Cooling structure for dry method coke quenching

A cooling structure and dry coke quenching technology, which is applied in coke cooling, coke oven, petroleum industry, etc., can solve the problems of high cost and unsuitability for large-scale production, and achieve the effect of saving water resources and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

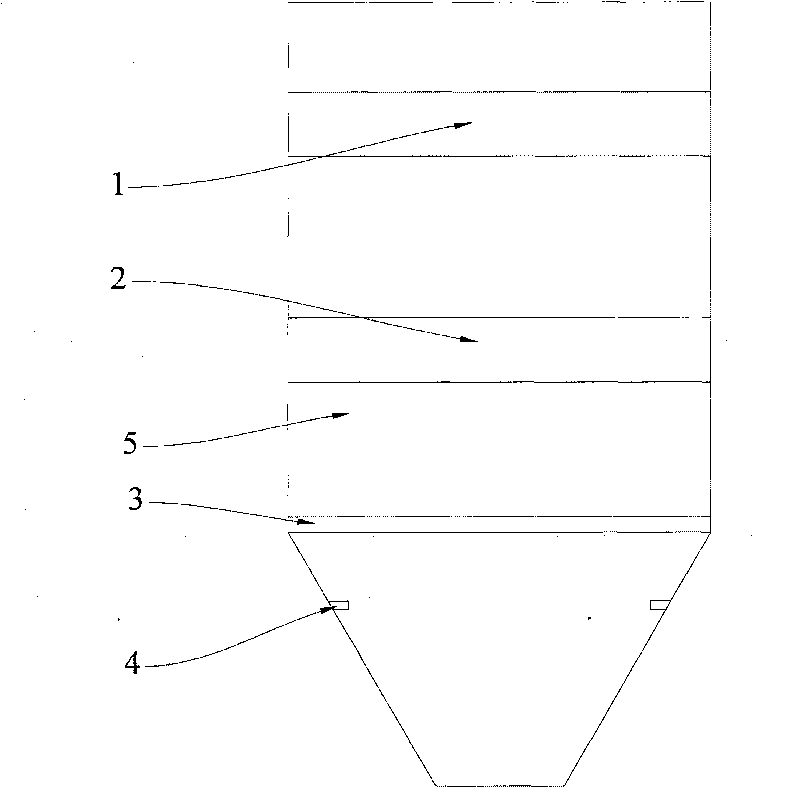

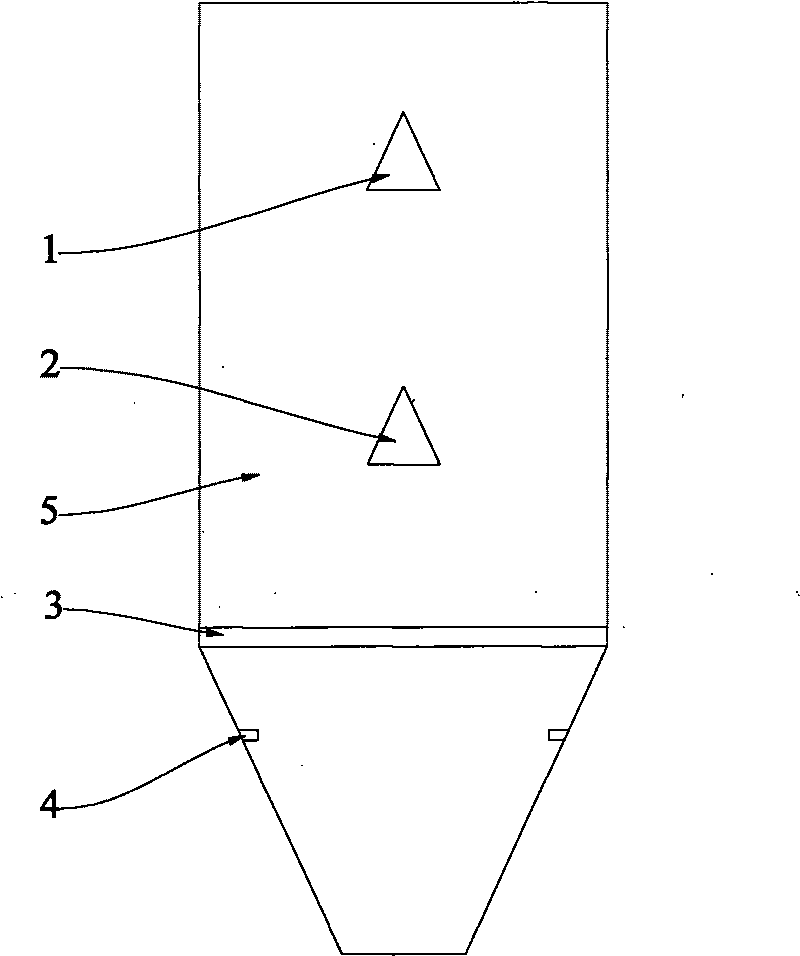

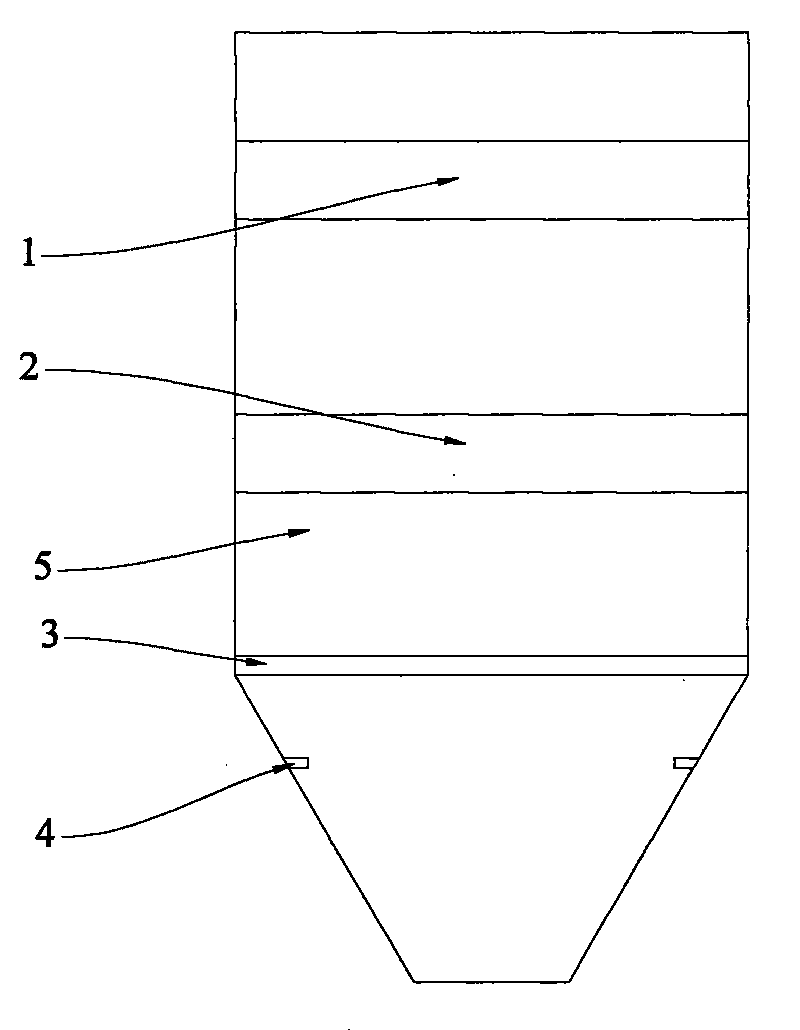

[0024] figure 1 and 2 A specific embodiment of the cooling structure for dry coke quenching of the present invention is shown. A cooling structure for dry coke quenching includes: a body 5; an air distribution pipe 2, which can be produced by drying the coal The cold smoke is conducted into the body 5 and arranged inside the body 5; an air collecting umbrella 1, which can discharge the heat-exchanged smoke out of the body 5, is arranged under the air distribution pipe 2; A feeding device, which can be used to accept the dry distillation product in the body and make the dry distillation product flow out of the cooling structure at a preset speed; a water spray device 4, which is arranged below the feeding device, can flow to the The dry distillation product at the lower part of the body 5 is cooled by spraying water. The part of the body 5 below the unloading device is in the shape of a cone with a large top and a small bottom to facilitate unloading. The unloading device is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com