Copper-containing printed circuit board wastewater treatment method

A copper printed circuit board and waste water treatment technology, applied in water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of poor sedimentation effect and high cost, and achieve small sludge production , low cost, and the effect of preventing the blackening of the effluent water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

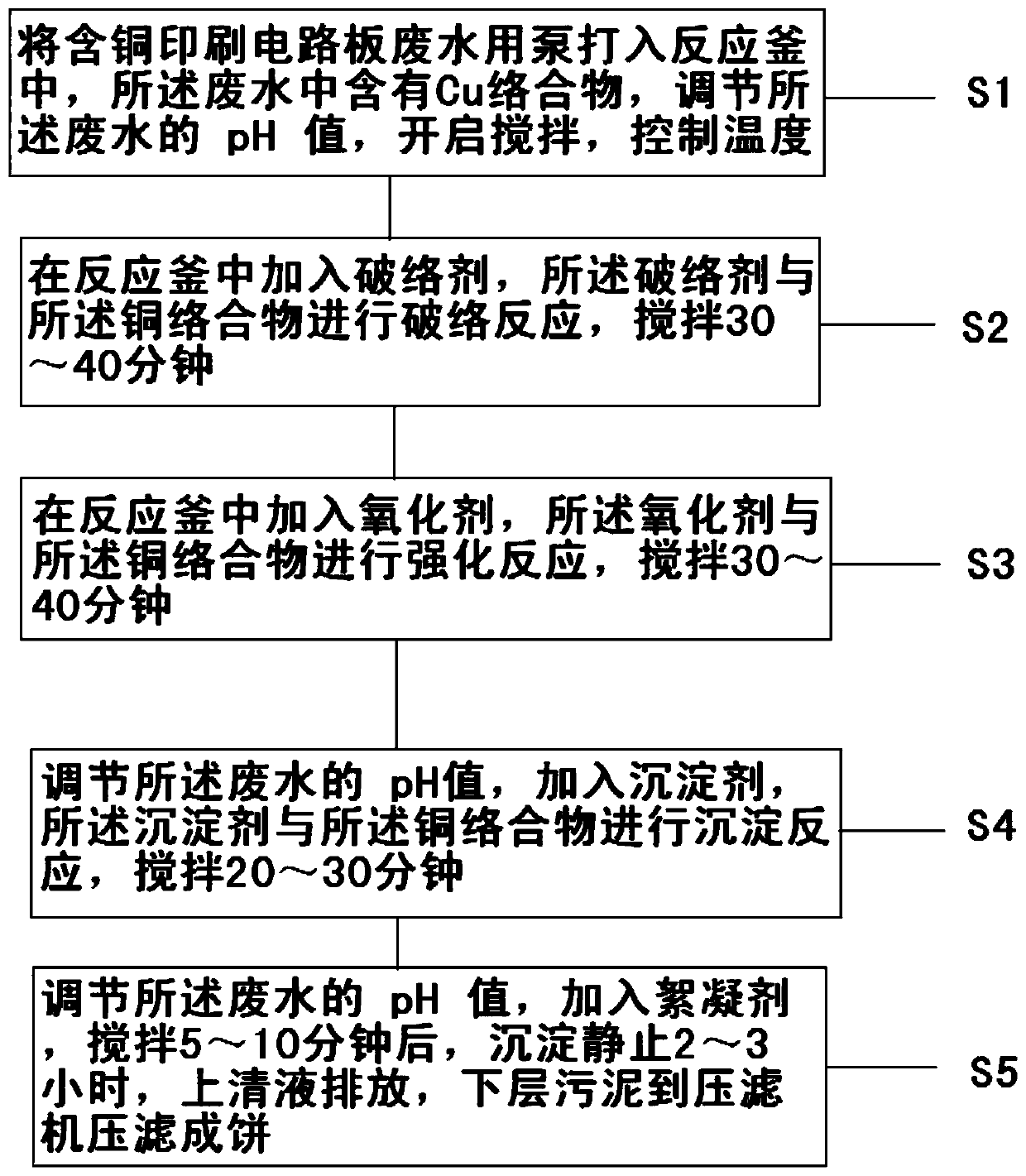

Method used

Image

Examples

Embodiment 1

[0052] A method for treating copper-containing printed circuit board wastewater, specifically: pumping copper-containing printed circuit board wastewater into a reaction kettle, the wastewater contains [Cu(NH 3 ) 4 ] 2+ complex, use sulfuric acid to adjust the pH value of the wastewater to 2.5, start stirring, and control the stirring temperature to 40°C; add complex-breaking agent ferrous sulfate particles in the reaction kettle, ferrous sulfate particles and containing [Cu(NH 3 ) 4 ] 2+ The complex compound carried out the complex reaction, stirred for 30 minutes; in the reactor, adding mass percent concentration was 30% hydrogen peroxide (H 2 o 2 ) as an oxidant, the oxidant and [Cu(NH 3 ) 4 ] 2+ Complex compound carries out intensified reaction, stirs 30 minutes; Adjust the pH value of waste water to be 7.0, add sodium sulfide as precipitating agent, precipitating agent and [Cu(NH 3 ) 4 ] 2+ The complex was precipitated and stirred for 20 minutes; the pH value of...

Embodiment 2

[0054] A method for treating copper-containing printed circuit board wastewater, specifically: pumping copper-containing printed circuit board wastewater into a reaction kettle, the wastewater contains copper chloride complex [Cu(Cl - ) 4 ] 2 , adjust the pH value of the waste water to 2.8, start stirring, and control the stirring temperature to 45°C; add complex-breaking agent ferrous sulfate particles in the reaction kettle, ferrous sulfate particles and copper chloride complex [Cu(Cl - ) 4 ] 2 Carry out decomplexation reaction, stir 35 minutes; In reaction kettle, add mass percent concentration and be 30% hydrogen peroxide (H 2 o 2 ) as an oxidizing agent, the oxidizing agent and the copper chloride complex [Cu(Cl - ) 4 ] 2- Carry out intensified reaction, stir 35 minutes; Regulate the pH value of waste water to be 7.5, add sodium sulfide as precipitation agent, precipitation agent and copper chloride complex [Cu(Cl - ) 4 ] 2- Carry out precipitation reaction, sti...

Embodiment 3

[0056] A method for treating copper-containing printed circuit board wastewater, specifically: pumping copper-containing printed circuit board wastewater into a reaction kettle, the wastewater containing copper EDTA complex [Cu(EDTA)] 2+ , adjust the pH value of the wastewater to 3.0, start stirring, and control the stirring temperature to be 50°C; add complexing agent ferrous sulfate particles in the reaction kettle, ferrous sulfate particles and [Cu(EDTA)] 2+ Carry out decomplexion reaction, stir 40 minutes; Add mass percent concentration in reactor and be the hydrogen peroxide (H2O2) of 30%. 2 o 2 ) as an oxidizing agent, the EDTA complex of the oxidizing agent and copper [Cu(EDTA)] 2+ Carry out intensified reaction, stir for 40 minutes; Adjust the pH of waste water to be 8.0, add sodium sulfide as precipitant, precipitant and [Cu(EDTA)] 2+ Carry out precipitation reaction, stir for 30 minutes; adjust the pH value of the wastewater to 8.0, add polyacrylamide solution with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com