Preparation method of nano-antibacterial fiber mixed fabric

A nano-antibacterial fiber and fabric technology, applied in the chemical characteristics of fibers, conjugated synthetic polymer rayon, conjugated rayon and other directions, can solve the problems of unsatisfactory antibacterial effect and short use time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

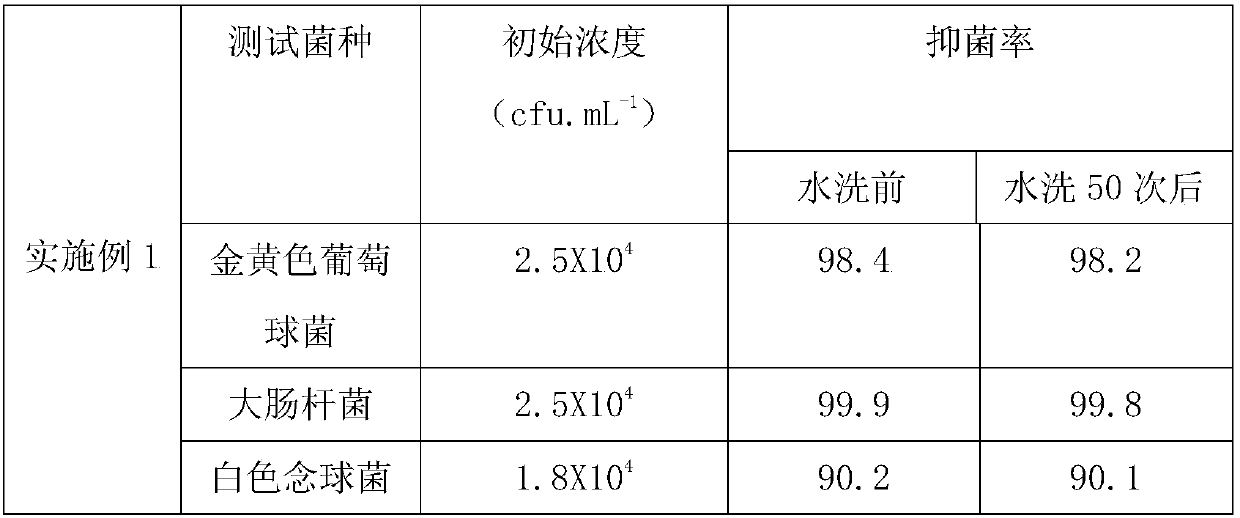

Embodiment 1

[0015] A method for preparing a nano-antibacterial fiber mixed fabric, which is made of the following raw materials in parts by weight: 78 parts of copper-modified polyester fiber, 6 parts of wheat starch, 3 parts of aloe, 12 parts of seaweed fiber, 2.5 parts of nano-zinc oxide, nano 1.5 parts of silver powder, 1.5 parts of pearl powder, 2.2 parts of M82 emulsifier, 3 parts of propylparaben, 2.2 parts of polyhexamethylene guanidine, 2.5 parts of olive oil, 3.5 parts of synthetic silk oil, 1.5 parts of sodium hyaluronate, 2.5 parts of Rauwolfia, 2.5 parts of mugwort leaves, 1.2 parts of bitter herbs, 1.2 parts of bitter beans, 1.5 parts of tea tree, 1.8 parts of thyme, and 1.6 parts of pearl powder.

[0016] The preparation method comprises the following steps: (1) preparing a mixed syrup; (2) grinding wheat starch to a particle size of 50-80um, placing it in a beaker, adding water according to the weight ratio of wheat starch and water as 1:3, and mixing Stir evenly, then add ...

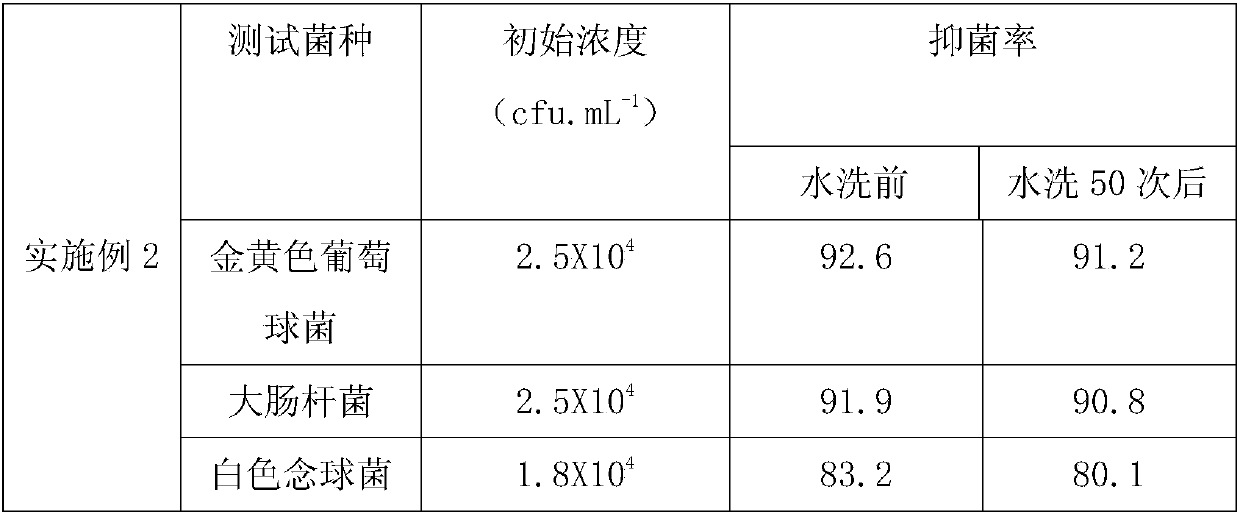

Embodiment 2

[0023] A method for preparing a nano-antibacterial fiber mixed fabric, which is made of the following raw materials in parts by weight: 80 parts of copper-modified polyester fiber, 8 parts of wheat starch, 4 parts of aloe, 16 parts of seaweed fiber, 3 parts of nano-zinc oxide, nano 1.7 parts of silver powder, 2.5 parts of pearl powder, 2.5 parts of M82 emulsifier, 4 parts of propylparaben, 2.5 parts of polyhexamethylene guanidine, 3.5 parts of olive oil, 4.5 parts of synthetic silk oil, 2.4 parts of sodium hyaluronate, 4.5 parts of Rauwolfia, 3.6 parts of mugwort leaves, 1.4 parts of bitter herbs, 1.6 parts of bitter beans, 2.4 parts of thyme, and 1.2 parts of pearl powder.

[0024]The preparation method comprises the following steps: (1) preparing a mixed syrup; (2) grinding wheat starch to a particle size of 50-80um, placing it in a beaker, adding water according to the weight ratio of wheat starch and water as 1:3, and mixing Stir evenly, then add synthetic silk oil, propyl...

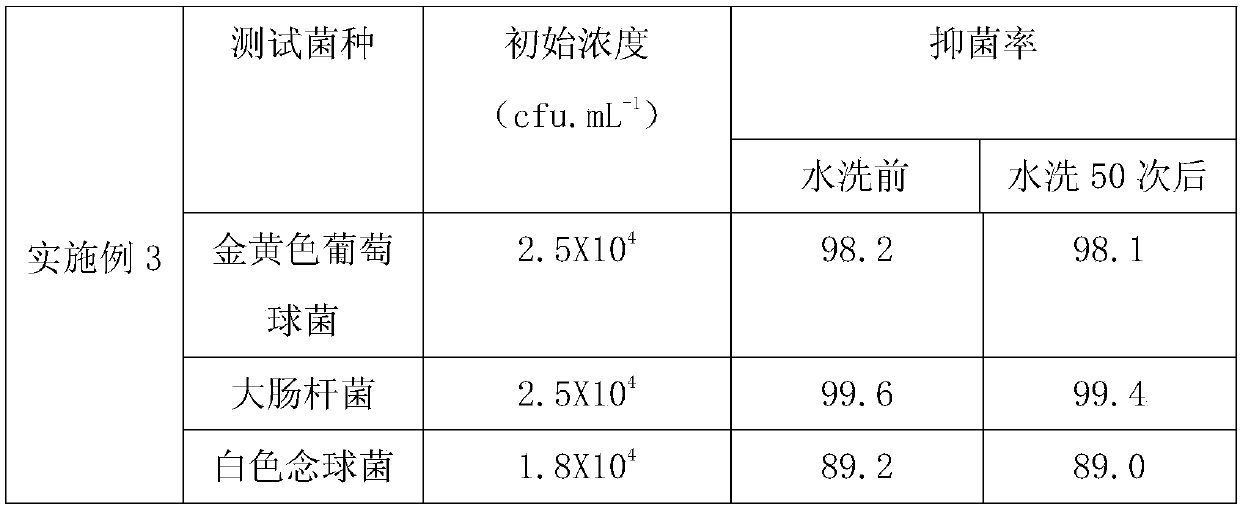

Embodiment 3

[0028] A method for preparing a nano-antibacterial fiber mixed fabric, which is made of the following raw materials in parts by weight: 82 parts of copper-modified polyester fiber, 8 parts of wheat starch, 5 parts of aloe, 20 parts of seaweed fiber, 4 parts of nano-zinc oxide, nano 2 parts of silver powder, 3 parts of pearl powder, 3 parts of M82 emulsifier, 5 parts of propylparaben, 3 parts of polyhexamethylene guanidine, 4 parts of olive oil, 5 parts of synthetic silk oil, 3 parts of sodium hyaluronate, 5 parts of Rauwolfia, 4 parts of mugwort leaves, 2 parts of bitter herbs, 2 parts of bitter beans, 3 parts of tea tree, 3 parts of thyme, 2 parts of pearl powder.

[0029] The preparation method comprises the following steps: (1) preparing the mixed medicine slurry, the preparation method of the mixed medicine slurry is: taking aloe vera, Rauwolfia, Artemisia argyi, bitter cabbage, bitter bean, tea tree, thyme and pearl powder according to the formula ratio, mixing and adding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com