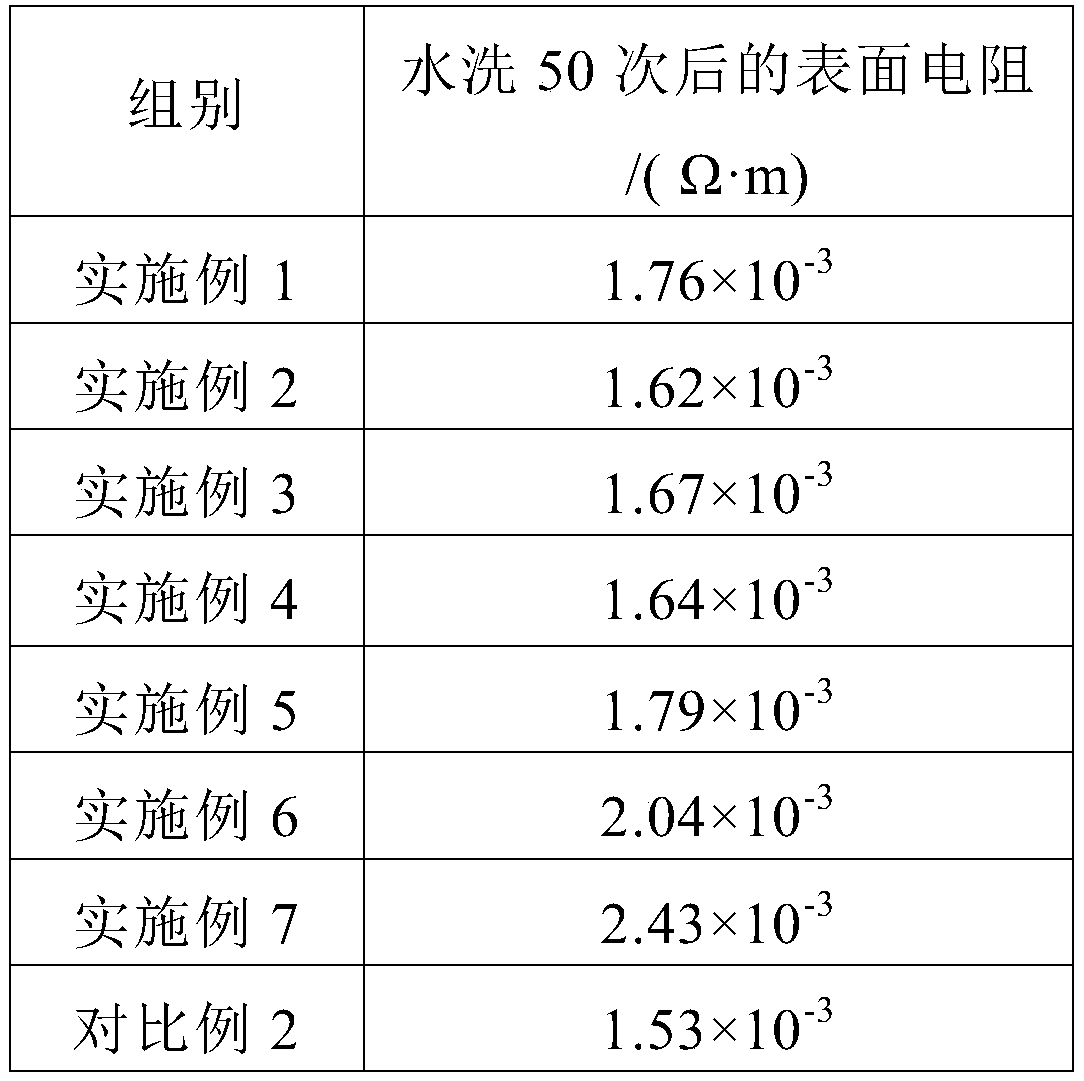

Antistatic textile fabric and preparation process thereof

PendingCN111074542AHas a natural antibacterialDeodorantBiochemical fibre treatmentLight resistant fibresPolymer scienceEngineering

The invention discloses an antistatic textile fabric and a preparation process thereof. The preparation process of the antistatic textile fabric comprises the following steps of I, pretreatment and II, blending. The preparation process is simple and non-toxic, the antistatic performance of the product can be effectively improved, static electricity is prevented from being generated in a dry environment, and the prepared antistatic textile fabric also has the functions of natural antibacterial property, deodorization, ultraviolet resistance and the like, and is widely applicable to the fields of manufacturing clothes, household textiles and the like.

Owner:闵兵

Warm-keeping fabric

InactiveCN105780250AGood warmth retentionImprove breathabilityWeft knittingWarp knittingPolyesterWater vapor

The invention provides a warm-keeping fabric which comprises far infrared fibers, Tencel fibers, silk, nylon, acrylic fibers, viscose, polyester staple fibers, spandex and vinylon. The fabric manufactured by the formula has the advantages of good warm-keeping performance, good air permeability, high instant water-absorption performance, high wear resistance and good dyeing performance, etc. In addition, the fabric is also equipped with functions including natural anti-microbial performance, anti-bacteria performance, acarus killing, deodorization and ultraviolet light resistance. Clothes made of the fabric are soft and raped, have a unique touching feeling, and are elegant and dynamic, permeable to air and water vapor, plain and glossy.

Owner:NANTONG JIANWEI YARN DYED CLOTHING CO LTD

Knitted fabric capable of improving flame-retardant performance and preparation method thereof

The invention discloses a knitted fabric capable of improving flame-retardant performance. The knitted fabric is prepared from the following raw materials in parts by weight: 24 to 30 parts of preprocessed bamboo fibers, 16 to 22 parts of polypropylene fibers, 12 to 14 parts of pure cotton, 8 to 12 parts of needle-shaped wollastonite, 6 to 10 parts of a flame-retardant reinforcing agent, 4 to 8 parts of sepiolite fibers, 2 to 5 parts of sodium silicate, 1 to 3 parts of hindered phenol, 4 to 8 parts of micro-porous bamboo charcoal, and 1 to 3 parts of mullite powder. The invention aims at providing the knitted fabric capable of improving the flame-retardant performance. Compared with the knitted fabric in the prior art, the flame-retardant performance of the fabric is greatly improved. Theknitted fabric provided by the invention has high application value and good application prospect.

Owner:HEFEI YUANKE GARMENT DESIGN CO LTD

Flowering plant nutrient soil and preparation method thereof

The invention discloses flowering plant nutrient soil, and aims to provide the flowering plant nutrient soil and a preparation method thereof. The flowering plant nutrient soil is prepared from, by weight, 34-38 parts of a base material, 26-32 parts of coal gangue, 20-26 parts of porous limestone, 18-22 parts of peat, 14-18 parts of rice hull ash,12-16 parts of argillaceous sediment, 8-12 parts ofpretreated natrolite, 3-7 parts of super absorbent resin, 3-5 parts of Yunnan Tengchong volcanic mud, 2-4 parts of Faku clay, 2-4 parts of bamboo fiber and 12-18 deionized water. The flowering plantnutrient soil and the preparation method thereof have the advantages that the nutrient soil has high hygroscopic property and porosity, and the germination rate and plant height of flowering plants are improved, so that the use value is higher, and the application prospect is good.

Owner:来安县出尘茶业有限公司

Novel blended yarn

The invention relates to a novel blended yarn. The blended yarn is made of cotton fibers, seaweed carbon fibers, silkworm protein fibers and bamboo fibers. The blended yarn is characterized by comprising the following raw materials, by weight, 10-20 parts of the cotton fibers, 50-80 parts of the seaweed carbon fibers, 15-30 parts of the silkworm protein fibers and 15-30 parts of the bamboo fibers. The blended yarn has the advantages that the blended yarn is capable of emitting far infrared rays and generating anions, good in air permeability, moisture absorption and drapability, comfortable in hand feeling, high in wear resistance, and good in dyeing property, has the natural anti-microbial, anti-bacteria, snail killing, odor-resistant and uvioresistant functions, and can meet requirements of people.

Owner:邹雪芬

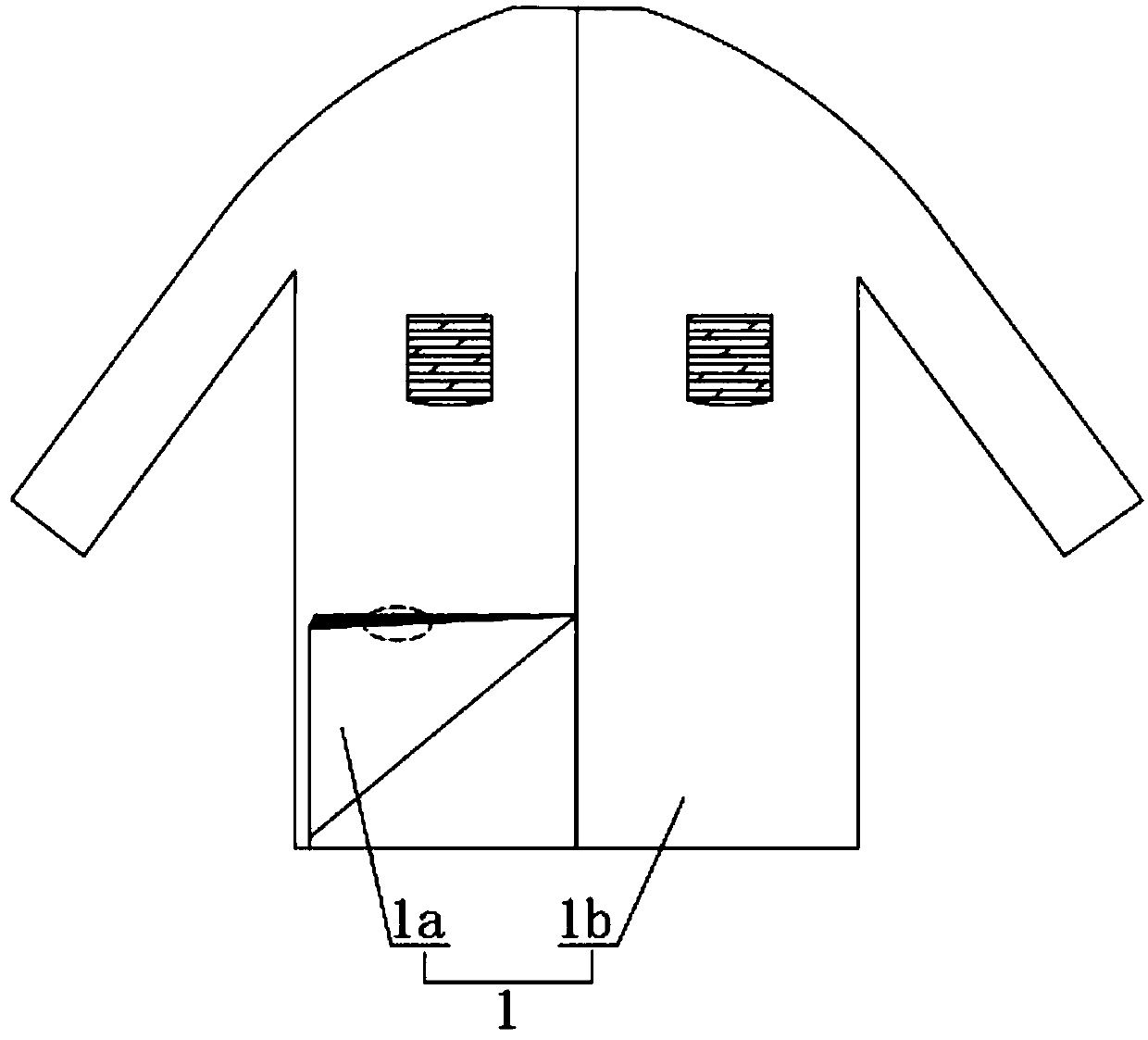

Graphene electric heating garment

InactiveCN109645590AImprove practicalityEasy to disassembleGarment special featuresSynthetic resin layered productsElectricityYarn

The invention discloses a graphene electric heating garment which comprises a garment surface layer and a thermal storage layer. The thermal storage layer is arranged in the garment surface layer, thegarment surface layer comprises a garment base layer and a garment outer layer, the garment base layer is close to the skin of human bodies, the garment outer layer is in contact with the external, the thermal storage layer is arranged between the garment base layer and the garment outer layer, composite fibers are spun and woven to form the garment surface layer and comprise bamboo fibers, temperature rise fibers and functional fibers, the bamboo fibers and the temperature rise fibers are used as yarn cores, and the functional fibers which are favorable for dehumidification are wound on theouter surfaces of the yarn cores; two sides of the thermal storage layer are connected with the garment base layer and the garment outer layer by snap buttons, the thermal storage layer comprises elastic air bags and heat conduction sheets, and the heat conduction sheets are arranged on the inner surfaces of the elastic air bags. The graphene electric heating garment has the advantages that the graphene electric heating garment is convenient to detach and clean, users can wear the graphene electric heating garment after the garment surface layer is filled with the heat storage layer in wintersand can wear the graphene electric heating garment after the heat storage layer is taken down in springs and autumns, and accordingly the practicality of the graphene electric heating garment can beimproved; excellent warmth retention effects further can be realized by the graphene electric heating garment, perspiration generated by the human bodies further can be quickly drained by the grapheneelectric heating garment, and accordingly the comfort level can be upgraded.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

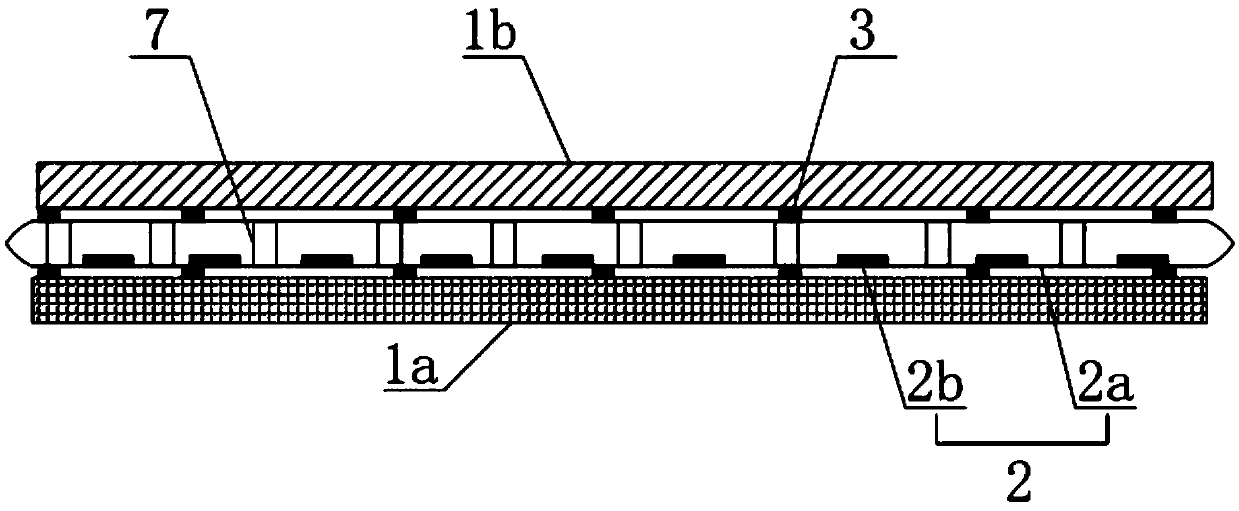

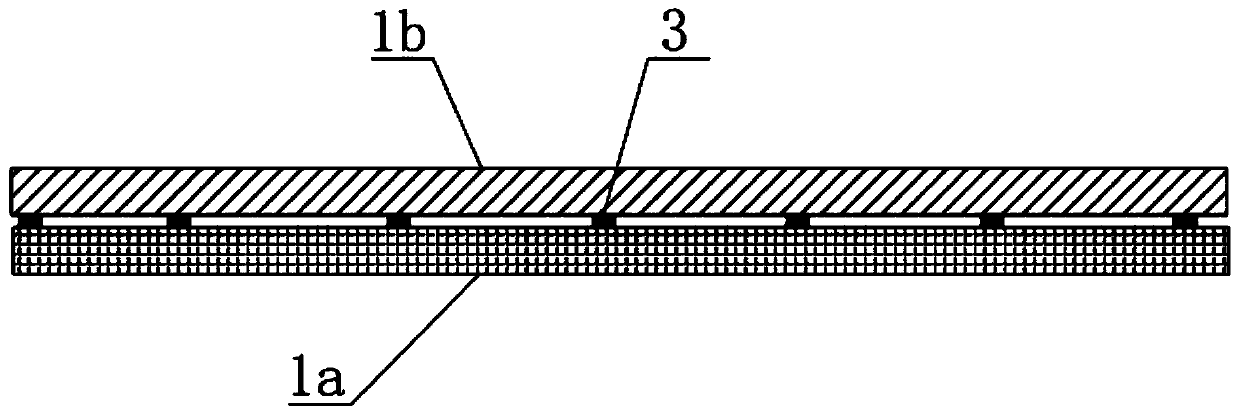

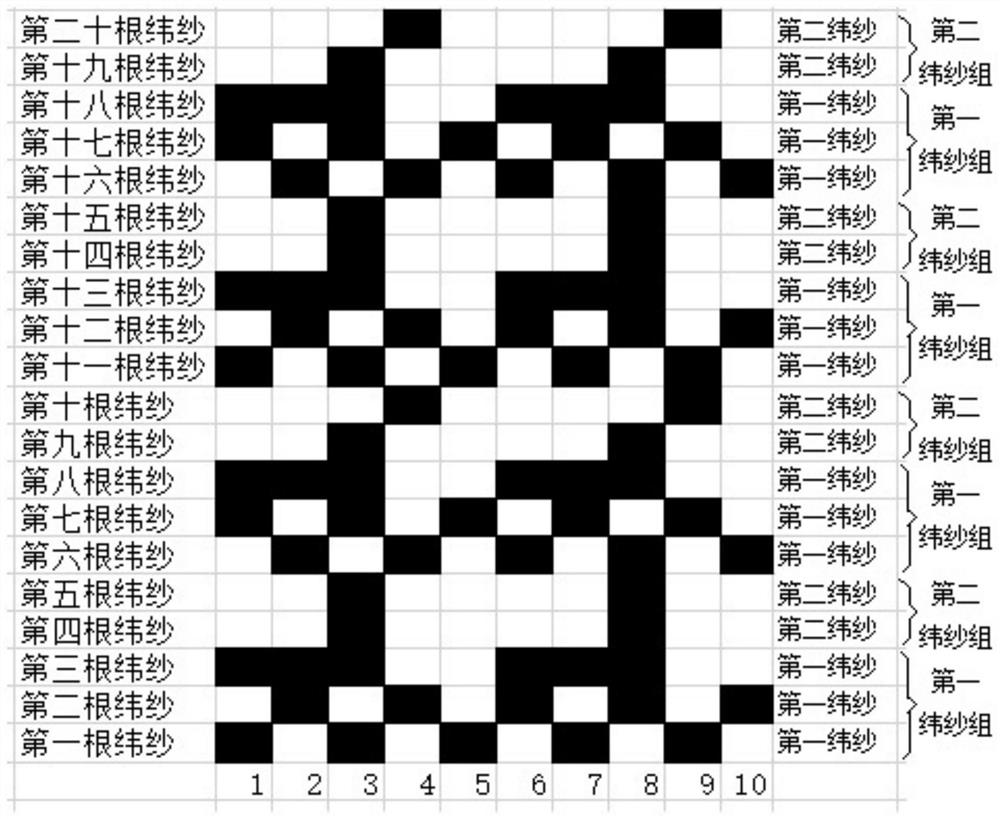

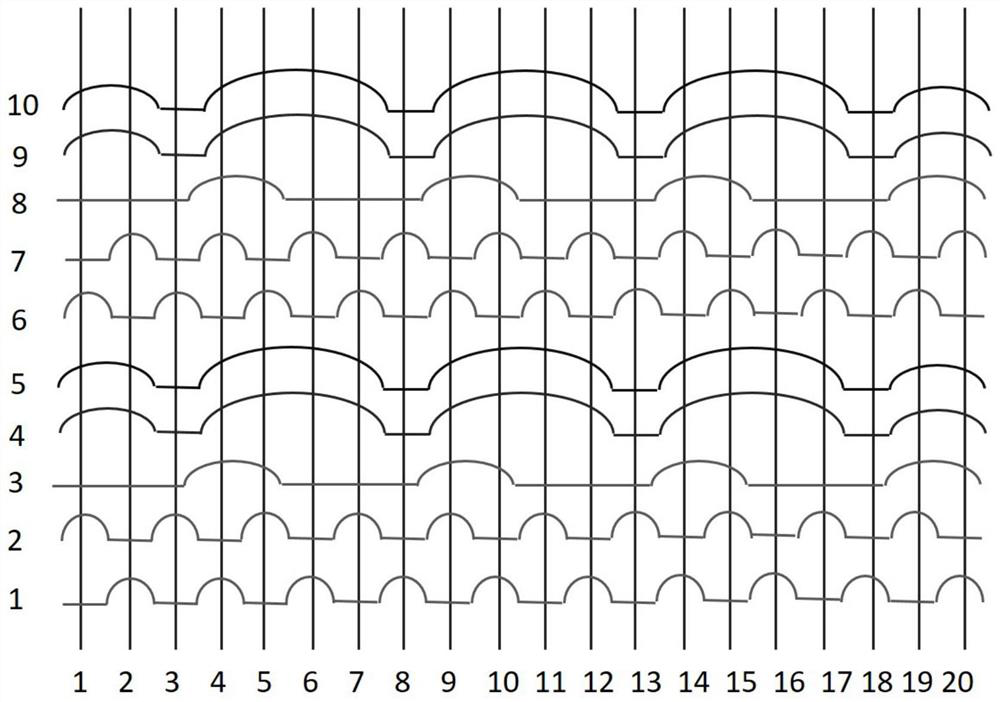

Antibacterial warm-keeping fabric, weaving method, preparation process and textile product

PendingCN112575429AHas a natural antibacterialGood flexibilityOrnamental textile articlesWoven fabricsCotton fibreProcess engineering

The invention discloses an antibacterial warm-keeping fabric, a weaving method, a preparation process and a textile product. The antibacterial warm-keeping fabric comprises warp yarns and weft yarns;the antibacterial warm-keeping fabric is formed by weaving the warp yarns and the weft yarns, and the warp yarns are blended yarns formed by blending cotton fibers and warm ginger fibers; the weavingmethod is mainly characterized in that yarns containing warm ginger fibers are adopted to weave the antibacterial warm-keeping fabric; the preparation process comprises the steps of spinning, weaving,gray fabric high-temperature steaming, velvet cutting, velvet brushing, singeing, blank inspecting, desizing, scouring and bleaching, reverse side light sanding, dyeing, shaping and finished productobtaining, wherein in the weaving process, yarn containing the warm ginger fibers needs to be woven into the antibacterial warm-keeping fabric. The fabric adopted by the textile product is the antibacterial warm-keeping fabric, or the adopted fabric applies the weaving method, or the adopted fabric applies the preparation process. The antibacterial warm-keeping fabric, the weaving method, the preparation process and the textile product have the advantages of being good in warm-keeping effect, good in antibacterial performance, high in safety, high in comfort and the like.

Owner:SHENZHEN PURCOTTON TECH

Vinylon, bamboo fiber and silkworm pupa protein fiber blended yarn

The invention provides vinylon, bamboo fiber and silkworm pupa protein fiber blended yarn which is composed of, by weight, 55-65 parts of vinylon, 20-30 parts of bamboo fibers and 10-30 parts of silkworm pupa protein fibers. The vinylon, bamboo fiber and silkworm pupa protein fiber blended yarn integrates characteristics of the vinylon, the bamboo fibers and the silkworm pupa protein fibers to bring advantages of the same into play.

Owner:NANTONG MEIMING CHINLON

Bamboo fiber mat

InactiveCN109090898AImprove breathabilityImprove wear resistanceStuffed mattressesSpring mattressesPolyesterSurface layer

The invention discloses a bamboo fiber mat. The bamboo fiber mat is formed by mixing and hot pressing of bamboo fibers and polyester fibers, wherein the weight percentage of the bamboo fibers in the fiber mat body is 82% to 84%, the balance is the polyester fibers, the bamboo fibers are raw bamboo fibers, and the raw bamboo fibers are natural bamboo fibers, bamboo pulp fibers or bamboo charcoal fibers. The bamboo fiber mat using the bamboo fibers has high air permeability, instant water absorption, strong wear resistance, high dyeability and the like, and has natural antibacterial, anti-mite,deodorant and anti-ultraviolet functions. According to the bamboo fiber mat made by a bamboo fiber mat manufacturing process, not only is an integrated fiber layer formed, but also the bamboo fiber mat does not have upper and lower surface layers, does not have a three-layer structure or even a polyester fiber layer, so the air permeability and the instant water absorption are more prominent.

Owner:GUANGDONG YIXIN HOUSEHOLD MATERIALS GROUP CO LTD

Method for processing copper fiber, bamboo fiber and cotton fiber blended yarns

The invention discloses a method for processing copper fiber, bamboo fiber and cotton fiber blended yarns. The method includes bamboo fiber strip processing working procedures, combed cotton silver processing working procedures and blending processing working procedures. The method is characterized in that the copper fiber, bamboo fiber and cotton fiber blended yarns comprise, by weight, 25-49% of bamboo fibbers, 20-39% of copper fibers and the balance cotton fibers. According to the scheme, the method has the advantages that the copper fiber, bamboo fiber and cotton fiber blended yarns on the basis of integration of the copper fibers, the cotton fibers and polyester fibers are extremely high in comfort and have certain strength, antistatic capacity, electromagnetic radiation resistance and sterilization characteristics.

Owner:NANTONG JINSHAN TEXTILE

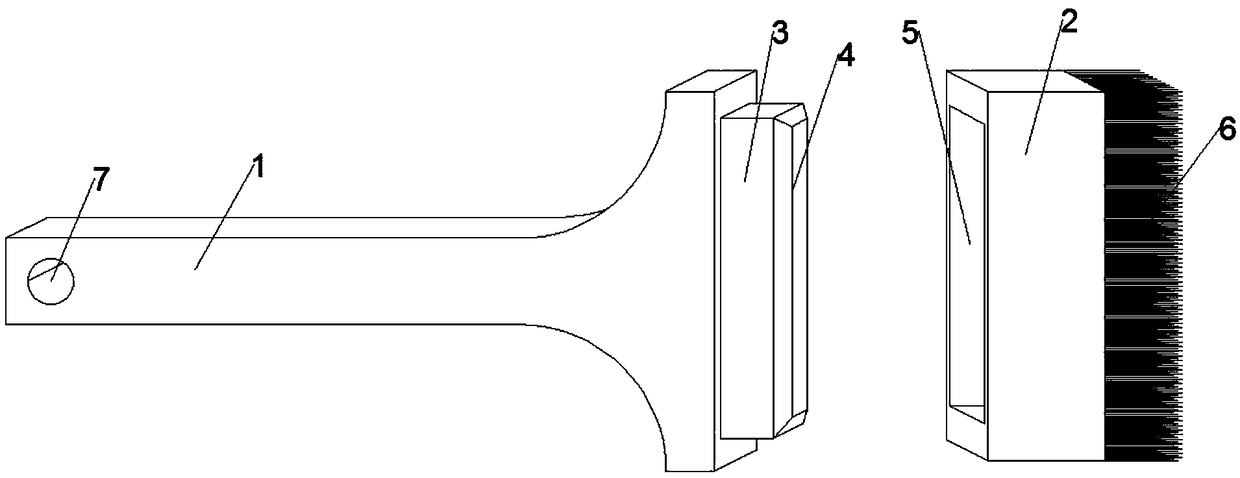

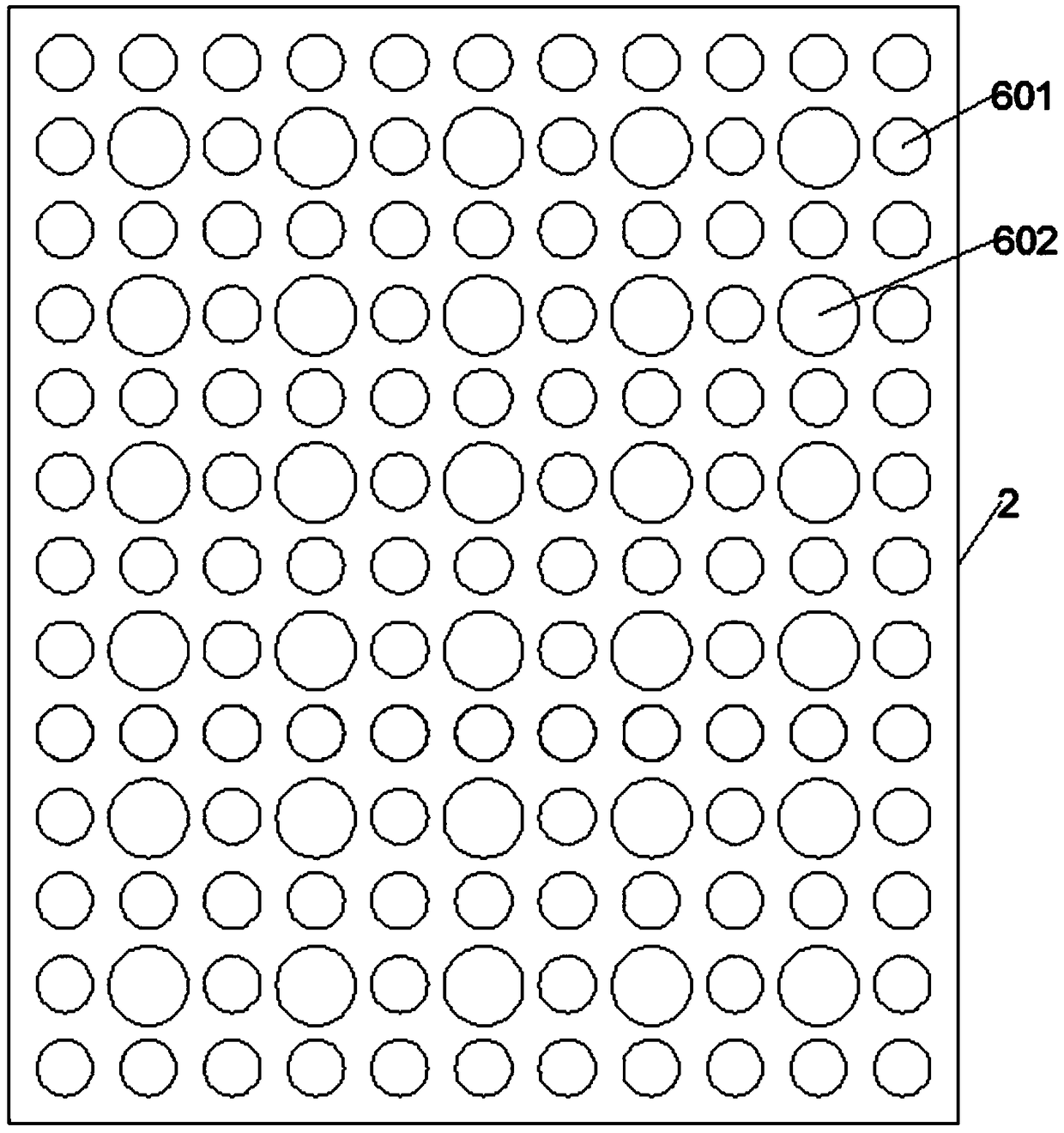

All-wood brush

InactiveCN109008175AGood air permeabilityStrong wear resistanceBrush bodiesBristleEngineeringBristle

The invention discloses an all-wood brush comprising a brush handle and a brush head. One end of the brush handle is provided with a clamp block. One end of the clamp block is provided with a prismatic block. The brush handle, the clamp block and the prismatic block are integrally formed. One end of the brush head is provided with a clamp groove matching the clamp block and the prismatic block. The brush handle, the brush head, the clamp block and the prismatic block are all carved from wood. The other end of the brush head is provided with bristles. The all-wood brush is environmentally friendly and durable, and the bristles are not easy to mildew, so that the service life of the bristles can be prolonged.

Owner:安徽玉达工具有限公司

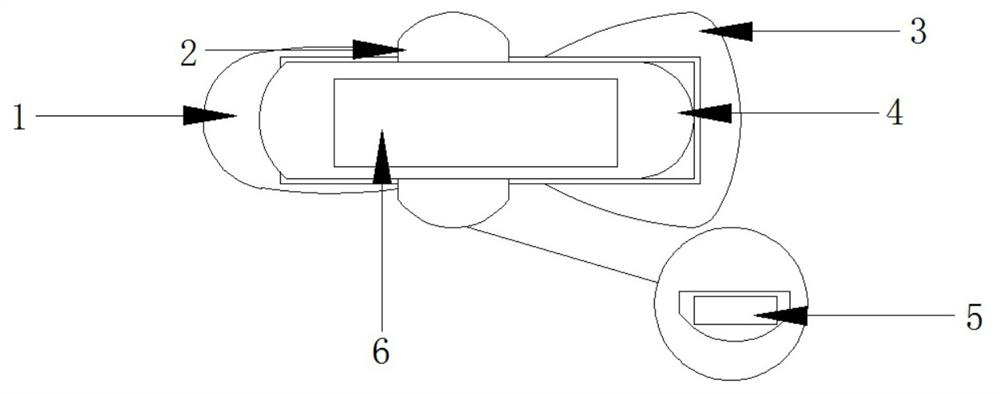

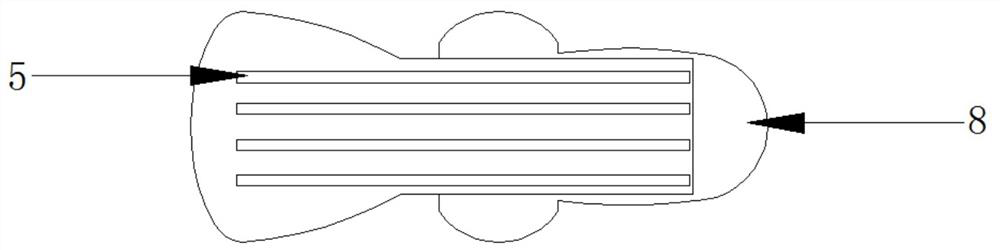

Graphene sanitary napkin core and production method therefor

The invention discloses a graphene sanitary napkin core and a production method therefor. The graphene sanitary napkin core comprises a sanitary napkin body, wherein flanks are arranged and mounted at the left and right sides of the sanitary napkin body, a tail fin is arranged at the bottom end of the sanitary napkin body, a surface layer is arranged and mounted at the middle end of the sanitary napkin body, a functional core is arranged and mounted at an internal middle part of the surface layer, a basilar film is arranged and mounted on the back of the sanitary napkin body, backing adhesives are separately arranged and mounted on the back of the basilar film and backs of the flanks, and materials such as elemental graphene and high-activity bamboo charcoal powder are arranged in the functional core. The graphene sanitary napkin core has natural antibacterial, bacteriostatic, anti-mite and deodorization functions; ionic micro-arrays are formed by high-activity bamboo charcoal, so that durability can be strengthened through webbing the graphene and distributing the graphene into the entire core, and the bactericidal and bacteriostatic effects of the core are improved greatly; and by adding some traditional Chinese medicine ingredients, the feeling of a female's private part can be relieved, meanwhile, off odors can be dispelled, and embarrassments of female in daily lives are relieved.

Owner:佛山市创洁无纺科技有限公司

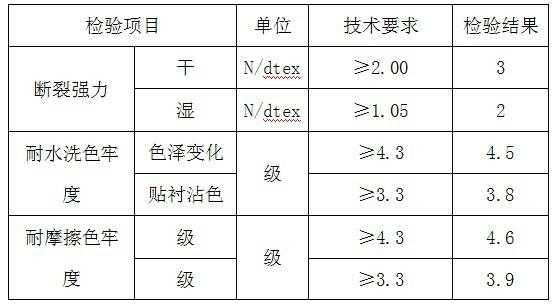

Manufacturing method for multifunctional wool spinning fabric

InactiveCN105401297ABreak through the limitations of taking seasonOvercoming the shortcomings of the cooling approachSolvent-treatmentDyeing processYarnTransmittance

The invention relates to a manufacturing method for a multifunctional wool spinning fabric. The fabric comprises non-shrinkable wool whose specifications are 70 S-80 S of fineness and 60-70 mm of length, and ultraviolet prevention bamboo fibers whose specification is 4-5 dtex*(65-70) mm. Mass percent of the two components of the non-shrinkable wool and the ultraviolet prevention bamboo fibers is 30-60% to 70-40%. The non-shrinkable wool balls are dyed to make into color wool tops. The ultraviolet prevention bamboo fibers are dyed, through silver blending, the yarns are woven into spun yarns, and through posterior spinning, fine yarns are obtained. A wool spinning fabric is made by the manufacturing method, and the fabric is made into the multifunctional wool spinning fabric through two-time soaking and binding fabric processing. The fabric and the manufacturing method can effectively improve transmittance, moisture permeability and air permeability. The fabric has good ultraviolet protection performance, fastness to rubbing, color fastness to washing, and has good antistatic property, flame retardant property, and permeability, and has health care effect.

Owner:JIANGSU SUNSHINE

Bamboo carbon fiber fly-knitted vamp

InactiveCN109736096AImprove breathabilityInstant water absorptionMonocomponent polyurethanes artificial filamentFiberHot weather

The invention relates to the technical field of fly-knitted vamps and particularly relates to a bamboo carbon fiber fly-knitted vamp knitted by virtue of bamboo carbon fibers. The bamboo carbon fibershave the characteristics of good air permeability, instant water-absorbing property, relatively strong wear resistance, winter warmness, summer coolness and the like, further have a series of functional characteristics of natural antibacterial property, bacteriostatic property, mite removal property, deodorization property and ultraviolet resistance and are applied to the fly-knitted vamps, the fly-knitted vamps can be dry, comfortable, air-permeable, healthy and odor-free when being worn in outdoor hot weather, are cool and comfortable when being worn in winter, are warm in winter and cool in summer and can meet the mental and wearing comfortable feels of customers. The fly-knitted vamps have great market superiorities and breakthrough effects.

Owner:东莞市喜宝体育用品科技有限公司

Preparation method of bamboo fiber antibacterial rag

InactiveCN111979762AImprove breathabilityInstant water absorptionCarpet cleanersBiochemical fibre treatmentBiotechnologyFiber

The invention discloses a preparation method of a bamboo fiber antibacterial rag. The preparation method of the bamboo fiber antibacterial rag mainly comprises the following steps of material preparation, processing instrument preparation, material processing and finished product testing. The bamboo fibers have the characteristics of good air permeability, instantaneous water absorption, strong wear resistance, good dyeability and the like in the actual use process, and also have the functions of natural antibiosis, bacteriostasis, acarus killing, deodorization and ultraviolet resistance, andwormwood matched with the bamboo fibers contains rich eucalyptol, so that the eucalyptol substance can effectively inhibit growth and division of bacteria and virus and even has a bactericidal effecton part of bacteria, the bacteriostatic rag is produced based on the bamboo fibers and the wormwood, beneficial components of the two natural substances can be effectively mixed, flora can be efficiently inhibited after the rag is used, and on the premise of meeting the use functions of a conventional rag, good antibacterial and degerming effects can be achieved.

Owner:CHANGSHU YISHENG COMMODITY

Intelligently-designed digital printed fabric production process with energy-saving effect

InactiveCN112853781AHas a natural antibacterialWith UV protectionFibre typesTypewritersDigital printingSizing

An intelligently-designed digital printed fabric production process with an energy-saving effect comprises the following steps: S1, weaving: doubling cotton, bamboo fibers and mulberry silk into double-plied yarn, and then weaving the double-plied yarn into real silk-cotton single-sided plain knitted cloth; S2, singeing: treating the cloth in the step S1 by adopting double-sided singeing; S3, mercerizing: mercerizing the cloth treated in the step S2 by adopting a knitting mercerizing machine; S4, boiling off: sequentially carrying out neutralizing treatment, bleaching treatment, neutralizing deoxidizing treatment and whitening treatment on the mercerized cloth treated in the step S3; S5, ground color shaping: carrying out ground color shaping on the cloth treated in the step S4; S6, printing: sequentially performing sizing and shaping treatment, pattern design treatment, digital printing, ageing treatment and water washing treatment on the cloth treated in the step S5; S7, softening and setting: treating the cloth treated in the step S6 by adopting a setting machine; S8, decating treatment: carrying out decating on the cloth treated in the step S7; and S9, preshrinking treatment: preshrinking the cloth treated in the step S8 by adopting a preshrinking machine.

Owner:ZHEJIANG FURUN DYEING & PRINTING

Antibacterial skin-beautifying socks containing alginate fibers

InactiveCN111567904AHas the effect of heat storage and heat preservationHas antibacterial propertiesSynthetic resin layered productsHandkerchiefsPolymer scienceCarbon fibers

The invention discloses a pair of antibacterial skin-beautifying socks containing alginate fibers. Each sock comprises a sock main body, wherein the sock main body is internally composed of an alginate fiber wrapping layer, a cotton cloth layer, a bamboo fiber layer and a spandex surface layer, the spandex surface layer wraps the outer surface of the bamboo fiber layer, the bamboo fiber layer wraps the outer surface of the cotton cloth layer, and the alginate fiber wrapping layer internally comprises an antibacterial master batch layer, an alginate carbon fiber layer and an alginate mineral substance layer. Bamboo fibers are arranged in the fabric, the fabric has the characteristics of good air permeability, instantaneous water absorption, relatively strong wear resistance, good dyeing property and the like; the functions of natural antibiosis, bacteriostasis, acarus killing, deodorization and ultraviolet resistance are realized; meanwhile, the alginate fiber wrapping layer and the alginate carbon fiber fabric have dual effects of heat preservation and health care, heat reaction is generated by friction of human body molecules after long-term wearing, blood circulation of the bodyis promoted, a heat storage and heat preservation effect is achieved, and the socks woven by the alginate carbon fibers have the effects of heat preservation, antibiosis and deodorization.

Owner:义乌市完型科技有限公司

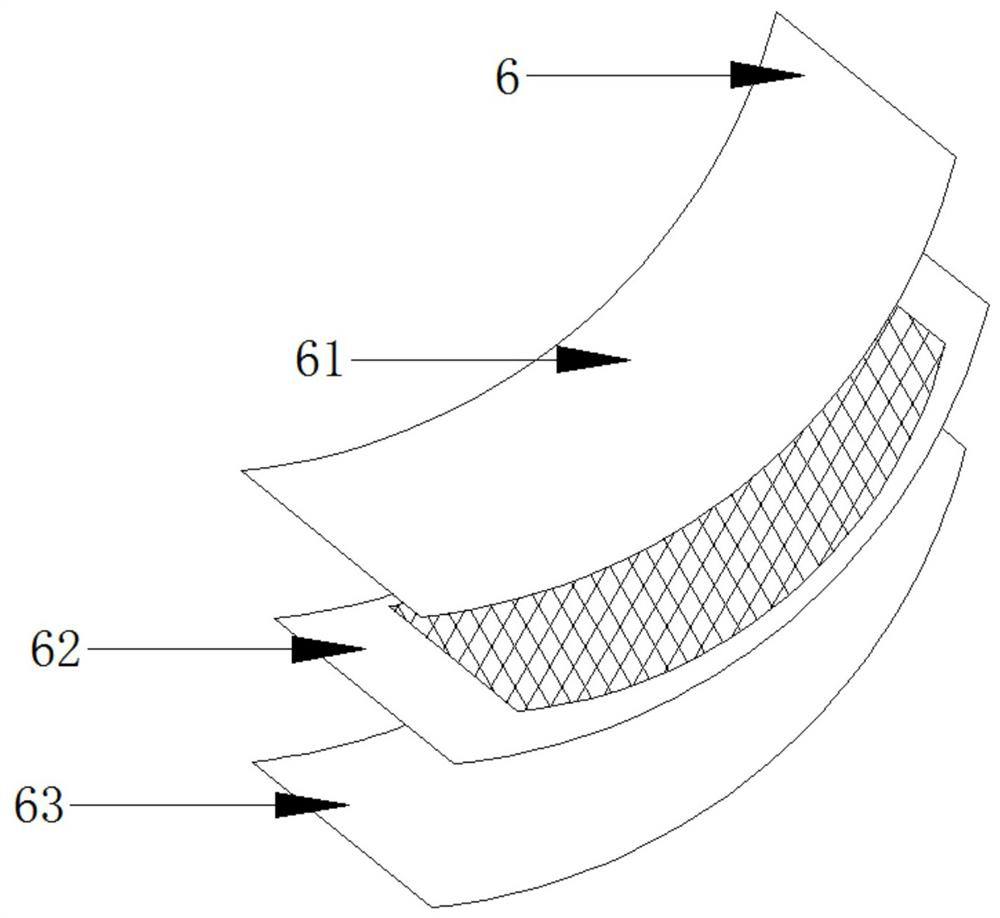

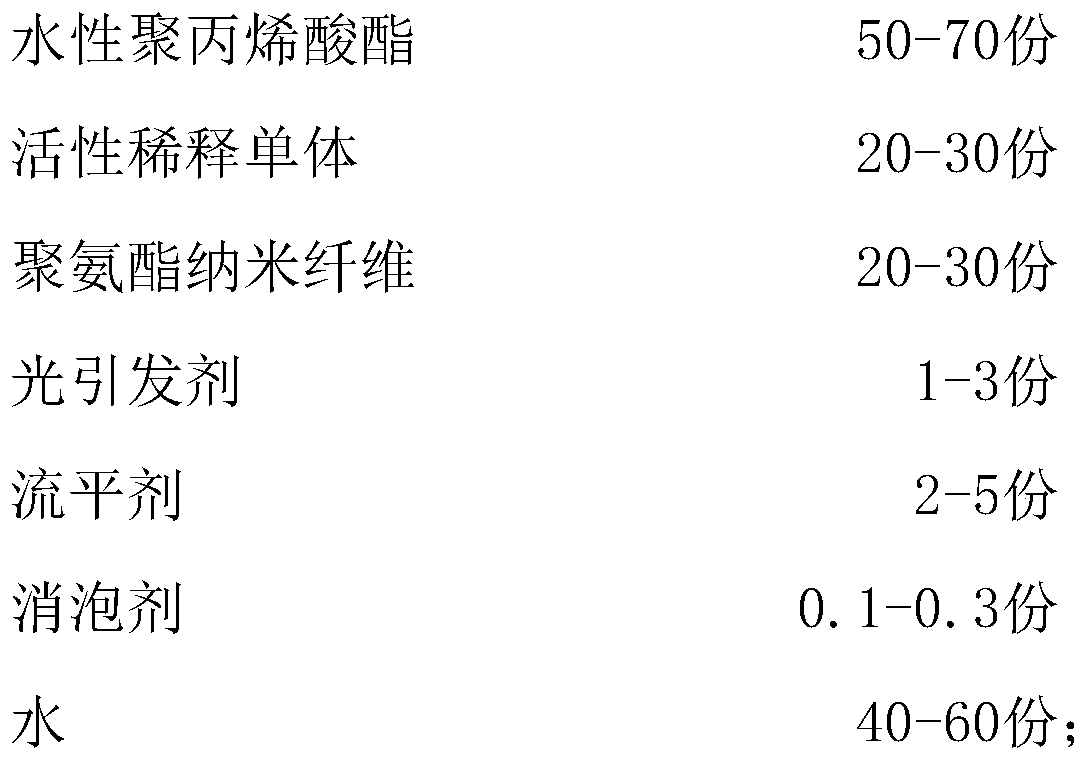

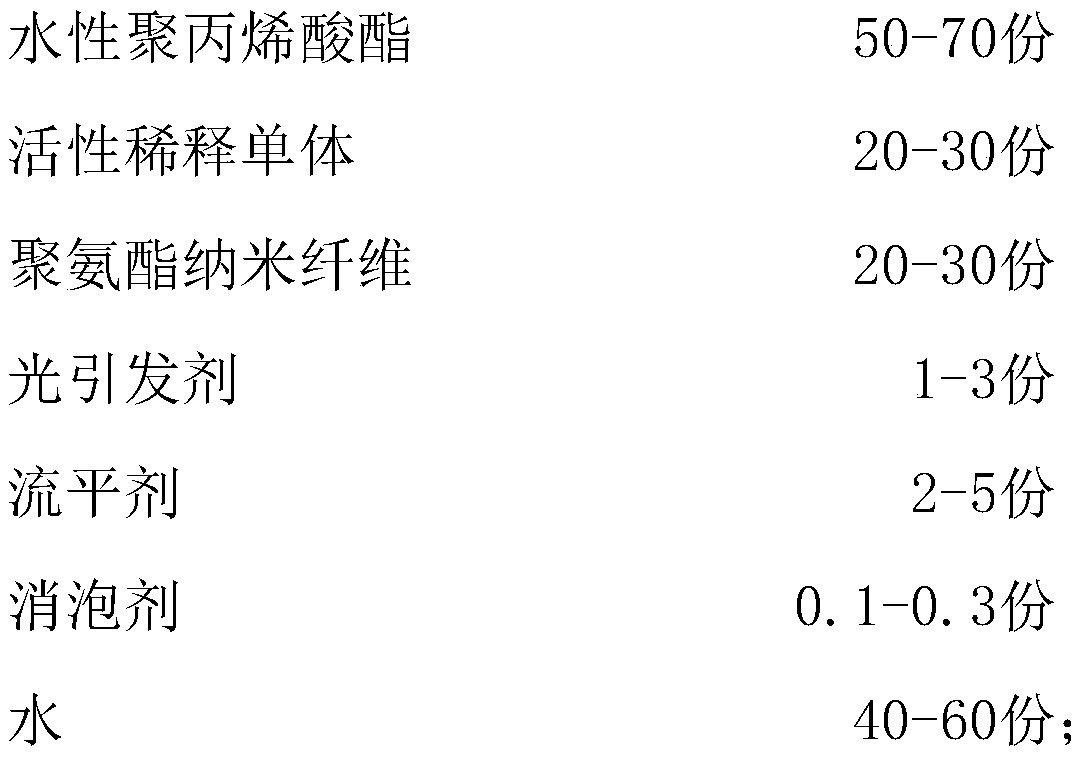

TPU composite fabric

InactiveCN111890747AImprove waterproof performanceGood deodorizing effectSynthetic resin layered productsWoven fabricsPolyesterPolymer chemistry

The invention provides a TPU composite fabric. The TPU composite fabric comprises base cloth and a TPU film adhered to the surface of the base cloth, wherein the base cloth is formed by interweaving warp yarns and weft yarns, the warp density of the warp yarn interwoven fabric is 90-150 pieces per centimeter, the weft density of the weft yarn interwoven fabric is 40-50 pieces per centimeter, the warp yarns are bamboo fiber yarns, and the weft yarns are mulberry silk and polyester drawn textured yarns which are alternately arranged; the TPU film is prepared from the following raw materials: TPUparticles, white carbon black, plant polyphenol, a leveling agent and a stripping aid; the TPU composite fabric is formed by bonding and compounding the TPU film and the base cloth, the base cloth isformed by blending the bamboo fiber yarns, the mulberry silk and the polyester drawn textured yarns, and the TPU composite fabric has good deodorization, air permeability and antibacterial and mildew-proof properties and is matched with the air-permeable and waterproof TPU film attached to the outer side, so that the waterproofness of the composite fabric is enhanced.

Owner:昆山市悦宏复合面料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com