An anti-icing cable

A technology for anti-icing and cables, which is applied in the manufacture of power cables, insulated cables, and cables/conductors. It can solve the problems of short service life, low insulation toughness and strength, etc., and achieve low elongation at break and excellent anti-coverage Effect of ice performance and excellent hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

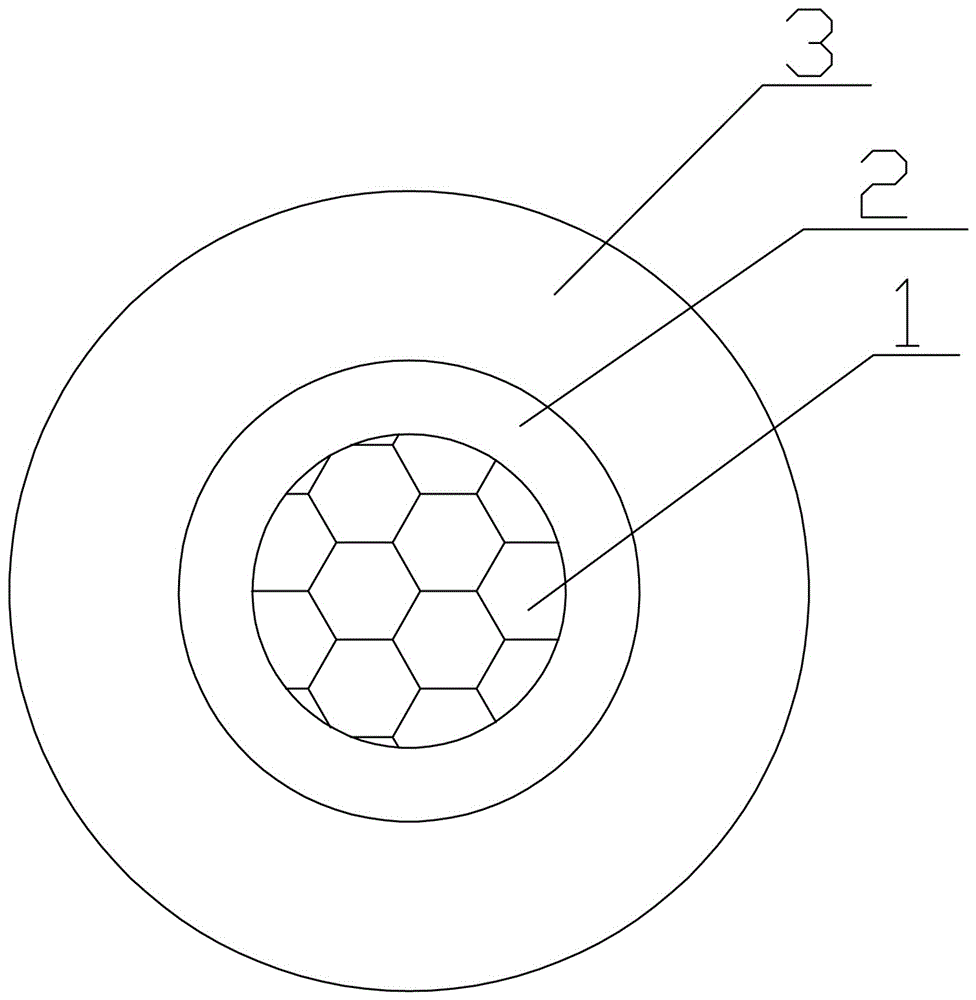

[0031] An ice-resistant cable such as figure 1 As shown, it includes a core 1, a shielding layer 2 and an anti-icing layer 3 arranged sequentially from the inside to the outside. The anti-icing layer includes the following raw materials in parts by weight: 60 parts of fluorosilicone resin, methyl vinyl silicone rubber 30 parts, SiO 2 - 10 parts glass fiber gel, 5 parts polypropylene fiber powder, nano SiO 2 5 parts, nano TiO 2 4 parts, 0.25 parts each of glyceryl tristearate and polyvinyl alcohol as a dispersant, 0.25 parts each of magnesium hydroxide and aluminum hydroxide as a flame retardant, 1 part of vinyl triethoxysilane as a silane coupling agent, and 264 parts of anti-aging agent Makes 2 servings.

[0032] Of which SiO 2 -The preparation method of glass fiber gel comprises the following steps:

[0033] (1) After soaking the glass fiber in 1mol / L hydrochloric acid for 2 hours, wash it with deionized water until neutral, and dry it at 90°C, wherein the glass fiber ...

Embodiment 2

[0041] An ice-resistant cable such as figure 1 As shown, it includes a core 1, a shielding layer 2 and an anti-icing layer 3 arranged sequentially from the inside to the outside. The anti-icing layer includes the following raw materials in parts by weight: 62 parts of fluorosilicone resin, methyl vinyl silicone rubber 28 parts, SiO 2 - 11 parts of glass fiber gel, 6 parts of polypropylene fiber powder, nano-SiO 2 4.5 parts, Nano TiO 2 4.2 parts, 0.3 parts of glyceryl tristearate and polyvinyl alcohol as dispersants, 0.3 parts of magnesium hydroxide and aluminum hydroxide as flame retardants, 1.2 parts of aminopropyl triethoxysilane as silane coupling agent, anti-aging agent 445 for 1.8 parts.

[0042] Of which SiO 2 -The preparation method of glass fiber gel comprises the following steps:

[0043] (1) After immersing the glass fiber in 1.5mol / L nitric acid for 1 hour, wash it with deionized water until neutral, and dry it at 100°C. The diameter of the glass fiber monofil...

Embodiment 3

[0051] An ice-resistant cable such as figure 1 As shown, it includes a core 1, a shielding layer 2 and an anti-icing layer 3 arranged sequentially from the inside to the outside. The anti-icing layer includes the following raw materials in parts by weight: 65 parts of fluorosilicone resin, methyl vinyl silicone rubber 26 parts, SiO 2 - 12 parts of glass fiber gel, 7 parts of polypropylene fiber powder, nano-SiO 2 4 parts, Nano TiO 2 4.5 parts, 0.35 parts of glyceryl tristearate and polyvinyl alcohol as dispersants, 0.35 parts of magnesium hydroxide and aluminum hydroxide as flame retardants, 1.4 parts of γ-aminopropyl trimethoxysilane as silane coupling agent, anti-aging Agent 445 and antioxidant 264 are each 0.8 parts.

[0052] Of which SiO 2 -The preparation method of glass fiber gel comprises the following steps:

[0053] (1) Soak the glass fiber in 2mol / L nitric acid for 1.5h, wash it with deionized water until neutral, and dry it at 95°C. The diameter of the glass f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com