Loofah sponge fiber antibacterial packaging paper and preparation method

A technology of loofah fiber and packaging paper, applied in the field of papermaking, can solve the problems of increasing raw materials and processing procedures, increasing packaging costs, etc., and achieves the effects of excellent performance, reduced burden on the environment, and high cellulose content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

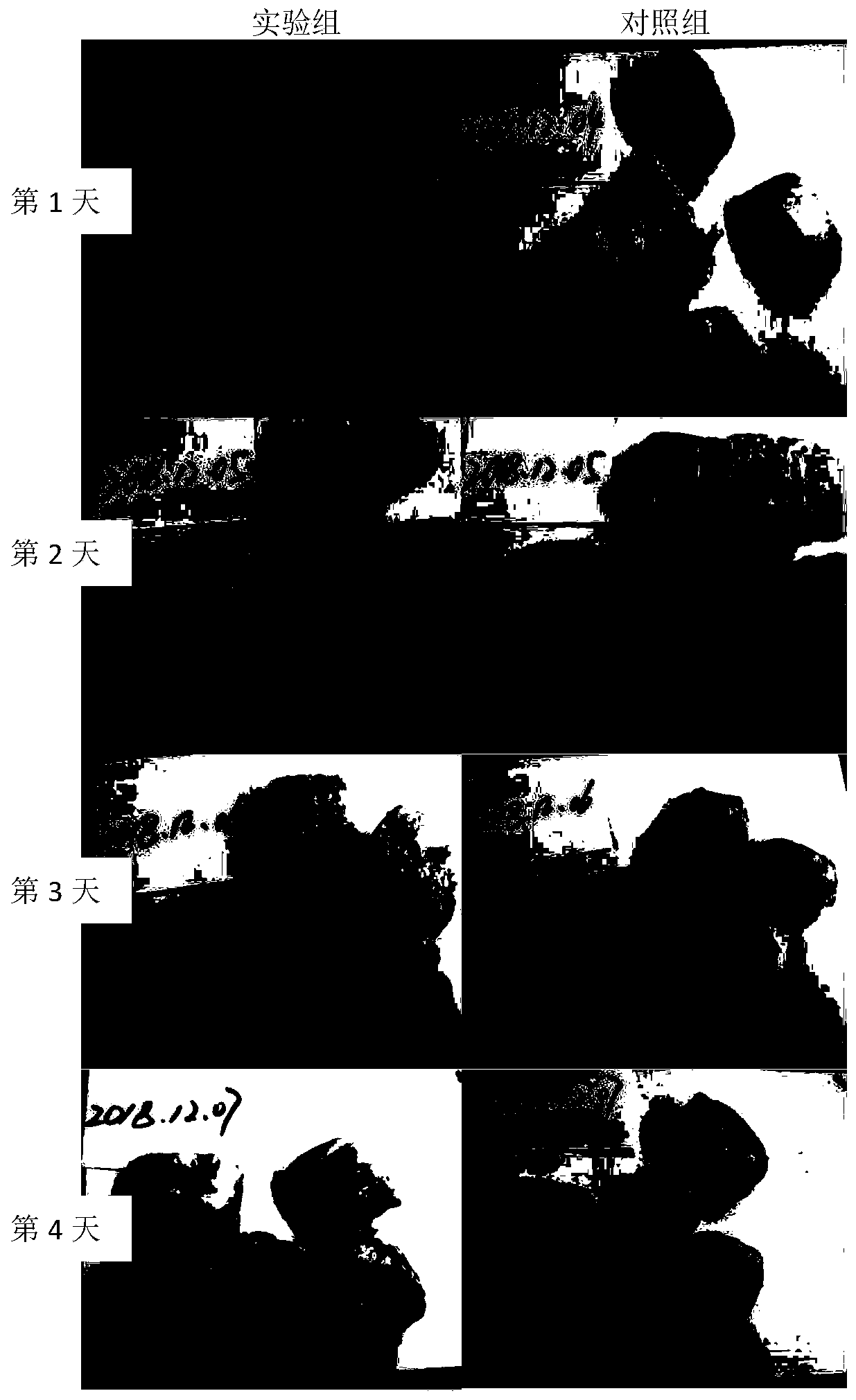

Image

Examples

Embodiment 1

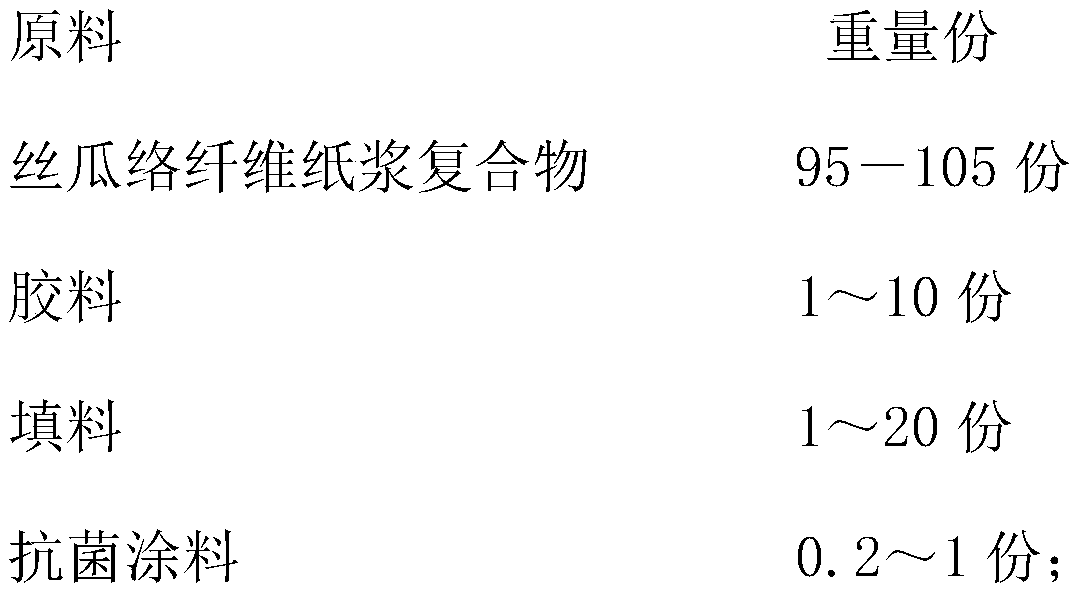

[0047] A kind of loofah fiber antibacterial wrapping paper, it is made of the raw material of following dry weight parts:

[0048]

[0049] Wherein the loofah fiber pulp compound is a compound in which loofah fibers and pulp fibers are mixed in a mass ratio of 1:5.

[0050] Further, the filler is two to five or any one of them in calcium carbonate, silicon dioxide, montmorillonite, titanium dioxide or talcum powder; the sizing agent is chitosan and cornstarch by 1: The mass ratio of 5 is mixed; the antibacterial coating is 1% chitosan solution.

[0051] A preparation method of loofah fiber antibacterial wrapping paper:

[0052] 1. Raw material preparation: Weigh the raw materials of loofah fiber pulp compound, rubber compound, filler and antibacterial coating in proportion for later use;

[0053] 2. Pretreatment of the loofah fiber pulp compound: put the loofah in an oven at 82°C for 30 minutes, soak the dried loofah in NaOH solution with a mass fraction of 10%, and place...

Embodiment 2

[0061] A kind of loofah fiber antibacterial wrapping paper, it is made of the raw material of following dry mass parts:

[0062]

[0063] Wherein the loofah fiber pulp compound is a compound in which loofah fiber and pulp fiber are mixed in a mass ratio of 1:3.

[0064] Further, the filler is two to five or any one of them in calcium carbonate, silicon dioxide, montmorillonite, titanium dioxide or talcum powder; The mass ratio of 1 is mixed; the antibacterial coating is 1% chitosan solution.

[0065] A preparation method of loofah fiber antibacterial wrapping paper:

[0066] 1. Raw material preparation: Weigh the raw materials of loofah fiber pulp compound, rubber compound, filler and antibacterial coating in proportion for later use;

[0067] 2. Pretreatment of the loofah fiber pulp compound: put the loofah in a 78°C oven to dry for 32 minutes, soak the dried loofah with 10% NaOH solution, and place it in a 58°C water bath for 20 minutes. Rinse the loofah fiber repeated...

Embodiment 3

[0075] A kind of loofah fiber antibacterial wrapping paper, it is made of the raw material of following dry mass parts:

[0076]

[0077] Wherein the loofah fiber pulp compound is a compound in which loofah fibers and pulp fibers are mixed in a mass ratio of 1:1.

[0078] Further, the filler is two to five or any one of them in calcium carbonate, silicon dioxide, montmorillonite, titanium dioxide or talcum powder; the sizing agent is chitosan and corn starch according to 3: The mass ratio of 1 is mixed; the antibacterial coating is 1% chitosan solution.

[0079] A preparation method of loofah fiber antibacterial wrapping paper:

[0080] 1. Raw material preparation: Weigh the raw materials of loofah fiber pulp compound, rubber compound, filler and antibacterial coating in proportion for later use;

[0081] 2. Pretreatment of the loofah fiber pulp compound: put the loofah in an oven at 80°C for 28 minutes, soak the dried loofah in NaOH solution with a mass fraction of 10%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com