Silk fabric detergent and preparation method thereof

A technology for laundry detergent and fabrics, applied in chemical instruments and methods, polymer surface active compounds, surface active detergent compositions, etc., can solve problems such as loss of silk fabrics, weak decontamination ability, etc. Pollution ability, the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

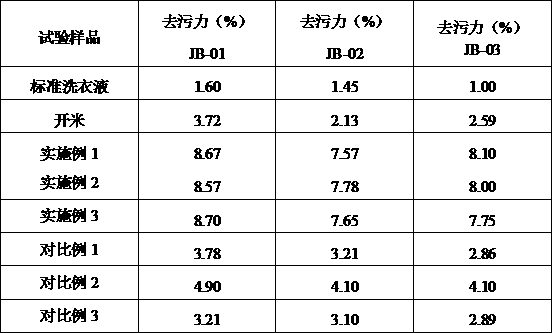

Examples

Embodiment 1

[0022] A laundry detergent for silk fabrics, comprising the following raw materials in mass percentage: 8-13% of alkyl glycosides, 10% of alkylphenol polyoxyethylene ethers, 10% of α-alkenyl sulfonates, 5% of potassium coconut oleate soap %, isomerized tridecyl alcohol polyoxyethylene ether 8%, lauryl sucrose ester 3-8%, coconut oil diethanolamide 1%, chitosan 1%, sodium citrate 0.1%, D-limonene 1% , ethylene glycol 1%, and the rest is deionized water.

[0023] The alkyl glycoside is any one of the alkyl glycosides with 12 carbon atoms in the alkyl group and 14 carbon atoms in the alkyl group.

[0024] A preparation method of silk fabric laundry detergent, comprising the following steps:

[0025] S1. According to the formula of laundry detergent, configure the raw materials of relevant weight;

[0026] S2. In the reaction kettle, add alkylphenol polyoxyethylene ether, α-alkenyl sulfonate, isomeric tridecyl alcohol polyoxyethylene ether, dodecyl sucrose ester, mix and stir fo...

Embodiment 2

[0030] A laundry detergent for silk fabrics, comprising the following raw materials in mass percentage: 13% of alkyl glycosides, 15% of alkylphenol polyoxyethylene ethers, 15% of α-alkenyl sulfonates, 10% of potassium coconut oleate soap, Isomerized tridecyl alcohol polyoxyethylene ether 13%, lauryl sucrose ester 8%, coconut oil diethanolamide 5%, chitosan 5%, sodium citrate 5%, D-limonene 5%, ethylene glycol 5%, and the rest is deionized water.

[0031] The alkyl glycoside is any one of the alkyl glycosides with 12 carbon atoms in the alkyl group and 14 carbon atoms in the alkyl group.

[0032] A preparation method of silk fabric laundry detergent, comprising the following steps:

[0033] S1. According to the formula of laundry detergent, configure the raw materials of relevant weight;

[0034] S2. In the reaction kettle, add alkylphenol polyoxyethylene ether, α-alkenyl sulfonate, isomeric tridecanyl polyoxyethylene ether, dodecyl sucrose ester, mix and stir for 10 minutes,...

Embodiment 3

[0038] A laundry detergent for silk fabrics, comprising the following raw materials in mass percent: 10% alkyl glucoside, 13% alkylphenol polyoxyethylene ether, 13% α-alkenyl sulfonate, 8% potassium coconut oleate soap, Isomerized tridecyl alcohol polyoxyethylene ether 10%, lauryl sucrose ester 5%, coconut oil diethanolamide 4%, chitosan 4%, sodium citrate 0.4%, D-limonene 5%, ethylene glycol 3%, and the rest is deionized water.

[0039] The alkyl glycoside is any one of the alkyl glycosides with 12 carbon atoms in the alkyl group and 14 carbon atoms in the alkyl group.

[0040] A preparation method of silk fabric laundry detergent, comprising the following steps:

[0041] S1. According to the formula of laundry detergent, configure the raw materials of relevant weight;

[0042] S2. In the reaction kettle, add alkylphenol polyoxyethylene ether, α-alkenyl sulfonate, isomeric tridecyl alcohol polyoxyethylene ether, dodecyl sucrose ester, mix and stir for 8 minutes, and finally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| detergency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com