Jute fiber and synthetic fiber blended yarn and method for preparing same

A synthetic fiber and hemp fiber technology, applied in fiber treatment, plant fiber, yarn, etc., can solve problems such as severe static electricity, easy to generate static electricity, and difficult spinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

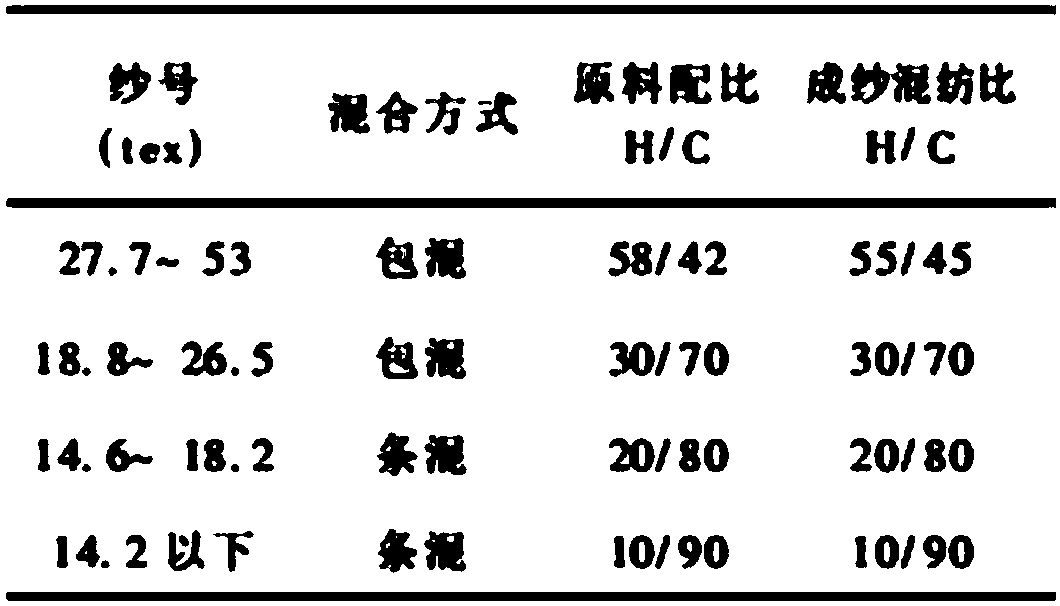

Method used

Image

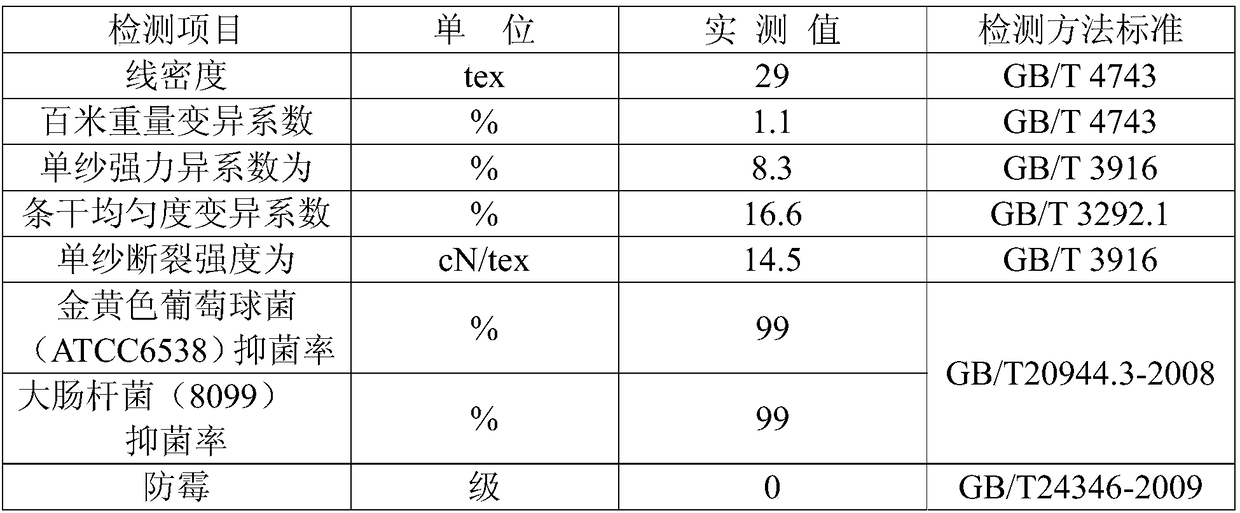

Examples

Embodiment 1

[0034] (1) Surface modification of hemp fiber

[0035] Sodium dodecylsulfonate is formulated into an aqueous solution with a mass percentage of 3%, the hemp fiber is arranged into a loose state, and then the above-mentioned aqueous solution is sprayed on the surface of the hemp fiber, and the spraying quality of the aqueous solution is 8%, it is enough to stand still for 72 hours in an environment with a relative humidity of 75% and a temperature of 25°C.

[0036] (2) Surface modification of polyester

[0037] Ethoxylaurylamide is prepared into an aqueous solution with a mass percentage of 4%, the polyester is arranged into a loose state, and then the above-mentioned aqueous solution is sprayed on the surface of the polyester. The spraying quality of the aqueous solution is 4%. The humidity is 75%, and the temperature is 25°C, and it can be left to stand for 72 hours.

[0038] (3) blended

[0039] The above-mentioned surface-modified hemp fiber and polyester are blended, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com