Smelting method of martensite steel for air valve of internal combustion engine

A smelting method and technology of internal combustion engine, applied in the field of iron and steel smelting, can solve the problems of easy oxidation and burning of chromium, increase smelting cost, etc., and achieve the effect of high alloy recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Smelting of 45Cr9Si3 martensitic valve steel:

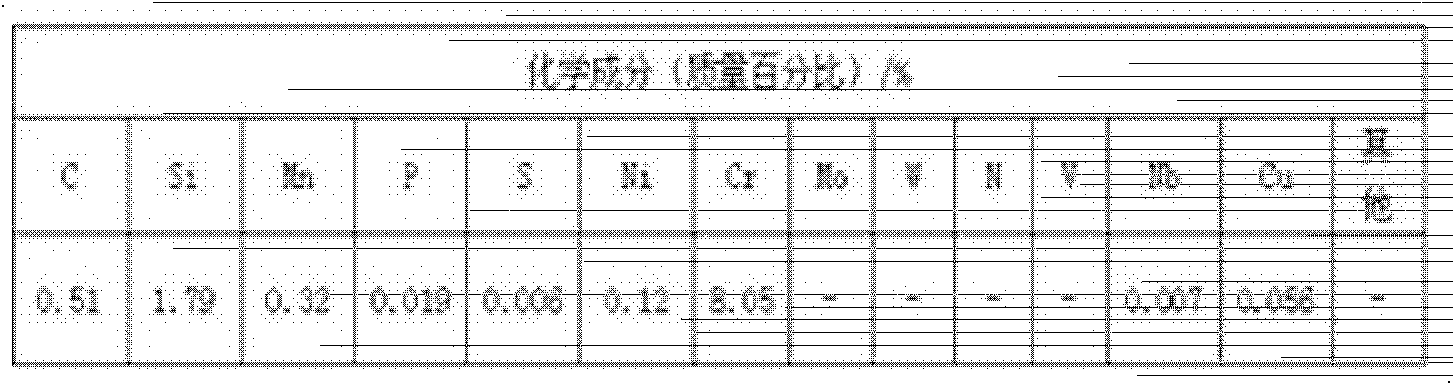

[0025] 1), the chemical composition of 45Cr9Si3 steel is shown in Table 1

[0026] Table 1 Chemical composition of 45Cr9Si3 steel

[0027]

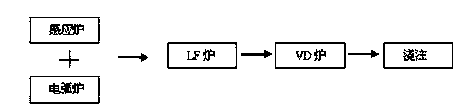

[0028] 2), process flow

[0029] ①Electric arc furnace: about 15t of scrap steel is added, lime is added at 20Kg / ton of steel, smelted by oxidation method, the slag alkalinity is ≥ 1, the scrap steel is fully melted and the slag is removed by shaking the furnace, and silicon carbide 1-1.5kg / t is added in the later stage. Reduction slag, full analysis of sampling before tapping, control C≤0.10%, P≤0.02%, when the temperature is greater than or equal to 1600 °C, no slag is tapped, and 10t of qualified molten steel is guaranteed.

[0030] ② Induction furnace: Add about 5t of chromium-containing stainless steel 430, 2.5t of 0Cr17 stainless steel, 1.5t of low-carbon ferrochrome, and 1.5t of ferrosilicon. After electrification and full melting, the temperature is not less than 1560°C ...

Embodiment 2

[0039] Smelting of 40Cr10Si2Mo martensitic valve steel:

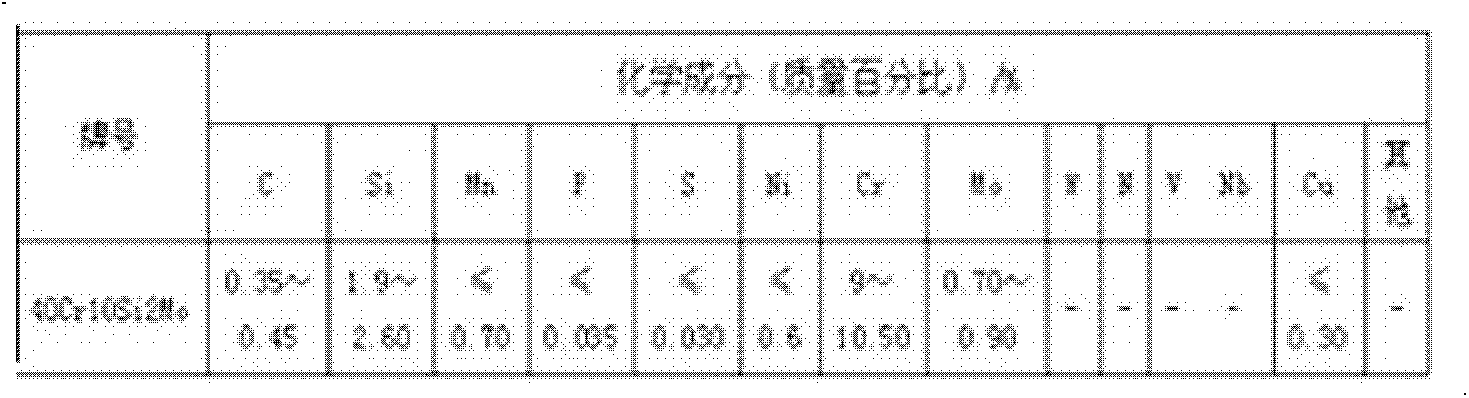

[0040] 1), the chemical composition of 40Cr10Si2Mo steel is shown in Table 1

[0041]

[0042] Table 1 Chemical composition of 40Cr10Si2Mo steel

[0043] 2) Process flow

[0044] Electric arc furnace: Add about 15t of scrap steel, the smelting method is similar to Example 1, the tapping temperature is not less than 1600°C, the molten steel is controlled to have C≤0.10%, P≤0.02%, 10t of slag-free tapping, and 5t of remaining steel.

[0045] Induction furnace: equipped with 250Kg of high-carbon ferrochrome, 3t of return material of valve steel 45Cr9Si3, 2t of 430 stainless steel, 5t of OCr17 stainless steel, 250Kg of ferrosilicon. Electric furnace tapping molten steel.

[0046] In this example, the return material of gas valve steel 45Cr9Si3, which can be used as an alloy material, is added to the induction furnace. Other steel types can be flexibly selected according to the actual production situation. The raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com