Production method for plastic mold steel refined cast ingot low in sulfur, phosphorus and inclusion content

A technology of plastic mold steel and low inclusions, applied in the field of metallurgy, can solve the problems of reducing the service life of the mold and low impact energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

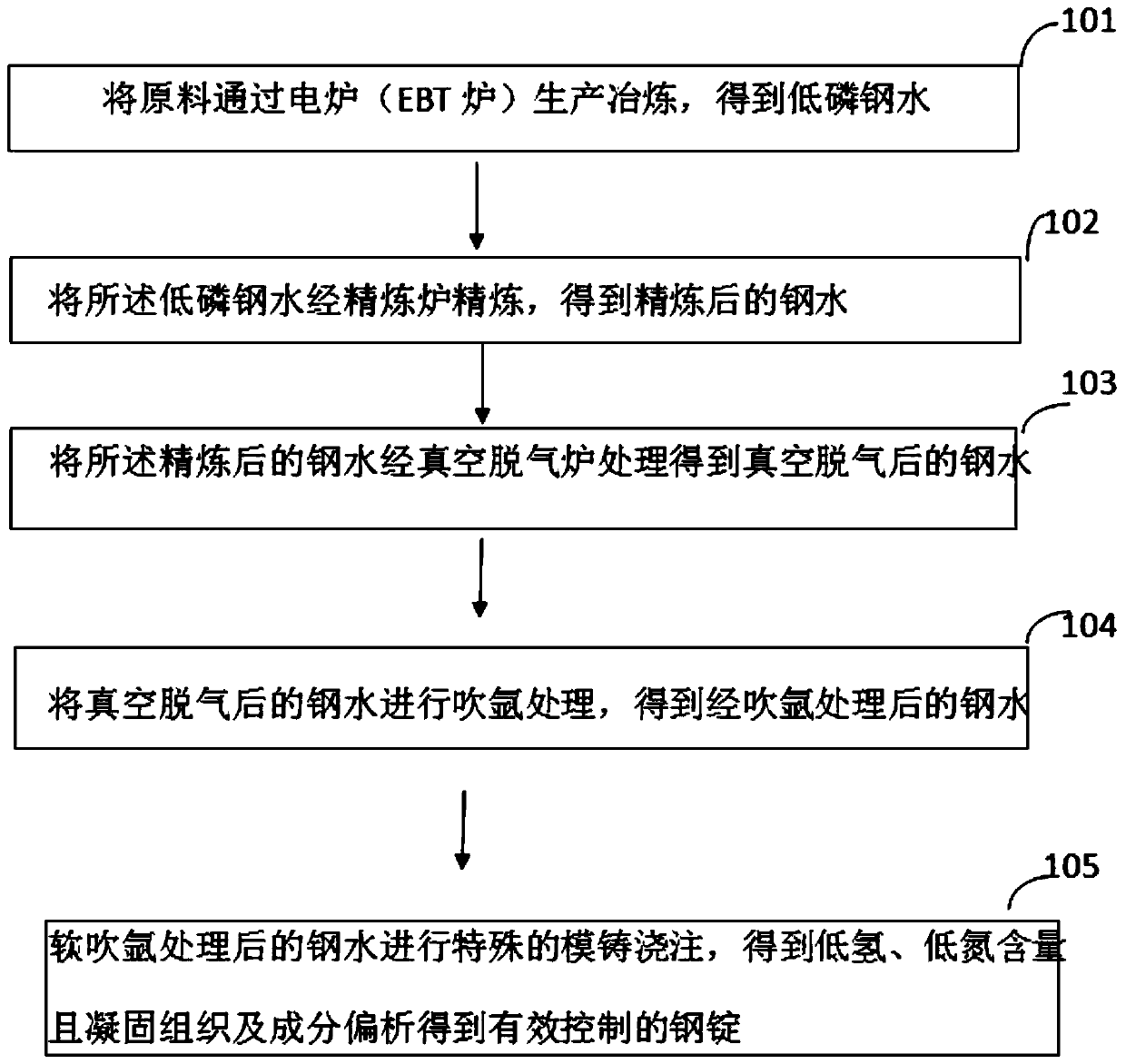

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0025] In the embodiment of the present invention, a production method of 718 type plastic mold steel refined ingot with low sulfur, phosphorus and low inclusion content is provided, including the following steps, please refer to figure 1 :

[0026] Step 101: Smelting the raw materials through an electric furnace (EBT furnace) to obtain low-phosphorus molten steel:

[0027] In step 101, the raw materials are smelted in an electric furnace (EBT furnace) to obtain low-phosphorus molten steel.

[0028] Specifically, the raw materials used may be steel scrap concentrates. In addition, in this step, attention should be paid to controlling the content range of various elements in the raw materials in the smelting process, especially the content range of phosphorus, sulfur, and copper elements. Through practical experience, the 718 type plastic mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com