Low-temperature cold-pressing and bivariate continuous refining and processing method for oiltea camellia seed oil

A technology of camellia oleifera seed oil and processing method, which is applied in the fields of fat oil/fat refining, edible oil/fat, fat oil/fat production, etc. It can solve the problems of affecting the quality of finished oil, high baking temperature, and excessive benzopyrene harmful substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1. The present invention carries out according to the following processing steps:

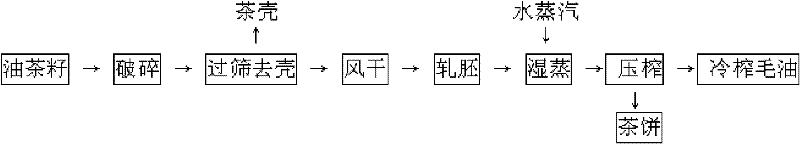

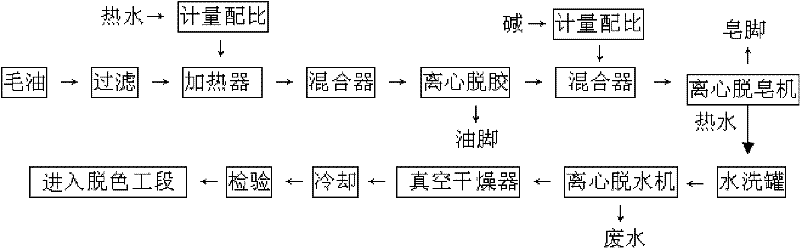

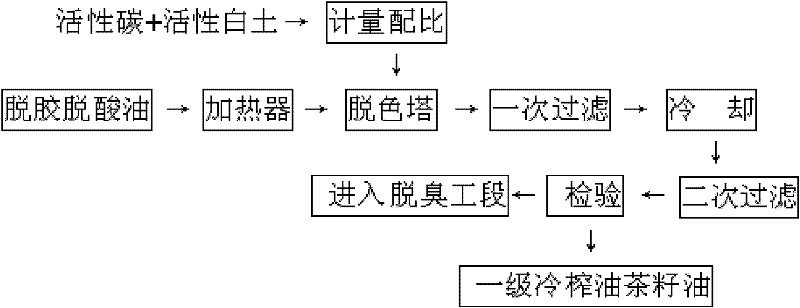

[0025] (1) Squeeze: if figure 1shown. After cleaning and removing impurities, the Camellia oleifera seeds are sent to the crusher for crushing, and then sieved to remove the tea shells to make them into pure Camellia oleifera seeds, and then sent to the wind room for air drying by conveyor belt. The time, temperature and air volume of air-drying are controlled according to the water content of camellia oleifera seeds. If the water content is high, the conveying speed of the conveyor belt should be slowed down and the air volume should be increased to make the water content of camellia oleifera seeds meet the air-drying requirements. After the Camellia oleifera seeds are air-dried to meet the requirements, they are sent to the flaking machine by the elevator for flaking, and the rolled embryos enter the steaming and frying pan for steaming and frying, and direct steam is added d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com